Low-temperature hot air circulation heat treatment furnace for magnetic core and application method of heat treatment furnace

A technology of heat treatment furnace and hot air circulation, which is applied in the field of low-temperature hot air circulation heat treatment furnace, can solve the problems of poor heat treatment effect and low treatment efficiency, and achieve the effects of reduced energy consumption, increased furnace loading, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

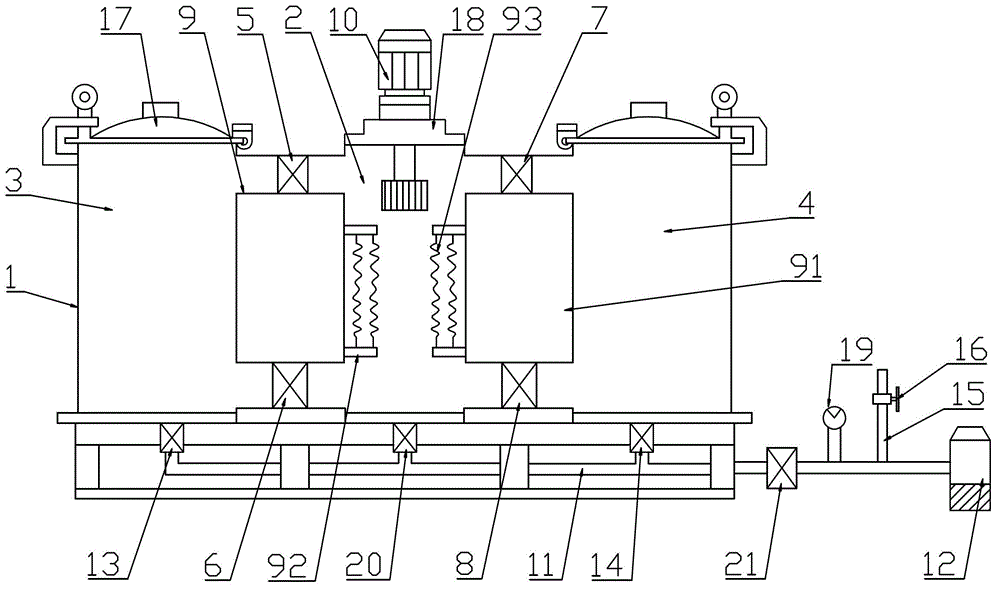

[0027] As attached to the manualfigure 1 As shown, a low-temperature hot air circulation heat treatment furnace for a magnetic core includes a furnace body 1, a heating furnace 2, a first heat treatment furnace 3 and a second heat treatment furnace 4 are arranged in the furnace body 1, and the first heat treatment furnace 3 The upper and lower parts of the furnace are connected with the heating furnace 2, and the control valve I5 and the control valve II6 are set respectively. The heating furnace 2 and the first heat treatment furnace 3 form a circulation loop, and the upper and lower parts of the second heat treatment furnace 4 are both It communicates with the heating furnace 2, and sets the control valve III7 and the control valve IV8 respectively. The heating furnace 2 and the second heat treatment furnace 4 form a circulation loop. The heating furnace 2 is equipped with a centrifugal fan 10, which is connected to the heating furnace. On the furnace 2, the connection betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com