Vibrating Parts Conveyor

A conveying device and vibrating technology, which is applied in the field of vibrating component conveying devices, can solve the problems of lowering the natural vibration frequency, lowering the driving frequency, and increasing the mass of the abutment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

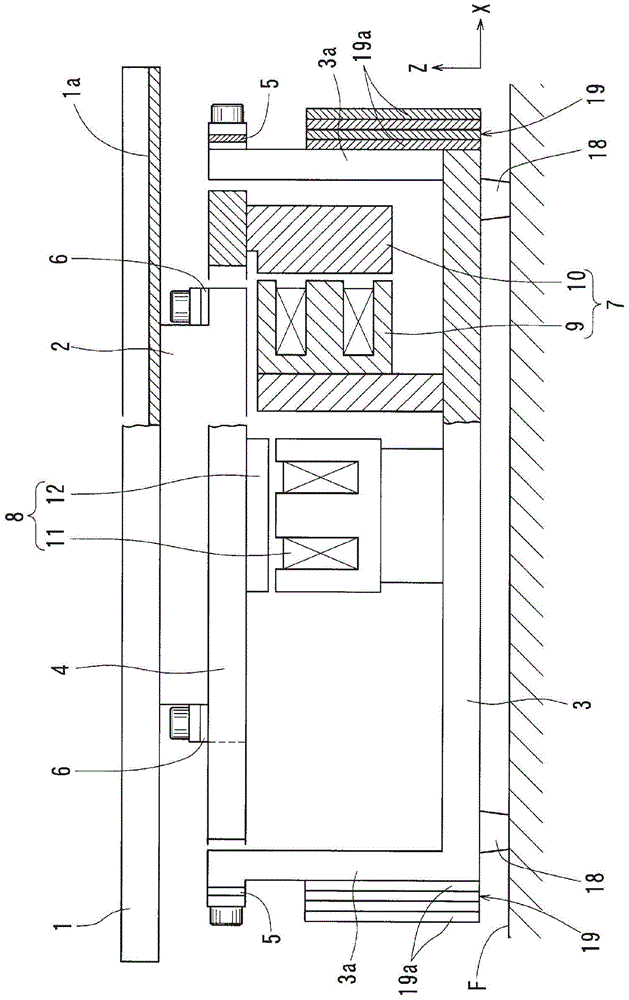

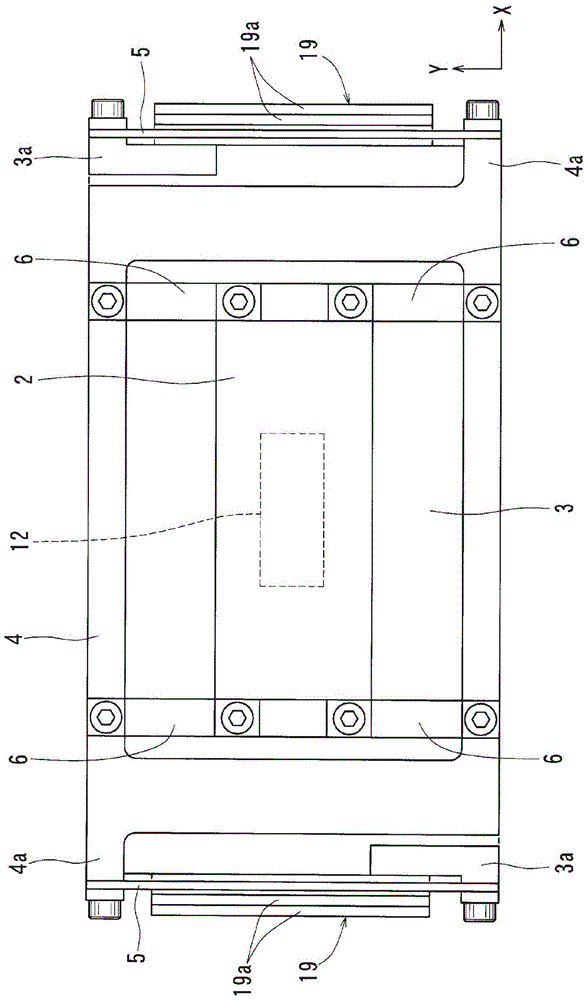

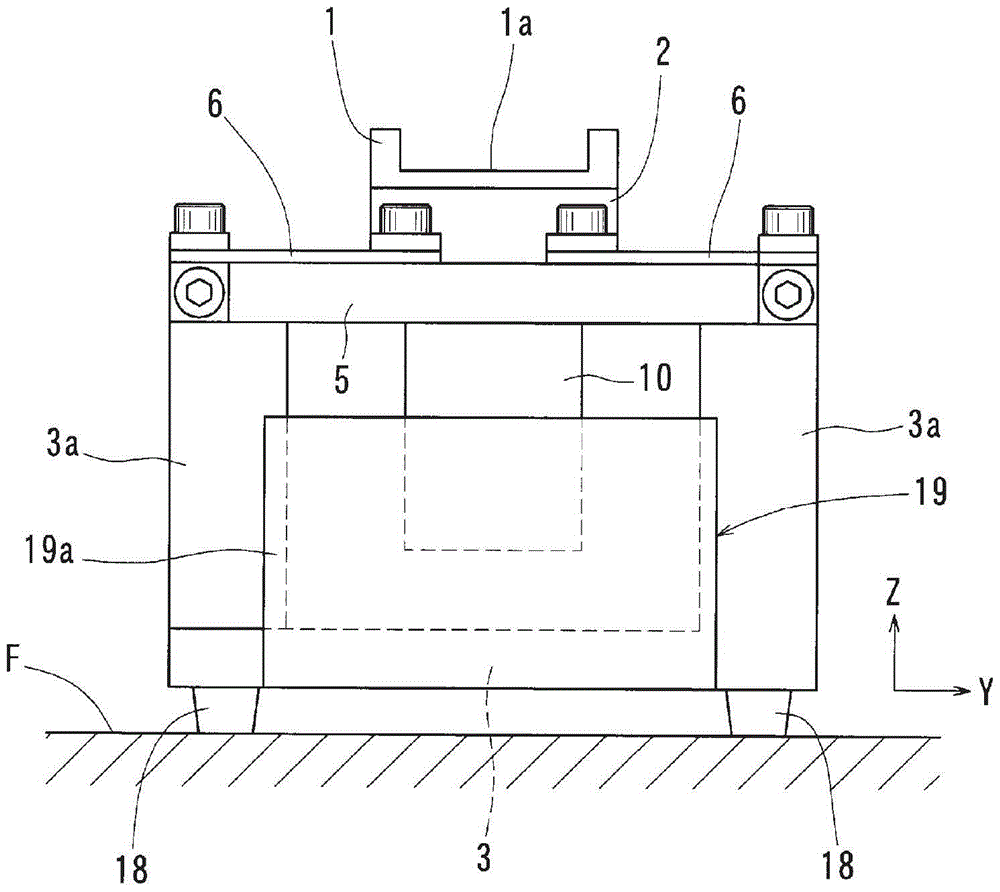

[0043] Embodiments of the present invention will be described below with reference to the drawings. Such as Figure 1 to Figure 3 As shown, in this vibratory component conveying device, a trough (part conveying member) 1 formed with a linear conveying path 1a is mounted on the upper surface of an upper vibrating body 2, and the upper vibrating body 2 and the ground An intermediate vibrating body 4 is arranged between the bases 3, and the intermediate vibrating body 4 is connected to the base 3 by two leaf springs 5 as the first elastic members, and the upper part is vibrated by four leaf springs 6 as the second elastic members. The body 2 is connected with the intermediate vibrating body 4, and the first vibrating mechanism 7 that generates vibrations in the horizontal direction (parts conveying direction, X direction in the figure) is provided between the intermediate vibrating body 4 and the base 3, and the upper vibrating body 2 A second vibration excitation mechanism 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com