Point pouring type high-efficiency and high-accuracy injection mold

An injection mold, high-precision technology, applied in the field of high-resolution materials, can solve the problems of poor product quality, affecting the feeding speed, and slow feeding speed, so as to achieve fast entry into the cavity, ensure the delivery speed, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

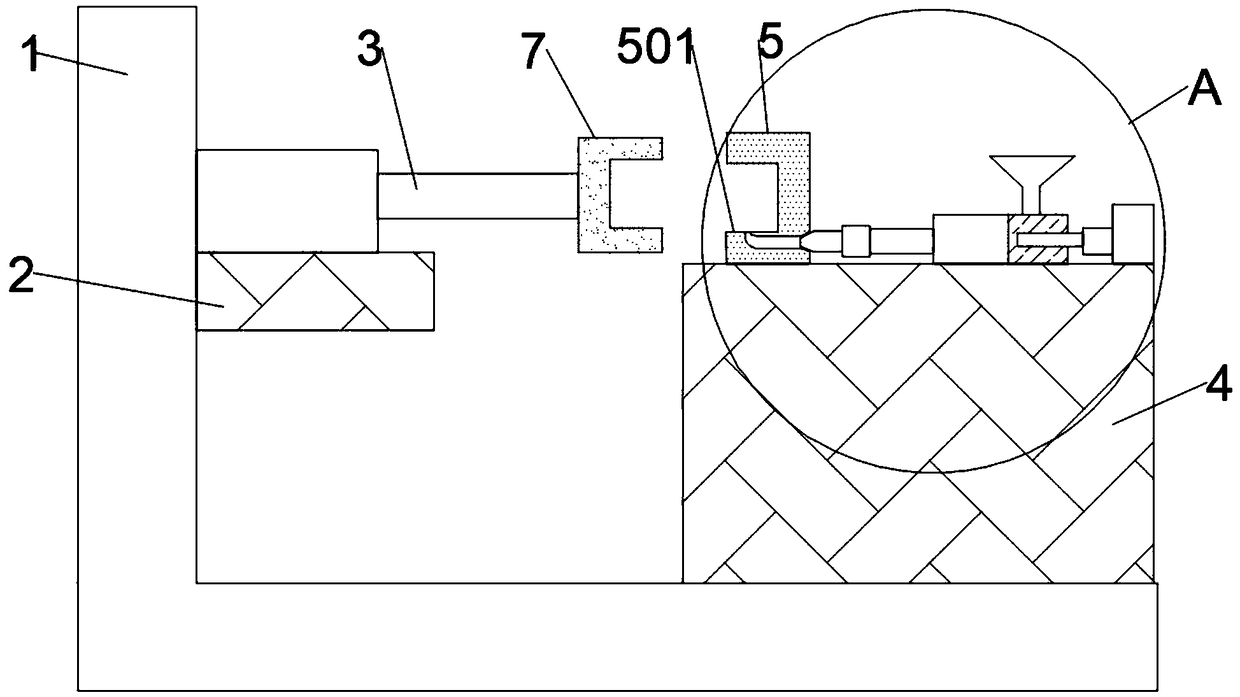

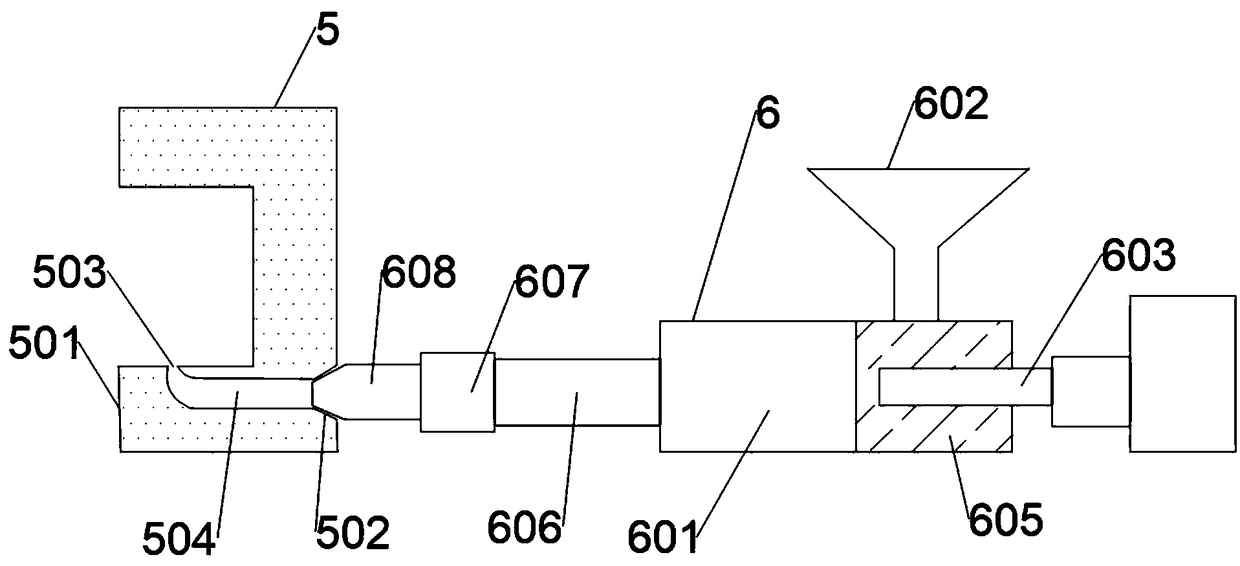

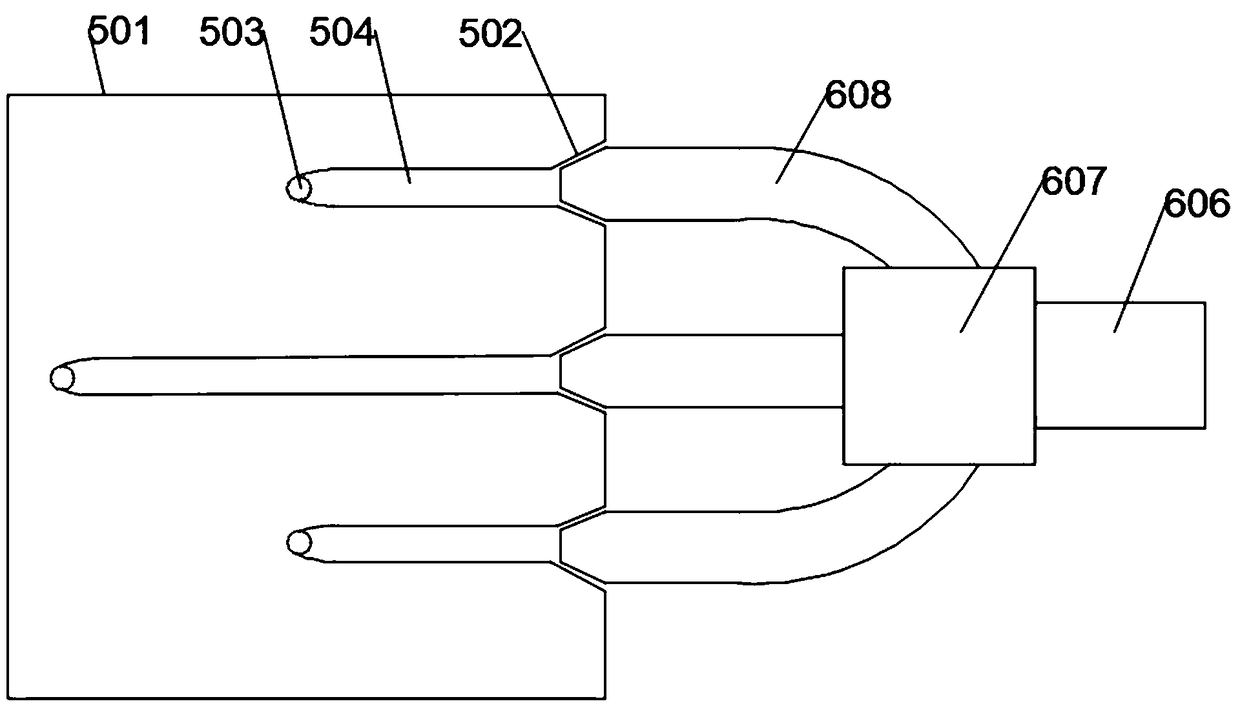

[0028] Such as figure 1 and figure 2 As shown, the present invention provides a spot-casting type high-efficiency and high-precision injection mold, including a plate frame 1, the shape of the end surface of the plate frame 1 is "L" shape, and the injection molding device is better installed, and the left side of the plate frame 1 The side plate is equipped with a hydraulic rod 3 through the support plate 2, and the support plate 2 ensures the stable movement of the hydraulic rod 3. The top surface of the bottom plate of the plate frame 1 is fixedly installed with a fixed mold 5 and an injection device 6 through a support seat 4.

[0029] Such as figure 1 As shown, the right end of the hydraulic rod 3 is fixedly connected with the movable mold 7, the hydraulic rod 3 is driven by a hydraulic cylinder, and the axis of the hydraulic rod 3 passes through the center of the movable mold 7 and the fixed mold 5 horizontally, so that the hydraulic rod 7 can move The force of the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com