Patents

Literature

41results about How to "Guaranteed delivery speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

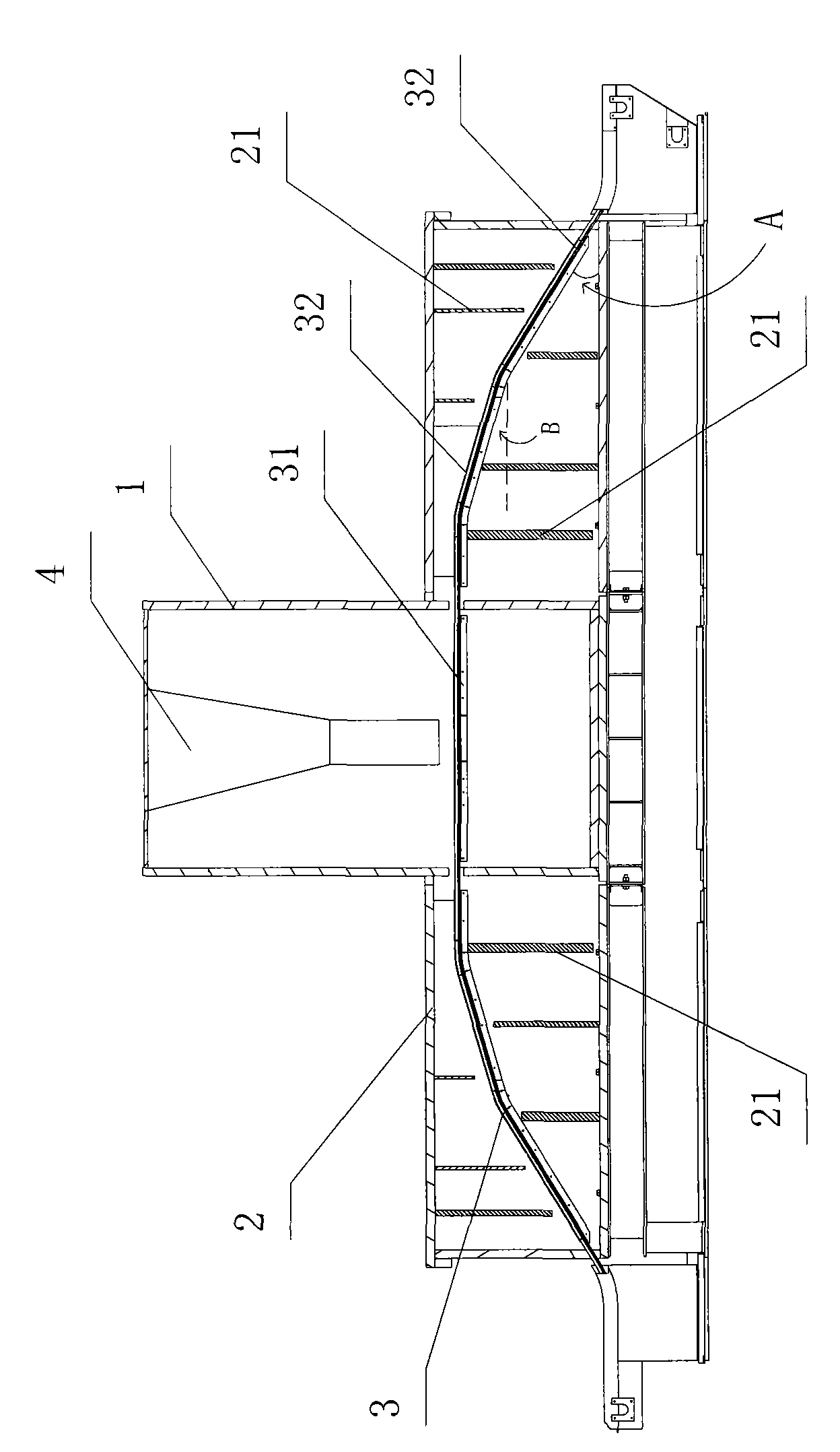

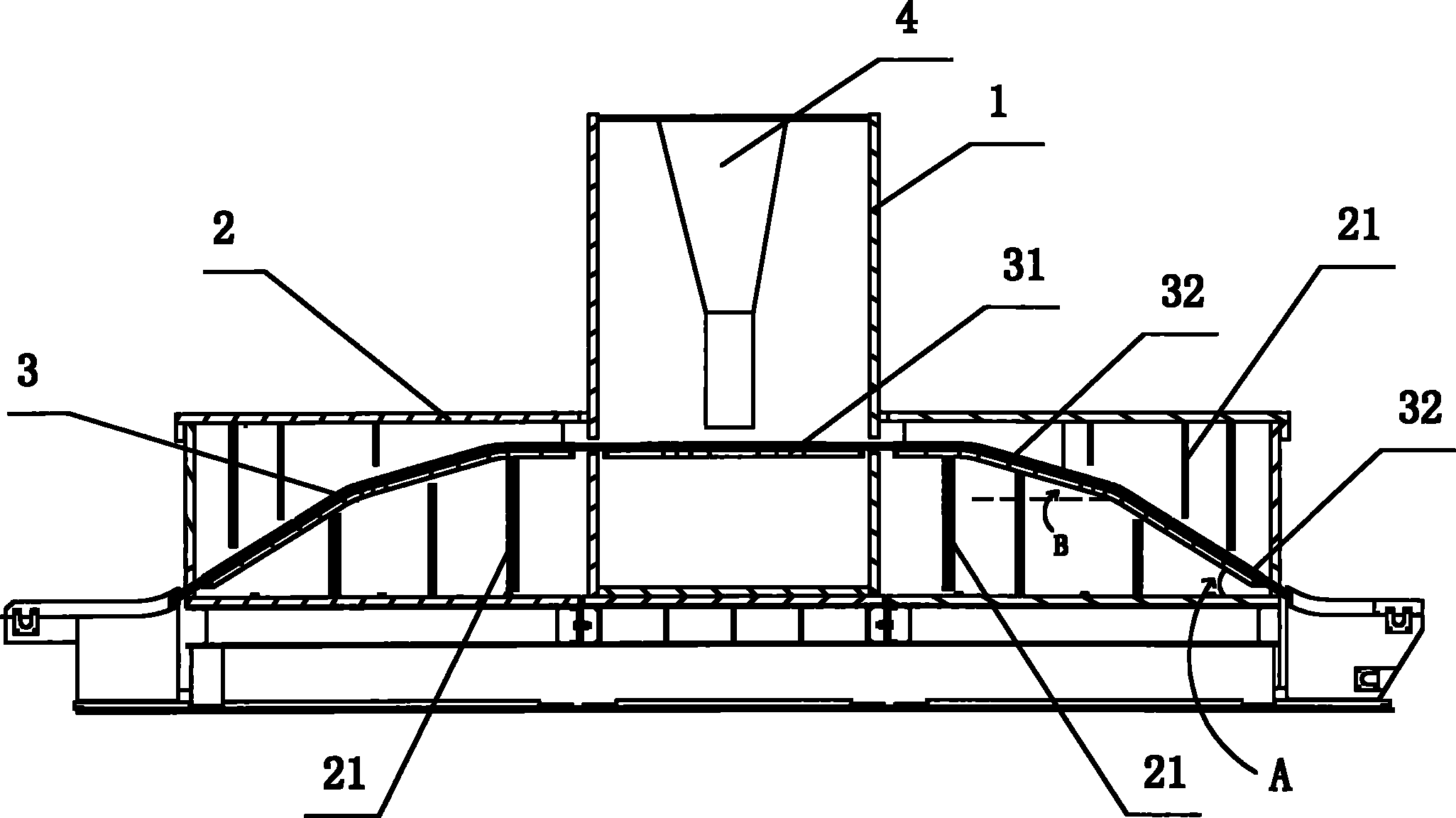

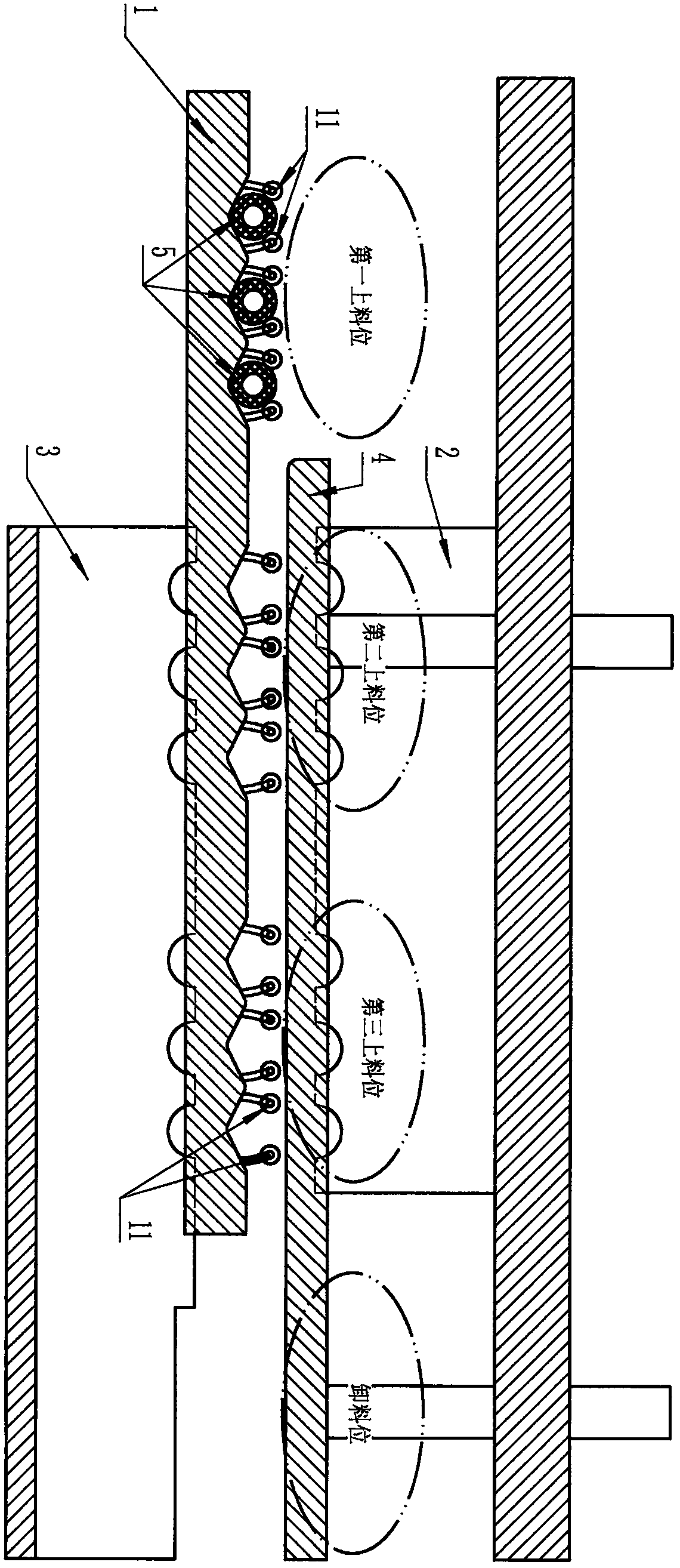

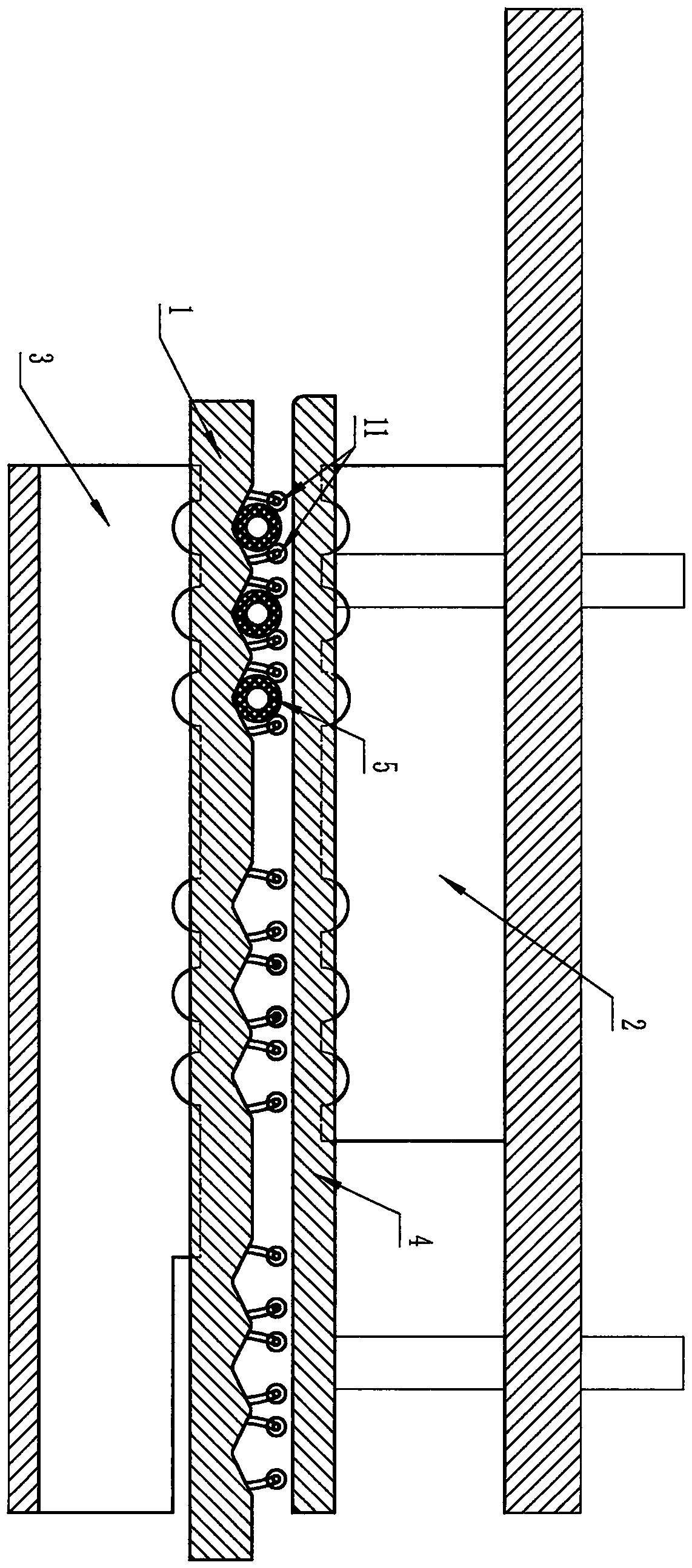

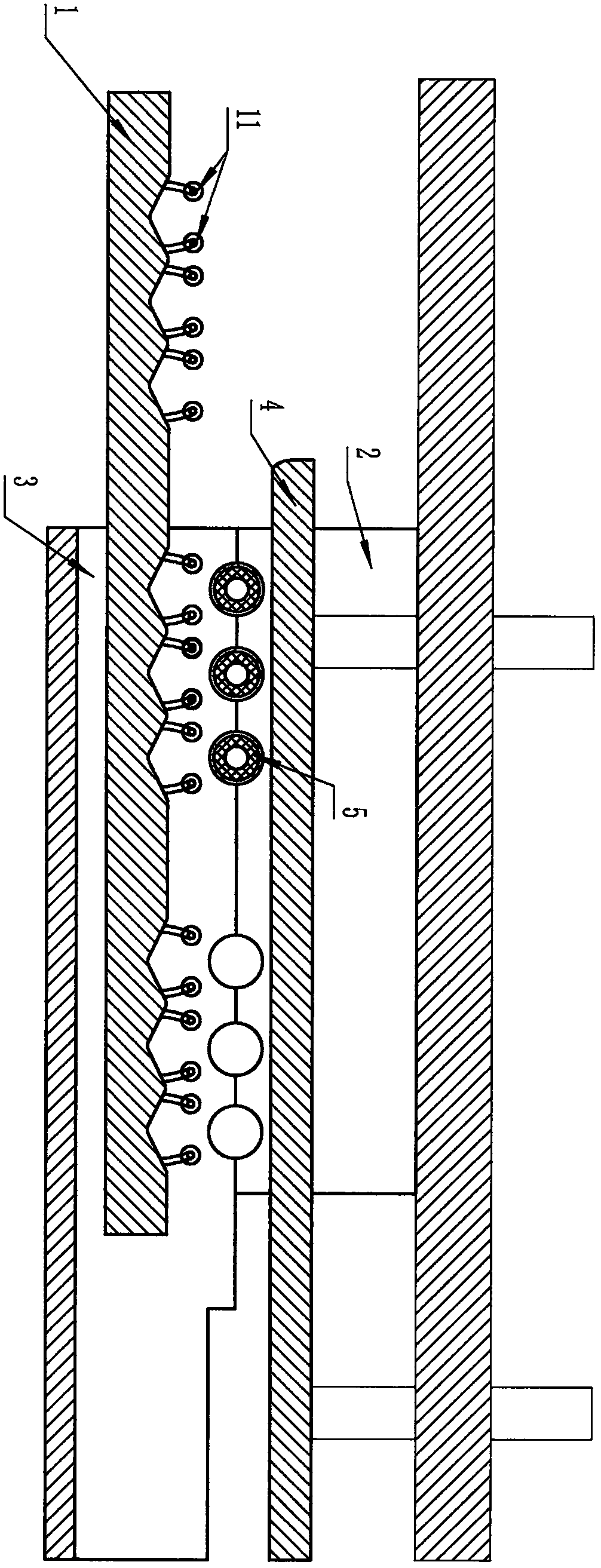

Tire rubber sheet electron radiation crosslinking pretreatment device and method

ActiveCN102092111AStrong penetrating powerIncrease the number of reflectionsTyresUltrasound attenuationPretreatment method

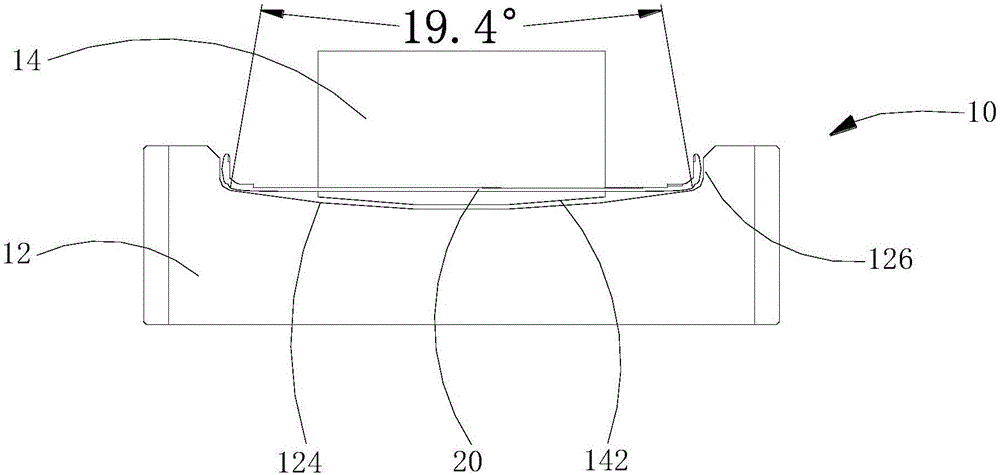

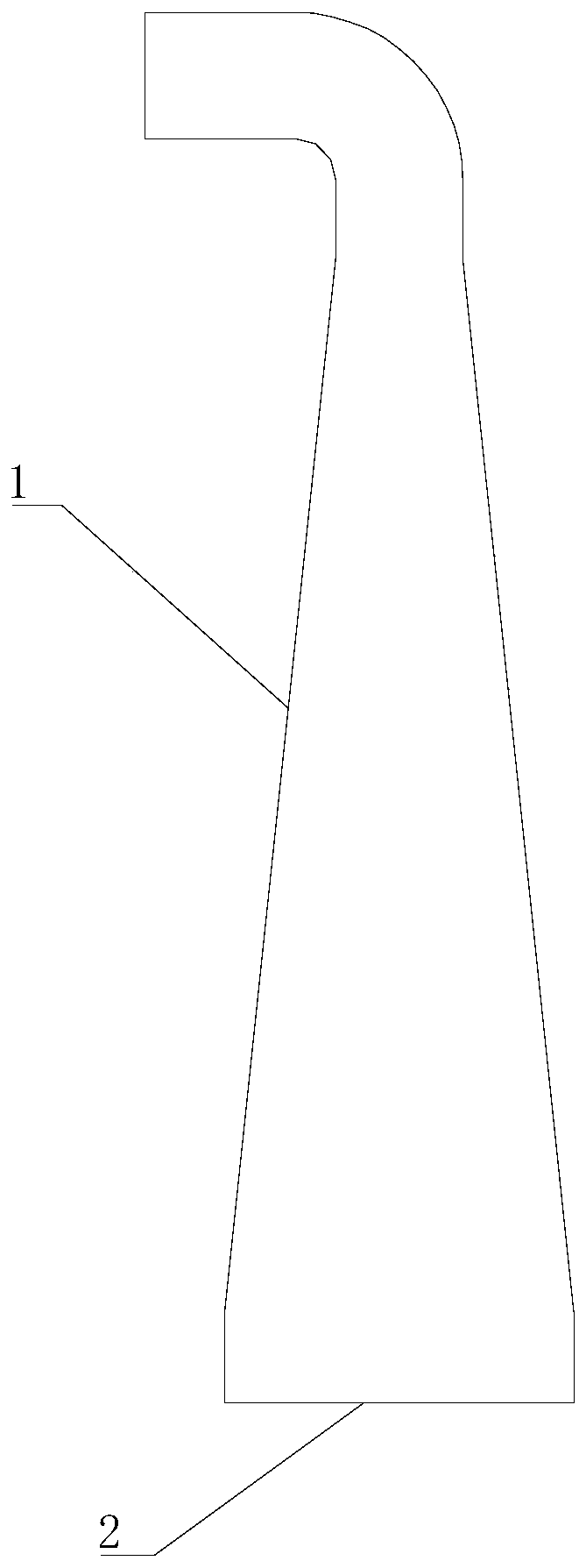

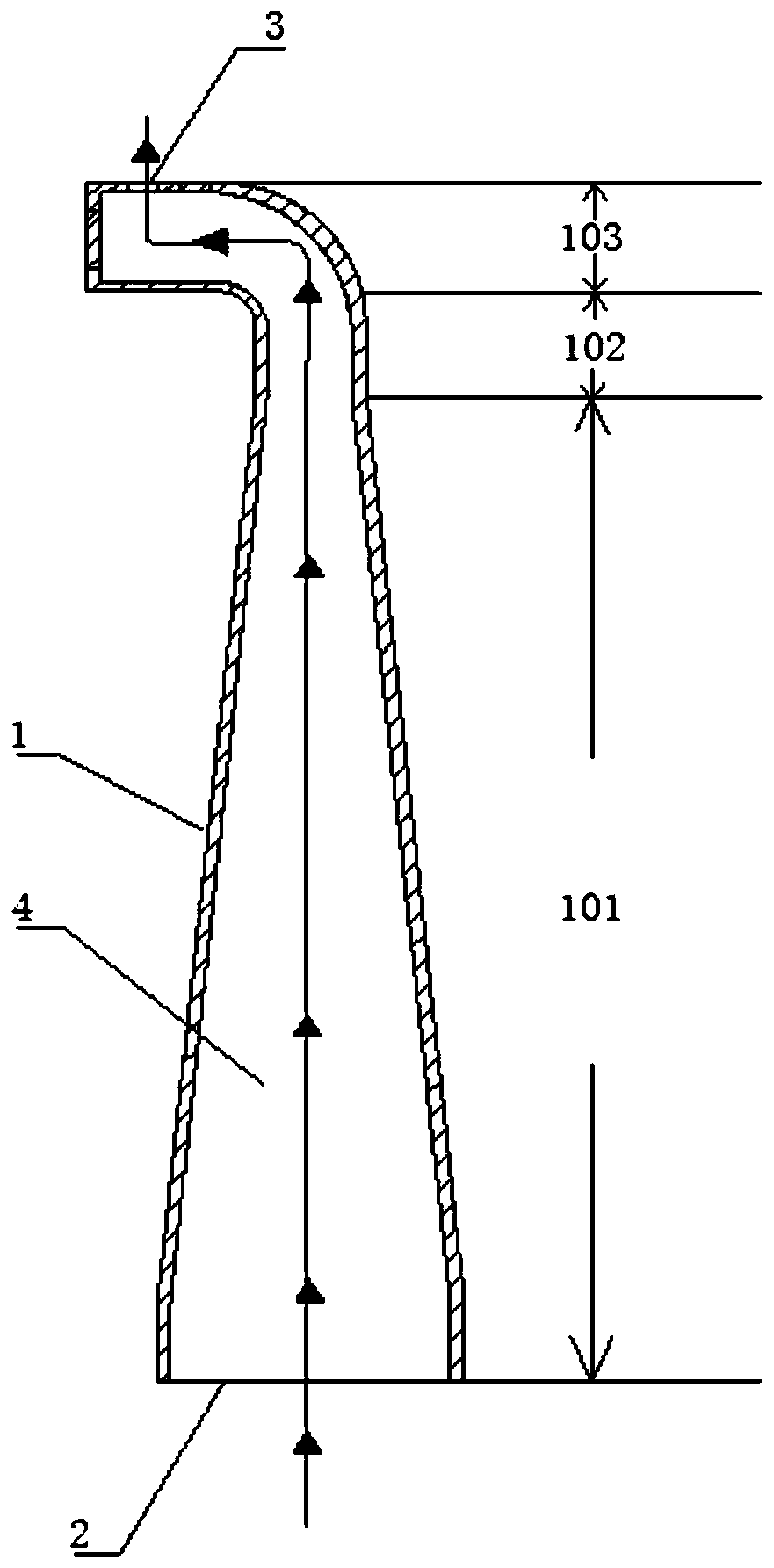

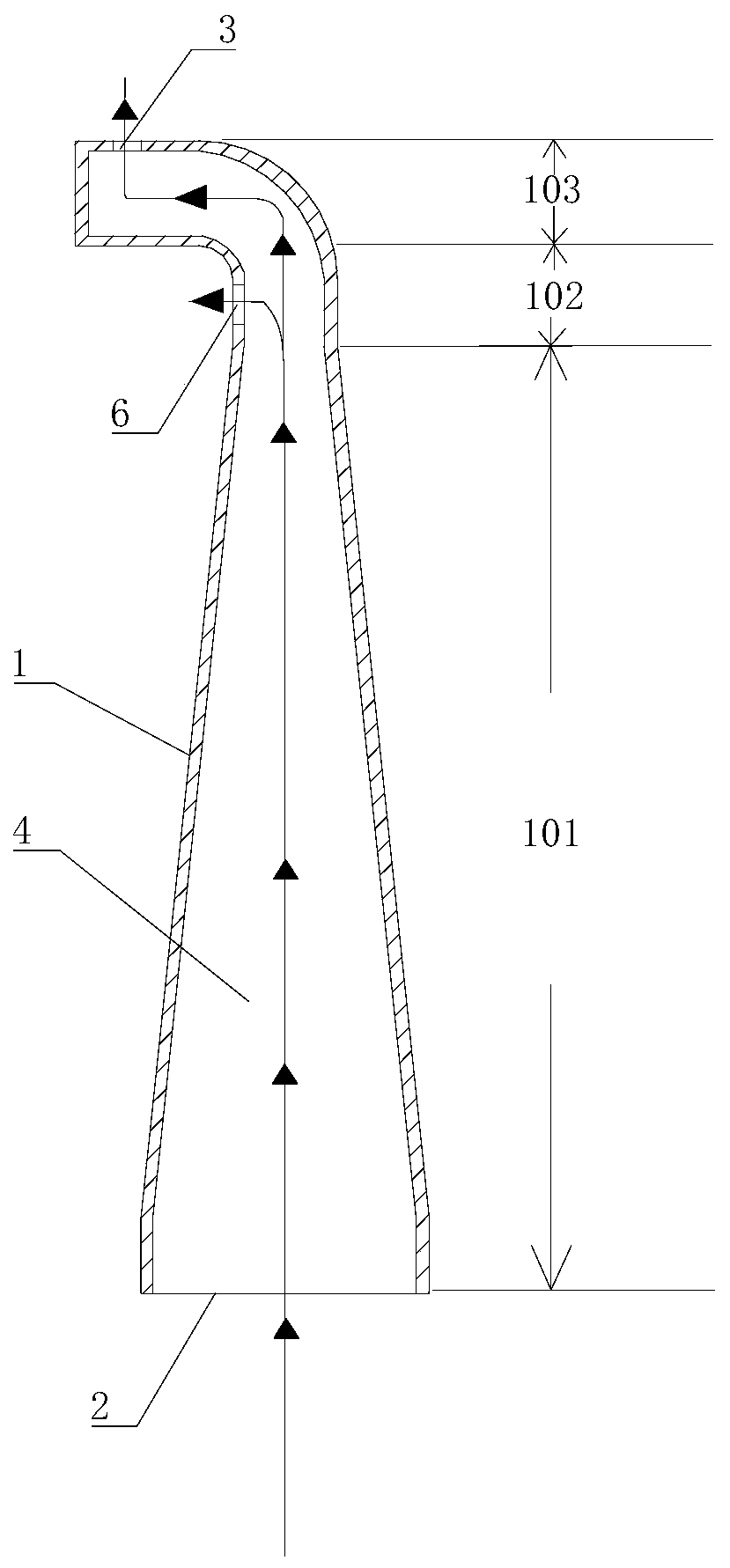

The invention discloses a tire rubber sheet electron radiation crosslinking pretreatment device and a tire rubber sheet electron radiation crosslinking pretreatment method. A conveyor belt used for realizing an arc-shaped conveying track is arranged in a shielding room; based on the ray absorption by the interior wall of the shielding room, the ratio of attenuation generated by multiple times of refraction is increased by increasing the reflection times of rays, and thus, the rays can be absorbed to a maximum degree and the ray leakage can be reduced so as not to pollute the environment and hurt the body the operators. The device mainly comprises a radiation room, the shielding room and the conveyor belt for conveying rubber sheets, wherein an electron accelerator is arranged in the radiation room and above the conveyor belt, and the conveyor belt runs through the radiation room and the shielding room. Ray absorbing plates are adhered on all of the inner walls of the radiation room and the shielding room. The conveyor belt comprises a horizontal conveying part arranged in the radiation room and below the electron accelerator and an oblique conveying part arranged in the shielding room. The oblique conveying part has at least one group of left and right symmetric and vertically bent continuous conveying section.

Owner:MESNAC

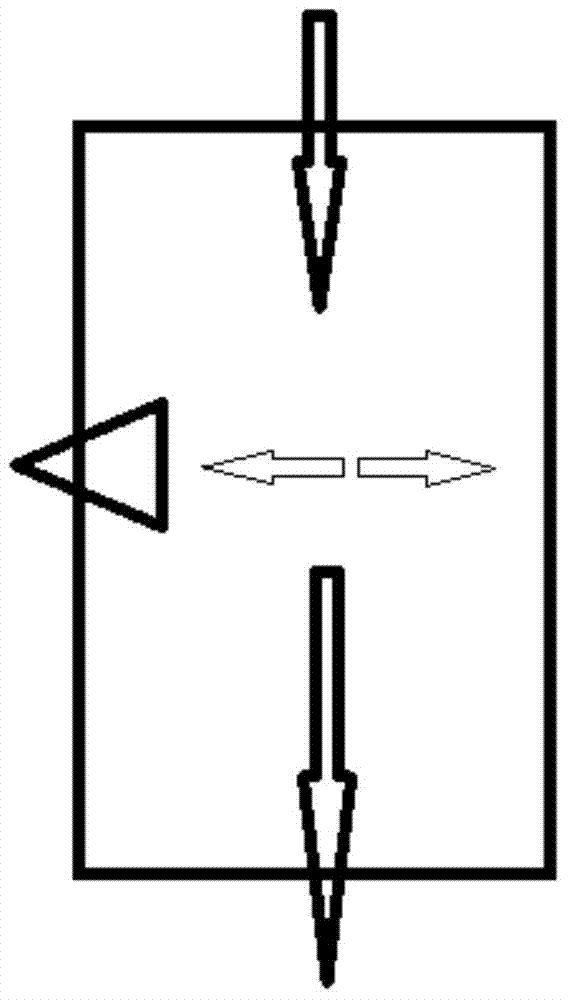

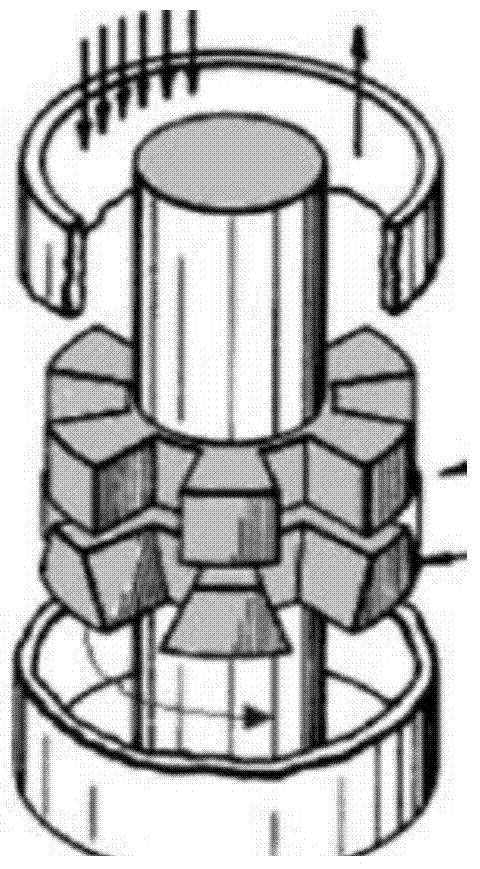

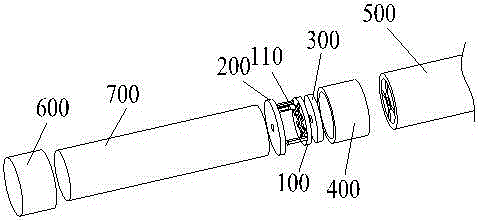

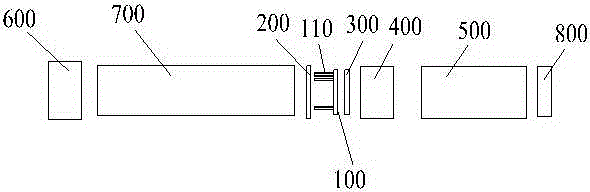

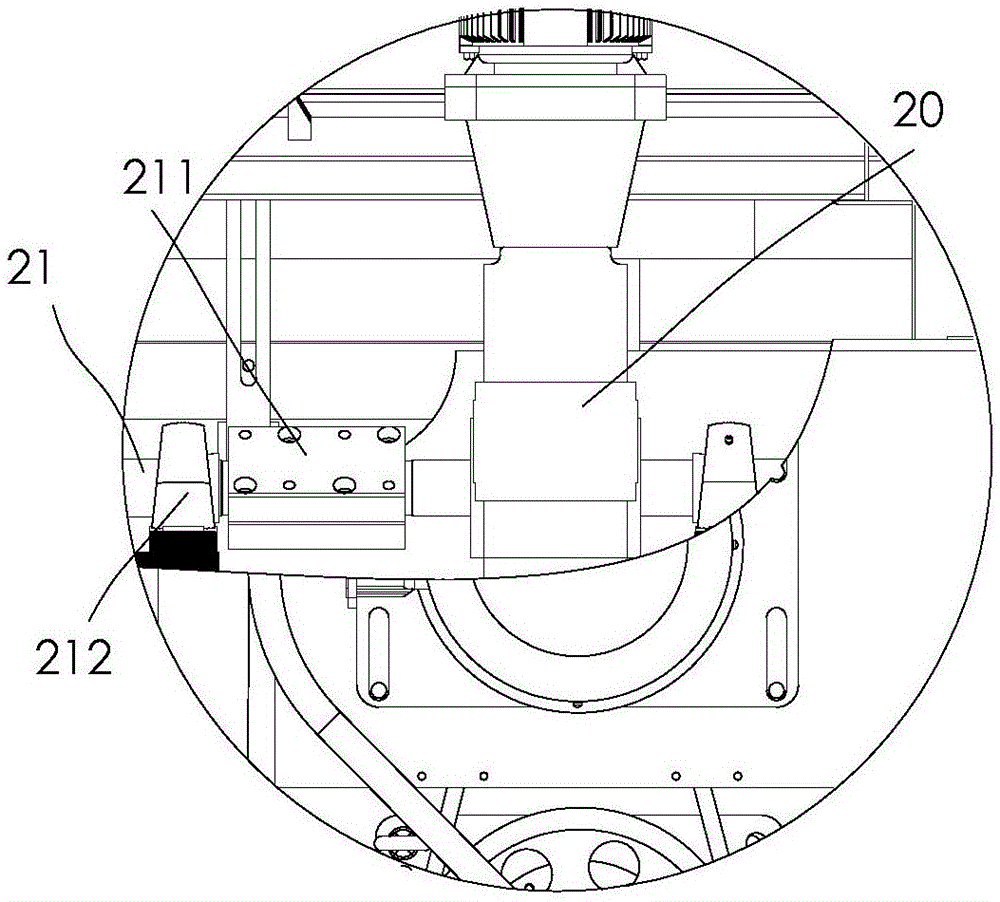

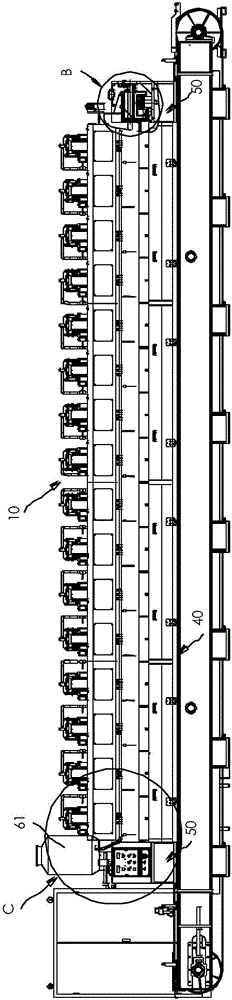

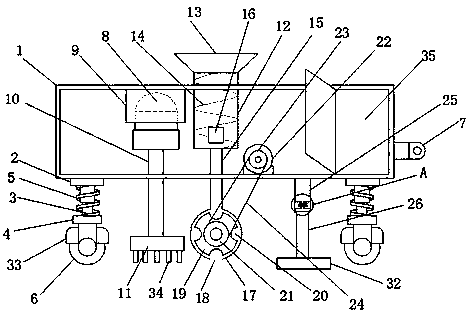

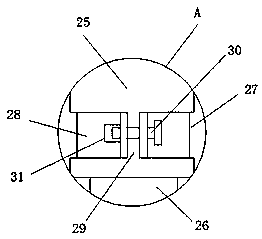

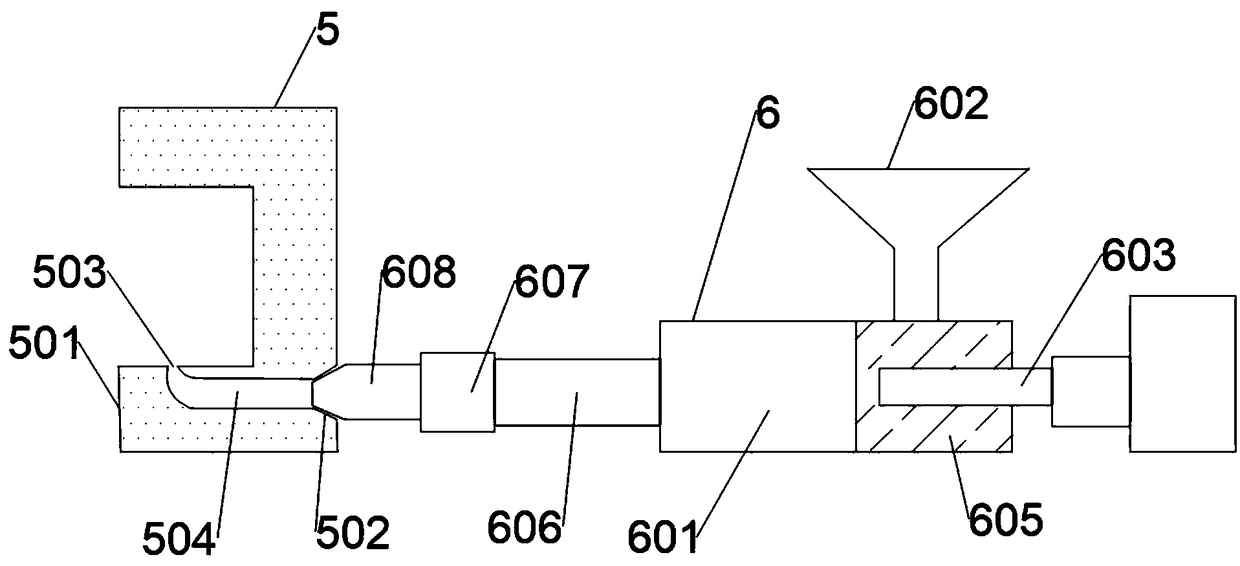

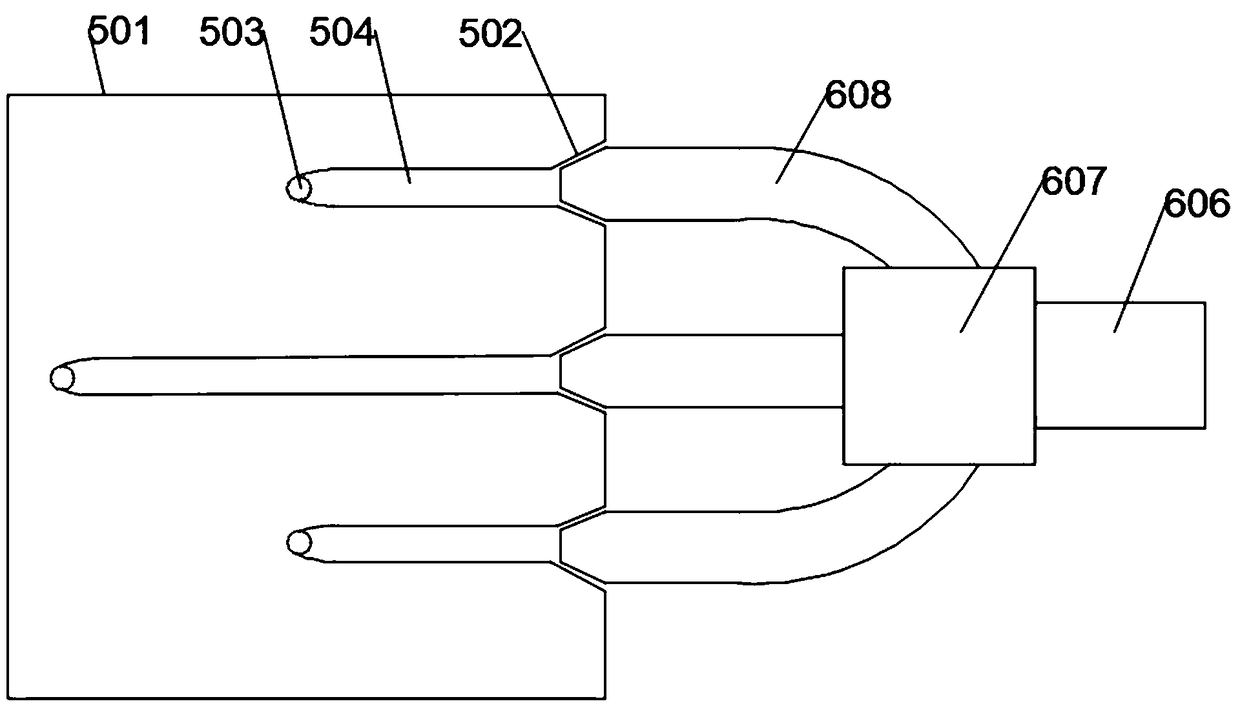

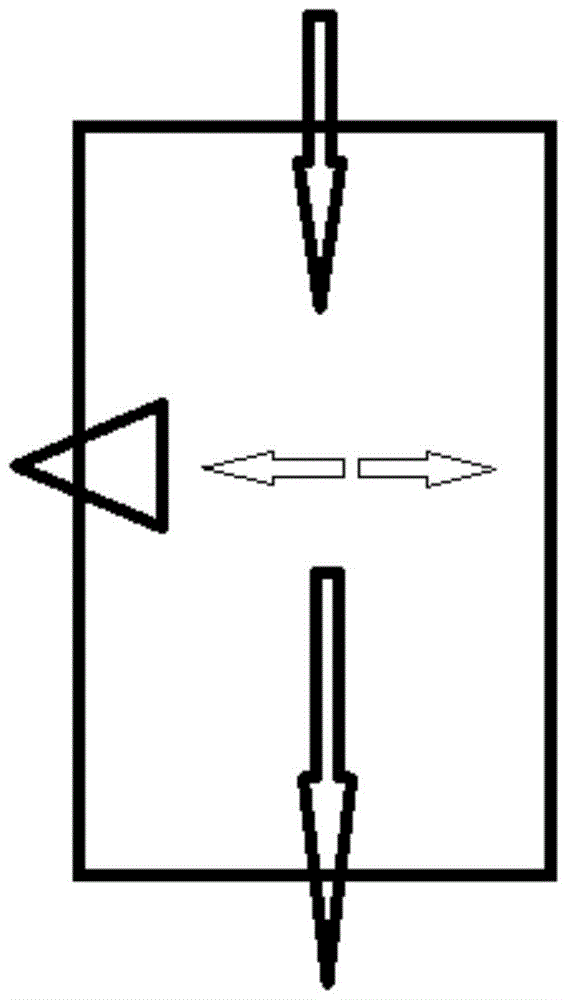

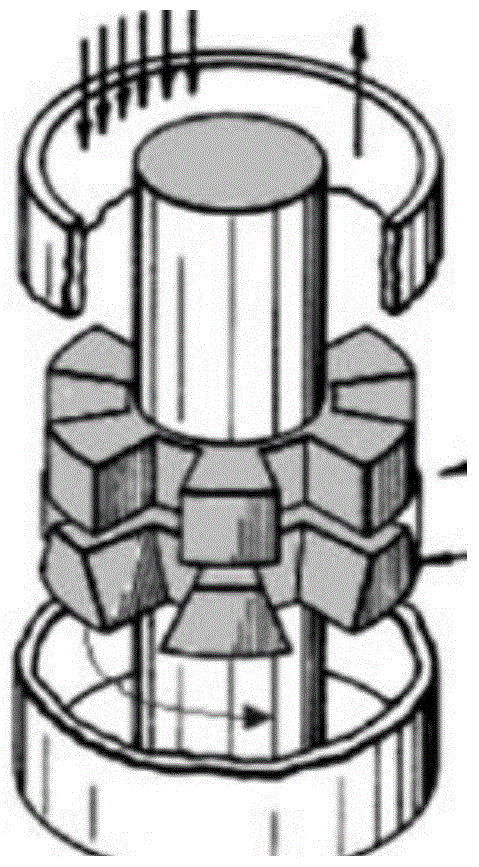

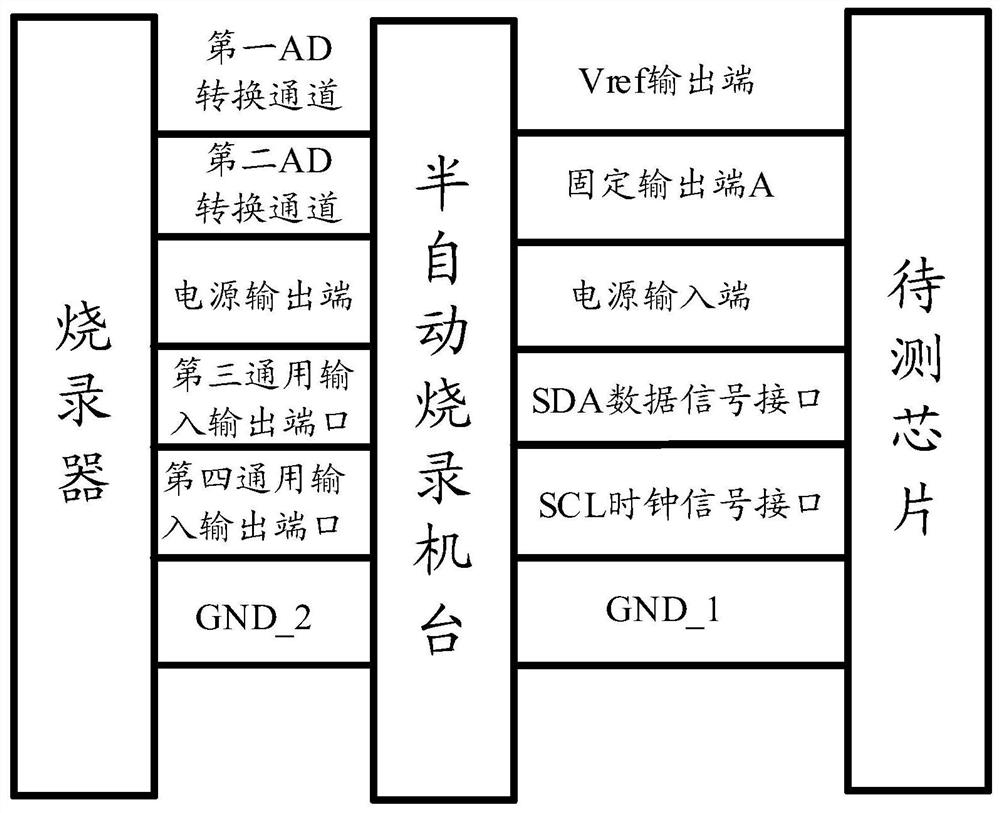

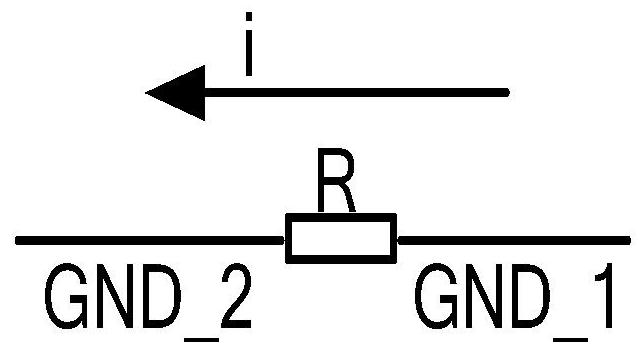

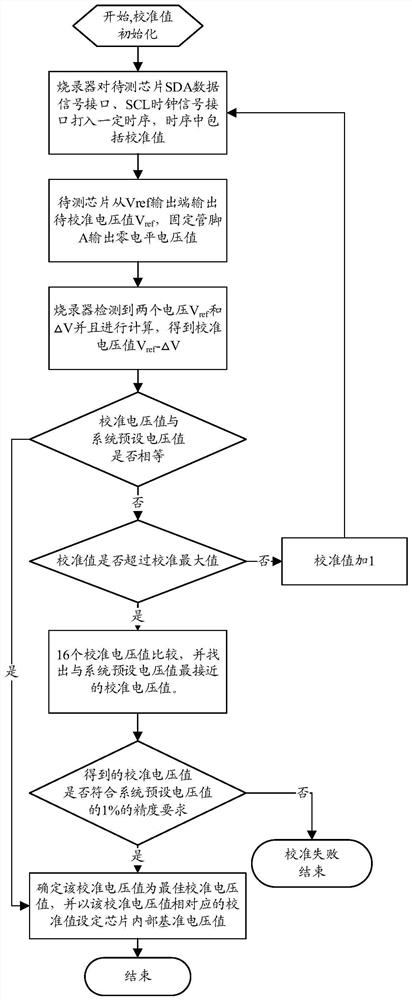

Down-hole slurry pulse signal generation device

ActiveCN103670380AIncrease transfer rateGuaranteed transmission speedSurveyDepth in a wellCommunications system

The invention provides a down-hole slurry pulse signal generation device. The down-hole slurry pulse signal generation device comprises a plurality of driving valves and a plurality of communication systems corresponding to the driving valves in a one-to-one mode. Due to the arrangement of the multiple driving valves, the types of generated data signals while drilling is more; due to the arrangement of the independent communication systems, the overall transmission speed can be effectively guaranteed, and the precision of detection is guaranteed to a certain extent. In addition, in combination with multiple modulation modes, the data transmission rate is further increased. The signals can be controlled to be strong or weak through selection of the outer diameter of each driving valve and the inner diameter of a limiting base so that the transmitting speed of the data signals while drilling can be guaranteed, the downhole slurry pulse signal generation device can be suitable for working environments with different wells, different displacements and different well depths, and therefore the adaptability to the various environments is greatly improved; the number of working driving valves can be controlled, and therefore high flexibility is obtained.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

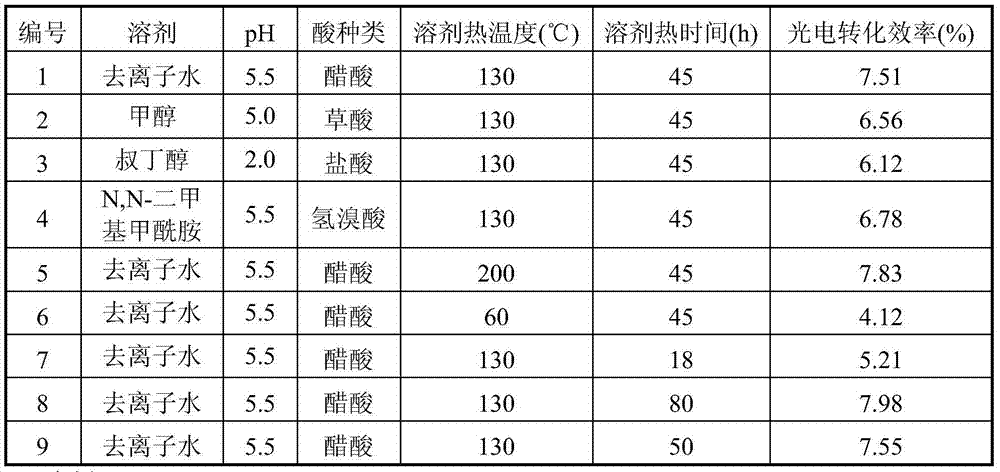

Graphene/iron-nickel sulfo-spinel composite catalyst, preparation method therefor, and method for preparing dye-sensitized solar cell

ActiveCN105448526AStable structureLower resistanceLight-sensitive devicesFinal product manufactureManufacturing technologyNon platinum

The invention discloses a graphene / iron-nickel sulfo-spinel composite catalyst, and the composite catalyst comprises graphene oxide serving as a substrate, and iron-nickel sulfide which is in in-situ growth on graphene and is in a spinel structure. The atom ratio of iron, nickel and sulfur in the iron-nickel sulfide is x: (3-x): 4, wherein x is greater than zero and less than three. The invention also provides a preparation method for the composite catalyst, and a method for preparing a dye-sensitized solar cell. The composite catalyst is ingenious in design, is simple in manufacturing technology, well solves problems that a non-platinum system catalyst is low in catalytic efficiency and a platinum catalyst is high in cost, and can meet the demands of the industrial production well. Therefore, the composite catalyst is wide in application range, and is very suitable for large-scale production.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

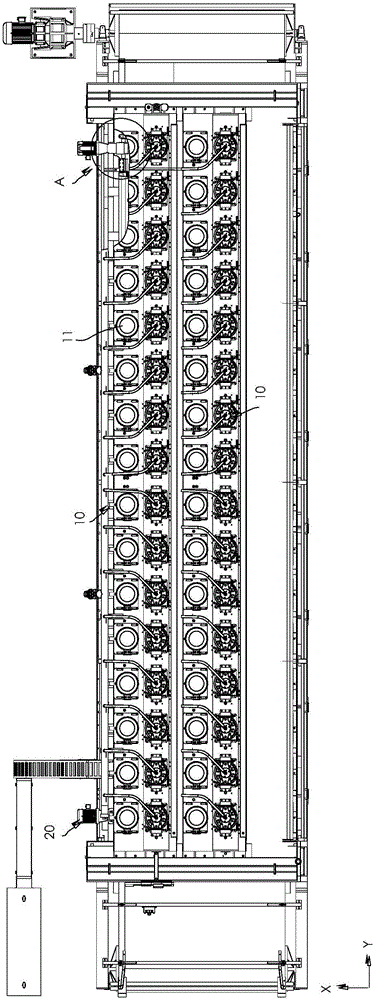

Efficient polishing machine

InactiveCN106514478ANo need to reduce conveying speedReduce swingGrinding carriagesPolishing machinesEngineeringMechanical engineering

The invention discloses an efficient polishing machine. The efficient polishing machine comprises a conveying mechanism, at least two sets of polishing assemblies and a first driving mechanism, wherein the conveying mechanism conveys outside workpieces to be machined in the first direction; the polishing assemblies are used for polishing to-be-machined faces of the workpieces to be machined and arranged in the second direction in a space mode; the second direction intersects with the first direction; and the first driving mechanism is used for driving the polishing assemblies to reciprocate in the second direction. According to the efficient polishing machine, the polishing swing amplitude can be effectively reduced; and meanwhile, higher workpiece feeding speed is met, and the polishing efficiency is improved.

Owner:GUANGDONG EDING IND

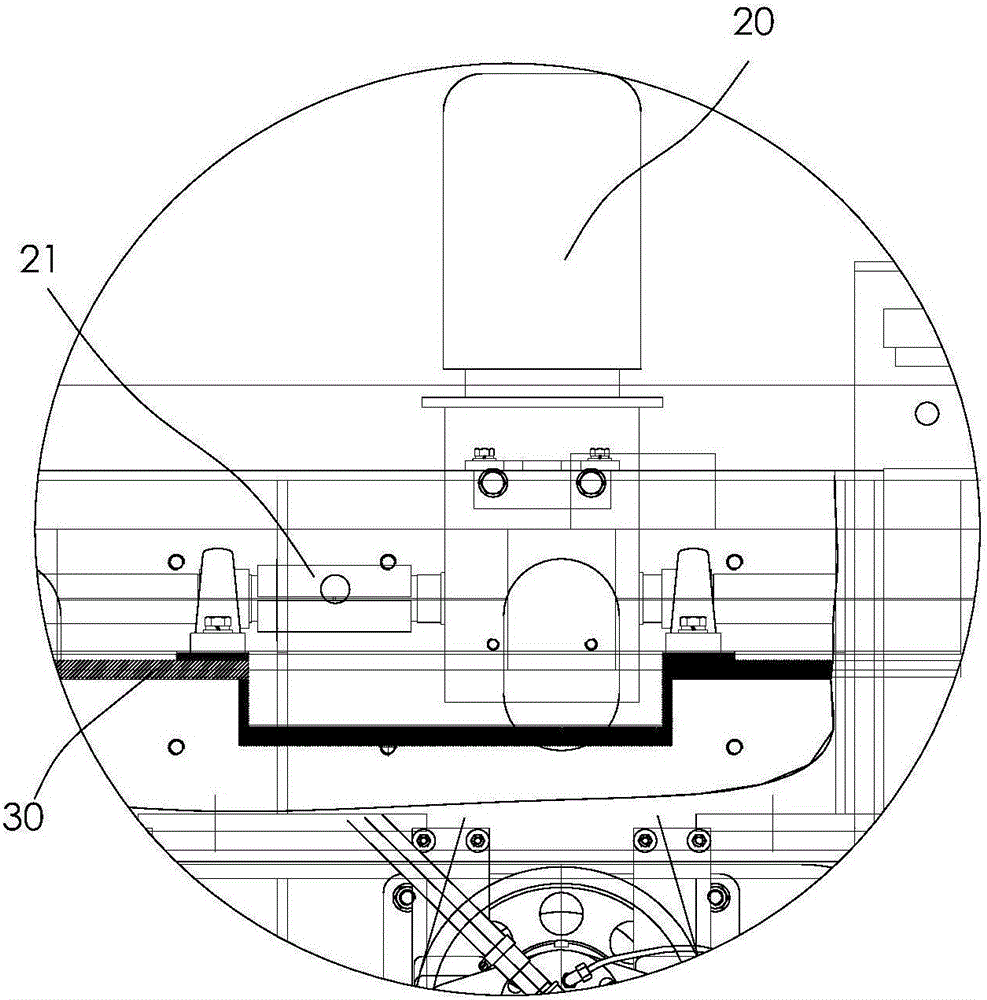

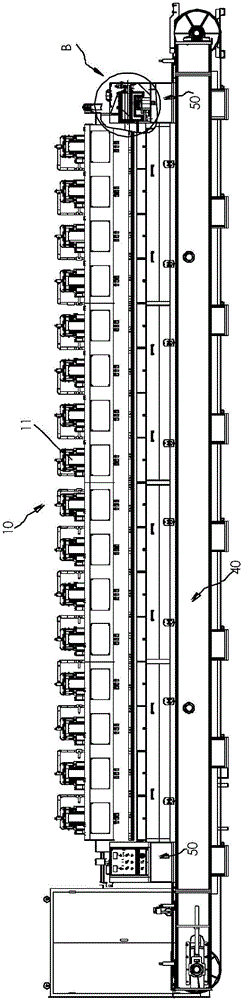

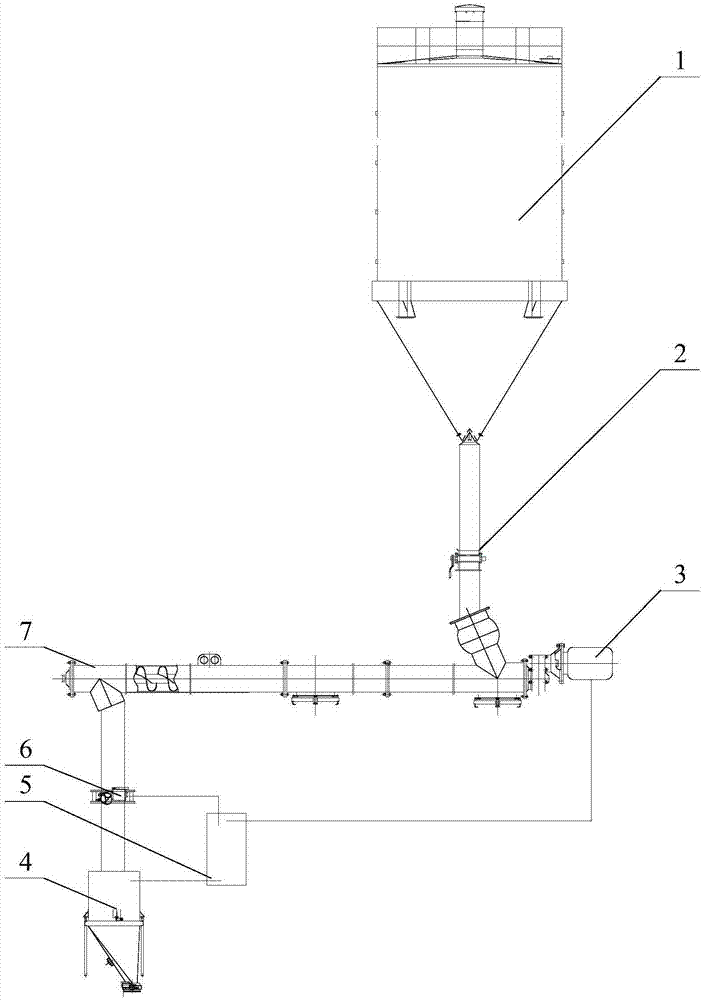

Powder material metering and conveying device of mixing plant and control method of powder material metering and conveying device

InactiveCN102615711AControl the feeding amountGuaranteed delivery speedControl apparatusSold ingredients supply apparatusEngineeringScrew conveyor

The invention discloses a powder material metering and conveying device of a mixing plant and a control method of the powder material metering and conveying device. The powder material metering and conveying device of the mixing plant comprises a material storage bin, a screw conveyer, a feed regulating valve, a metering hopper and a control part, wherein the screw conveyer is provided with a material inlet and a material outlet and the material inlet is connected with the material storage bin; the feed regulating valve is provided with an input end and an output end and the input end is connected with the material outlet; the metering hopper is connected with the output end; and the control part is connected with the feed regulating valve and the metering hopper and is used for receiving the metering signal of the metering hopper and controlling the feed regulating valve to adjust feed caliber. The powder material metering and conveying device of the mixing plant and the control method of the powder material metering and conveying device have the advantages that the powder materials can be rapidly conveyed, the working efficiency is high and the metering accuracy is high.

Owner:SANY HEAVY IND CO LTD (CN)

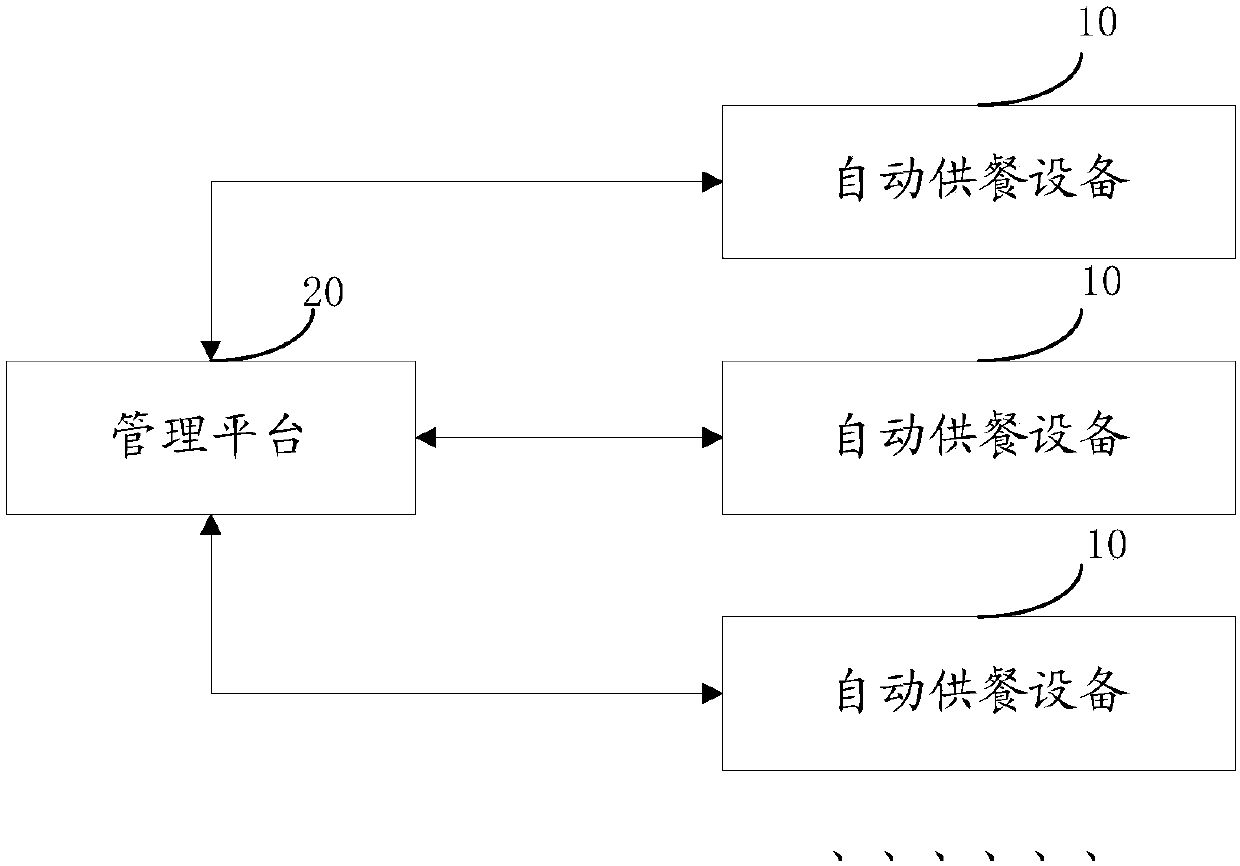

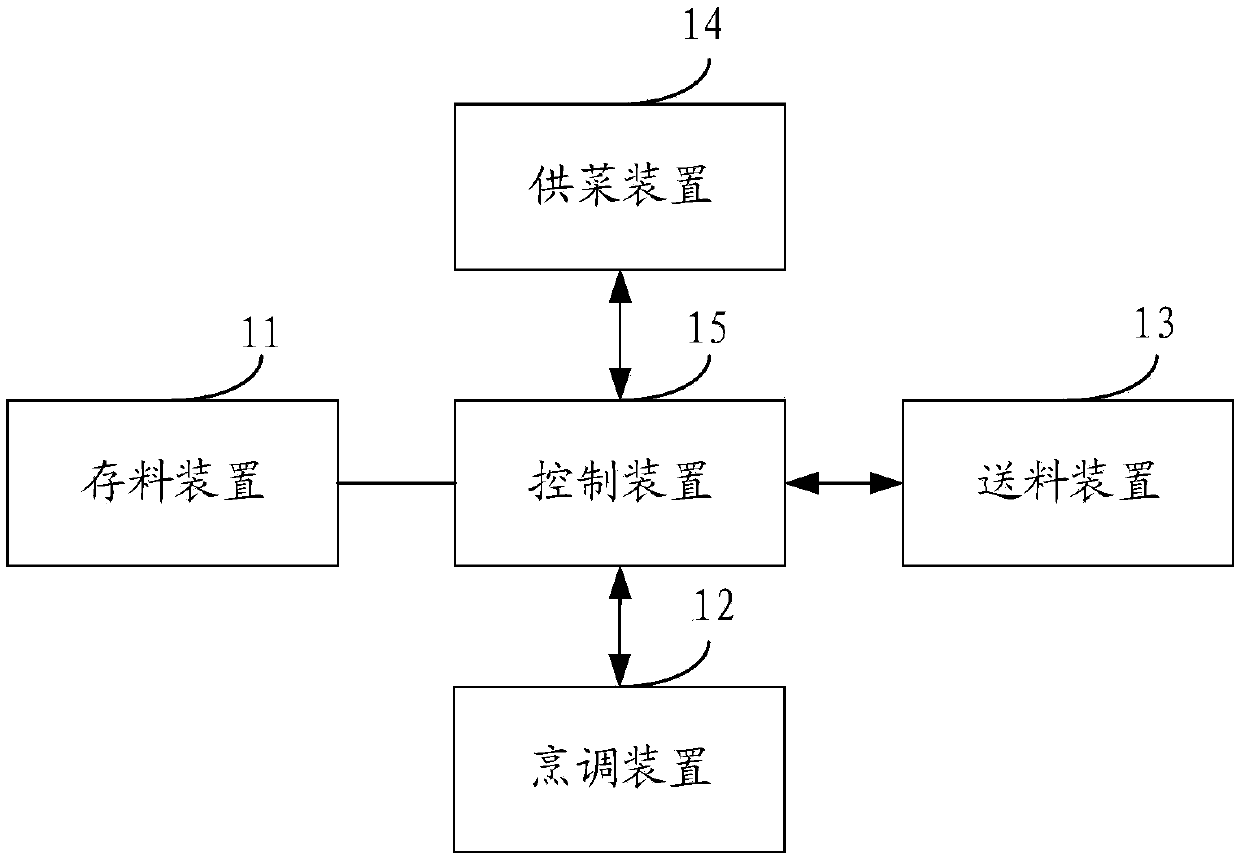

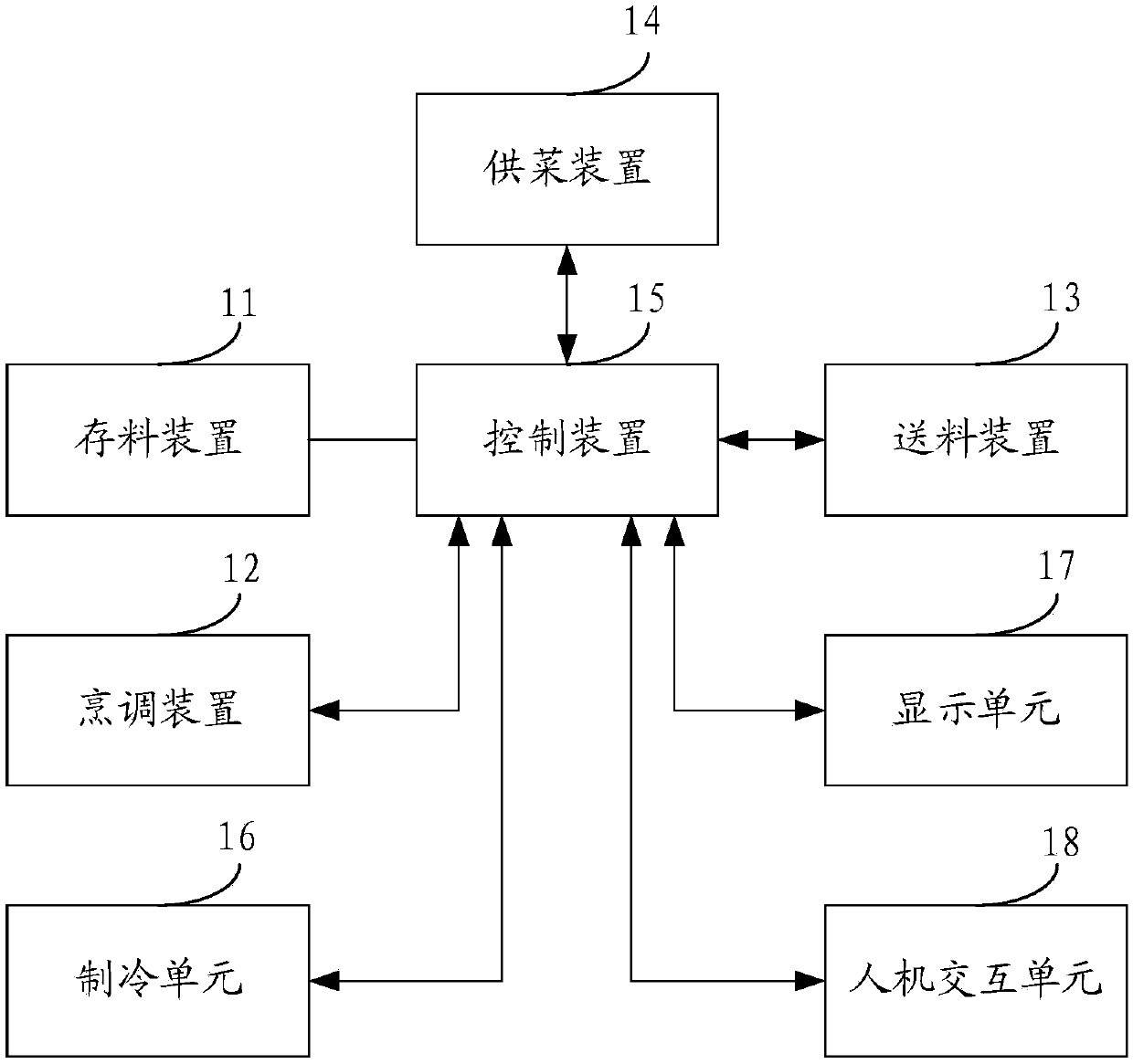

Automatic meal supply system

PendingCN110136028AGuaranteed delivery speedEnhance the dining experienceBuying/selling/leasing transactionsResourcesEngineeringSanitation

The invention is applicable to the technical field of catering, and provides an automatic meal supply system. The automatic meal supply system comprises a management platform and at least one automatic meal supply device connected and communicated with the management platform. The automatic meal supply device is provided with at least one cooking device. The management platform can communicate with a plurality of meal ordering entrances for receiving meal ordering information of the user, and distributing cooking tasks to the automatic meal supply device matching the meal ordering informationof the user; and the automatic meal supply device automatically cooks the dishes customized by the user according to the cooking tasks distributed by the management platform and provides the dishes for the user. According to the automatic meal supply device, a series of processes from ordering of the user to outputting of cooked dishes to the user are completed; sanitation, taste and meal supply speed of the meal are guaranteed; and the labor cost is greatly reduced.

Owner:深圳卡帕智能系统有限公司

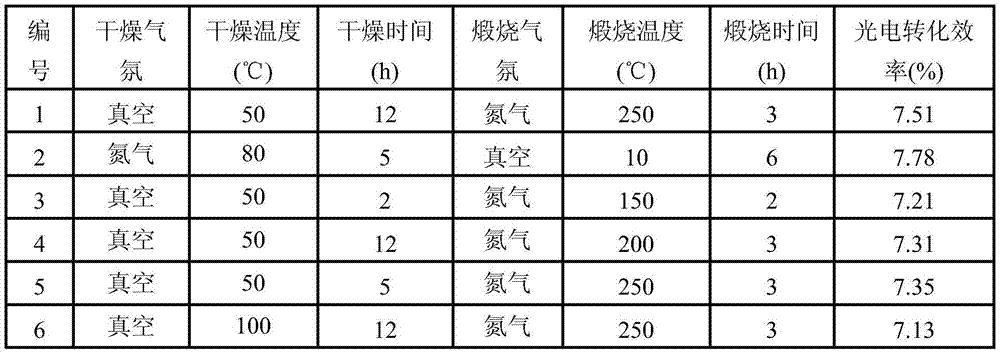

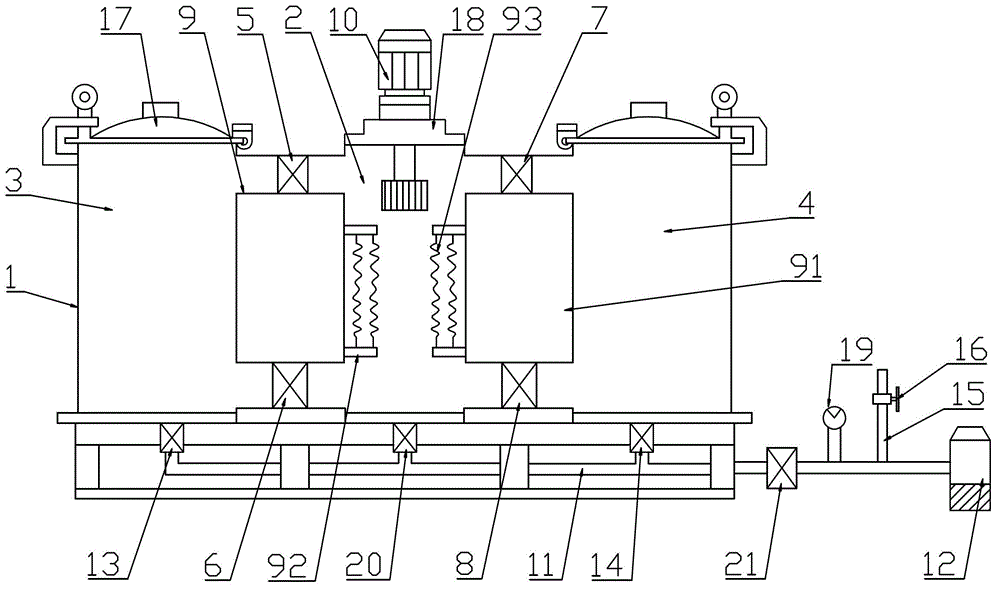

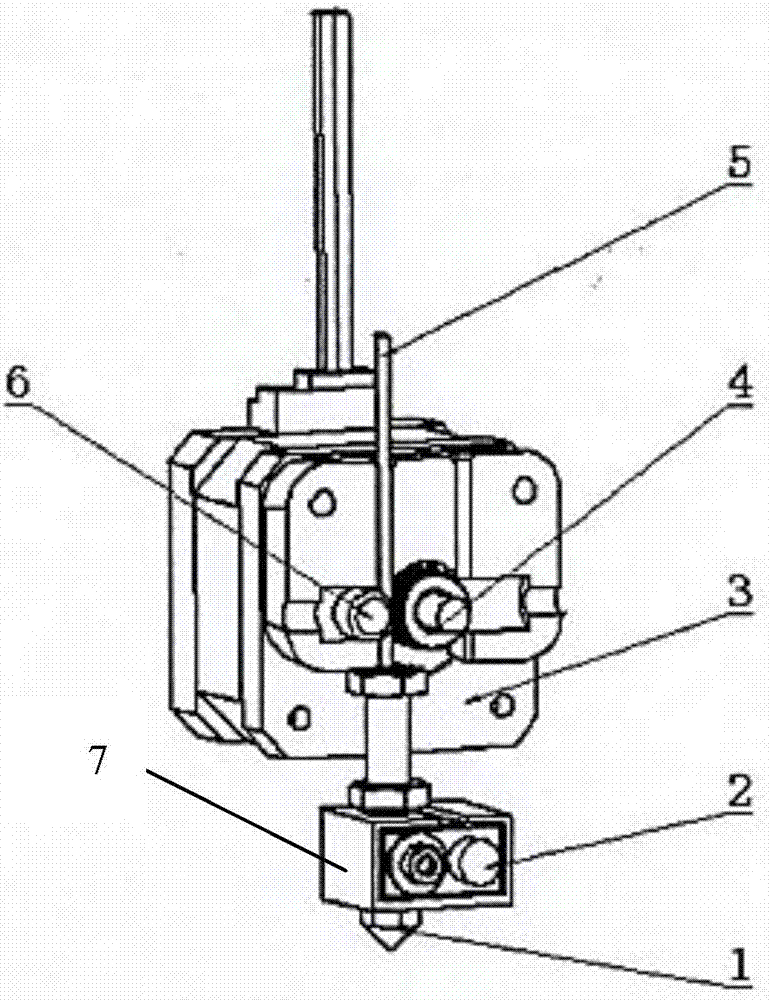

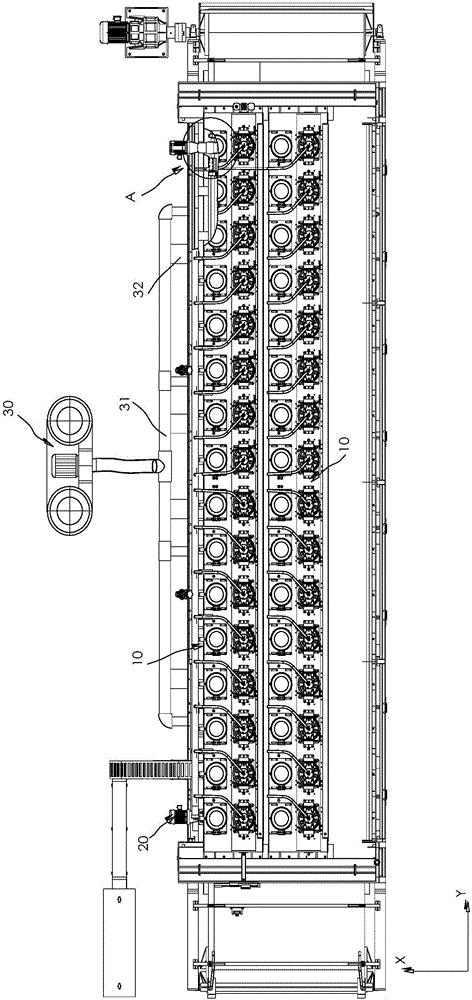

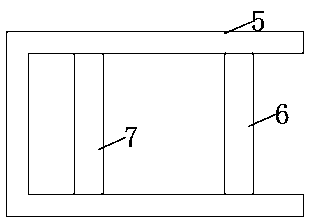

Low-temperature hot air circulation heat treatment furnace for magnetic core and application method of heat treatment furnace

InactiveCN103331446AReduce energy consumptionEnsure uniformity and delivery speedMagnetic coreGas pipeline

The invention relates to a low-temperature hot air circulation heat treatment furnace applicable to a non-crystalline or ultra-crystalline magnetic core or a magnetic ring, and an application method of the heat treatment furnace. The heat treatment furnace comprises a furnace body, wherein a heating furnace pipe, a first heat treatment furnace pipe and a second heat treatment furnace pipe are arranged in the furnace body; the first heat treatment furnace pipe is provided with a control valve I and a control valve II; the second heat treatment furnace pipe is provided with a control valve III and a control valve IV; the heating furnace pipe is internally provided with a heating device and a centrifugal fan; the furnace body is externally provided with a gas pipeline connected with a vacuumizer; and the gas pipeline is communicated with the two furnace pipes, provided with a ventilation valve I and a ventilation valve II, and connected with a gas inlet pipeline communicated with inert shielding gas. The heat treatment furnace and the application method have the benefits that 1) the two heat treatment furnace pipes are alternately used, so that waste heat is utilized effectively, and the energy consumption is reduced; 2) a convective heat transfer mode is adopted, so that temperature uniformity and the transfer speed are ensured, and the product quality is improved; and 3) the furnace loading quantity of a product is increased; a heat treatment space of the product is utilized effectively; and the energy consumption of the single magnetic core is reduced.

Owner:ZHEJIANG ZHENGNUO COMPOSITE MATERIAL

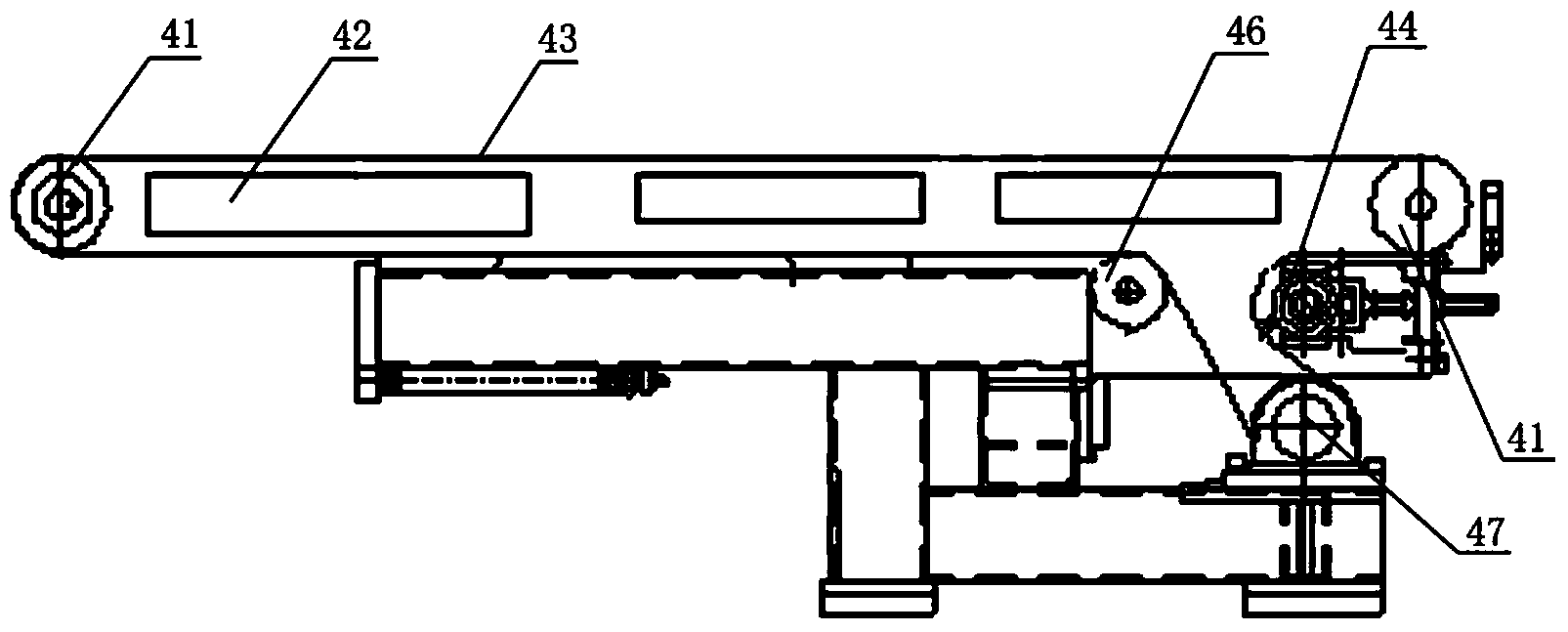

Discharge mechanism of sheet metal shearing machine

InactiveCN104001829AReduce frictionGuaranteed delivery speedMetal-working feeding devicesPositioning devicesThin slabEngineering

The invention relates to a discharge mechanism of a sheet metal shearing machine. The discharge mechanism comprises a slowdown motor, a conveying belt, an electromagnet and two roll shafts; one of the two roll shafts is fixedly mounted at the discharge side of a shearing die while the other one is fixedly mounted at the entrance of the next work position; the conveying belt is sleeved outside the two roll shafts; the slowdown motor is connected to the roll shaft and drives the roll shafts to rotate; the electromagnet used for increasing surface friction between a board material and the conveying belt is fixedly mounted at the lower side of the conveying belt. As the on-off time and the magnetic size of the electromagnet arranged in a discharged material conveying device are controlled, on one hand, the conveying speed is guaranteed, and on the other hand, the relative friction between the surface of the board material and the conveying belt is reduced to the maximum extent, and accordingly the surface quality is protected.

Owner:HANGZHOU HENGLI CUTTING EQUIP

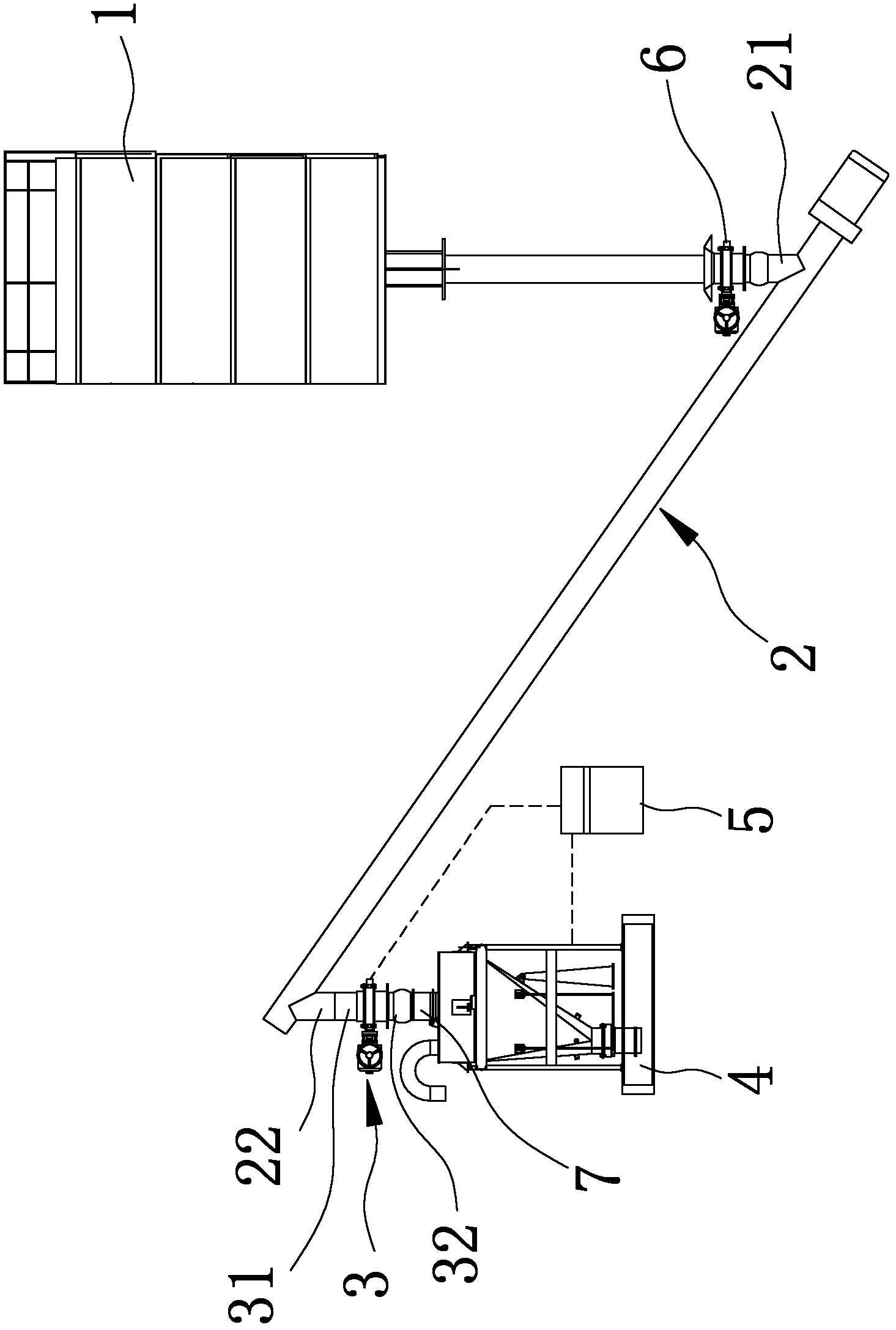

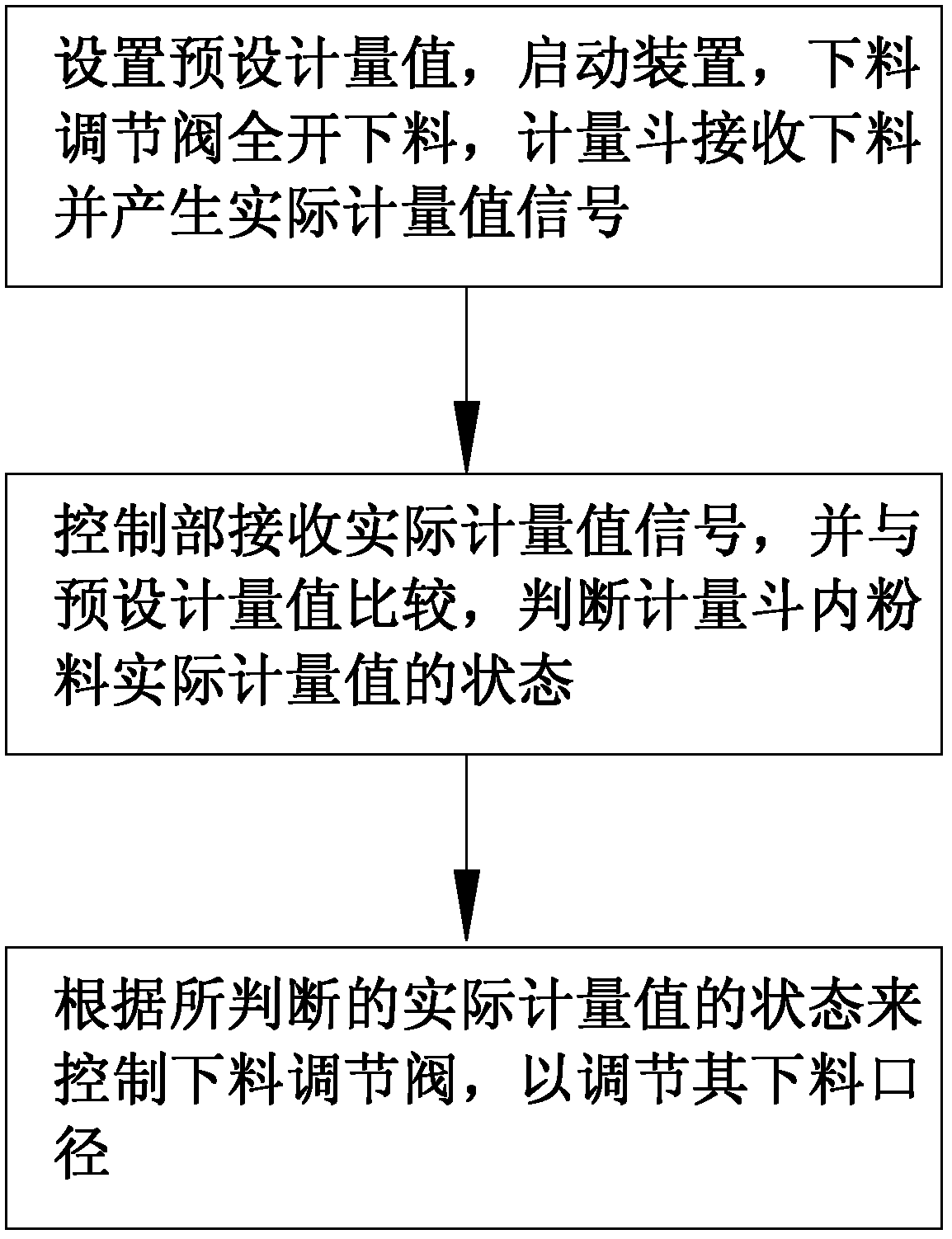

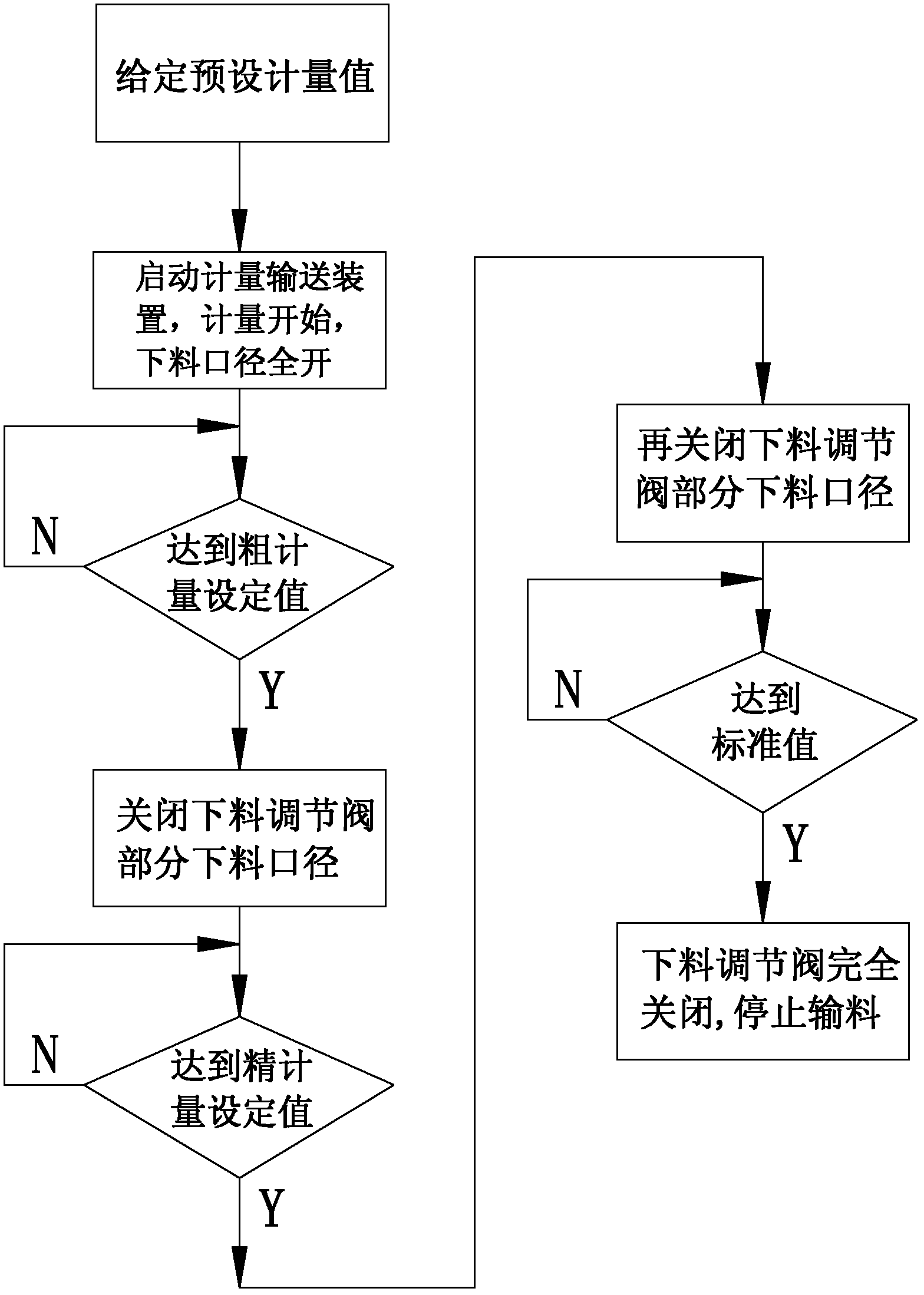

Powder measuring and conveying system and method

PendingCN106865260ARealize real-time multi-level precise controlBlanking speed reducedLoading/unloadingEngineeringDelivery system

The invention discloses a powder measuring and conveying system comprising a conveyor, a feeding device, a measuring hopper, a blanking regulating valve and a control device; the feeding device is arranged at a feeding hole of the conveyor; the measuring hopper is arranged at a discharging hole of the conveyor; the blanking regulating valve is arranged between the discharging hole and an inlet of the measuring hopper; and the control device is used for controlling the blanking regulating valve and the conveyor according to the relation between a preset measured value and an actual measured value of powder in the measuring hopper and is connected with the blanking regulating valve, the conveyor and the measuring hopper. In the powder measuring and conveying system, the blanking speed can be changed at the right moment according to the actual blanking condition due to the control action of the control device, so that the multistage precise control for the blanking regulating valve and the conveyor is realized, the measuring precision and the production quality of the system can be favorably improved, and the work efficiency is relatively high. The invention also discloses a powder measuring and conveying method by which the high-speed precise control for blanking can be realized.

Owner:FENY

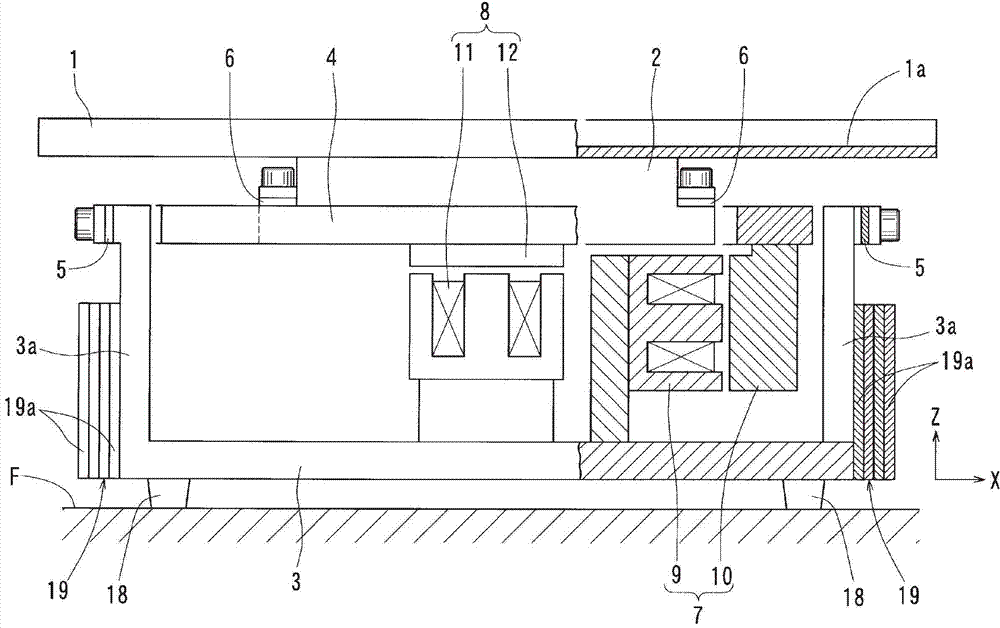

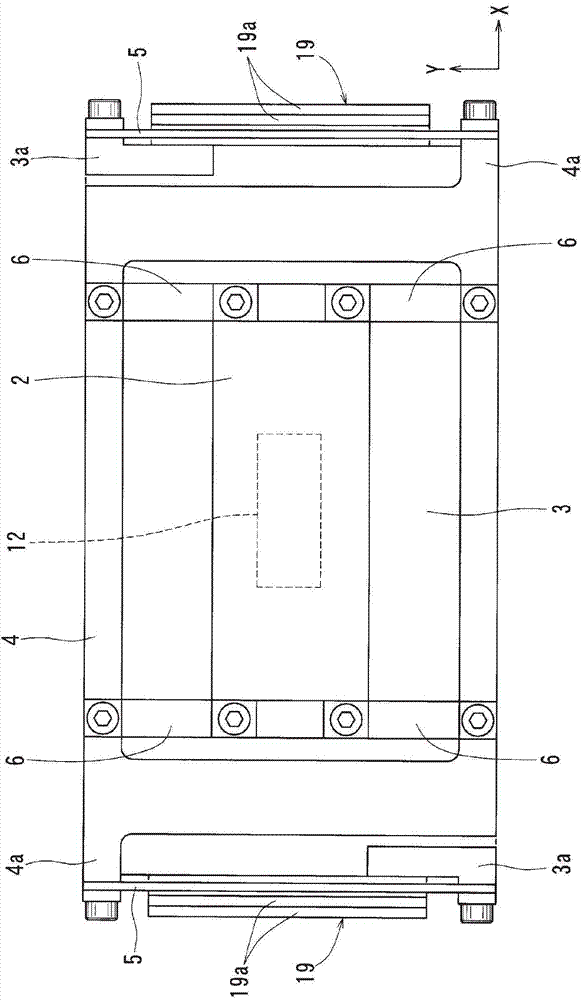

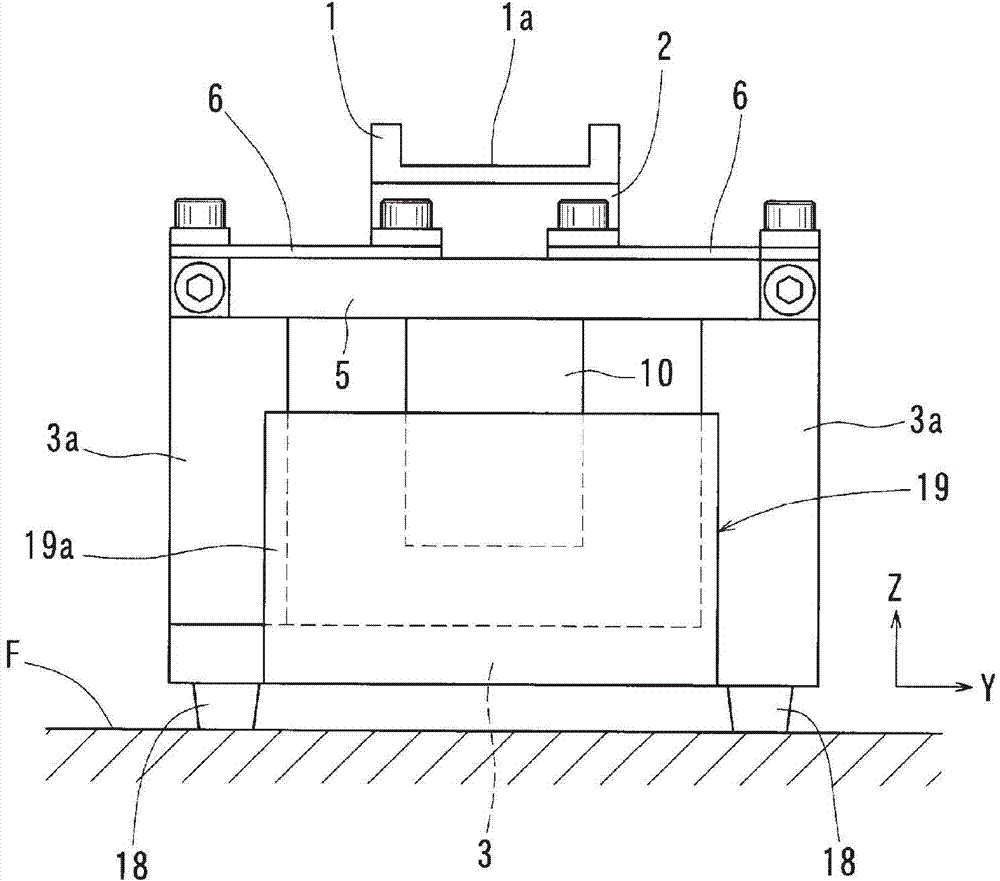

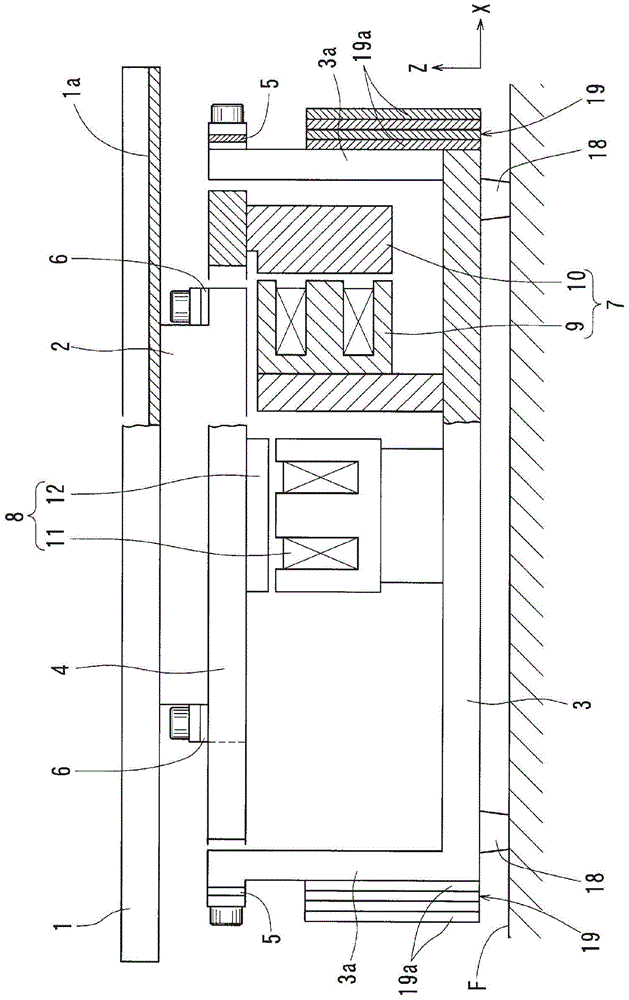

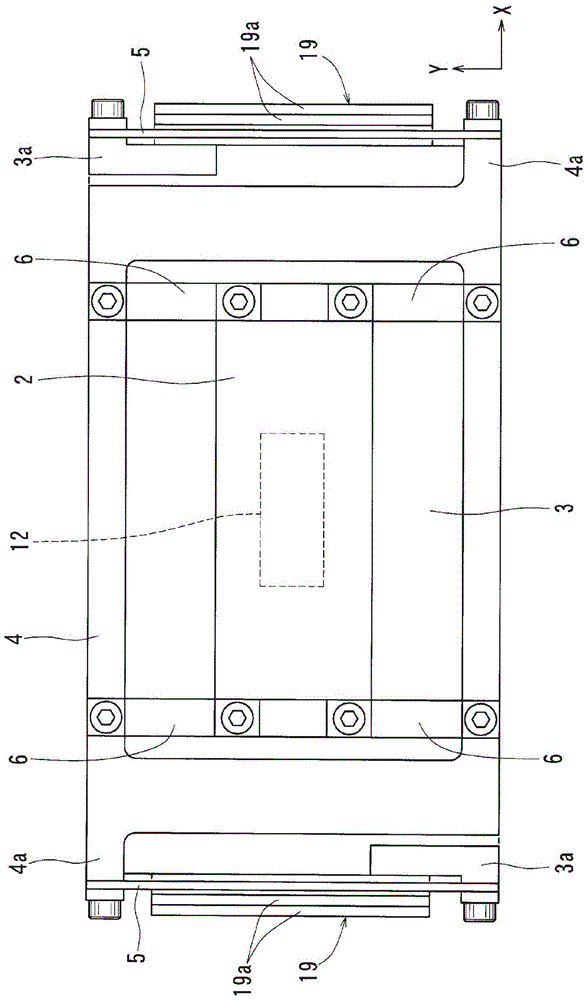

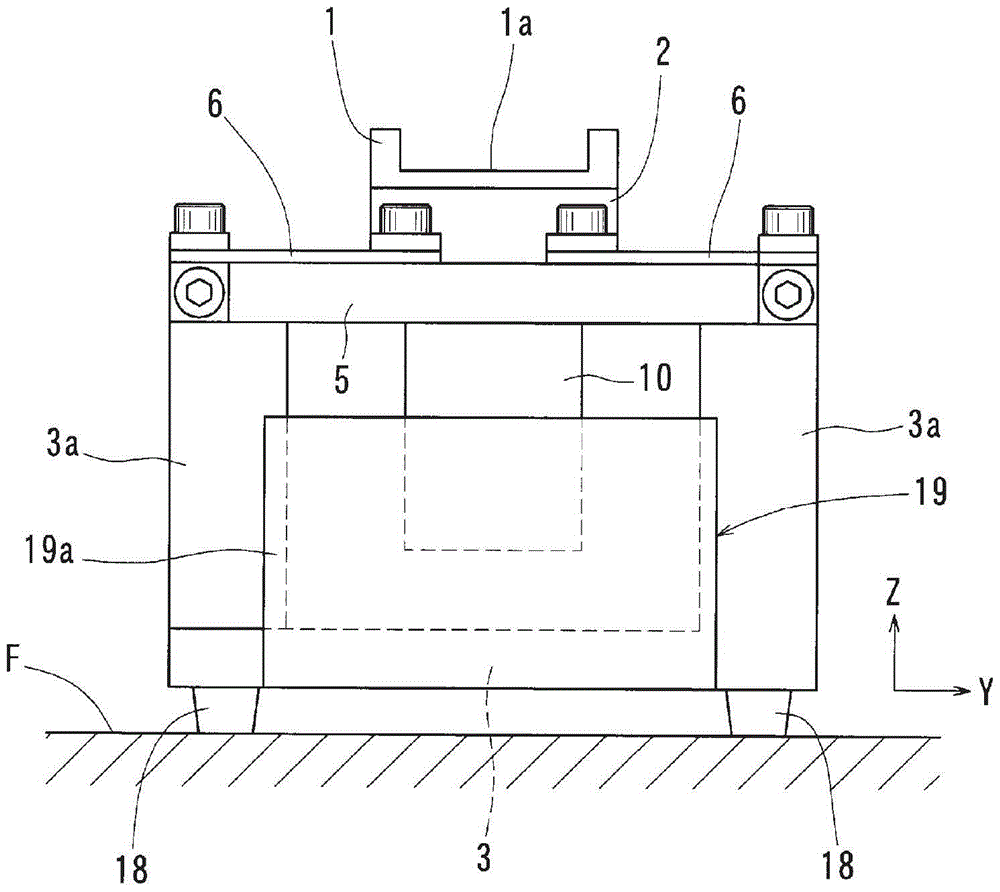

Vibrating parts transport device

ActiveCN104736460AStable deliveryGuaranteed delivery speedJigging conveyorsRotational vibrationEngineering

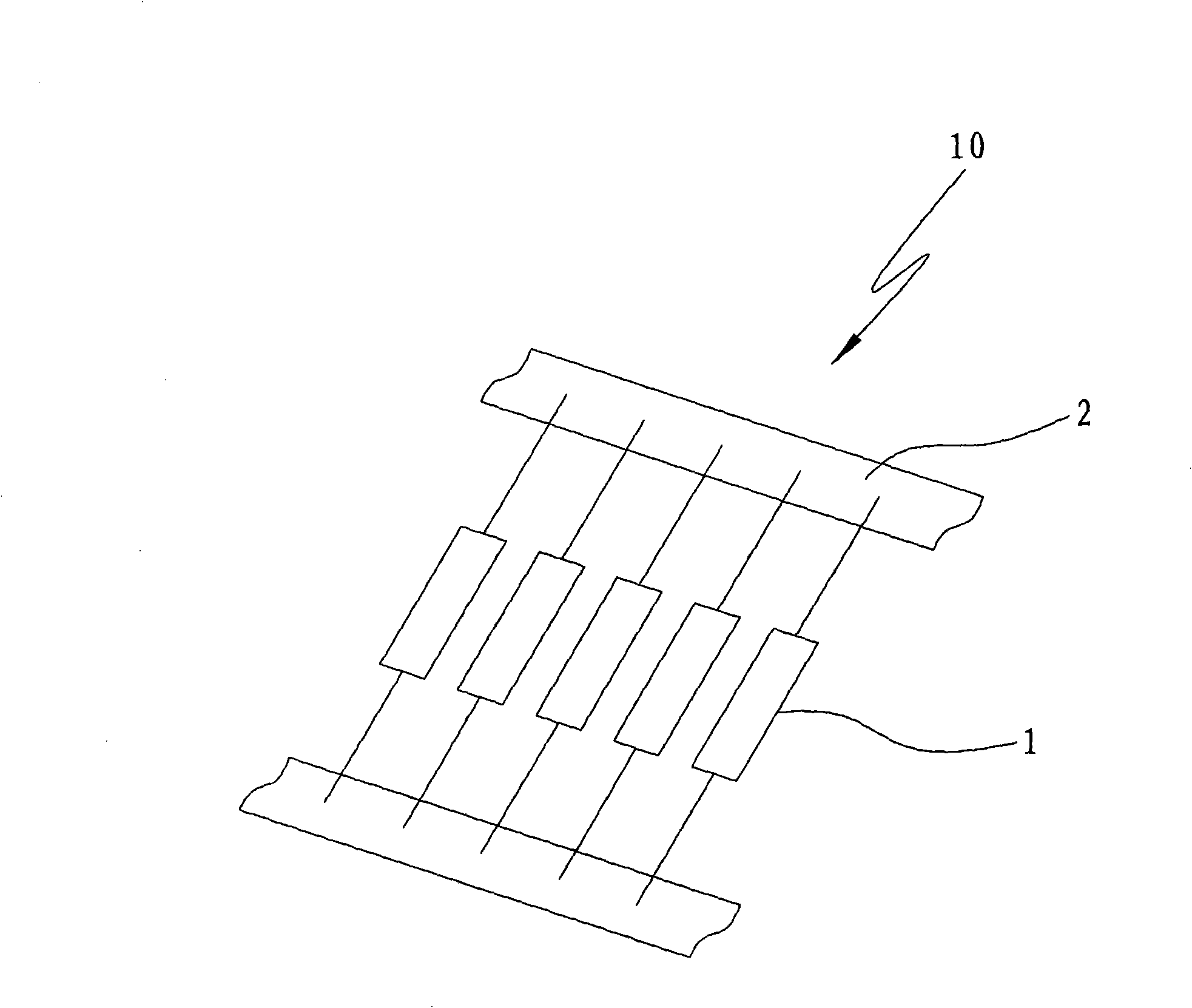

A complex vibrating type parts transport device that can maintain the parts transport speed and suppress pitching motion of a parts transport member (1). After increasing the eigenfrequency of the rotational vibration (rotational vibration mode for vibration in the horizontal direction) generated in an intermediate vibrating body (4) and a base (3) to be greater than the eigenfrequency of a rotational vibration (rotational vibration mode for vibration in the vertical direction) generated in the parts transport member (1) and a upper vibrating body (2), the pitching motion of the parts transport member (1), viewed from the floor, can be suppressed and the parts transport speed can be maintained without a decrease in the eigenfrequency of a translational vibration mode for vibration in the horizontal direction by adjusting the mass of the base (3) so that the amplitude of the pitching motion (vibration level of the rotational vibration mode for vibration in the horizontal direction) of the base (3) is near the amplitude of the relative pitching motion (vibration level of the rotational vibration mode for vibration in the vertical direction) corresponding to the base (3) of the parts transport member (1).

Owner:NTN CORP

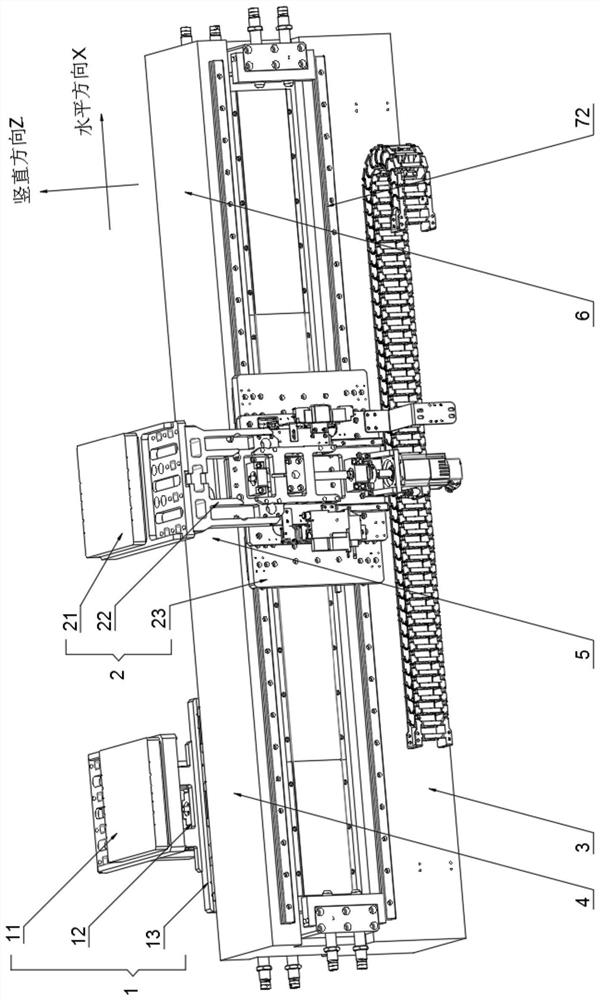

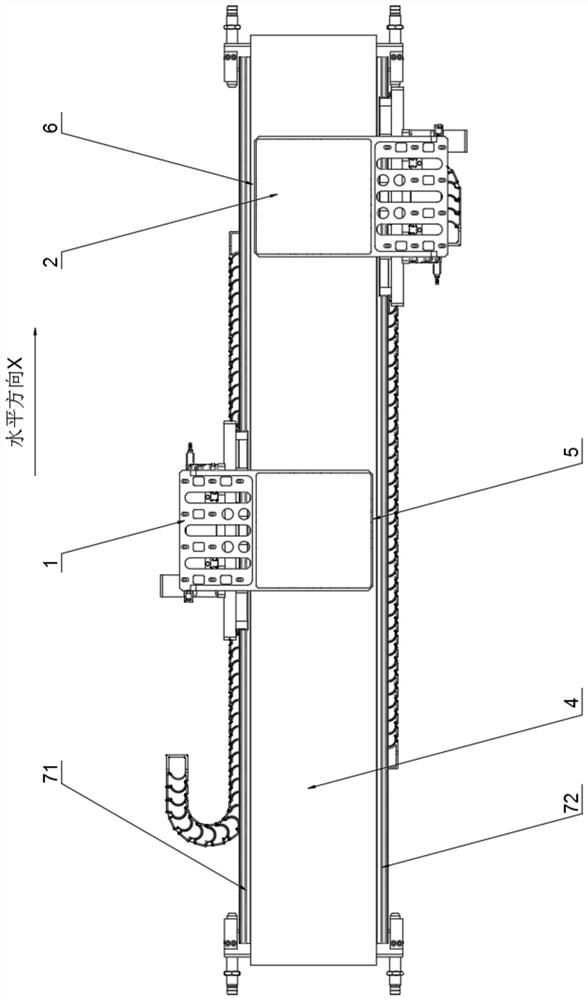

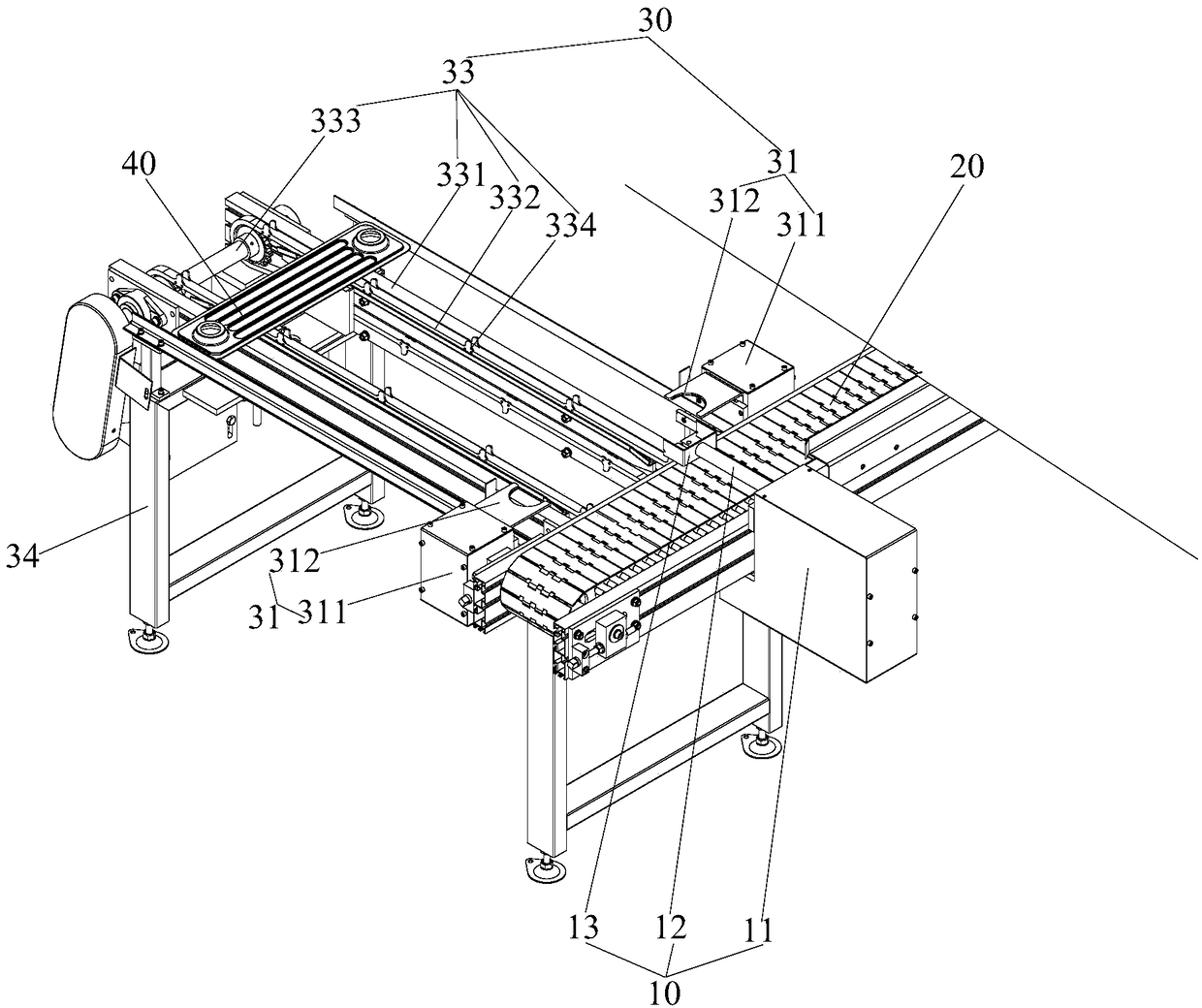

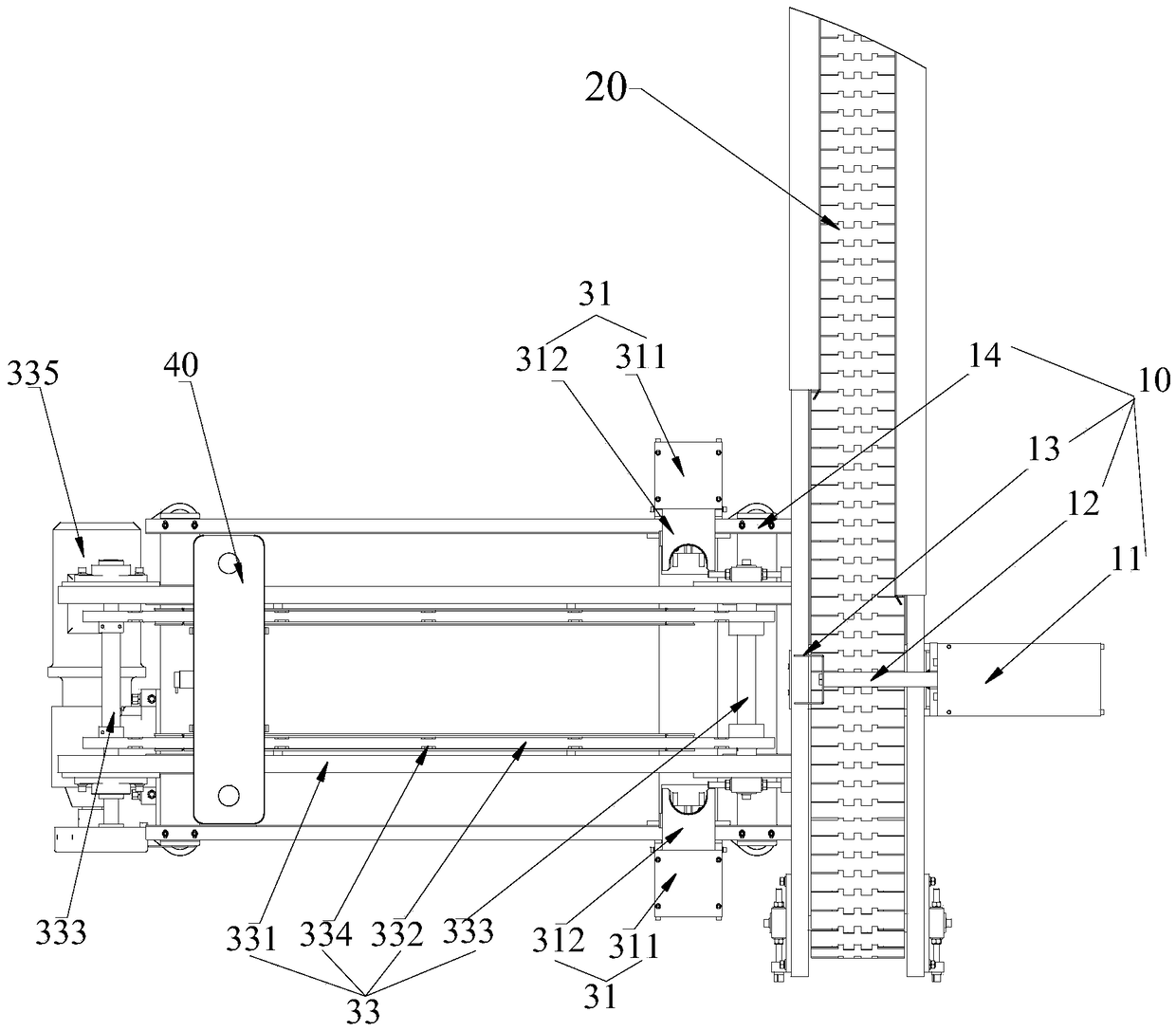

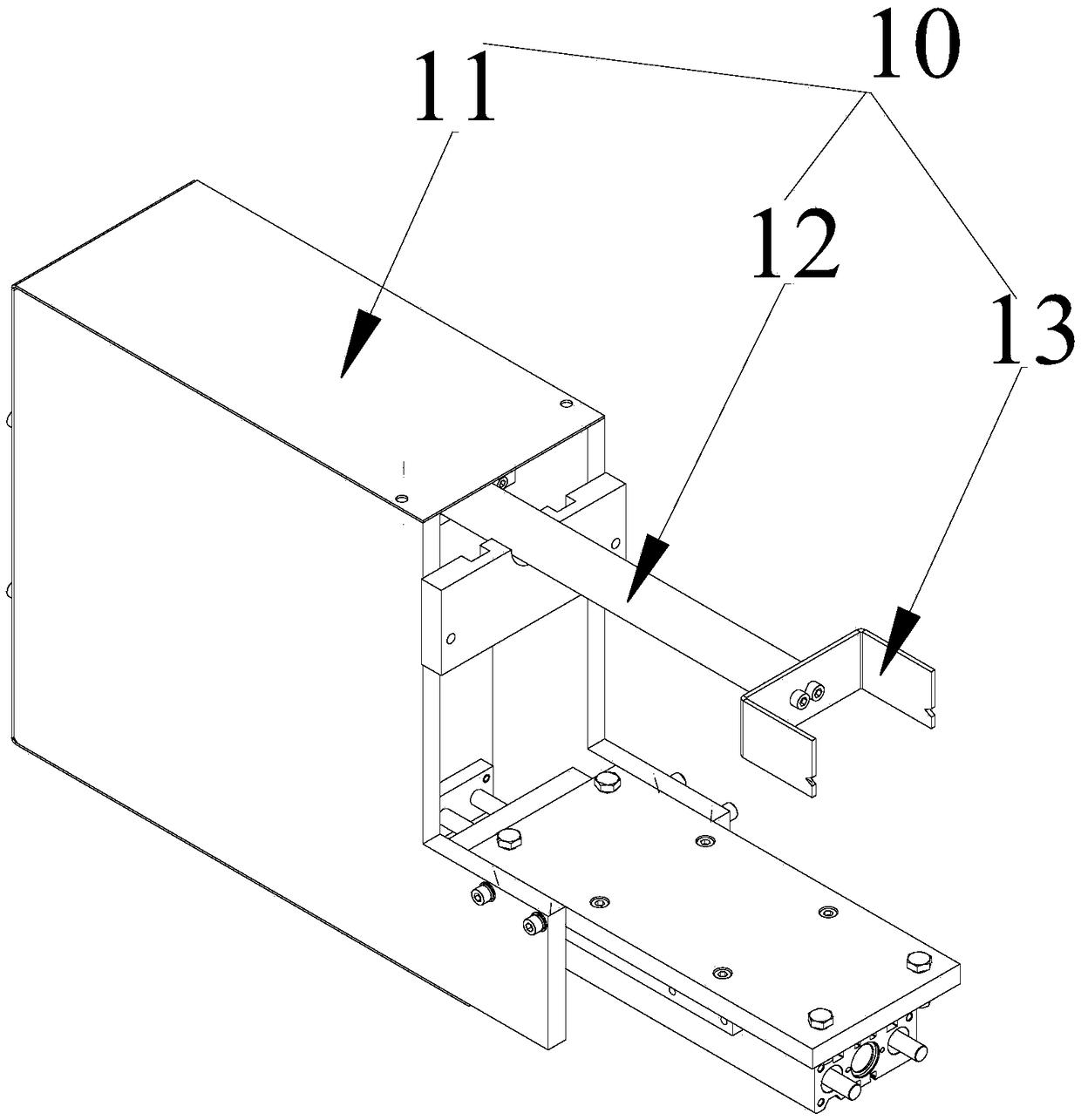

High-precision three-station two-jig flexible stepping circulating device

PendingCN111924439AGuaranteed delivery speedGuaranteed Reset AccuracyConveyorsMaterial transferWorkbench

The invention discloses a high-precision three-station two-jig flexible stepping circulating device. The high-precision three-station two-jig flexible stepping circulating device comprises a base, a first moving jig platform, a second moving jig platform, a first track and a second track; a workbench is arranged on the upper surface of the base, and a feeding station, a working station and a discharging station are sequentially arranged on the workbench in the horizontal direction X; the first track and the second track are arranged on the two sides of the base correspondingly; the first moving jig platform comprises a first jig assembly, a first Z-direction lifting device and a first X-direction moving device; and the second moving jig platform comprises a second jig assembly, a second Z-direction lifting device and a second X-direction moving device. According to the high-precision three-station two-jig flexible stepping circulating device, two sets of independent moving jig platforms are adopted to eliminate deviation caused by hardware manufacturing and assembling, upper and lower channel operation is realized through the lifting devices, flexible stepping type circulating operation of the two platforms is realized, the resetting precision of equipment is ensured, and the material transfer speed is ensured.

Owner:中辰昊智能装备(江苏)有限公司

A temperature-controlled electronic atomization device and atomization method thereof

The invention discloses a temperature-controlled electronic atomization device and an atomization method thereof. The temperature-controlled electronic atomization device comprises: an atomization heating sheet, a temperature sensing element is attached to one side of the atomization heating sheet, and is connected to a control circuit board connected; the other side of the atomized heating sheet is connected to one side of the porous ceramic through a high-temperature-resistant water-absorbing sheet, and the other side of the porous ceramic is in contact with the atomized liquid container, which is used to transfer the liquid in the atomized liquid container through the porous ceramic sheet The solution is transported to the high-temperature-resistant water-absorbing sheet, and contacts with the atomizing heating sheet for atomization; the temperature-controlled electronic atomization device also includes a pressure-regulating knob, and the airflow control switch is connected to the control circuit board through a battery. Through the full contact between the atomized heating sheet and the high-temperature-resistant water-absorbing sheet, compared with the previous heating method of glass fiber wire, the contact area is greatly increased, so that full atomization can be achieved without excessive temperature; in addition, an airflow control switch is added, By rotating and adjusting the temperature, the user can freely control the atomization effect.

Owner:SHENZHEN JINJIA TECH +1

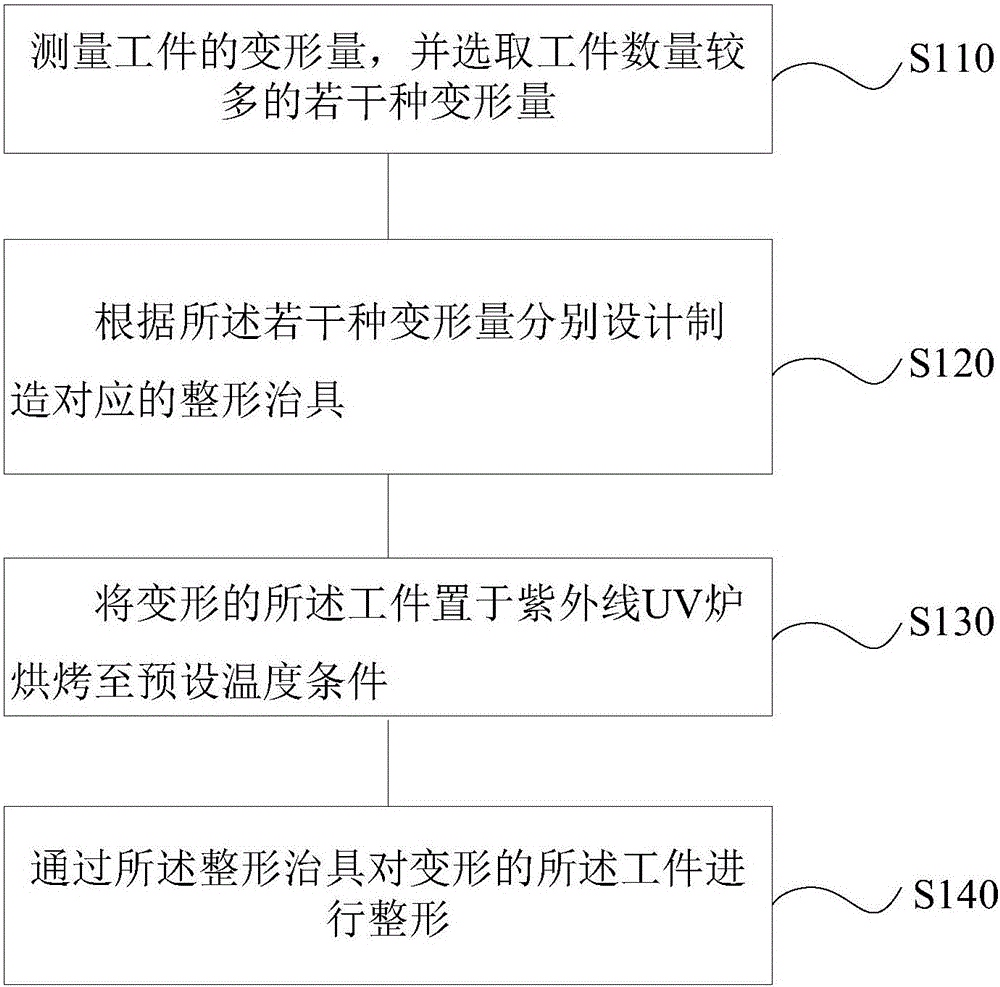

Workpiece reshaping method

The invention relates to a workpiece reshaping method which comprises the following steps of: measuring deformation amount of workpieces, and selecting a plurality of kinds of deformation amount of a larger number of workpieces; separately designing and manufacturing corresponding reshaping jigs according to the multiple kinds of deformation amount; putting the deformed workpieces into an ultraviolet-ray UV oven to rotate until a preset temperature condition; and reshaping the deformed workpieces through the reshaping jigs. Compared with the conventional reshaping method, a reshaping rebounding rate is reduced, the condition of appearing anode cracks after reshaping is improved, the yield of the workpieces is greatly increased, and assembly success and delivery speed are guaranteed.

Owner:GUANGDONG EVERWIN PRECISION TECH

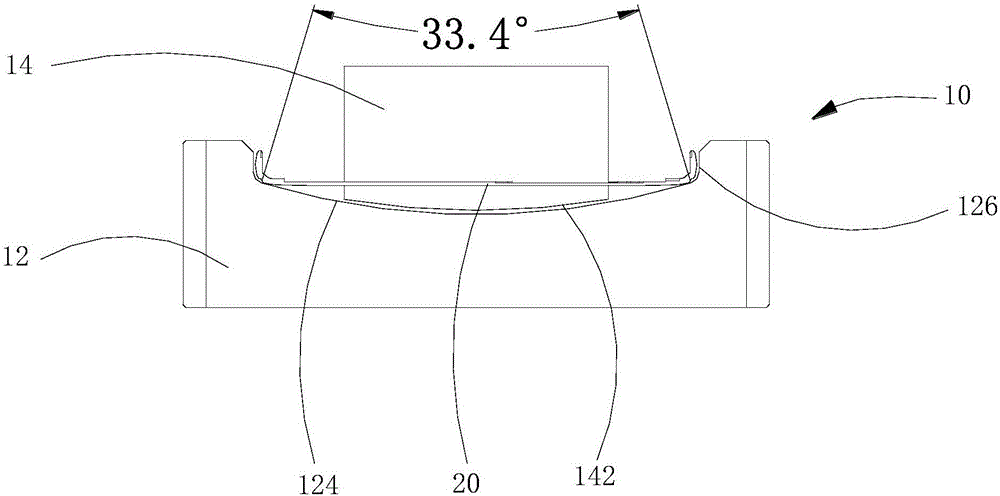

3D printer wire feeding mechanism

InactiveCN107031042AGuaranteed delivery speedExtrusion stabilityAdditive manufacturing apparatus3D object support structuresSpray nozzleDrive motor

The invention discloses a 3D printer wire feeding mechanism which comprises a nozzle. A heating block is arranged at the top end of the nozzle. A feeding pipe is arranged at the top of the heating block. A driving motor is arranged on the upper portion of the heating block. A wire material is arranged on the feeding pipe. A wire feeding friction wheel is arranged at the position, on the right side of the wire material, of the driving motor. An auxiliary friction wheel corresponding to the wire feeding friction wheel is arranged at the position, on the left side of the wire material, of the driving motor. A temperature measuring galvanic couple is arranged on the front face of the heating block. Wire material conveying is carried out in a friction wire feeding manner, the conveying speed on the wire material can be precisely controlled through a program when the wire feeding mechanism works to guarantee the stable extruding amount, the conveying speed of the material is guaranteed, and the printing efficiency and quality are improved.

Owner:渭南高新区金石为开咨询有限公司

Film making device

InactiveCN106541325ANo need to reduce conveying speedGuaranteed delivery speedPolishing machinesGrinding feedersEngineeringMechanical engineering

The invention discloses a film making device, which comprises a conveying mechanism, a material feeding mechanism, at least two groups of polishing-brushing components and a first driving mechanism, wherein the conveying mechanism conveys an external to-be-processed work piece along a first direction; the material feeding mechanism is used for applying a film making raw material to a to-be-processed surface of the to-be-processed work piece; the polishing-brushing components are used for polishing and brushing the film making raw material for the to-be-processed surface of the to-be-processed work piece; the at least two groups of polishing-brushing components are arranged at intervals along a second direction; the second direction intersects the first direction; the first driving mechanism is used for driving the at least two groups of polishing-brushing components to move to and fro along the second direction. By using the film making device provided by the invention, the polishing-brushing swing amplitude can be effectively decreased; a made film is uniform in thickness; moreover, a quicker piece sending speed is met; the film making efficiency is improved.

Owner:GUANGDONG EDING IND

Oil peony planting device

InactiveCN108781623AAvoid cloggingThe overall design is simple and reasonablePlantingFurrow making/coveringAgricultural engineering

Owner:明光大兴盛和牡丹农业科技有限公司

Oil heater cooling fin positioning buffer device and conveying system with same

PendingCN108820841AGuaranteed delivery speedConveyor partsEnergy efficient computingHeat sinkEngineering

The invention provides an oil heater cooling fin positioning buffer device and a conveying system with the same. The oil heater cooling fin positioning buffer device comprises a pushing mechanism anda buffer mechanism; the pushing mechanism is arranged on an oil heater cooling fin conveying line; the buffer mechanism and the pushing mechanism are oppositely arranged; the oil heater cooling fin conveying line is used for conveying oil heater cooling fins to move along a preset trajectory; and the pushing mechanism is used for pushing the oil heater cooling fins onto the buffer mechanism for buffer and grabbing by a robot when the oil heater cooling fins move to a first preset position opposite to the pushing mechanism. The oil heater cooling fins have no need to stop on the conveying linefor grabbing, so that the normal conveying speed of the oil heater cooling fin conveying line is guaranteed. The problem of influence on normal conveying speed of the oil heater cooling fins by grabbing waiting of the oil heater cooling fins on the conveying line in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Hydraulic oil degassing device for hydraulic mechanism of power circuit breaker

InactiveCN109139619AEasy to tiltEasy dischargeHigh-tension/heavy-dress switchesAir-break switchesAtmospheric airFuel tank

The invention discloses a hydraulic oil degassing device for a hydraulic mechanism of a power circuit breaker. The hydraulic oil degassing device comprises a supporting mechanism, a stirring mechanismand a purifying mechanism, the top of the supporting mechanism is provided with the stirring mechanism, and the purifying mechanism is arranged above the stirring mechanism. According to the hydraulic oil degassing device, an oil storage tank can incline conveniently, oil inside the oil storage tank is conveniently discharged out from an oil outlet, the collection time of treated hydraulic oil isshortened, collection of the hydraulic oil is more convenient and thorough, the collection efficiency is improved, and the labor intensity of a worker is improved. A cleaning brush and a filter net are arranged, filtered materials are cleaned away, blocking of the filter net is avoided, the exhaust effect is influenced, the smoothness of conveying of the exhaust gas is increased, and the gas transporting speed is guaranteed; and a purification tank is arranged, the exhaust gas is conveniently filtered, and impurities and odors are prevented from being discharged into the atmosphere and polluting the atmosphere.

Owner:柳圣池

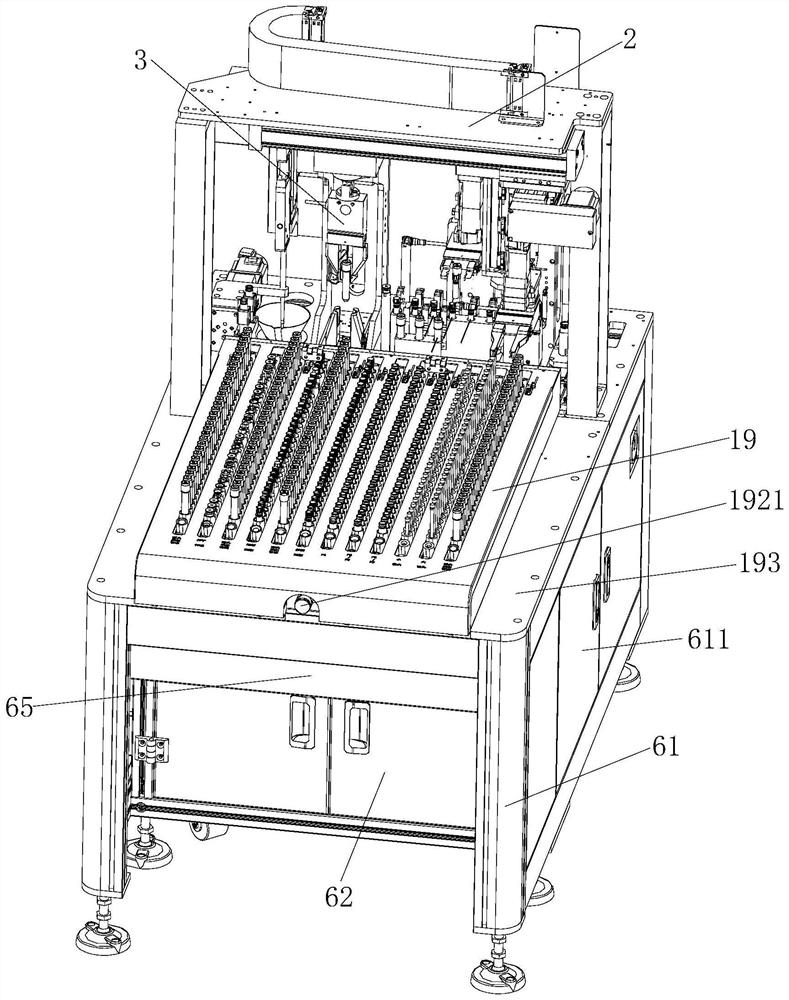

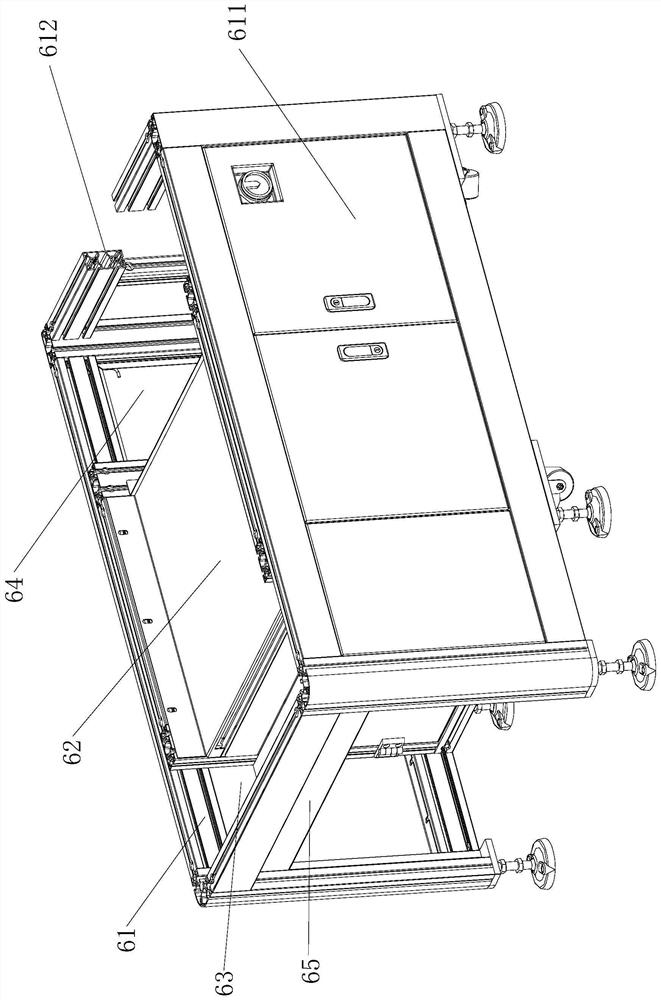

Automatic hose feeding device for intelligent assembling machine

ActiveCN110936121AGuaranteed delivery speedGuaranteed assembly accuracyMetal working apparatusEngineeringAssembly line

The invention relates to an automatic hose feeding device for an intelligent assembling machine. The automatic hose feeding device comprises a hose conveying mechanism, a hose clamping fixed die, a hose clamping movable die, a hose return pressing plate and hoses, wherein a plurality of sets of equidistantly-arranged hose arranging stations are arranged on the hose conveying mechanism; the hose clamping fixed die and the hose clamping movable die are opened and closed up and down directly, are arranged at one side end of the hose conveying mechanism, and are directly opposite to the pluralityof sets of equidistantly-arranged stations on the hose conveying mechanism in an assembling work position; the hose return pressing plate is movably connected to the upper end of the hose conveying mechanism and moves up and down, and the moving height is matched with the hoses conveyed on the hose conveying mechanism; and the hoses are transversely conveyed on the arranging stations of the hose conveying mechanism. An assembling mechanism greatly improves the production stability and the assembling efficiency of a whole intelligent automatic assembly line, and effectively saves the productionsite and manpower resources.

Owner:温岭市鼎工自动化设备科技有限公司

Vibrating Parts Conveyor

InactiveCN104736460BStable deliveryGuaranteed delivery speedJigging conveyorsRotational vibrationEngineering

A complex vibrating type parts transport device that can maintain the parts transport speed and suppress pitching motion of a parts transport member (1). After increasing the eigenfrequency of the rotational vibration (rotational vibration mode for vibration in the horizontal direction) generated in an intermediate vibrating body (4) and a base (3) to be greater than the eigenfrequency of a rotational vibration (rotational vibration mode for vibration in the vertical direction) generated in the parts transport member (1) and a upper vibrating body (2), the pitching motion of the parts transport member (1), viewed from the floor, can be suppressed and the parts transport speed can be maintained without a decrease in the eigenfrequency of a translational vibration mode for vibration in the horizontal direction by adjusting the mass of the base (3) so that the amplitude of the pitching motion (vibration level of the rotational vibration mode for vibration in the horizontal direction) of the base (3) is near the amplitude of the relative pitching motion (vibration level of the rotational vibration mode for vibration in the vertical direction) corresponding to the base (3) of the parts transport member (1).

Owner:NTN CORP

Jet stripping electric resection head and jet stripping electric resection device

PendingCN110664480AIncrease flow rateIncrease kinetic energyEndoscopesFluid jet surgical cuttersLaparoscopesAbdominal cavity

The invention relates to the technical field of surgical instruments, in particular to a jet stripping electric resection head and a jet stripping electric resection device. The jet stripping electricresection head comprises a metal pipe body internally provided with a gas channel, one end of the metal pipe body is closed, a gas inlet end port communicating with the gas channel is formed in the other end of the metal pipe body, and a gas outlet end port communicating with the gas channel is formed in the outer side wall, at the closed position of the metal pipe body or / and close to the closedposition of the metal pipe body, of the metal pipe body; the inner diameter of the gas channel gradually decreases or decreases in a stepwise mode from the gas inlet end port to the gas outlet end port; the structure design of the jet stripping electric resection head achieves that the flow rate of gas when the gas is ejected from the gas outlet end port is increased, the gas with certain kineticenergy is ejected to facilitate separation of the deep part of an abdominal cavity and tissue organs which tightly adhere one another; and potential gaps in the abdominal cavity can be blown open; and an efficient, accurate and safe laparoscopic surgical instrument for an operator is provided.

Owner:BEIJING TONGREN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

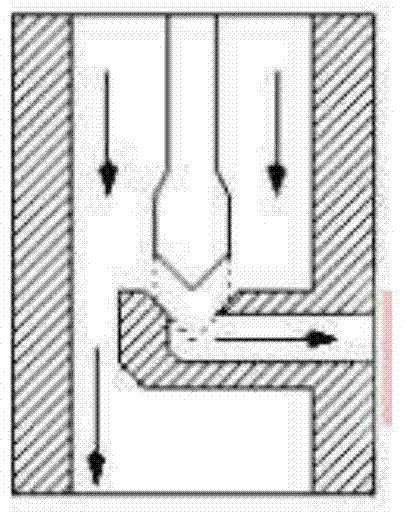

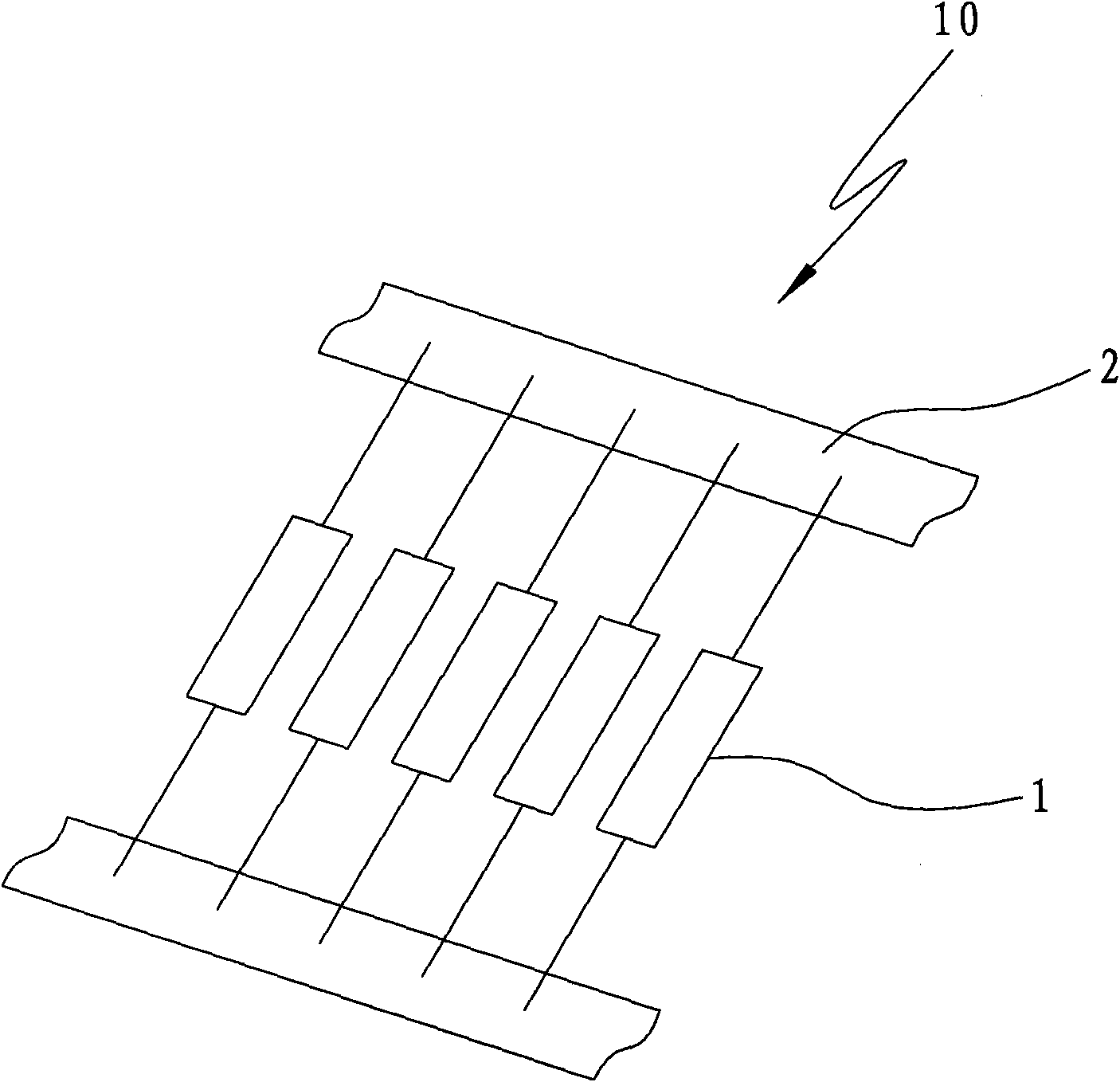

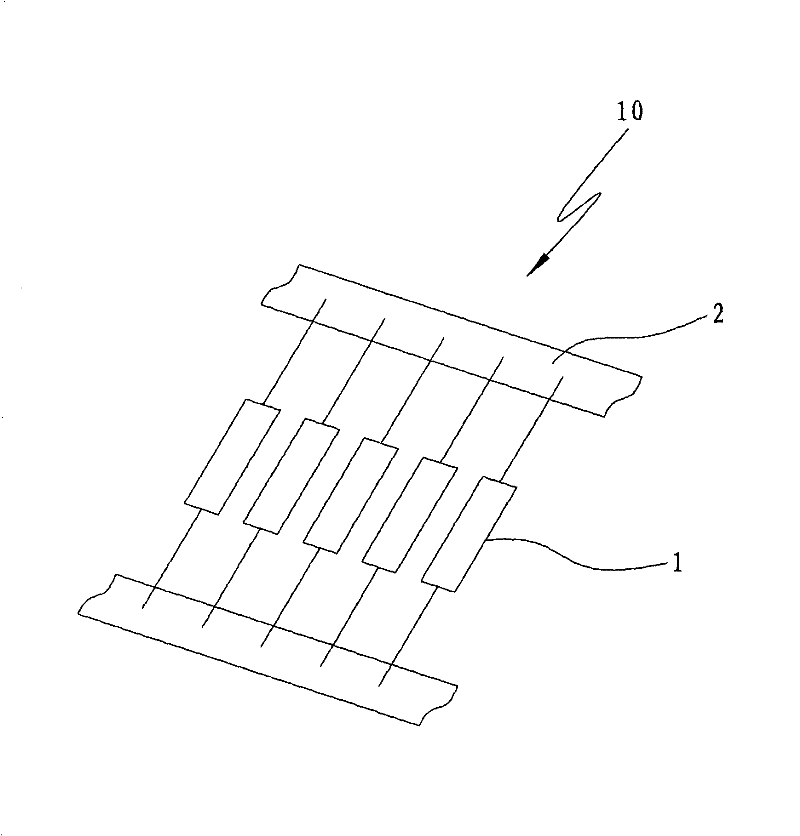

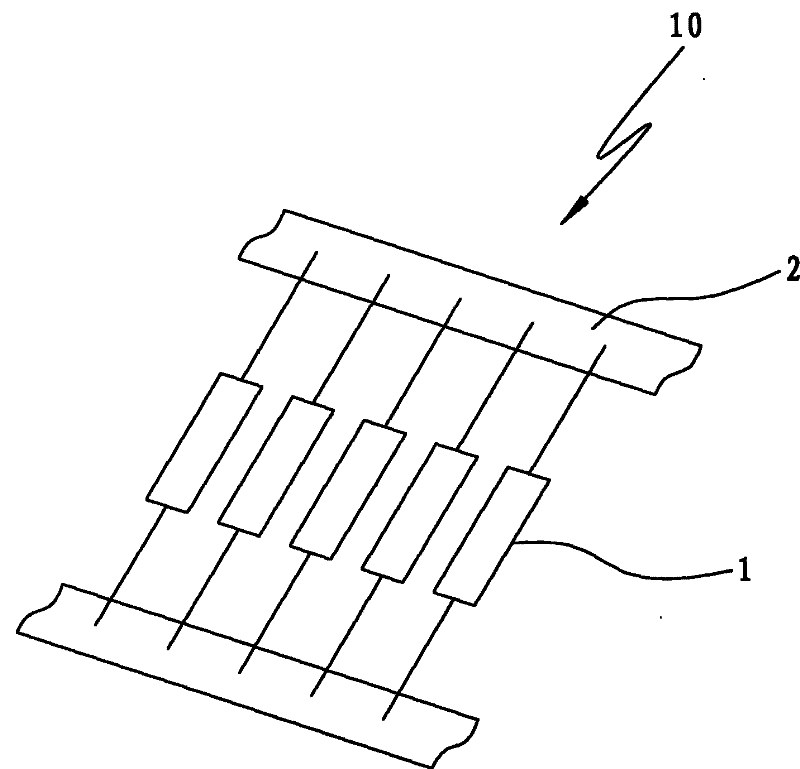

Process for producing low-power non-wire wound fixed resistors

InactiveCN101783216AAvoid bendingAvoid deformationEnvelope/housing resistor manufactureCopper wirePaper tape

The invention discloses a process for producing low-power non-wire wound fixed resistors, comprising a welding procedure and a coating procedure. A braiding procedure is additionally arranged between the welding procedure and the coating procedure and comprises the steps of adding paper tapes on both ends of welded resistor semi-finished products and controlling the semi-finished products by using a braiding control box to be automatically braided into bag-packaged products. Because the loose-packaged semi-finished products are automatically braided into bags in the braiding procedure, the products are arranged in order so that the bending and the deformation of the lead-out copper wires of the products are prevented; in the coating procedure, the semi-finished products braided into the bags are welded and are dismounted into chain gears through tape dismounting heads to be delivered into a coating track by a chain, the product bending and the deformation caused by artificial operation and vibrated blanking are effectively prevented so that the straightness of the products are ensured and the delivering speeds of the chain and the track in the automatic production of the products are also ensured, and the production speed is enhanced by one time, thereby improving the production efficiency.

Owner:厦门高明电子有限公司

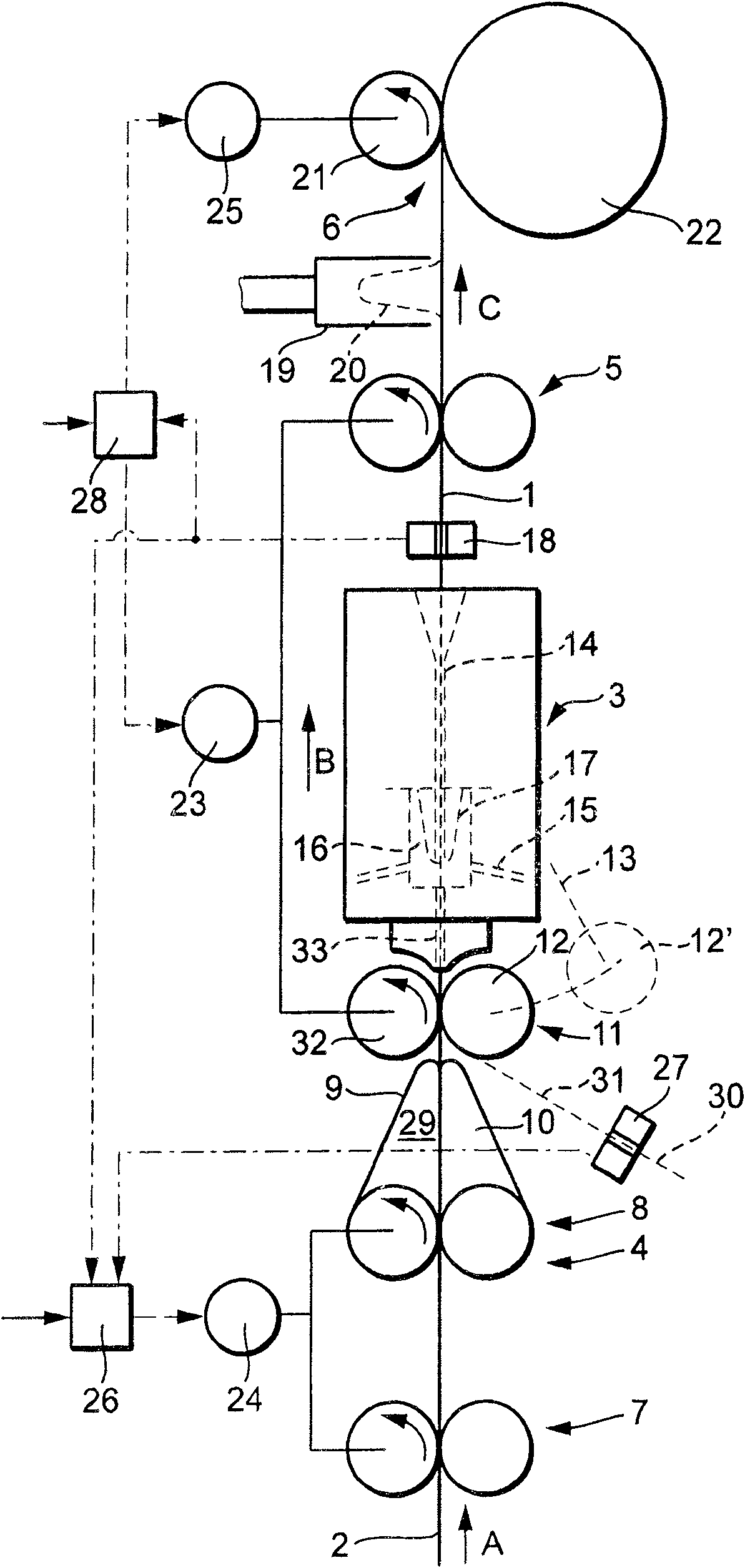

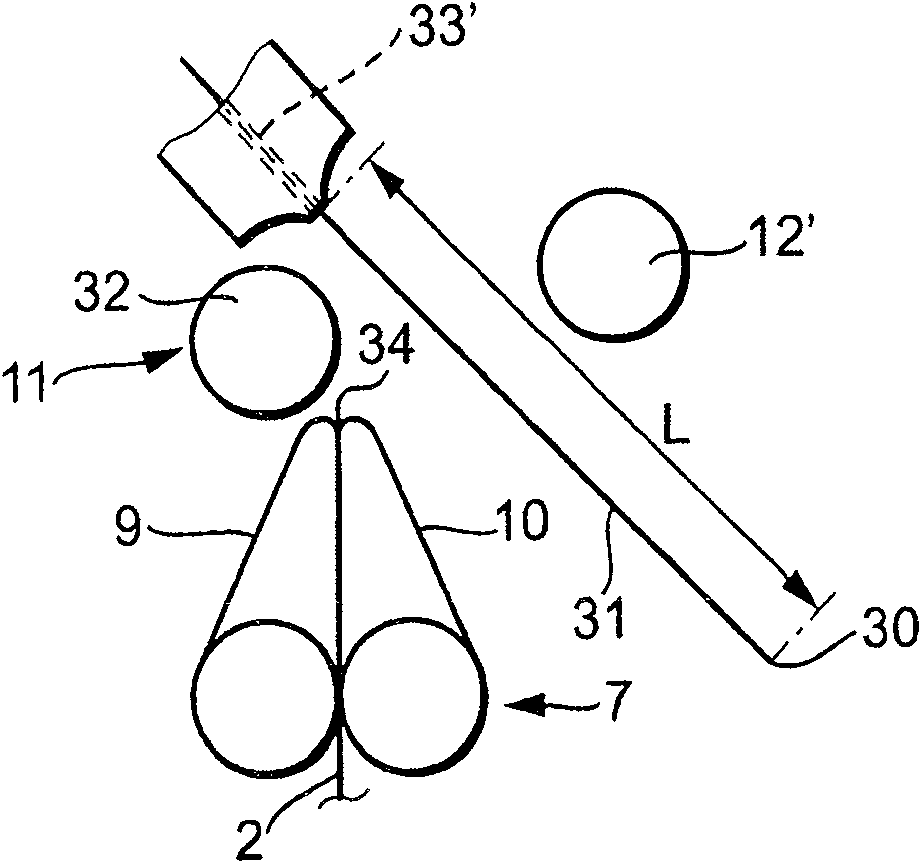

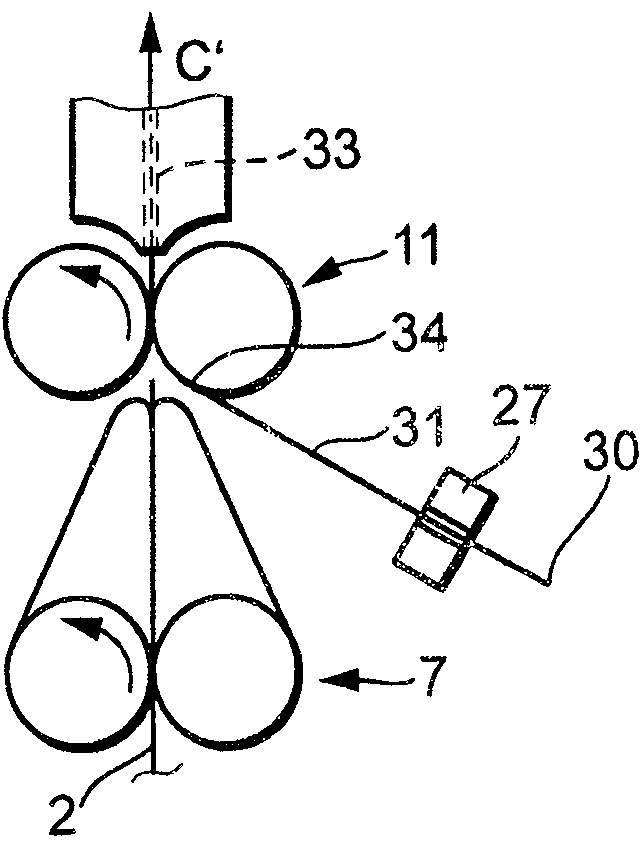

Method and apparatus for making interrupted spinning process to recovering production

InactiveCN100554542CConstant conveying speedEnhanced feedingPiercing arrangementsContinuous wound-up machinesFiberFeed drive

In a process to splice a broken thread in an air jet textile spinning assembly, the thread free end with loose filaments is positioned close to a pair of feed rollers. The thread is then advanced followed by a feed of staple sliver. During the splicing process, the speed of advance of each thread is determined by the position of the broken thread, both being at constant and reduced speeds. - During the splicing procedure both the thread and sliver are transported by the feed rollers. The position of the thread end is detected by a sensor that is linked to the sliver feed drive. The leading section of the sliver is discarded as waste between the feed roller and air jet before the splicing operation. After release of the waste normal spinning process resumes. Also claimed as a commensurate assembly.

Owner:MASCHINENFABRIK RIETER AG

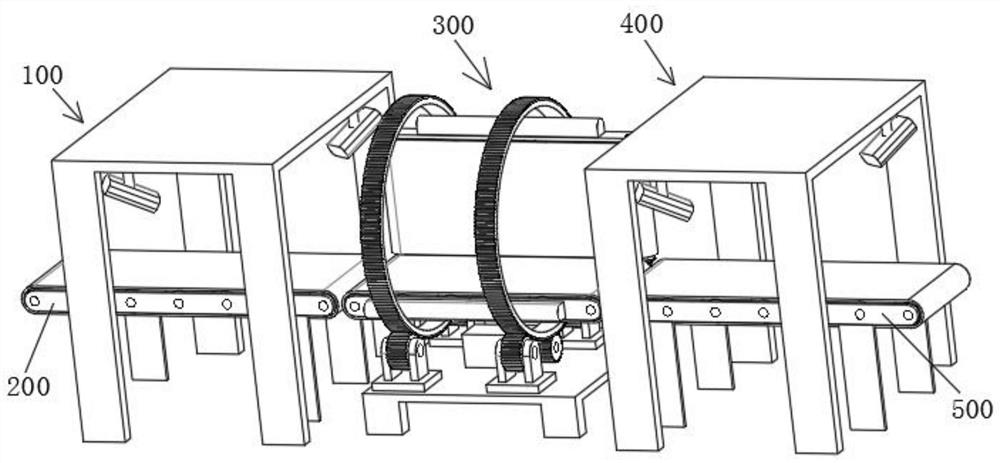

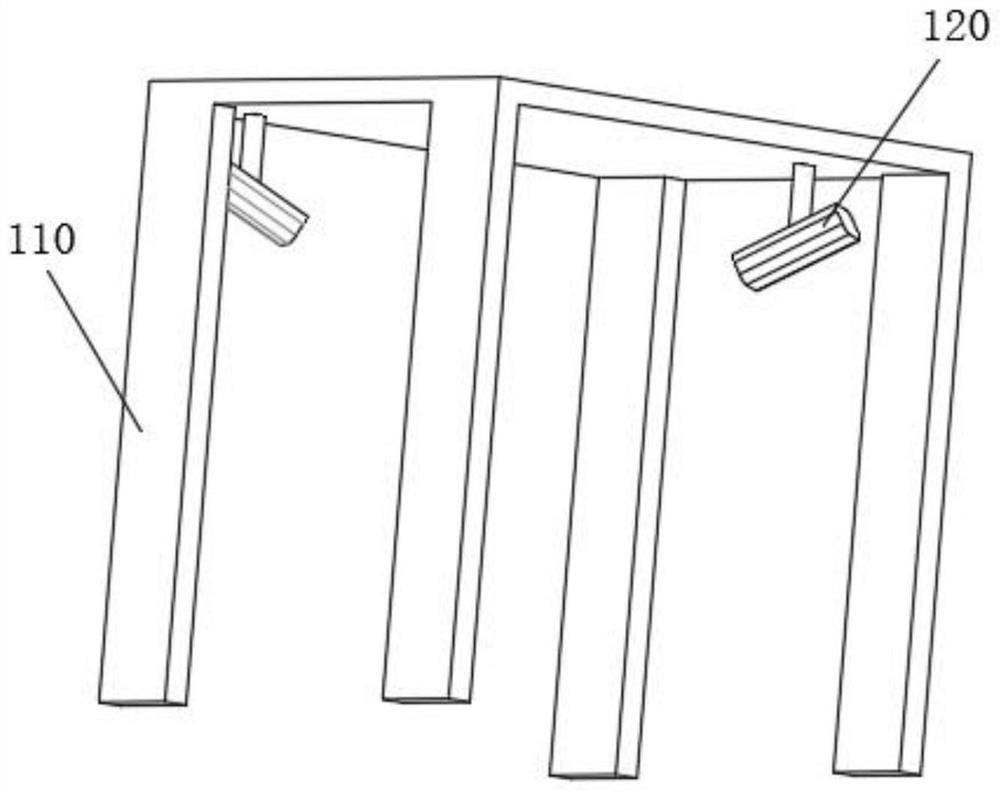

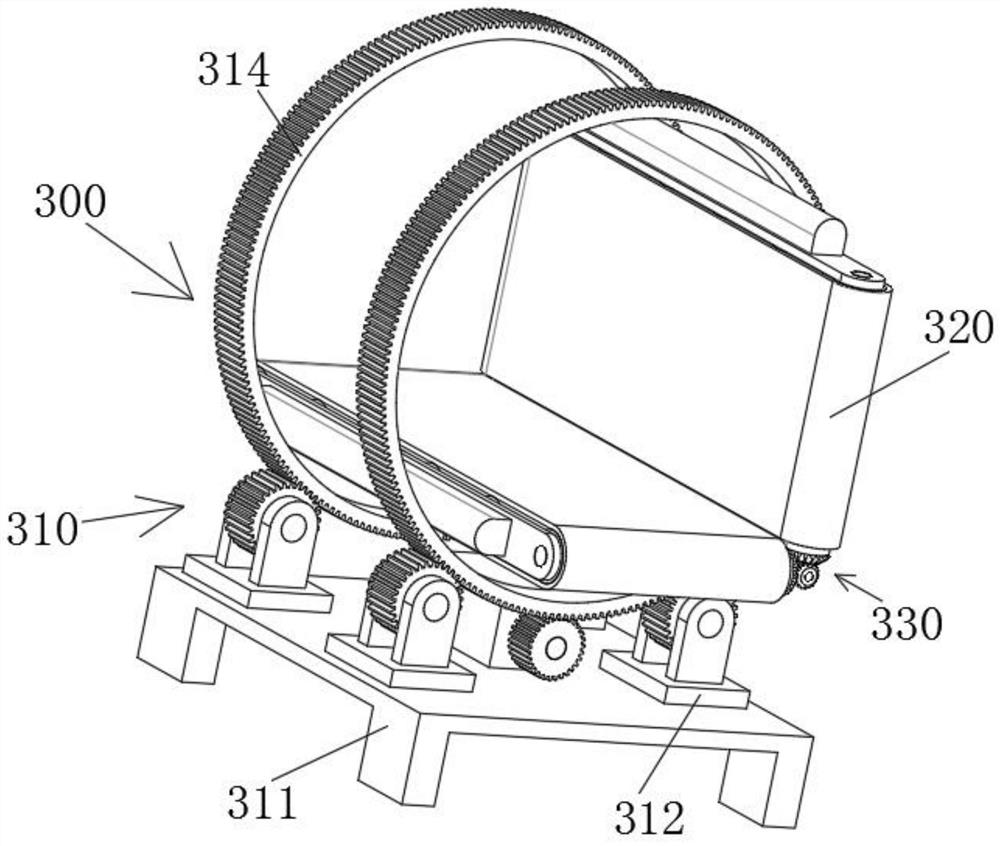

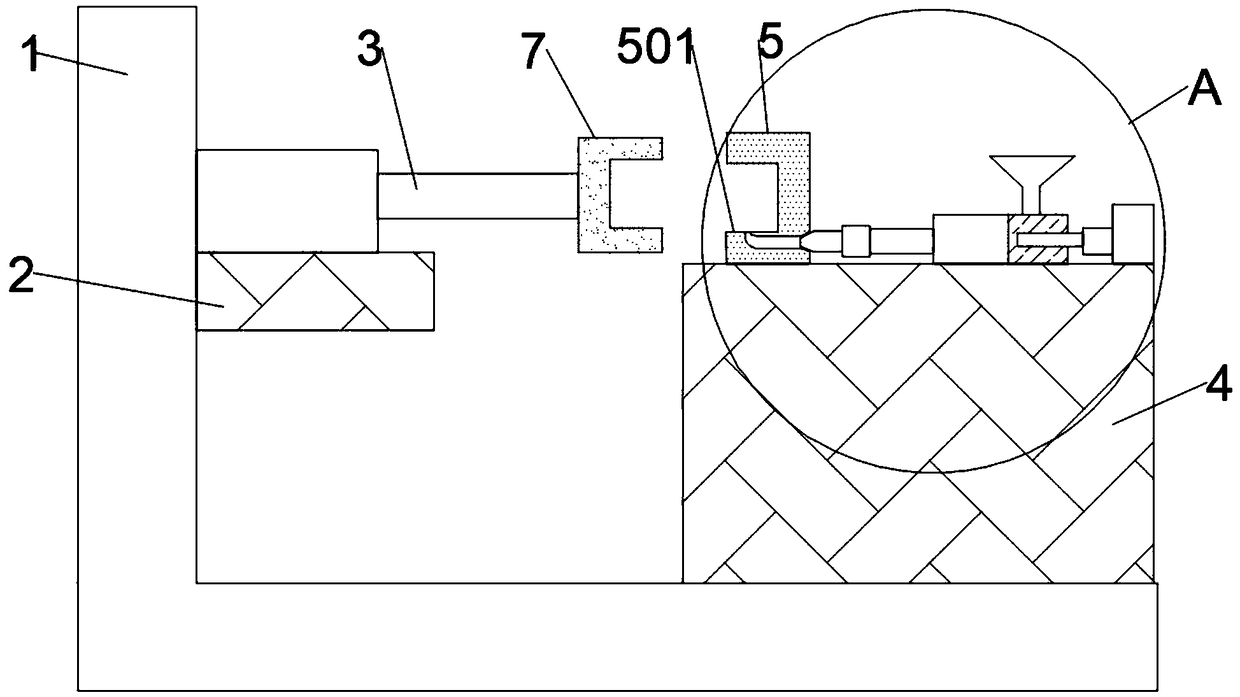

Multi-functional logistics recognition device for electronic commerce

PendingCN113182192AEasy to scan and identifyGuaranteed delivery speedSortingSensing by electromagnetic radiationLogistics managementElectric machinery

The invention relates to the technical field of logistics package recognition, in particular to a multi-functional logistics recognition device for electronic commerce. The multi-functional logistics recognition device comprises a first conveying belt and a second conveying belt; a turnover mechanism is arranged between the first conveying belt and the second conveying belt; a front code scanning mechanism is installed on the outer side of the first conveying belt; and a rear code scanning mechanism is installed on the upper side of the second conveying belt. The turnover mechanism comprises a rotating module. Through the rotating module and the two vertical conveying belts, a logistics item with an information code on the bottom face moves onto the conveying belt in the horizontal state, a first motor rotates to drive the two conveying belts to rotate through fixing ring, the conveying belt on the horizontal state is rotated to the vertical state, and the other conveying belt is rotated to the horizontal state. The logistics item is overturned onto the other conveying belt, the bottom face, with the information code, of the logistics item is overturned to the side face or the top face, the information code comes out, it is achieved that the logistics item is overturned, and convenience is brought to scanning recognition of the logistics item.

Owner:HENGSHUI UNIVERSITY

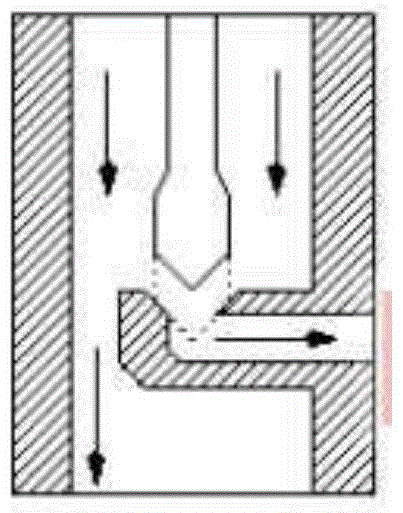

Point pouring type high-efficiency and high-accuracy injection mold

The invention discloses a point pouring type high-efficiency and high-accuracy injection mold. The point pouring type high-efficiency and high-accuracy injection mold comprises a plate frame. A hydraulic rod, a fixed mold and an injection device are installed on the plate frame. A movable mold is fixedly connected with the right end of the hydraulic rod and located on the exactly left side of thefixed mold. The fixed mold comprises a base plate, wherein the base plate is located at the bottom of the fixed mold. Three point pouring gates and three mold inlets are formed in the right side and the top surface of the base plate correspondingly, and connected through circular channels. The injection device comprises a rod sleeve. A feeding hopper is connected with the top side of the rod sleeve, an air pressure rod is arranged on the right side of the rod sleeve, and an injection port is formed in the left end of the rod sleeve. The air pressure rod is inserted into the rod sleeve, and a piston sleeve is connected with the outer side of the air pressure rod. A main material pipe is connected with the left end of the injection port and connected with three branch material pipes, and theleft ends of the branch material pipes are inserted into the three point pouring gates correspondingly. The feeding speed is high, feeding is stable, the production efficiency is high, a mold cavitycan be filled with raw material solutions, precision machining of products can be accomplished, and the machining quality of the products is high.

Owner:广东邦塑汽车精密模具有限公司

Process for producing low-power non-wire wound fixed resistors

InactiveCN101783216BAvoid bendingAvoid deformationEnvelope/housing resistor manufactureCopper wirePaper tape

Owner:厦门高明电子有限公司

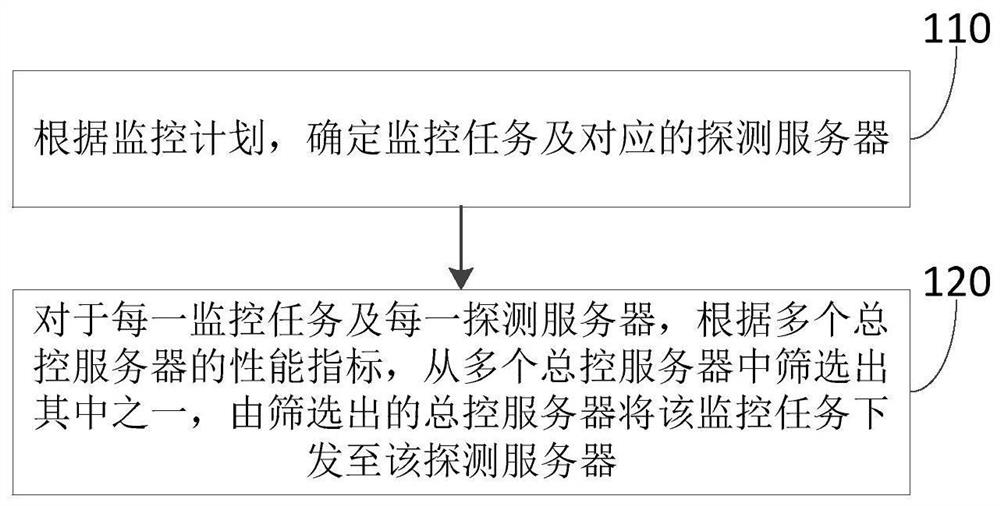

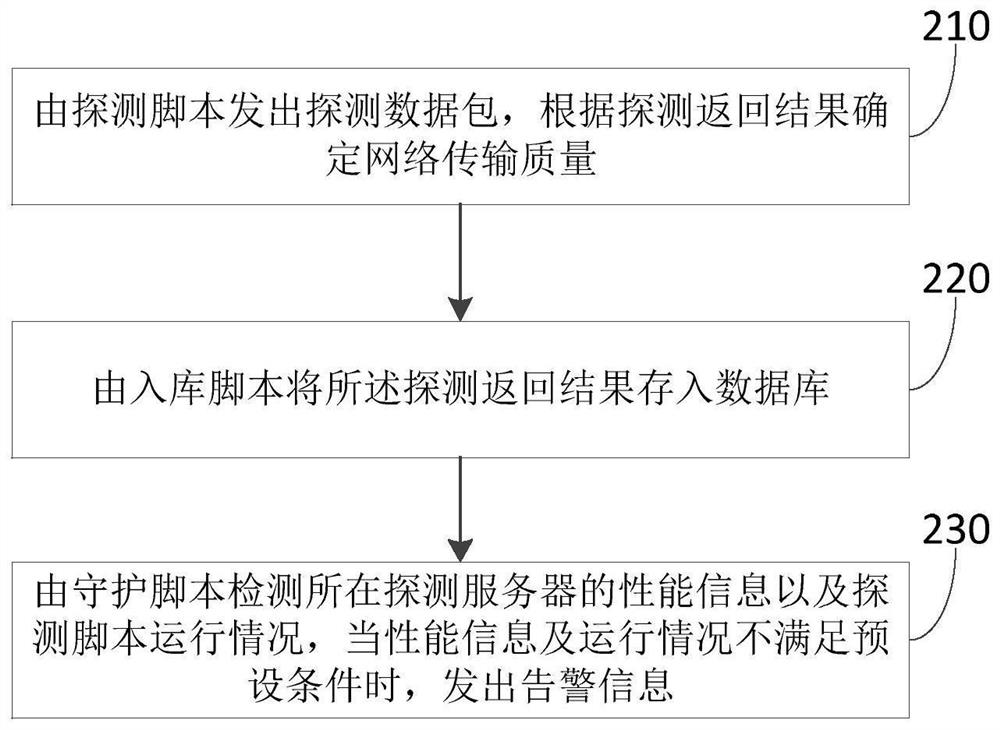

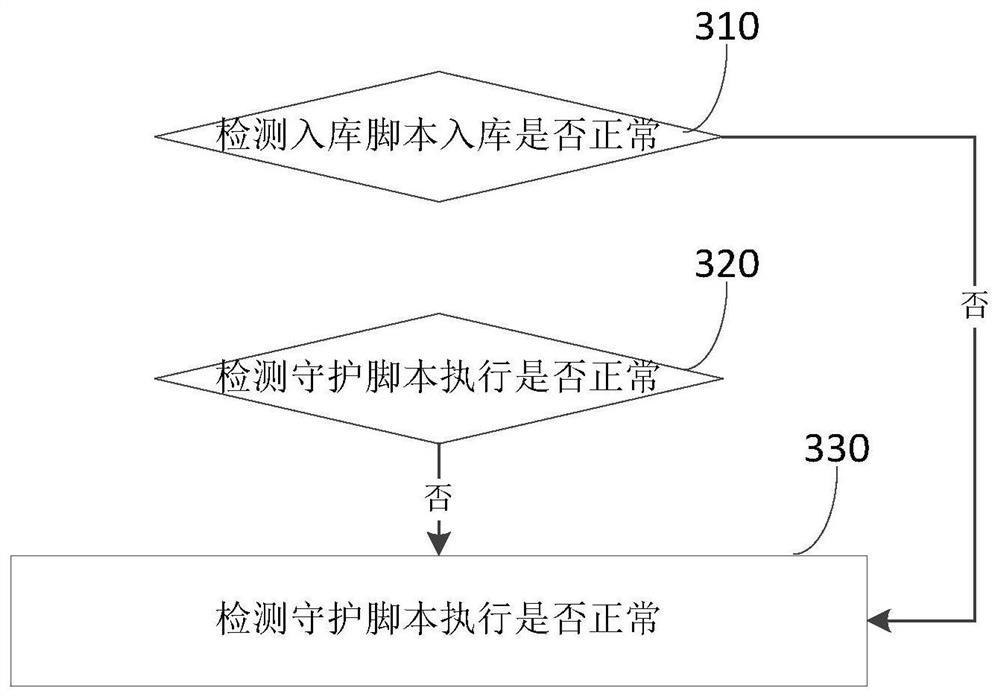

High-availability monitoring method and device, equipment and storage medium

PendingCN113645099AMake full use of resourcesGuaranteed delivery speedHardware monitoringData switching networksOperating systemMonitoring Plan

The invention provides a high-availability monitoring method, device and equipment and a storage medium, before the method is executed, monitoring scripts need to be deployed in a plurality of master control servers in advance, the monitoring scripts are used for detecting the execution condition of monitoring tasks in a detection server, and the method comprises the following steps: according to a monitoring plan, determining a monitoring task and a corresponding detection server; and for each monitoring task and each detection server, screening one of the plurality of general control servers according to the performance indexes of the plurality of general control servers, and issuing the monitoring task to the detection server by the screened general control server. According to the method, the execution condition of the monitoring task in the detection server can be detected in real time, network quality monitoring blind spots are avoided, resources of all the master control servers can be fully utilized, and the issuing speed of the monitoring task is guaranteed.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Feeding device of blood testing machine

PendingCN112730871ARealize simultaneous shippingRealize unified recyclingBiological testingBlood testFeed drive

The invention relates to a feeding device of a blood testing machine, the device comprises a plurality of feeding conveyor lines, each feeding conveyor line comprises a feeding conveyor belt, a feeding driving shaft and a feeding driven shaft, the feeding conveyor belt is sleeved on the feeding driving shaft and the feeding driven shaft, and a positioning fixture is fixed on the feeding conveyor belt. The positioning fixture is used for placing materials, and the feeding driving shaft is driven by a feeding motor. The feeding device also includes a recycling conveying line; And the recycling conveying line also comprises a feeding conveying belt, a feeding driving shaft, a feeding driven shaft, a positioning clamp and a feeding motor. Compared with the prior art, material conveying is achieved by arranging the feeding conveying belt, meanwhile, the recycling conveying line is further arranged, unified recycling of specimens is achieved, the material conveying speed is guaranteed, material damage in the feeding process is reduced, and the blood testing efficiency is greatly improved.

Owner:昕迪智能装备(东莞)有限公司

A device for generating downhole mud pulse signal

ActiveCN103670380BIncrease transfer rateGuaranteed transmission speedSurveyCommunications systemDepth in a well

The invention provides a down-hole slurry pulse signal generation device. The down-hole slurry pulse signal generation device comprises a plurality of driving valves and a plurality of communication systems corresponding to the driving valves in a one-to-one mode. Due to the arrangement of the multiple driving valves, the types of generated data signals while drilling is more; due to the arrangement of the independent communication systems, the overall transmission speed can be effectively guaranteed, and the precision of detection is guaranteed to a certain extent. In addition, in combination with multiple modulation modes, the data transmission rate is further increased. The signals can be controlled to be strong or weak through selection of the outer diameter of each driving valve and the inner diameter of a limiting base so that the transmitting speed of the data signals while drilling can be guaranteed, the downhole slurry pulse signal generation device can be suitable for working environments with different wells, different displacements and different well depths, and therefore the adaptability to the various environments is greatly improved; the number of working driving valves can be controlled, and therefore high flexibility is obtained.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com