Method for improving stability of resistance value of thermistor in vacuum environment

A thermistor and vacuum environment technology, applied in the direction of resistors with negative temperature coefficient, resistors with positive temperature coefficient, etc., can solve the problem of unstable resistance value, achieve good resistance value stability, and facilitate temperature control , the effect of small resistance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

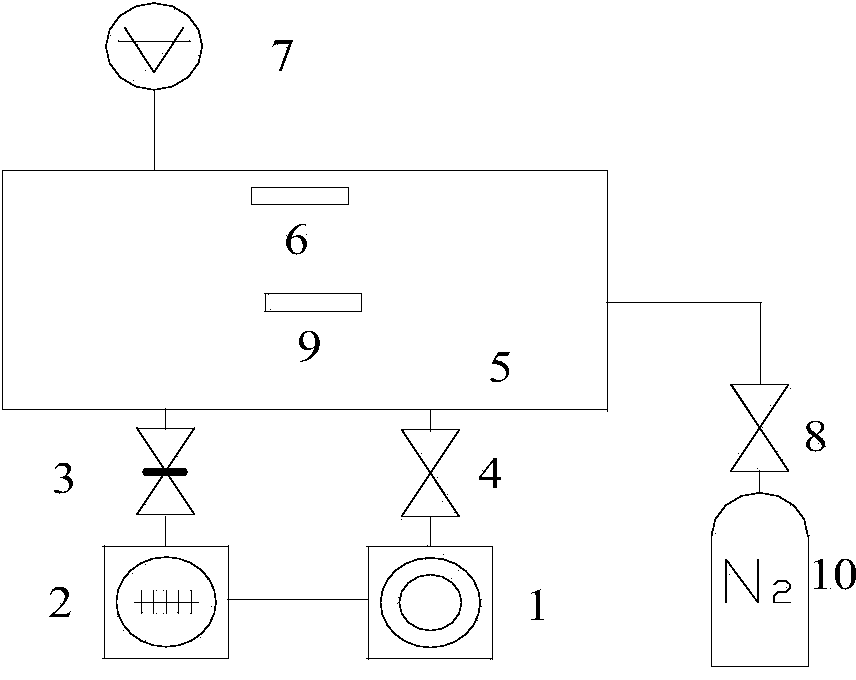

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

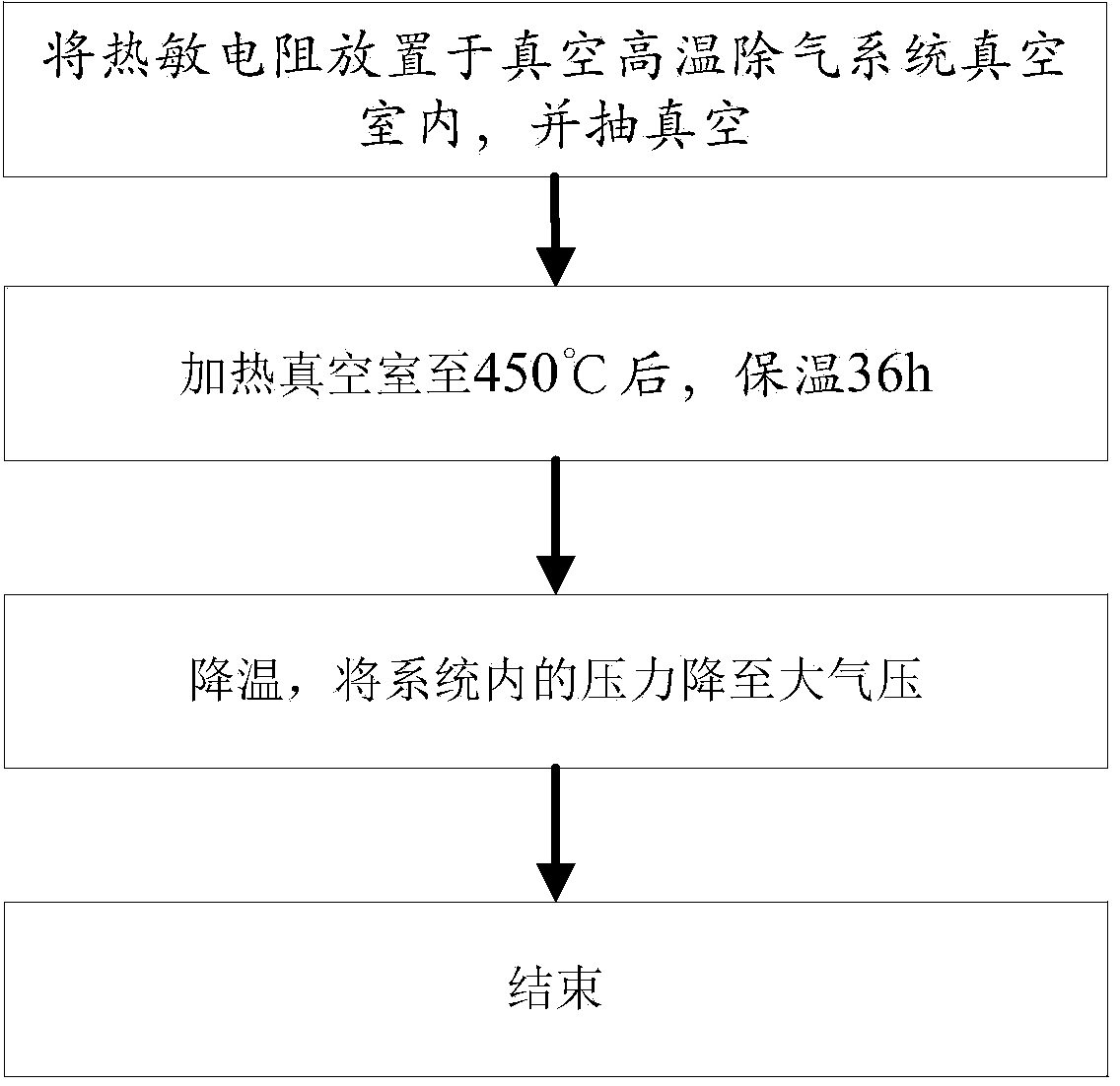

[0017] The invention provides a method for improving the resistance stability of a thermistor in a vacuum environment. The gas remaining in the resistor is removed through high-temperature baking and degassing, and the resistance value change caused by the temperature change caused by gas volatilization is reduced. , thereby improving the stability of the thermistor.

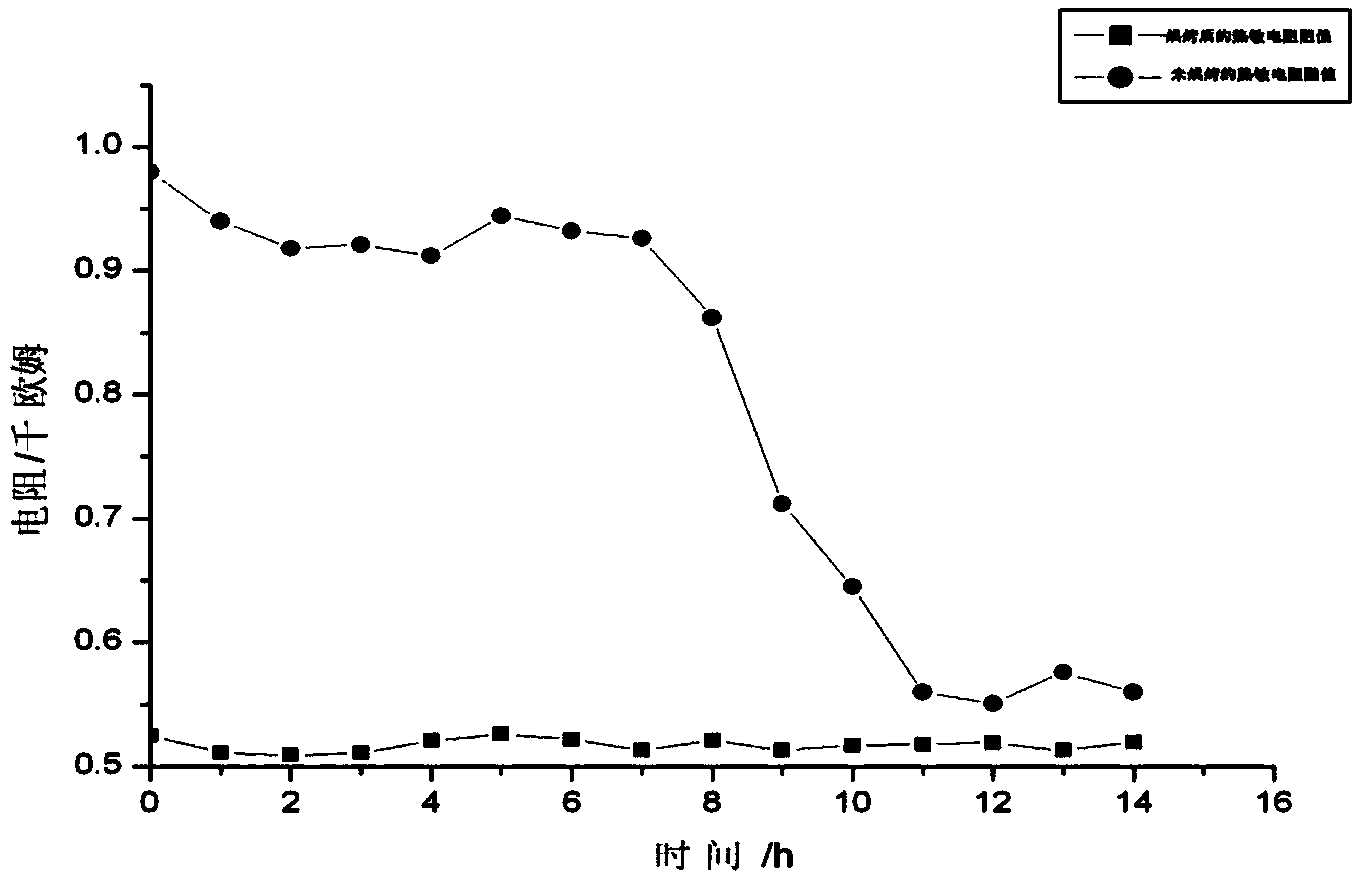

[0018] The thermistor is sintered with ceramic material, and the residual gas inside mainly contains N 2 、H 2 O, low molecular weight hydrocarbons, etc. During high-temperature vacuum baking, the outgassing peaks of these residual gases all appear before 400°C. In order to ensure the removal of residual gases without destroying the microstructure of the thermistor, the temperature selected for this process is 450°C. In the test, it is found that the holding time reaches 36h, which can mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com