Water-saving type reverse-osmosis pure water production method

A reverse osmosis pure water and production method technology, which is applied in the field of reverse osmosis pure water production in household water purification equipment, can solve the problems of concentrated water, water waste, discharge, etc., and achieve the effect of maintaining flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

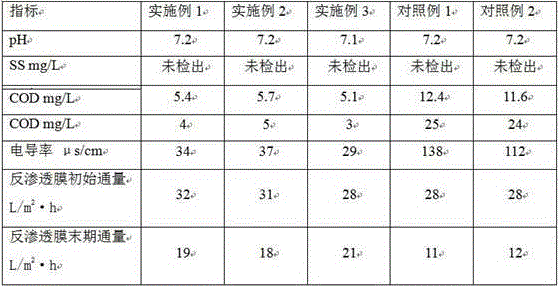

Examples

Embodiment 1

[0022] The described modified activated carbon is prepared by the following methods:

[0023] According to the weight of the weight, take 60 coconut fiber fiber, crushed it to fines, and mix with 20 sodium hydroxide, water 10 copies and 20 copies of ethanol; then place the mixture in a tube furnace, nitrogenIn the atmosphere, the parameters of the carbonization steps are: 10 ° C / min increased, carbonization temperature is 1200 ° C, carbonization time is 3 hours; after cooling, use the citric acid solution with 5%of the mass concentration, then use it with a 5%citric acid solution, and then use it with the quality concentration of 5%.Pure water was washed to neutral. After drying, grinding to obtain modified activated carbon.

[0024] Example 2

Embodiment 2

[0026] The described modified activated carbon is prepared by the following methods:

[0027] According to the weight, 80 copies of coconut fruit fiber fiber are crushed into fines, and then mixed with 25 sodium hydroxide, water 20 copies and 30 copies of ethanol;In the atmosphere, the parameters of the carbonization steps are: 10 ° C / min increased, carbonization temperature is 1200 ° C, and carbonization time is 5 hours; after cooling, use the citric acid solution with a citric acid solution with a mass concentration of 5%, and then use it with the quality concentration of 5%.Pure water was washed to neutral. After drying, grinding to obtain modified activated carbon.

[0028] Example 3

Embodiment 3

[0030] The described modified activated carbon is prepared by the following methods:

[0031] According to the weight, 70 copies of coconut fruit fiber are taken, crushed into fines, and then mixed with 22 sodium hydroxide, 15 copies and 25 copies of ethanol;In the atmosphere, the parameters of the carbonization steps are: 4 ° C / min increased, carbonization temperature is 1150 ° C, carbonization time is 4 hours; after cooling, use the citric acid solution with a citrate solution with a mass concentration of 5%, and then use it with the quality concentration of 5%.Pure water was washed to neutral. After drying, grinding to obtain modified activated carbon.

[0032] Comparison example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com