Downhole full-bore infinite sliding-pin slide bushing switch

A sliding sleeve switch, infinite level technology, applied in the direction of production fluid, wellbore/well components, wellbore/well valve device, etc., can solve the problem of unfavorable sliding sleeve tool maintenance and maintenance, repair and replacement process complex, working environment Complexity and other issues, to achieve the effect of simple structure, ensuring stability, and satisfying repeated switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Below in conjunction with accompanying drawing, the present invention will be further described:

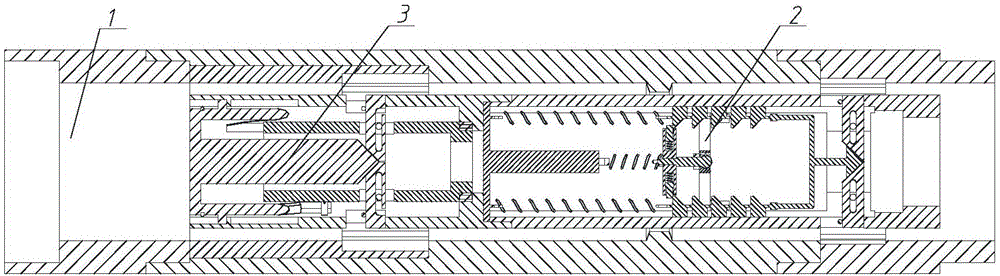

[0082] Depend on figure 1 As shown: the sliding pin sliding sleeve switch of the present invention includes a sliding sleeve main body 1 , a falcon block identification structure 2 and a falcon block switch mechanism 3 .

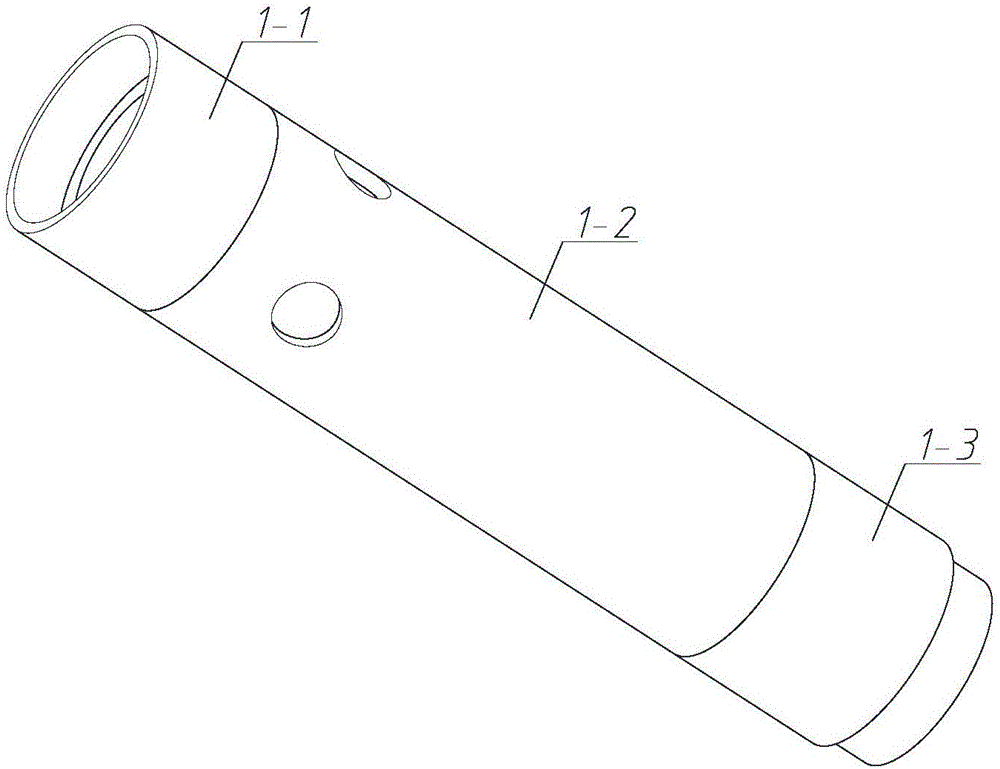

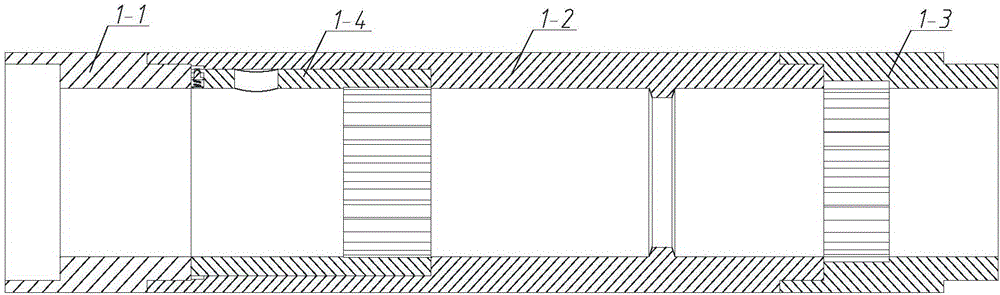

[0083] Depend on Figure 2A and Figure 2B As shown: the main body 1 of the sliding sleeve is lowered into the part to be fractured together with the casing, and is the actuator for opening and closing the fracturing. It specifically includes an upper head 1-1, a sliding sleeve shell 1-2, a lower head 1-3 and a fracturing drum 1-4.

[0084] Depend on image 3 As shown: the upper head 1-1 is cylindrical, and its upper port and lower port are respectively provided with internal threads and external threads.

[0085] Depend on Figure 4 and Figure 5 As shown: the sliding sleeve shell 1-2, its main body is cylindrical, the upper port and the lower po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com