Discharge mechanism of sheet metal shearing machine

A metal sheet and shearing machine technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as a lot of mold costs, shearing molds can only be used for special molds, affecting production efficiency, etc., to reduce the relative The effect of friction, ensuring conveying speed and protecting surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

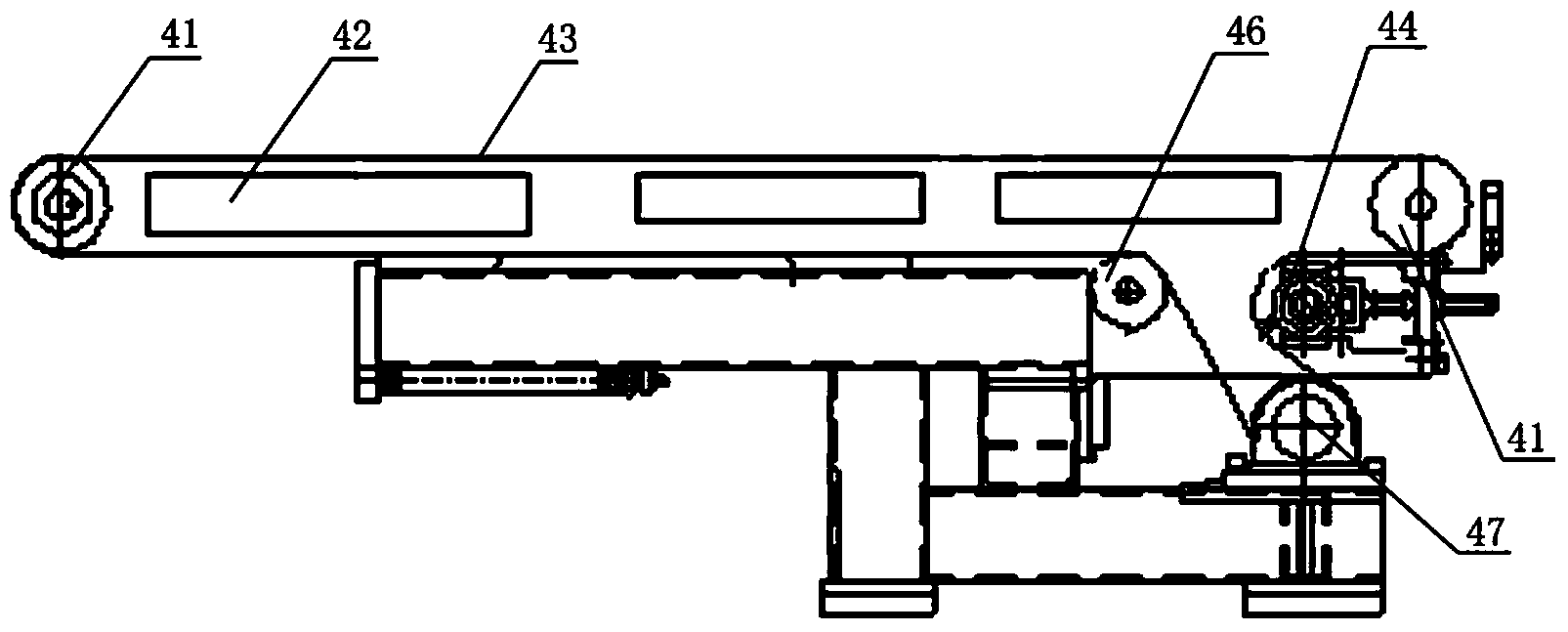

[0010] Such as figure 1 The discharge mechanism of a metal sheet shearing machine shown includes a discharge conveying device and a discharge supporting wheel mechanism, and the discharge conveying device includes a reduction motor 44, a conveying belt 43, an electromagnet 42 and two roller shafts 41, the two roller shafts 41, one is fixedly installed on the discharge side of the shearing die, and the other is fixedly installed at the entrance of the next station, and the conveying belt 43 is sleeved on the outside of the two roller shafts 41. The reduction motor 44 is connected with the roller shaft 41 and drives the roller shaft 41 to rotate. The electromagnet 42 is fixedly installed on the lower side of the conveyor belt 43, and the electromagnet 42 is connected with the control unit of the sheet metal shearing equipment. Bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com