Tire rubber sheet electron radiation crosslinking pretreatment device and method

A pretreatment device and electronic irradiation technology, which is applied in the field of rubber machinery and electronic radiation, can solve the problems of difficult application of rubber tire industrial production and low film conveying speed, so as to improve production efficiency and automatic control level, guarantee conveying speed, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

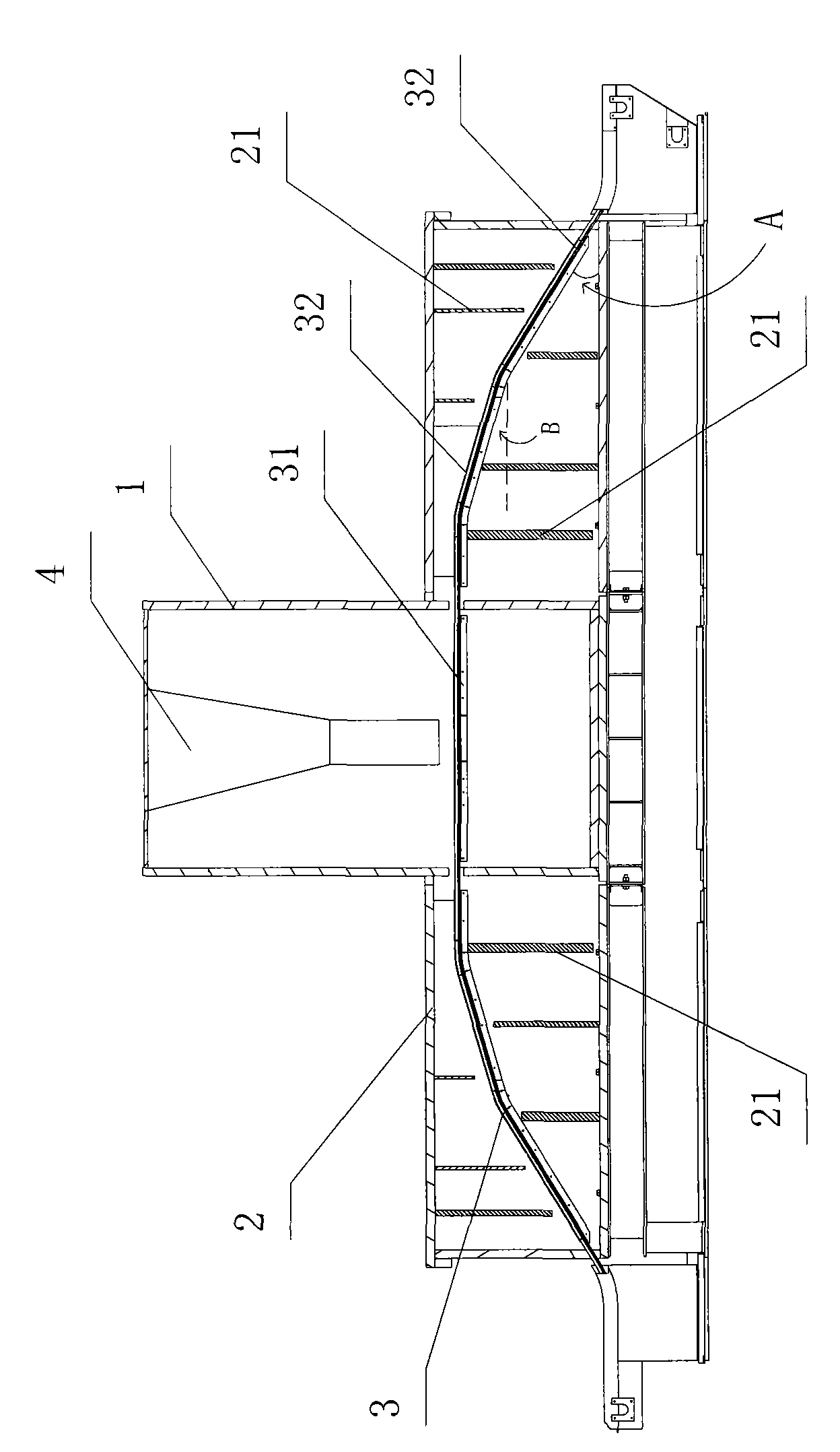

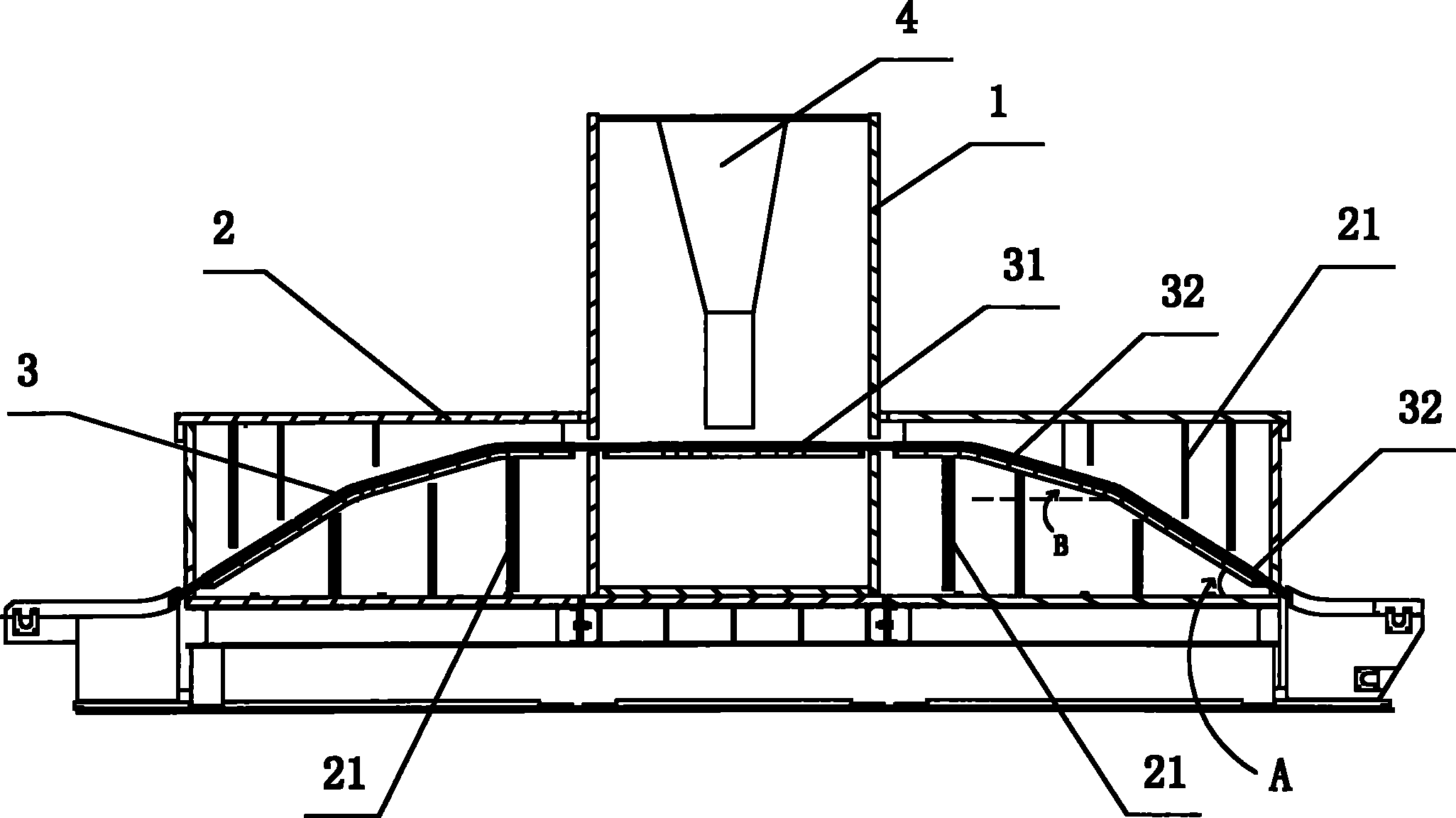

[0041] Example 1, such as figure 1 As shown, the tire film electronic irradiation crosslinking pretreatment device mainly includes an irradiation room 1 , a shielding room 2 , a conveyor belt 3 and an electron accelerator 4 . in,

[0042] On the inner walls of the irradiation room 1 and the shielding room 2, there are all attached ray-absorbing plates that can be made of lead plates or stainless steel plates.

[0043] An electron accelerator 4 is arranged inside the irradiation chamber 1 and above the conveyor belt 3,

[0044] The conveyor belt 3 is a stainless steel wire mesh structure as a whole, and extends through the irradiation room 1 and the shielding room 2 . The gap between the conveyor belt 3 and the entrance and exit of the irradiation chamber 1 and the shielding chamber 2 is 3-6 cm, so as to minimize the space for radiation leakage under the premise of allowing the conveyor belt 3 to carry the film through.

[0045] The conveyor belt 3 includes a horizontal conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com