Tipping paper heating rubbing connection method

A technology of tipping paper and tipping paper drum, which is used in the manufacture of cigarettes, etc., can solve problems such as deformation, increased suction resistance of filter rods, loss of normal working ability, etc., to avoid damage, reduce maintenance costs, and long-term reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

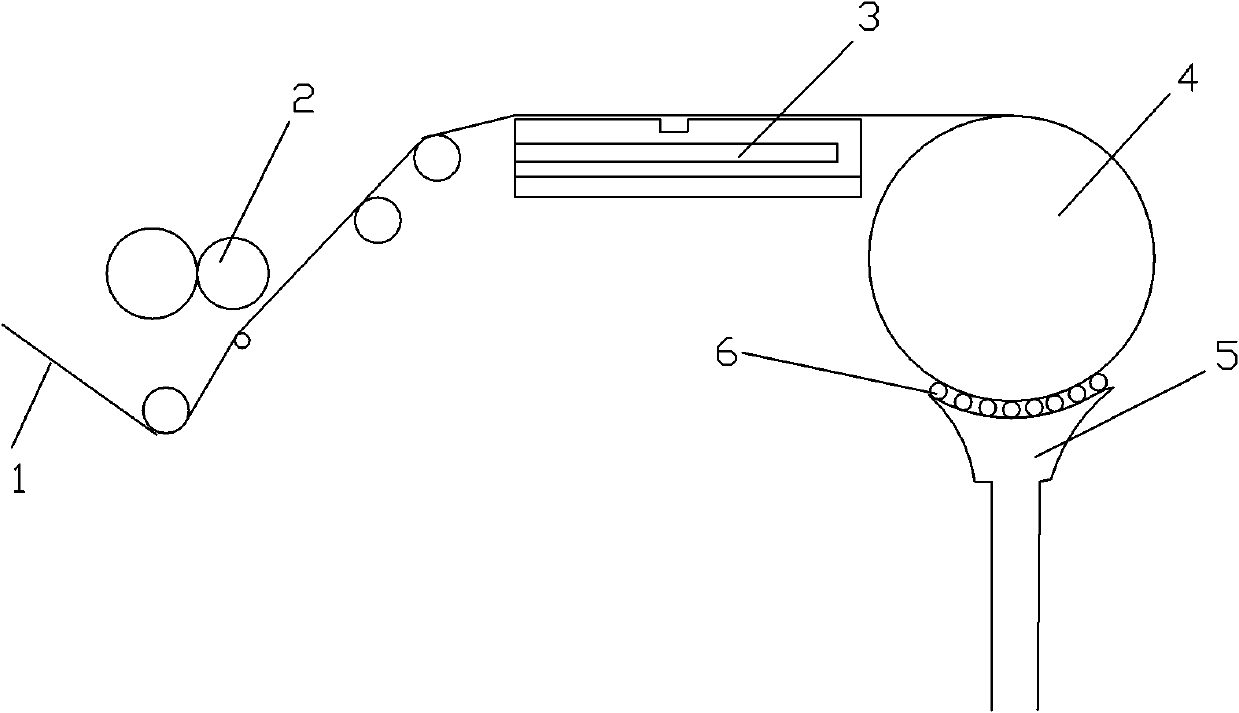

[0014] Such as figure 1 As shown, the tipping paper heating and rubbing method firstly applies glue on the surface of the tipping paper 1 by the top rubber roller 2 during implementation, and then heats the tipping paper 1 by a heater 3, and the heater 3 is an electric heater. Tube, the heating temperature of the heater 3 should be controlled at 180°C-200°C, preferably 200°C, and then the heated tipping paper 1 is wound on the tipping paper drum 4, and the tipping paper drum 4 is The tipping paper 1 provides a certain pulling force, the tipping paper drum 4 can cut the tipping paper, and at the same time cooperate with the washboard 5 to rely on friction to make the cut tipping paper 1 wrap around the filter rod 6 to complete the tipping paper 1 Rubbing on the filter tip filter rod 6. The temperature of the tipping paper drum 4 is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com