Method for controlling full-automatic optimization burning furnace of blast furnace coal injection system flue gas furnace

A blast furnace coal injection and blast furnace gas technology, which is applied in the field of iron and steel metallurgy blast furnace ironmaking, can solve problems such as operational errors, flue gas furnace combustion control process index fluctuations, and analysis results that cannot be standardized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

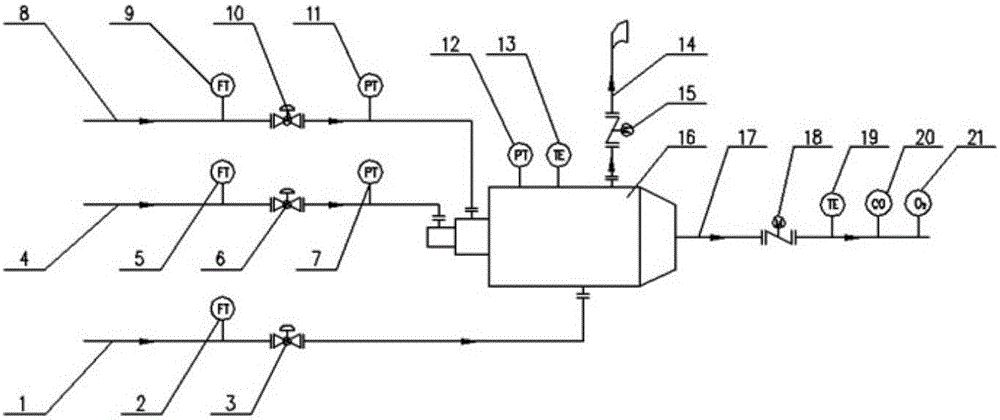

[0037] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

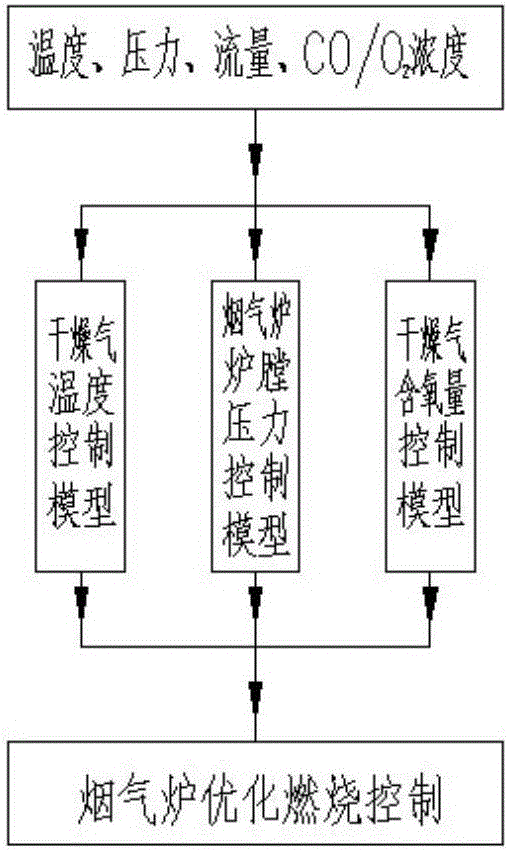

[0038] Such as figure 1 and figure 2 As shown, a blast furnace coal injection system flue gas furnace fully automatic optimization furnace control method, including the following steps:

[0039] S1. Model establishment: respectively establish a drying gas temperature control model, a flue gas furnace furnace pressure control model, and a drying gas oxygen content control model;

[0040] S2, parameter adjustment: the temperature, pressure, flow rate, CO concentration and O of the medium are adjusted by the three models in step S1 2 The concentration is adjusted to control the temperature of the drying gas, the pressure of the flue gas furnace and the oxygen content of the drying gas respectively.

[0041] The drying gas temperature control model controls the drying gas tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com