Method and apparatus for making interrupted spinning process to recovering production

A drafting device, technology of conveying process, applied in the field of production and device for resuming interrupted spinning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

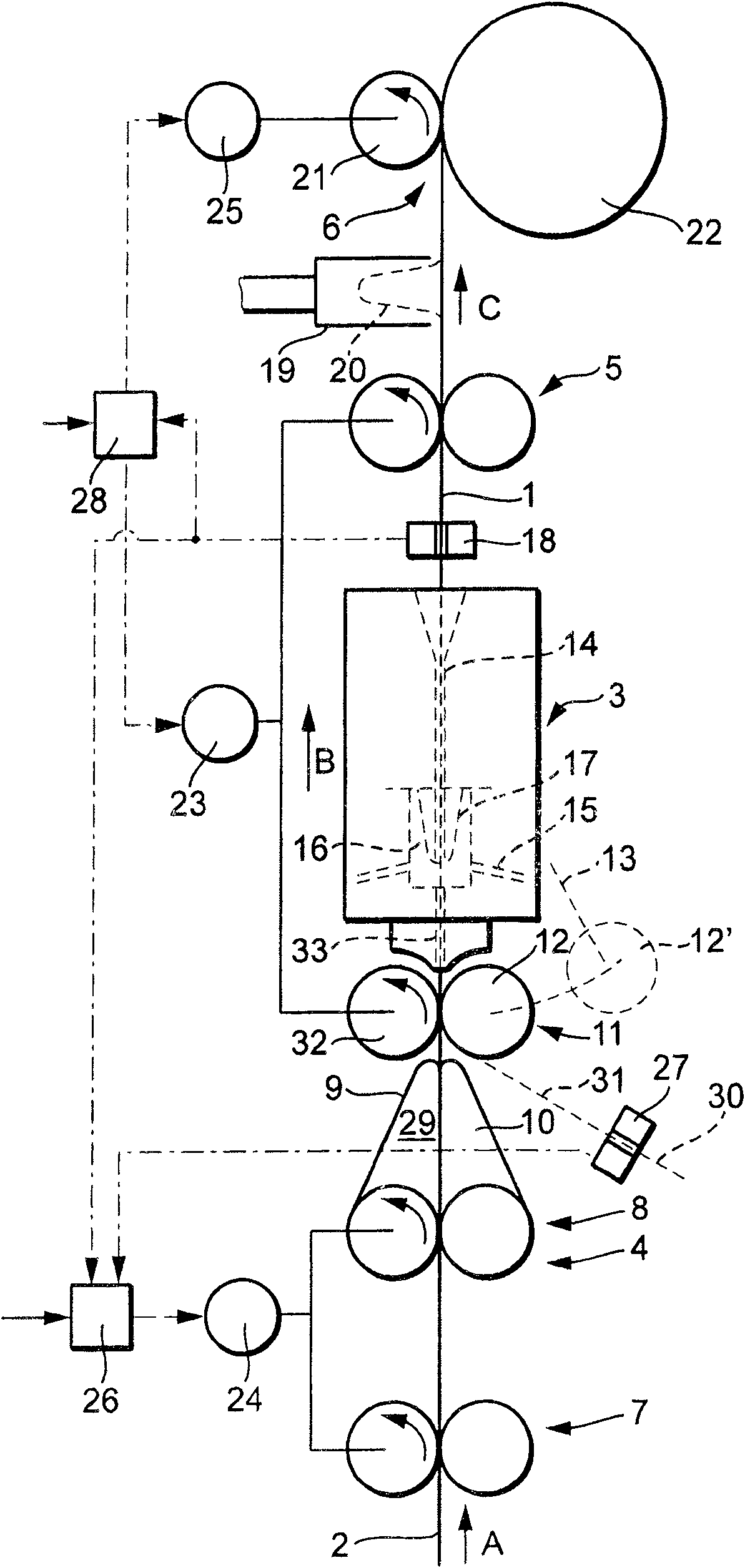

[0020] according to figure 1 The spinning equipment is used to spin a staple fiber 2 into a yarn 1. The main components of the spinning plant include an air injection device 3 - which can be designed, for example, according to the aforementioned EP 12 19 737 A1, and a drafting device 4 preferably designed as a three-roller drafting unit. , a pair of guide rollers 5 and a winding device 6.

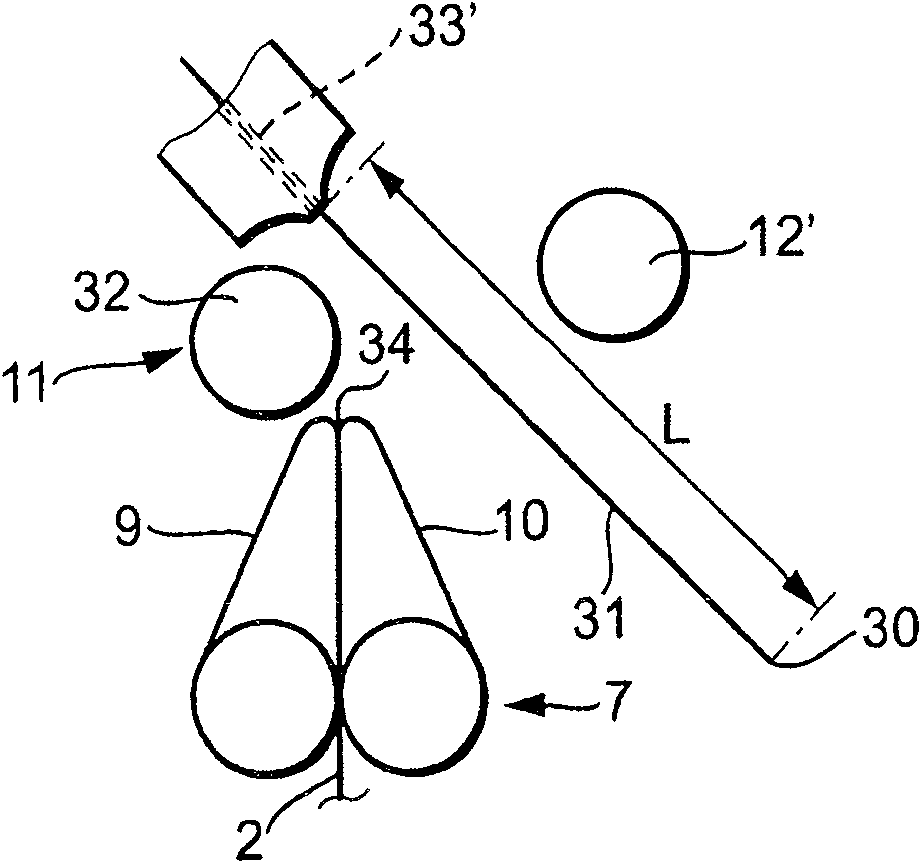

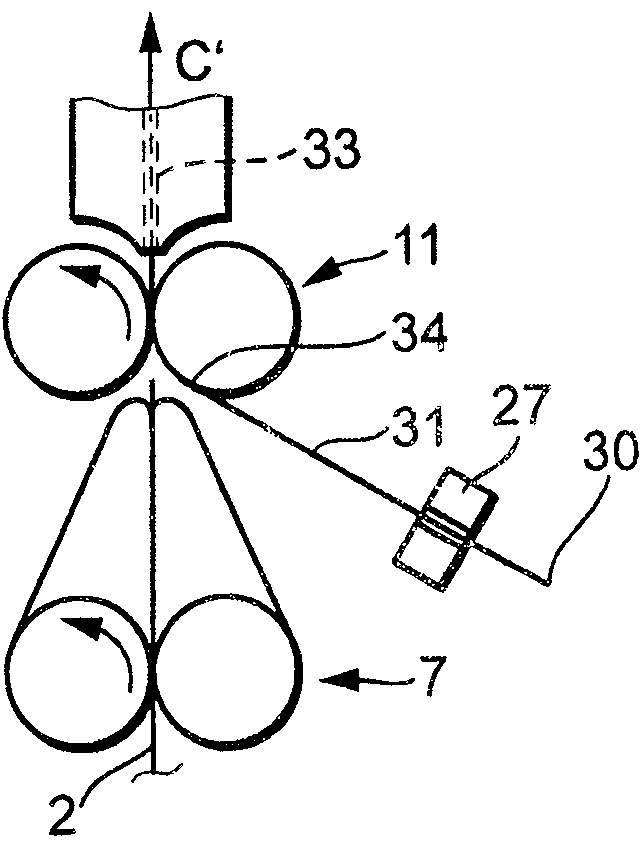

[0021] The illustrated drafting device 4 comprises a pair of feed rollers 7-a staple fiber 2 to be drawn is fed to the roller pair according to the feed direction A, and further comprises a pair of apron rollers 8-the apron rollers The pair consists of guide aprons 9 and 10 in a known manner and comprises a pair of output rollers 11 at which the drafting zone 29 of the drafting device 4 ends. In the drafting unit 4, the staple fibers 2 are drawn to the desired fineness in a known manner.

[0022] The delivery roller pair 11 consists of a driven bottom roller 32 and a pressure roller 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com