Full-automatic measurement device for magnetoelectric properties of magnetoelectric material and measuring method thereof

A technology of magnetoelectric materials and measuring devices, which is applied in the direction of magnetic field measurement, magnetic field size/direction, etc. by using electromagnetic devices, can solve the problems of increasing equipment cost, accuracy, insufficient frequency upper limit, and high cost, so as to improve measurement accuracy , working frequency expansion, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

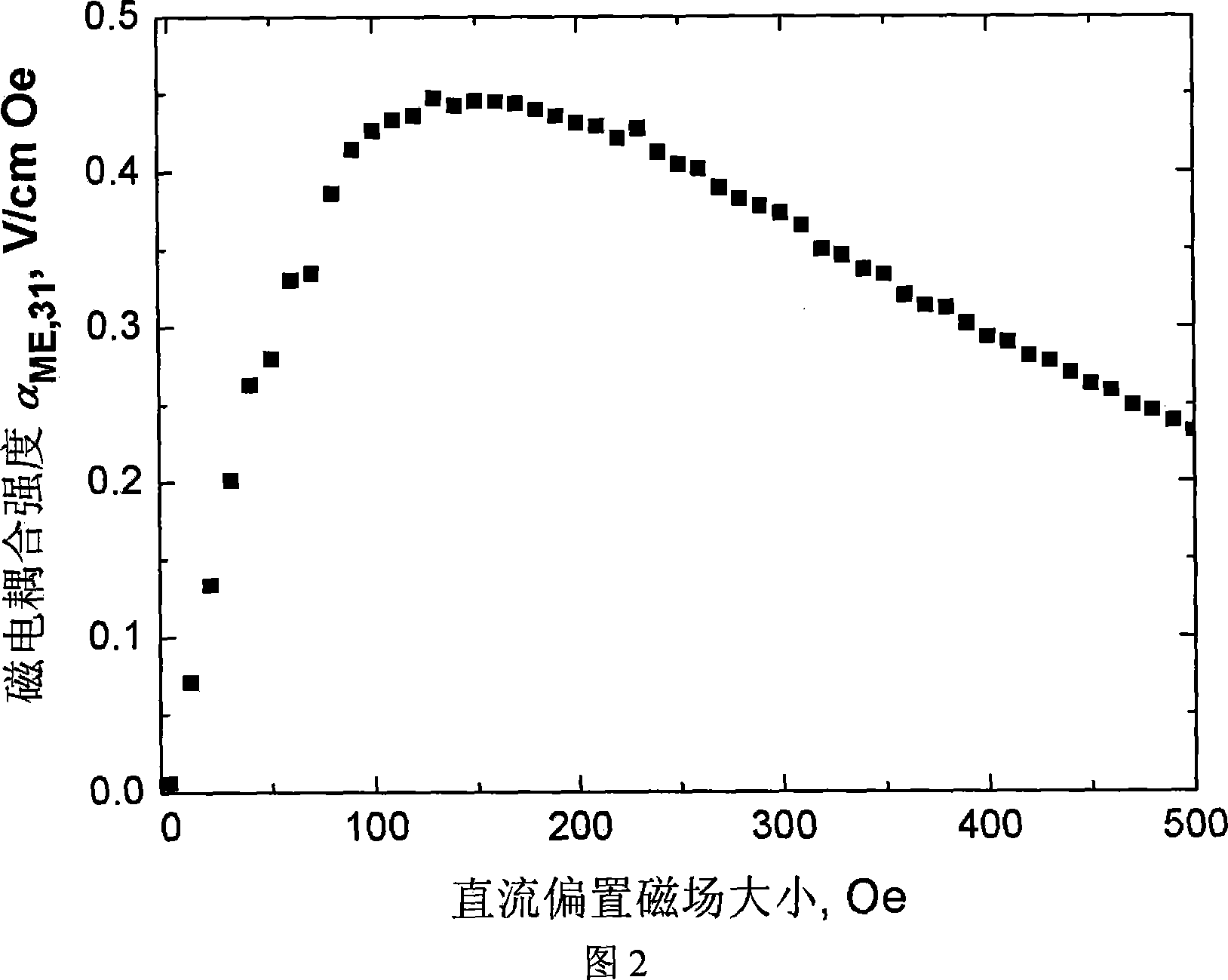

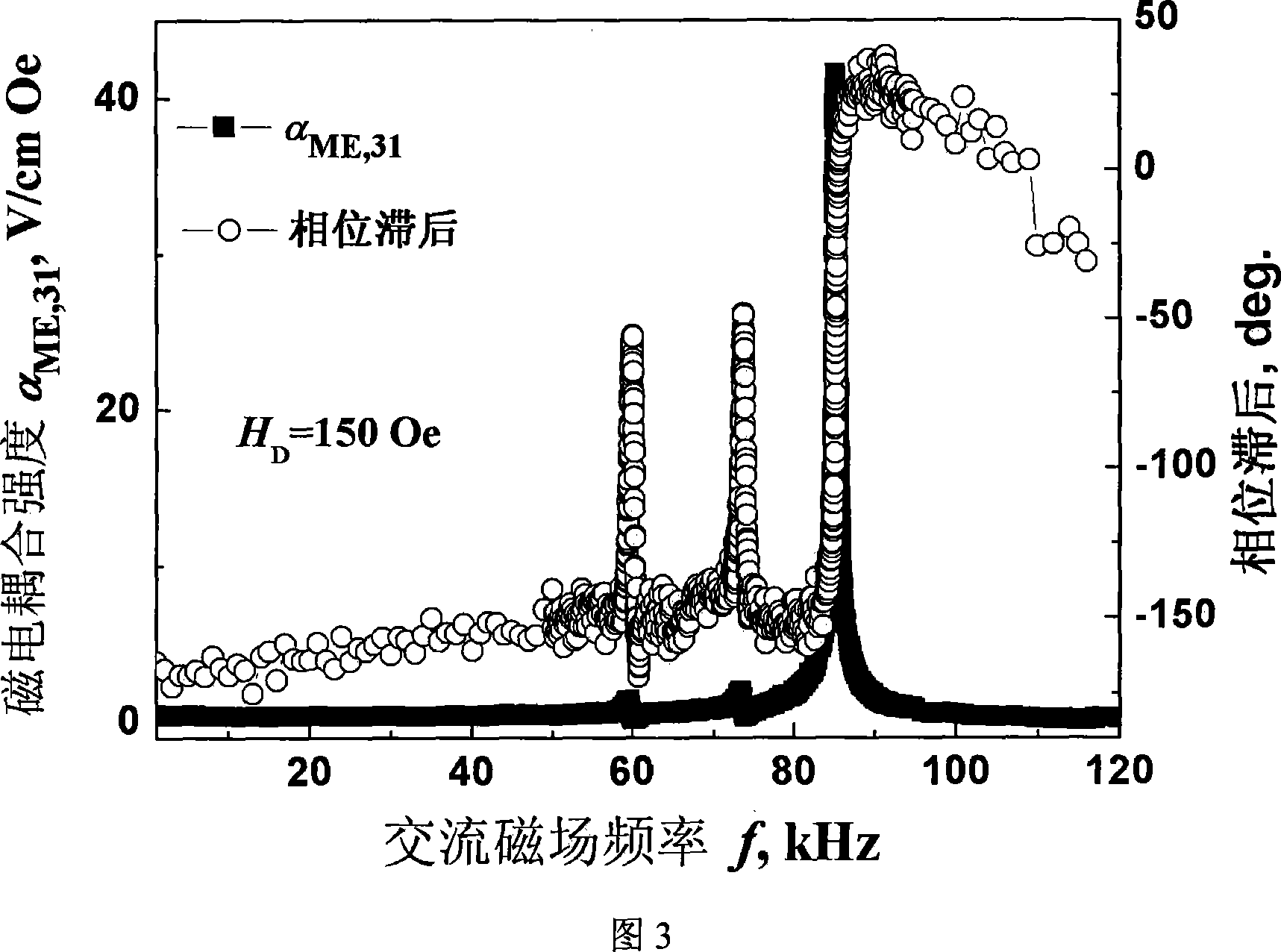

[0027]In embodiment 1, a typical test sample 5 uses a Ni / PZT / Ni layered composite material. Measuring Transverse Magnetoelectric Coupling Coefficient α of Ni / PZT / Ni Layered Composite ME,31 And the corresponding phase lag of magnetoelectricity.

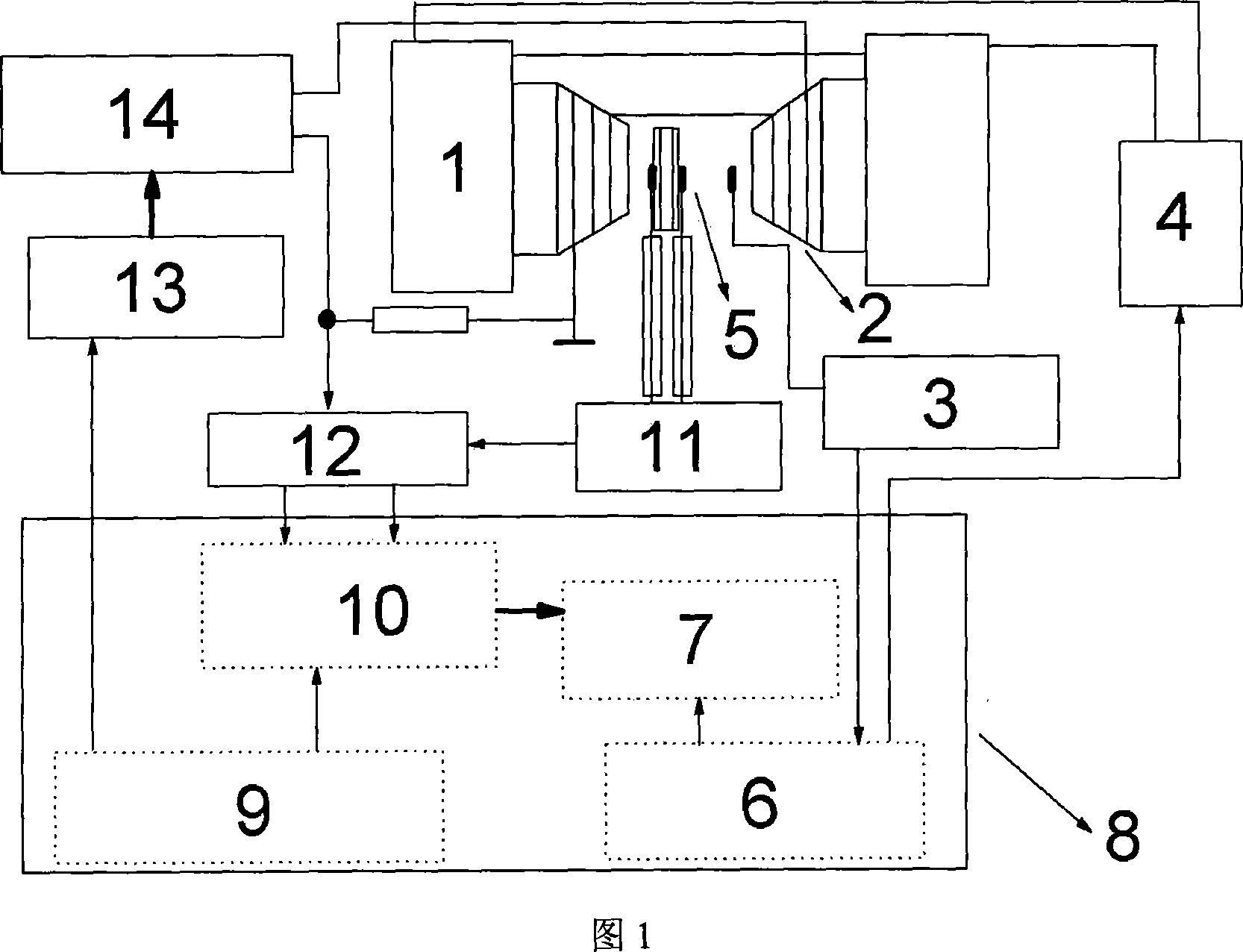

[0028] (1) Assemble the instrument according to the principle of Fig. 1, wherein the sensing resistance R=10Ω for generating the magnetic field. Data acquisition front end 12 is Rigol DS5062CA oscilloscope; signal generator 13 is Agilent 33220A; DC bias magnetic field system uses WWL-LSX21 three-phase DC power supply and SB175 electromagnet; Tesla meter 3 uses HT100; (1.6GHz, 256MB, 40GB, WindowsXP) Install the evaluation version of Labview8.0 as the development platform of the control program. According to the above principles, the corresponding measurement control software is written under Labview.

[0029] (2) The sample tested is a Ni / PZT / Ni layered composite square plate with Ni electroplated on a PZT ferroelectric ceramic with...

Embodiment 2

[0033] Embodiment 2, measuring the transverse magneto-generated electric field coefficient α of Ni / PZT / Ni layered composite material ME,31 and a 3D image of the phase lag of the magnetoelectric response as a function of applied bias magnetic field and applied AC magnetic field frequency.

[0034] (1) In order to increase the magnetic field automatic control module, AD / DA cards (AC6632 and AC6682) are installed in the PCI slot of the computer as the control interface of the DC bias magnetic field, and the hardware and software in the measurement system are correspondingly expanded. The rest are the same as Step 1 in Example 1

[0035] (2) The sample tested is the same as step 2 in Example 1.

[0036] (3) The amplitude of the output AC voltage of the fixed signal generator 13 is 1V, remains unchanged, change the frequency of the signal generator 13 output AC voltage and the size of the DC bias magnetic field (seeing 1 among Fig. 1) simultaneously, run The control program autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com