Powder material metering and conveying device of mixing plant and control method of powder material metering and conveying device

The technology of a conveying device and a control method is applied in the powder metering and conveying device of a mixing station and its control field, which can solve the problems of short service life, affecting the accuracy of weighing and proportioning, and prone to failure, so as to reduce operating costs and Maintenance cost, precise and diversified measurement control, and flexible implementation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but it is only a preferred embodiment and is not used to limit the essential scope of the present invention.

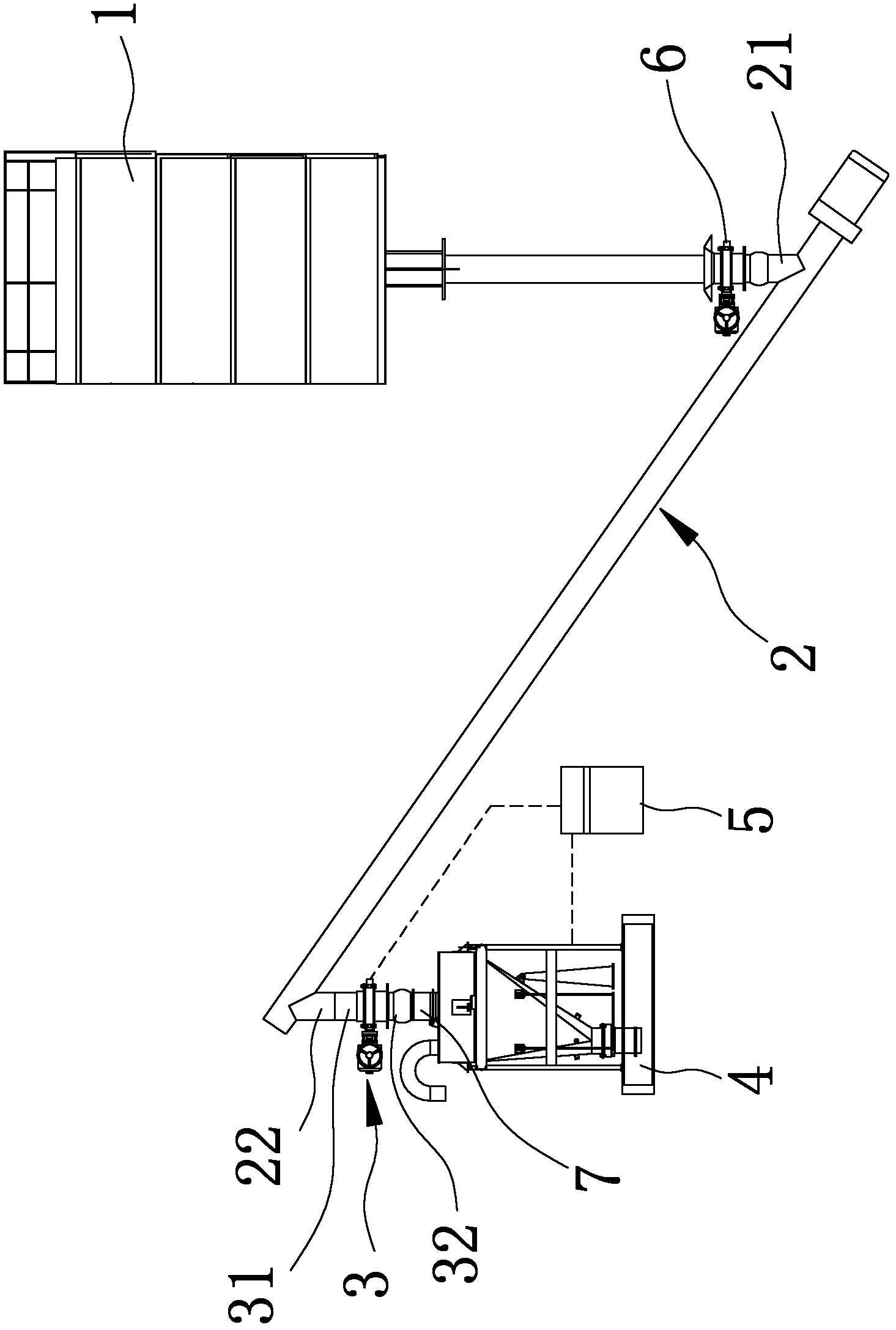

[0038] Please refer to figure 1 , is a schematic structural diagram of the powder metering and conveying device of the mixing station of the present invention. As shown in the figure, the powder metering and conveying device of the mixing station of the present invention mainly includes: a storage bin 1 for storing various powder materials to be added; screw conveying The machine 2 has a feed port 21 and a discharge port 22, wherein the feed port 21 is connected to the storage bin 1 to feed from the storage bin 1; the discharge regulating valve 3 has an input port 31 and an output port 32, Wherein the input port 31 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com