Hydraulic oil degassing device for hydraulic mechanism of power circuit breaker

A hydraulic mechanism and circuit breaker technology, applied in high-pressure air circuit breakers, fluid pressure actuating devices, circuits, etc., can solve the problems of inconvenient oil storage tank tilting, inconvenient oil discharge, rigid structure, etc., to achieve convenient and thorough collection and guarantee The effect of conveying speed and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

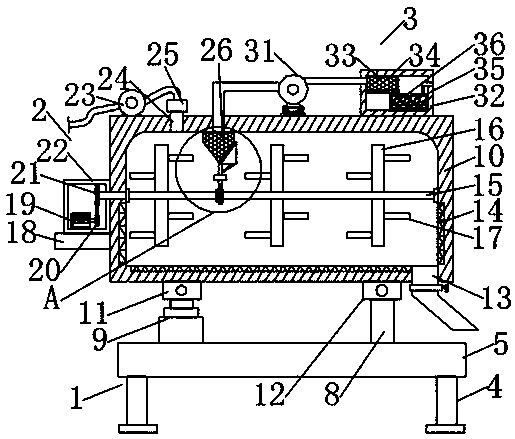

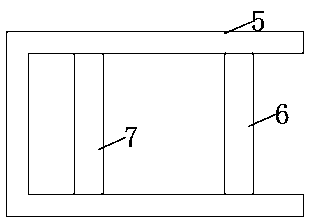

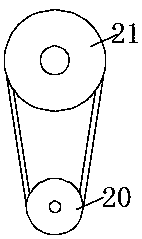

[0020] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a hydraulic oil degassing device for a hydraulic mechanism of a power circuit breaker, including a support mechanism 1, a stirring mechanism 2 and a purification mechanism 3, and the top of the support mechanism 1 is provided with a stirring mechanism 2 , the top of the mixing mechanism 2 is provided with a purification mechanism 3, and the support mechanism 1 is composed of a support leg 4, a support frame 5, a first support beam 6, a second support beam 7, a support rod 8 and a hydraulic cylinder 9. The bottom of the support frame 5 is equidistantly fixedly connected with the legs 4, one end of the inner side of the support frame 5 is fixedly connected with the first support beam 6, and the other end of the inner side of the support frame 5 is fixedly connected with the second support beam 7. The top of the first support beam 6 is symmetrically fixedly connected with a sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com