Graphene/iron-nickel sulfo-spinel composite catalyst, preparation method therefor, and method for preparing dye-sensitized solar cell

A composite catalyst and graphene oxide technology, which is applied in the field of dye-sensitized solar cells, can solve the problems of large electrode charge exchange resistance, large difference in catalytic activity, large difference in personality of platinum counter electrodes, etc., and accelerate charge exchange and transmission rate, guaranteed charge exchange rate, and the effect of reducing charge exchange resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The invention provides a novel composite catalyst, which can be coated on conductive glass and used as a counter electrode of a dye-sensitized solar cell. Composite catalyst of the present invention is graphene / iron-nickel sulfide spinel (Fe x Ni 3-x S 4 , 0<x<3) composite catalyst, which includes graphene oxide used as substrate, and iron-nickel sulfide grown in situ on graphene and spinel structure, the specific preparation process is as follows:

[0044] First, use graphene oxide suspension, ferrous iodide acidic solution, nickel salt and penicillamine as the substrate, iron source, nickel salt and sulfur source of the composite catalyst respectively (iron source, nickel salt and sulfur source as the precursor material), wherein the iron source, nickel salt, and penicillamine are calculated based on the content of Fe, Ni, and S, respectively, and the chemical element stoichiometric ratio of Fe, Ni, and S is 1:0.4~2.2:2~10. Described graphene oxide adopts improved ...

example 1

[0057] First take 10ml of graphene oxide suspension with a concentration of about 0.1mg / ml, and then take 20ml of pH=1 and a concentration of about 0.1g according to the ratio of stoichiometric ratio Fe:Ni:S=1:2:5 / ml FeI 2 Acidic solution, 3.22g of nickel acetate tetrahydrate and 4.82g of penicillamine were stirred evenly at room temperature, and then put into a 50ml polytetrafluoroethylene reactor lining. The temperature of the reactor was 130°C, and the reaction time was 45h to obtain the initial product.

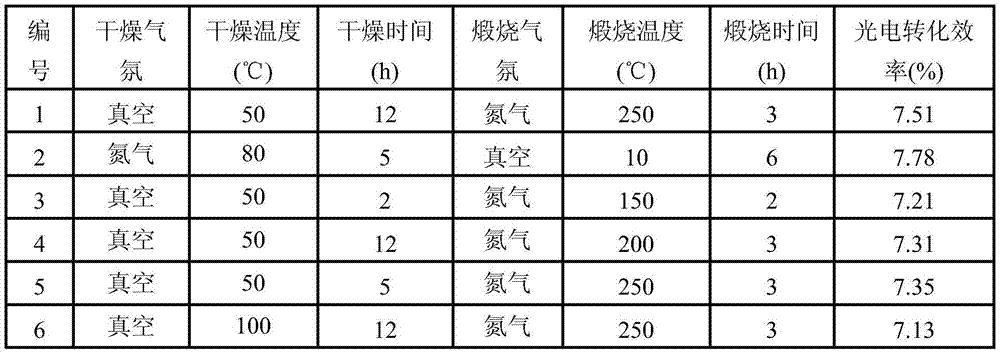

[0058] Then, the initial product was collected by centrifugation, washed with deionized water and absolute ethanol several times, then dried in a vacuum oven at 50 °C for 12 h, and finally sintered at 150 °C for 3 h in a nitrogen atmosphere. In this way, about 0.4g of graphene / FeNi can be obtained 2 S 4 Composite catalyst.

[0059] TiO with a thickness of 10 μm 2 The film was immersed in an ethanol solution of N719 dye, and after soaking for 12 hours, it was taken o...

example 2

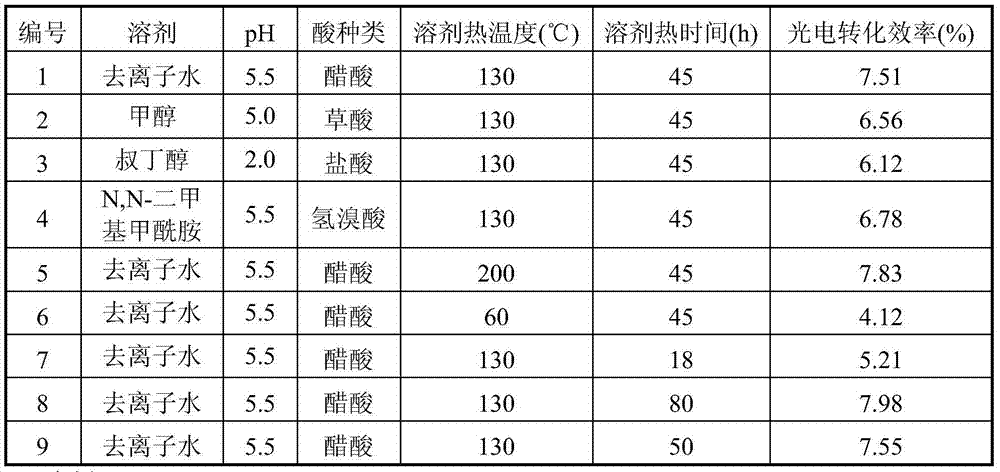

[0066] According to the step described in example 1, adopt nickel acetate as nickel salt, the stoichiometric ratio of Fe, Ni, S is 1:2:5, change respectively solvent kind, pH value (the kind of mineral acid), solvothermal temperature and Solvothermal time, on the premise that other conditions remain unchanged, the obtained DSC performance is shown in Table 2 below.

[0067] Table 2 Determination results under different solvents, pH value, solvothermal temperature and solvothermal time

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com