Dry transformer coil vertical coiling machine

A vertical winding machine and transformer coil technology, which is applied in coil manufacturing, inductor/transformer/magnet manufacturing, electromechanical devices, etc., can solve problems such as difficult maintenance, inaccurate number of coil turns, and influence on transformer performance, and achieve automatic control The effect of high level, accurate number of coil turns and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

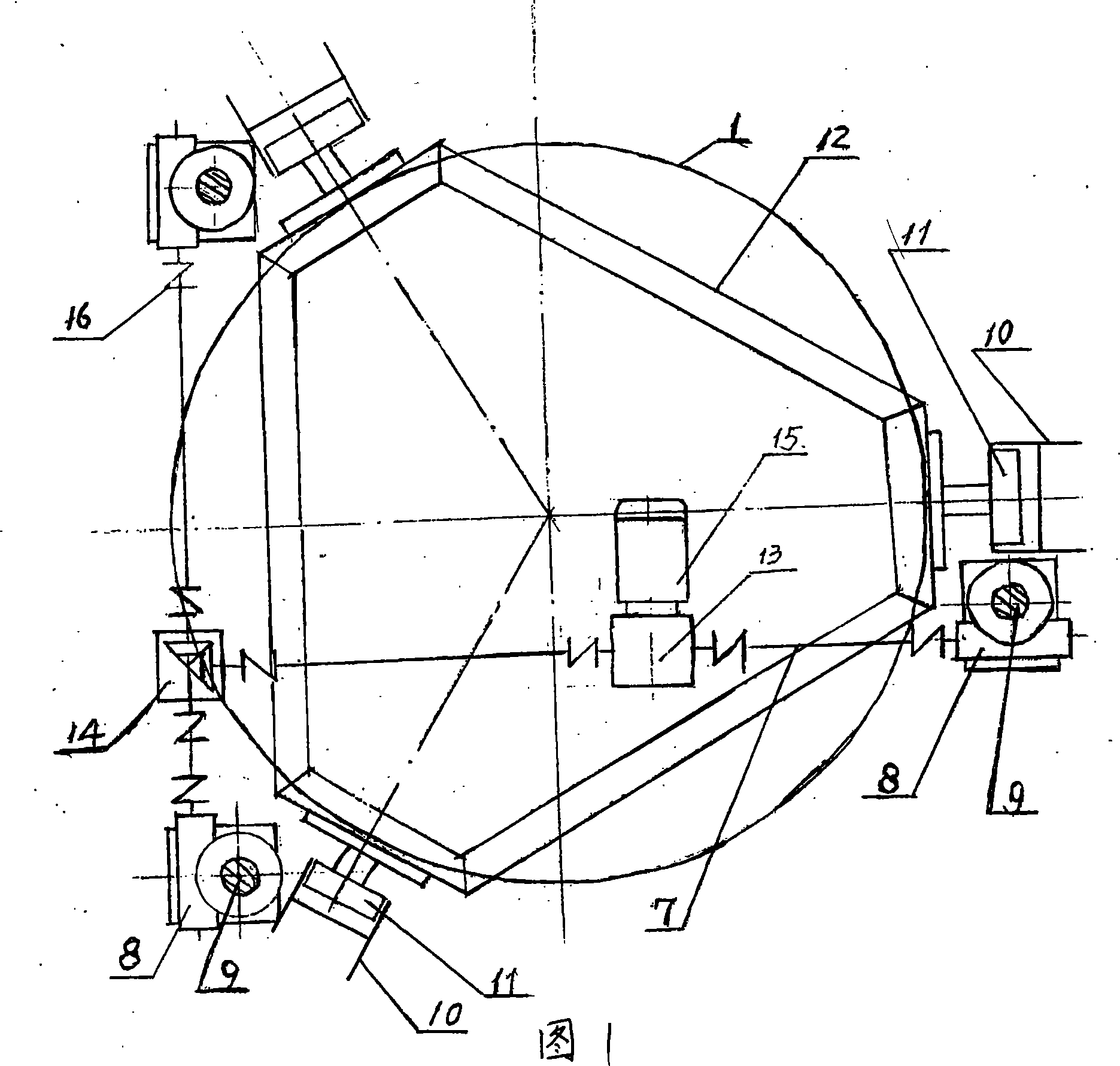

[0020] As shown in Figure 1, it is the structural representation of the lifting system of the present invention, and the lifting speed reducer 13 installed on the lifting seat 12 is driven by the frequency conversion lifting motor 15, and is connected with the three through the transmission shaft 7, the elastic coupling 16 and the steering box 14. 8 sets of worm gear screw lifts are connected to realize synchronous lifting. In order to move up and down smoothly along the screw mandrel 9, three guide columns 10 are set in equal parts, so that the guide block 11 on the lifting platform can be lifted and lowered along the guide columns to achieve stable lifting and adjustable speed.

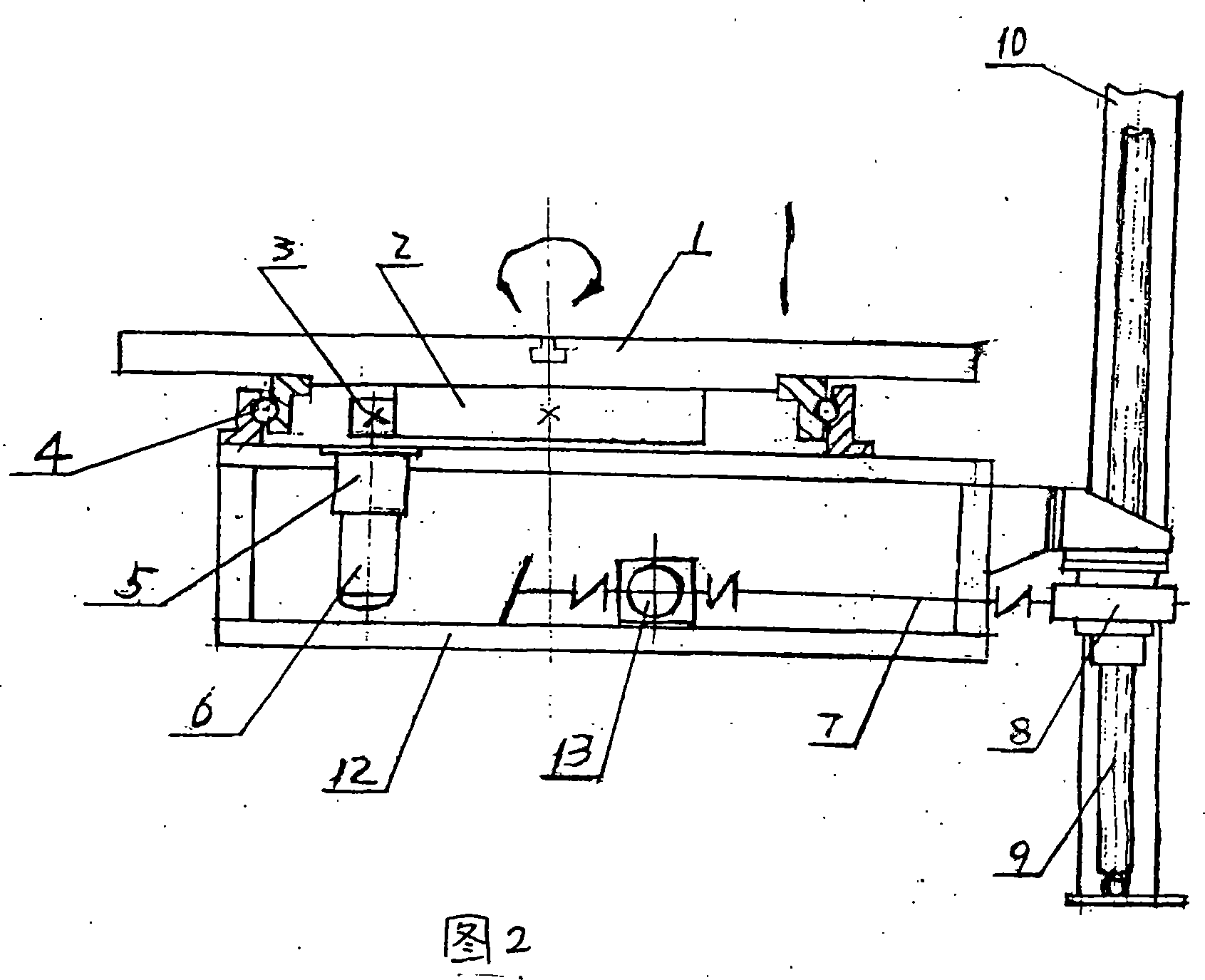

[0021] As shown in Figure 2, it is a schematic structural view of the winding and turning system of the present invention (with a guide column and a screw mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com