A temperature-controlled electronic atomization device and atomization method thereof

An electronic atomization device and a technology for atomizing liquid, applied in the field of atomizers, can solve problems such as excessive temperature and safety accidents, and achieve the effects of increasing the contact area, preventing safety accidents, and ensuring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

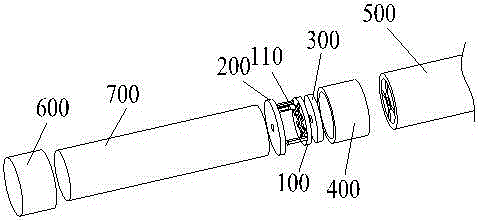

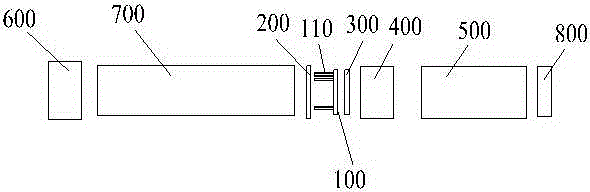

[0032] Please also refer to figure 1 and figure 2 , which is an exploded schematic view of the first and second viewing angles of a preferred embodiment of the temperature-controlled electronic atomization device of the present invention. As shown in the figure, the temperature-controlled electronic atomization device provided by the present invention includes: an atomization heating sheet 100, a temperature sensing element 110 is attached to one side of the atomization heating sheet 100, and is connected to a control circuit board 200; The other side of the heating sheet 100 is connected to one side of the porous ceramic 400 through a high-temperature resistant water-absorbing sheet 300, and the other side of the porous ceramic 400 is in contact with the atomized liquid container 500, which is used to transfer the atomized liquid through the porous ceramic sheet 400. The solution in the container 500 is transported to the high-temperature-resistant water-absorbing sheet 300...

Embodiment 2

[0047] read on image 3 , which is a schematic diagram of another embodiment of the temperature-controlled electronic atomization device of the present invention.

[0048] The difference from the above embodiments is that the temperature-controlled electronic atomization device 20 adopts a split design, such as the atomizer (including the atomized liquid container and part of the control circuit board) and the battery (including part of the control circuit) are set separately , we call it a two-stage setting (further, the atomized liquid container, atomizer (including part of the control circuit board) and battery (including part of the control circuit) can be set separately and we call it a three-stage setting). In this way, for the two-stage setting, the user can conveniently remove the original atomizer when the atomized liquid is consumed, and replace the new atomizer with a battery (including the control part) to continue using. For the three-stage arrangement, in additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com