Jet stripping electric resection head and jet stripping electric resection device

A technology of electrocution and air jet, which is applied in the field of surgical instruments, can solve the problems of inability to separate safely and effectively, difficulty in anatomy of deep abdominal organs, etc., and achieve the effect of convenient operation, precise dissection and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

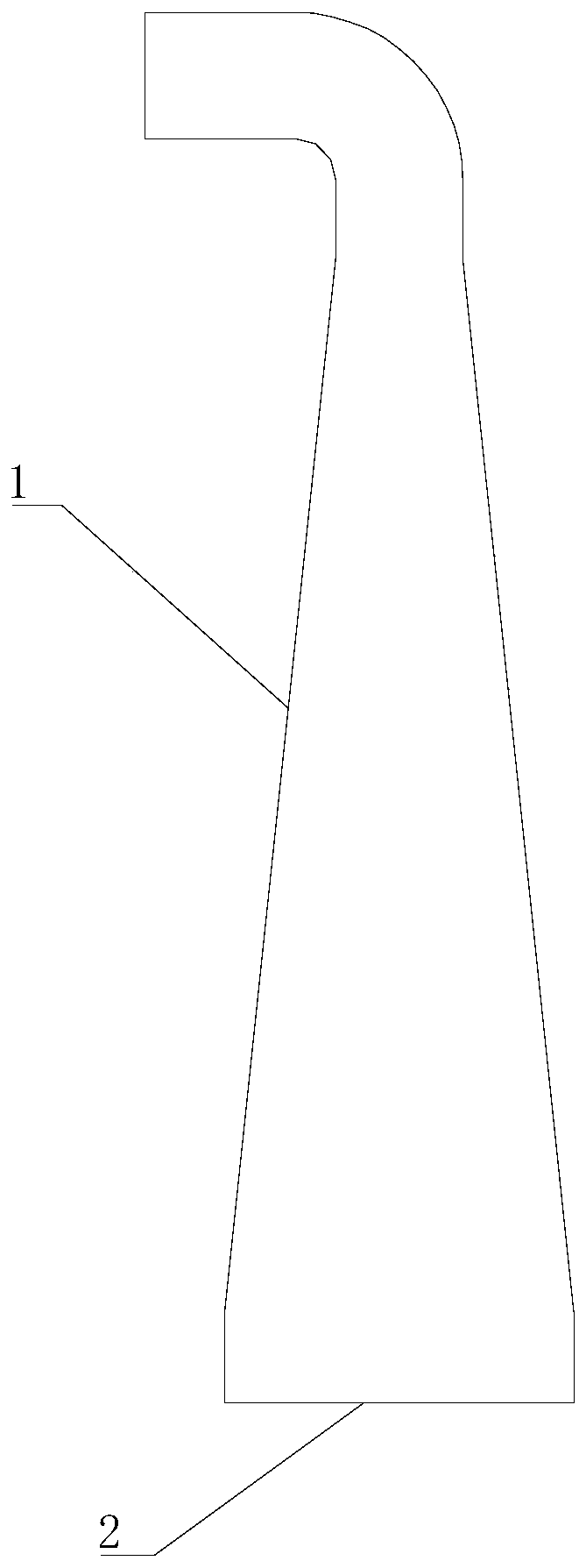

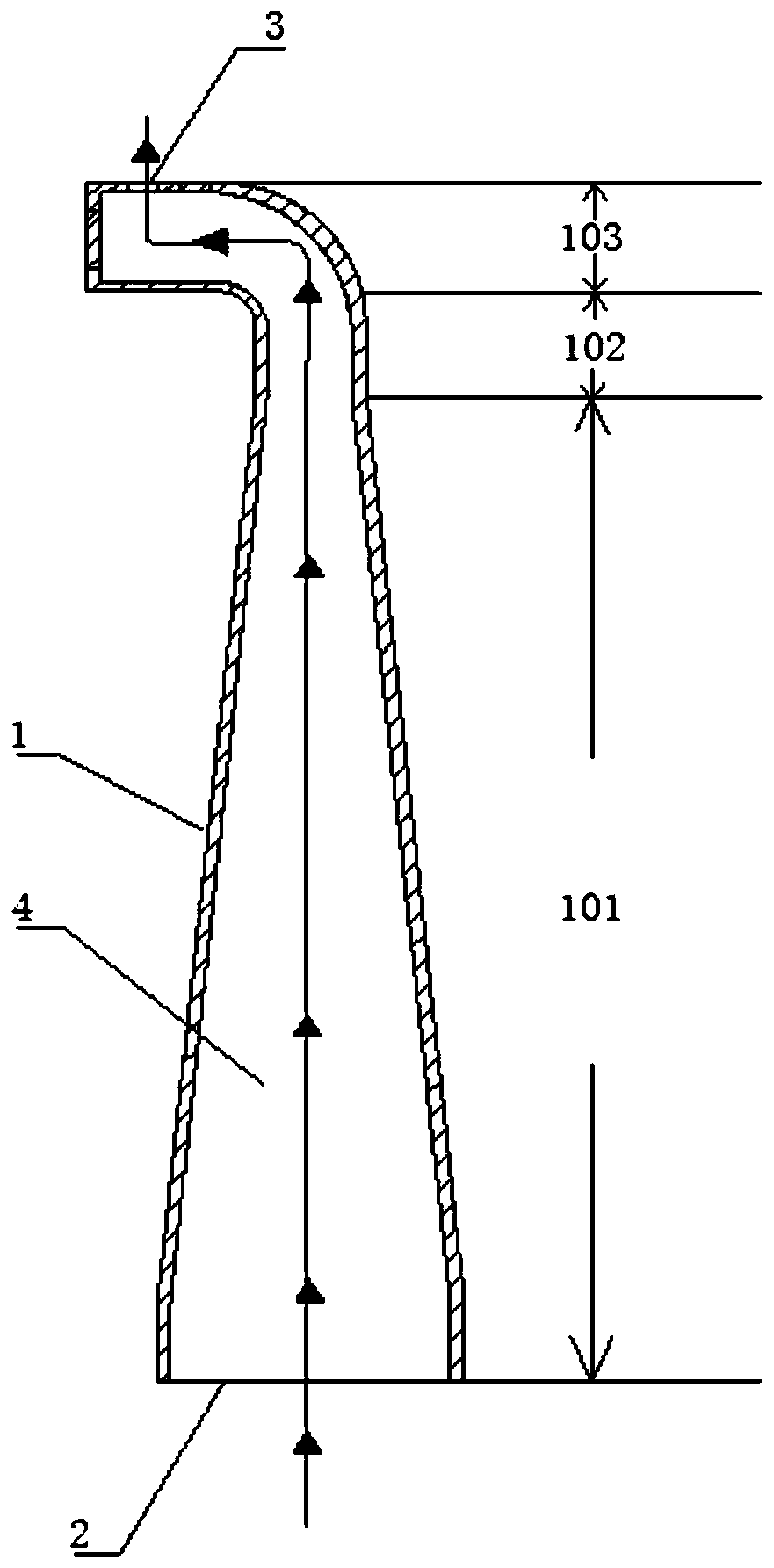

[0050] Such as figure 1 , figure 2 As shown, this embodiment provides a gas jet stripping electric cutting head, including a metal pipe body 1 with a gas flow channel 4 inside, one end of the metal pipe body 1 is closed, and the other end is provided with an air inlet port communicating with the gas flow channel 4 2. There is an outlet port 3 communicating with the gas flow channel 4 at the closed part of the metal tube body 1 or / and on the outer wall of the metal tube body 1 close to the closed part of the metal tube body 1; the inner diameter of the gas flow channel 4 is determined by the inlet The gas port 2 gradually decreases or decreases stepwise toward the gas outlet port 3; the specific scheme of this implementation is that a gas outlet connected to the gas flow channel 4 is provided on the outer wall of the metal tube 1 close to the closed part of the metal tube 1. port 3.

[0051] In the present invention, one end of the metal pipe body 1 is closed, and the other ...

Embodiment 2

[0071] Such as Figure 8 As shown, the metal pipe body 1 in the present invention is an improvement on the basis of the first embodiment. The technical content disclosed in the first embodiment will not be described repeatedly, and the content disclosed in the first embodiment also belongs to the content disclosed in this embodiment.

[0072] The longitudinal section of the connecting section 101 in this embodiment is square.

[0073] In the present invention, the longitudinal section of the connecting section 101 is designed to be square to ensure the air intake of the metal pipe body 1 and ensure the effective separation of organs. At the same time, the longitudinal section of the connecting section 101 is designed to be rectangular, which is convenient for processing. The section can be rectangular or square.

Embodiment 3

[0075] The difference between the present embodiment and the first embodiment lies only in the opening position of the air outlet port 3. The technical content disclosed in the first embodiment will not be described repeatedly, and the content disclosed in the first embodiment also belongs to the content disclosed in this embodiment.

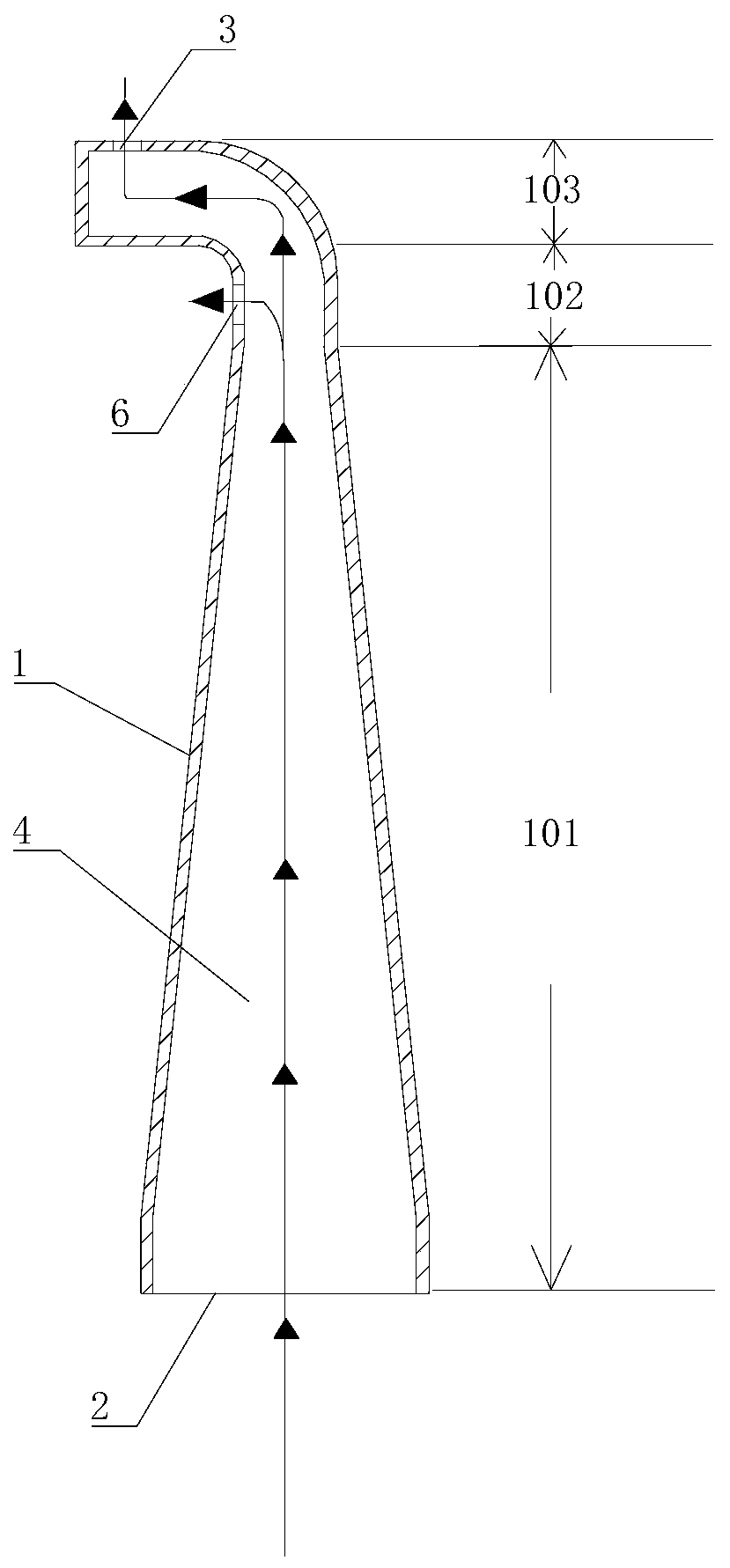

[0076] Such as Figure 9 As shown, this embodiment provides a gas jet stripping electric cutting head, including a metal pipe body 1 with a gas flow channel 4 inside, one end of the metal pipe body 1 is closed, and the other end is provided with an air inlet port communicating with the gas flow channel 4 2. There is an outlet port 3 communicating with the gas flow channel 4 at the closed part of the metal tube body 1 or / and on the outer wall of the metal tube body 1 close to the closed part of the metal tube body 1; the inner diameter of the gas flow channel 4 is determined by the inlet The gas port 2 gradually decreases or decreases stepwise to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com