Elastic heater and preparation method thereof

A heater and elastic technology, applied in ohmic resistance heating parts, equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, etc., can solve the problems of non-deformable and non-elastic physiotherapy heaters, etc., to achieve The resistance change is small, the preparation method is simple and efficient, and the effect of ensuring heating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

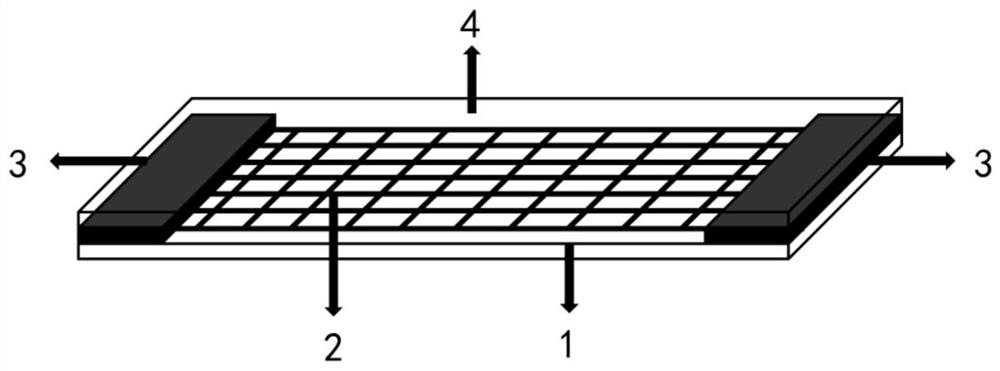

[0033] In this embodiment, the structure of the elastic heater is as figure 1 As shown, it is composed of elastic substrate 1, conductive material 2, electrode 3, and encapsulation layer 4. Two electrodes 3 are symmetrically covered on both ends of the elastic substrate; conductive material 2 is attached to the elastic substrate not covered by electrodes On the top, the stripe spacing of the mesh stripes is about 200 μm, and the elastic substrate 1 , the conductive material 2 and the electrode 3 are provided with an encapsulation layer 4 .

[0034] Among them, the elastic substrate 1 is a polydimethylsiloxane film, which is stretchable and non-conductive; the conductive material 2 is a gallium-indium alloy liquid metal; the electrode 3 is made of a gallium-indium alloy liquid metal, and the encapsulation layer 4 is polydimethylsiloxane base siloxane film.

[0035] Due to the good transparency of the polydimethylsiloxane film and the gallium-indium alloy liquid metal, the elas...

Embodiment 2

[0044] In this embodiment, the elastic heater is composed of an elastic substrate, a conductive material, an electrode, and an encapsulation layer, and the two electrodes are symmetrically covered on both ends of the elastic substrate; the conductive material is attached to the elastic substrate not covered by the electrodes in a mesh stripe , the stripe spacing of the mesh stripes is about 20 μm, and the elastic substrate, the conductive material and the electrodes are provided with an encapsulation layer.

[0045] Among them, the elastic substrate is polydimethylsiloxane film, which is stretchable and non-conductive; the conductive material is gallium indium tin alloy liquid metal; the electrode is made of gallium indium alloy liquid metal, and the packaging layer is polydimethylsiloxane alkane film.

[0046] Due to the good transparency of the polydimethylsiloxane film, the gallium indium tin alloy liquid metal and the gallium indium tin alloy liquid metal, the elastic heat...

Embodiment 3

[0052] In this embodiment, the elastic heater is composed of an elastic substrate, a conductive material, an electrode, and an encapsulation layer, and the two electrodes are symmetrically covered on both ends of the elastic substrate; the conductive material is attached to the elastic substrate not covered by the electrodes in a mesh stripe , the stripe spacing of the mesh stripes is about 800 μm, and the elastic substrate, conductive material and electrodes have encapsulation layers.

[0053] Among them, the elastic substrate is polyethylene terephthalate film, which is stretchable and non-conductive; the conductive material is polypyrrole; the electrodes are made of graphene, and the packaging layer is polyethylene terephthalate film.

[0054] The preparation method of the elastic heater comprises the following steps:

[0055] (1) symmetrically evenly coat graphene on both ends of the polyethylene terephthalate film upper surface to form electrodes;

[0056] (2) pre-stretch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com