Manufacturing method of package and package manufacturing device using same

A manufacturing method and a technology for a manufacturing device, which are applied in the field of packaging manufacturing devices and can solve problems such as falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

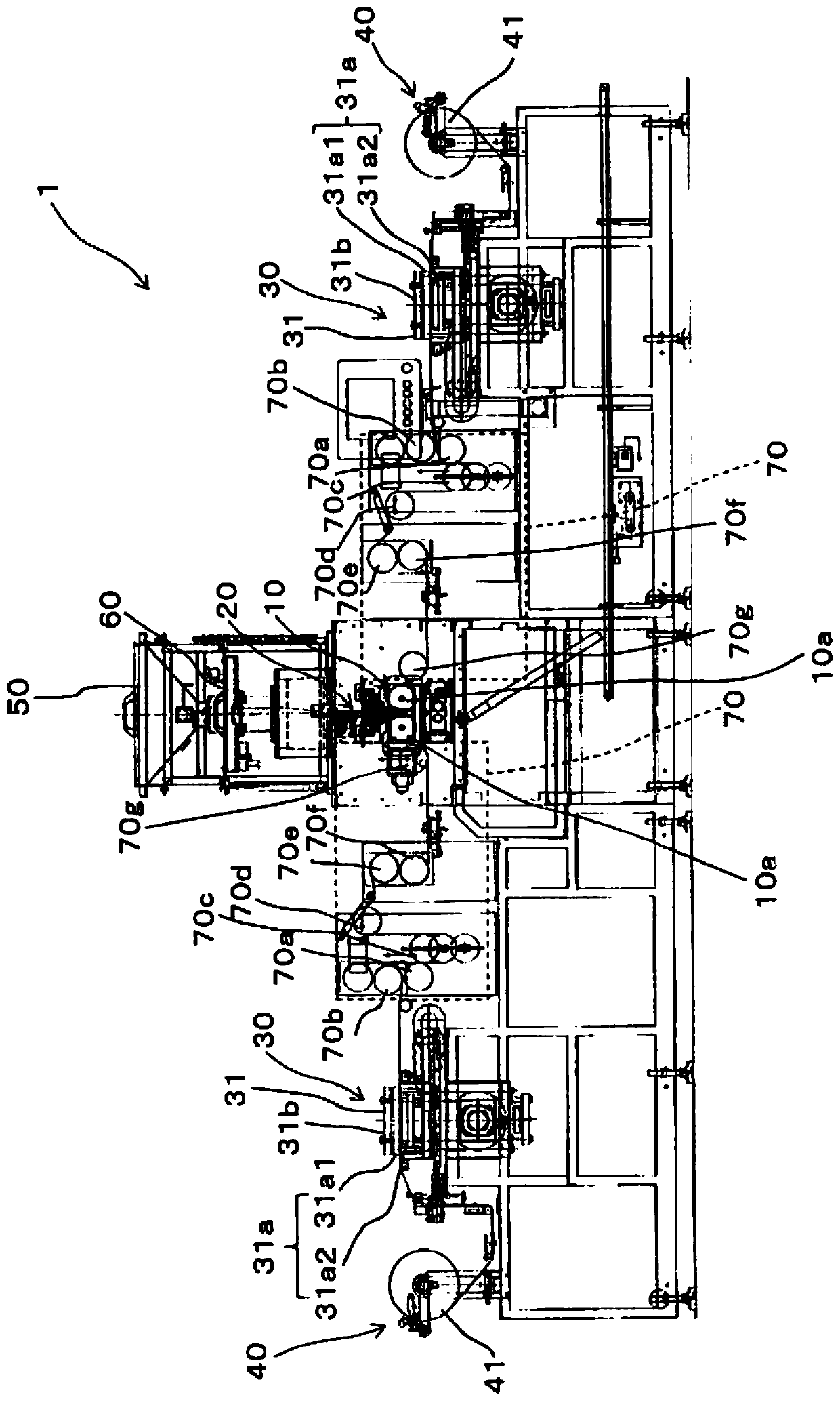

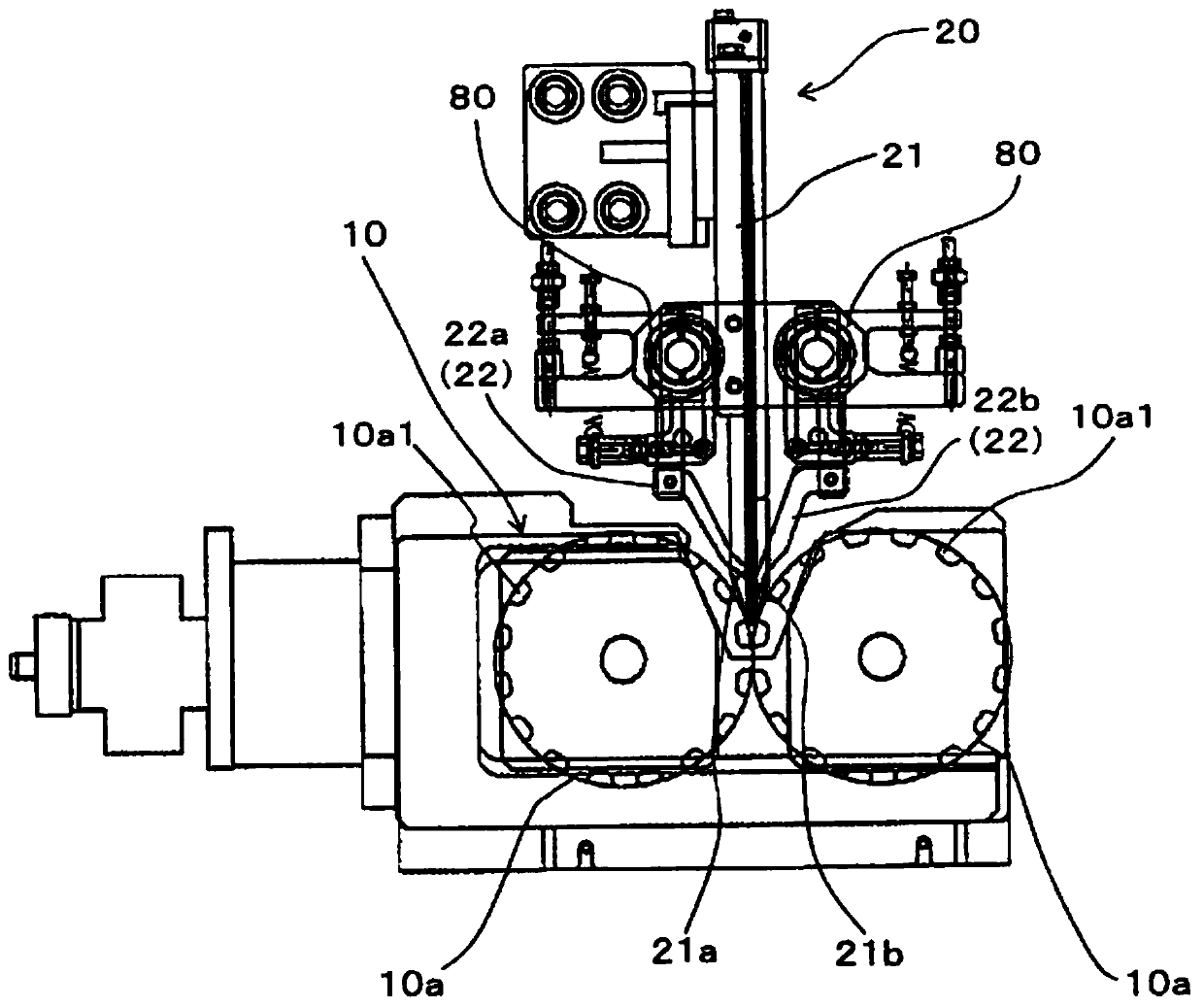

[0051] The packaging manufacturing device 1 in an embodiment of the present invention will be further described below with reference to the accompanying drawings. In addition, in the description of the package manufacturing apparatus 1 below, the side where the hopper 50 is provided is defined as the upper side, and the opposite side is defined as the lower side.

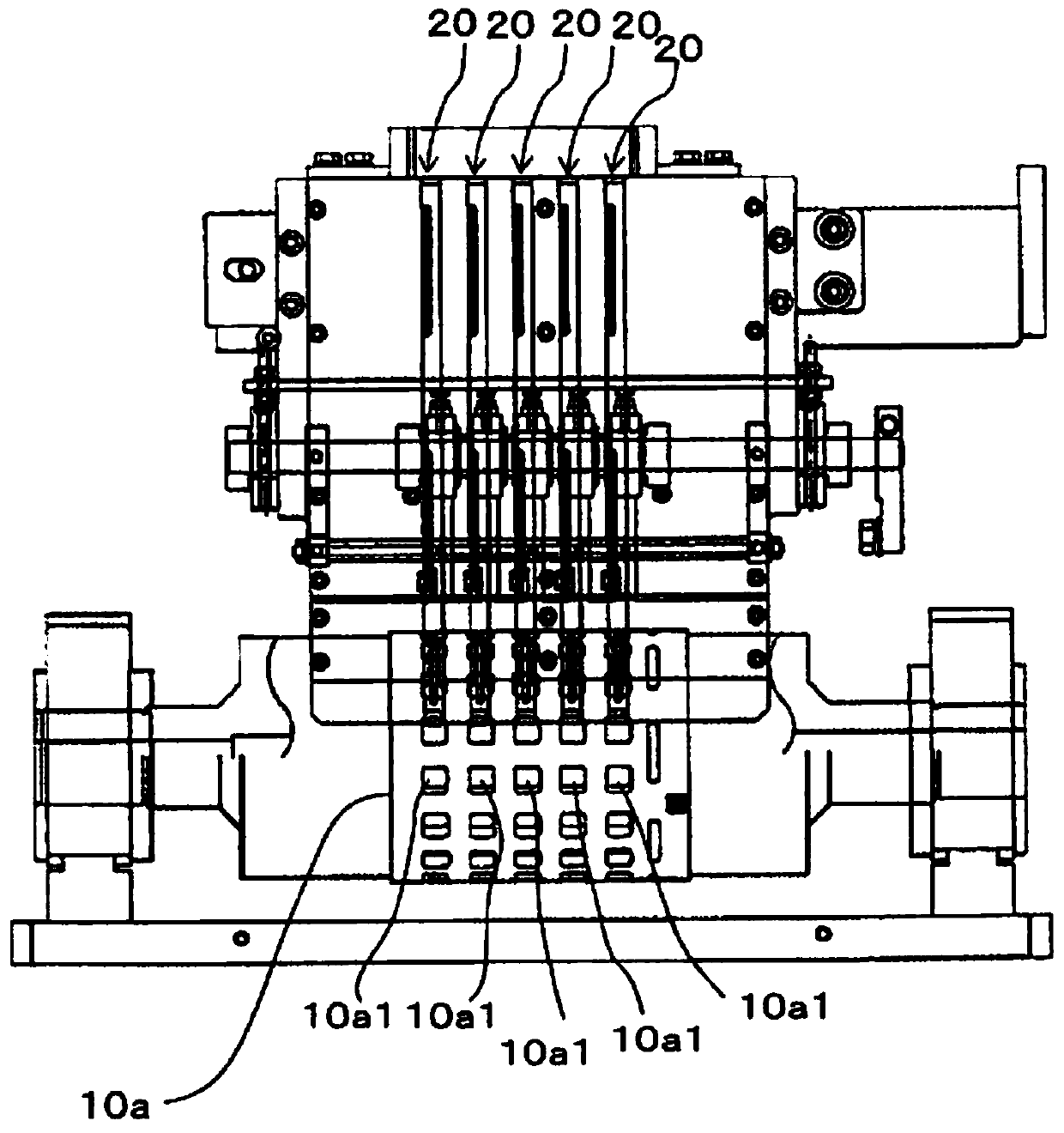

[0052] In addition, in the following, after the film is sent out by the film sending mechanism, grooves are arranged and formed on two strip-shaped films at intervals along the length direction and the width direction as an example for description.

[0053] In addition, the following description will be made by taking the tablet delivery into the groove as an example.

[0054] The packaging manufacturing device 1 closes the two films formed with the grooves, conveys the tablets into the opposite grooves, and simultaneously starts sealing from the part of the edge of the end of the two films located at the side of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com