Automatic control method for improving uniformity of temperature of sleeve kiln

A uniformity and controller technology is applied in the field of automatic control to improve the temperature uniformity of the sleeve kiln, which can solve problems such as temperature difference, and achieve the effects of improving uniformity, improving the level of automatic control, and uniform and stable lime quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

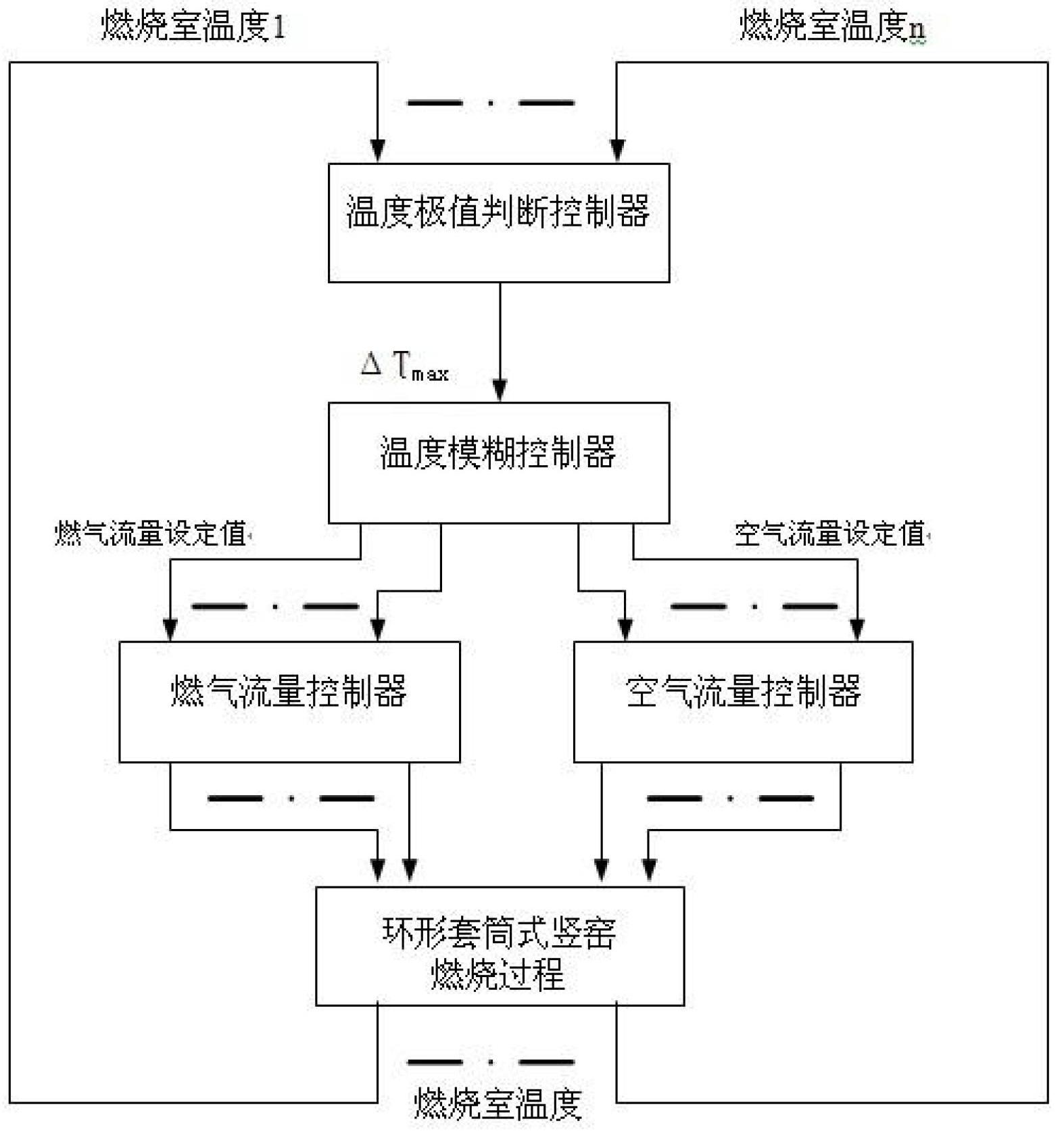

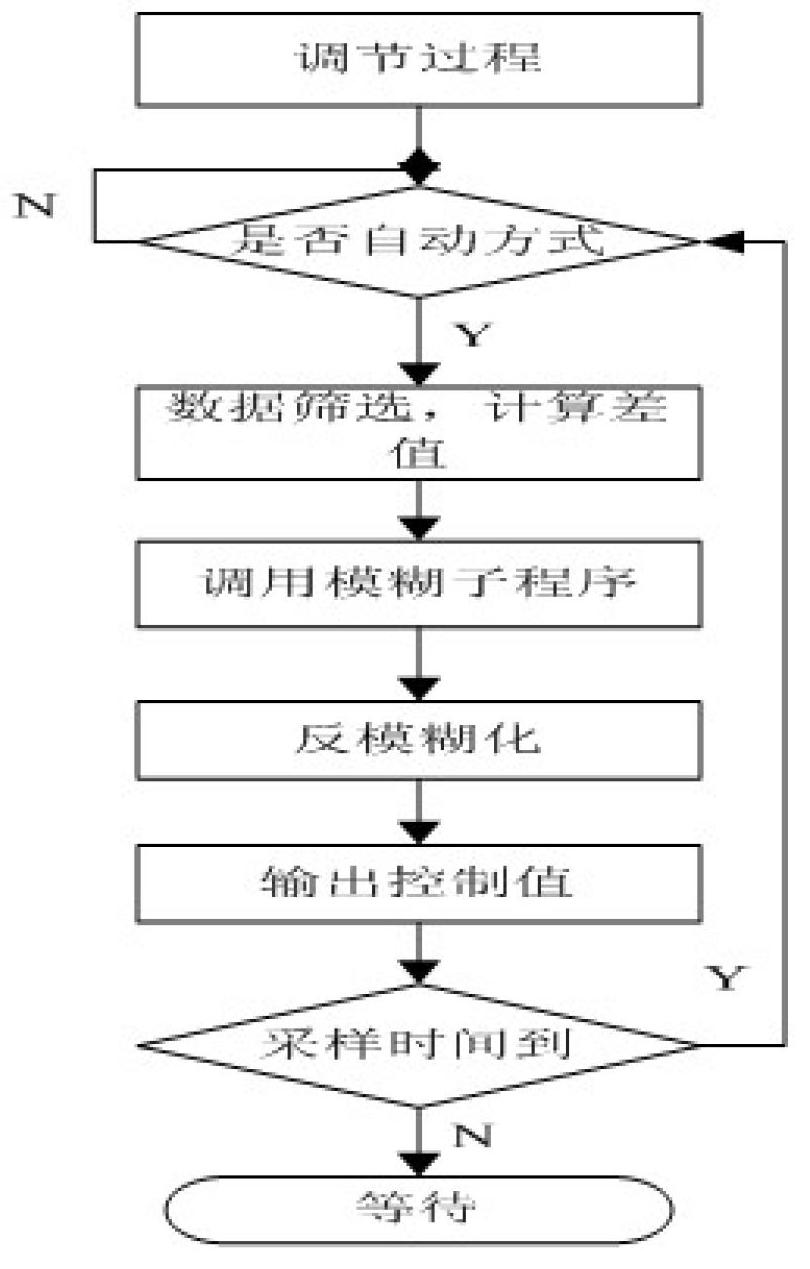

[0031] See figure 1 with figure 2 .Set temperature extreme value judgment controller, temperature fuzzy controller, gas flow regulation controller and combustion air flow controller in programmable logic controller (PLC),

[0032] Use the following methods to control the combustion chamber temperature, gas flow and air flow of the annular sleeve type shaft kiln:

[0033] (1) The current single combustion chamber temperature T is calculated by the temperature extreme value judging controller n and the average temperature T of the combustion chamber in the same layer avg The deviation value ΔT n , select the maximum deviation value ΔT that exceeds the process requirements max As the output of the temperature extreme value judgment controller.

[0034] (2) The maximum deviation value ΔT obtained in step (1) max As the input variable of the temperature fuzzy controller.

[0035] Among them, the specific design steps of the temperature fuzzy controller are as follows:

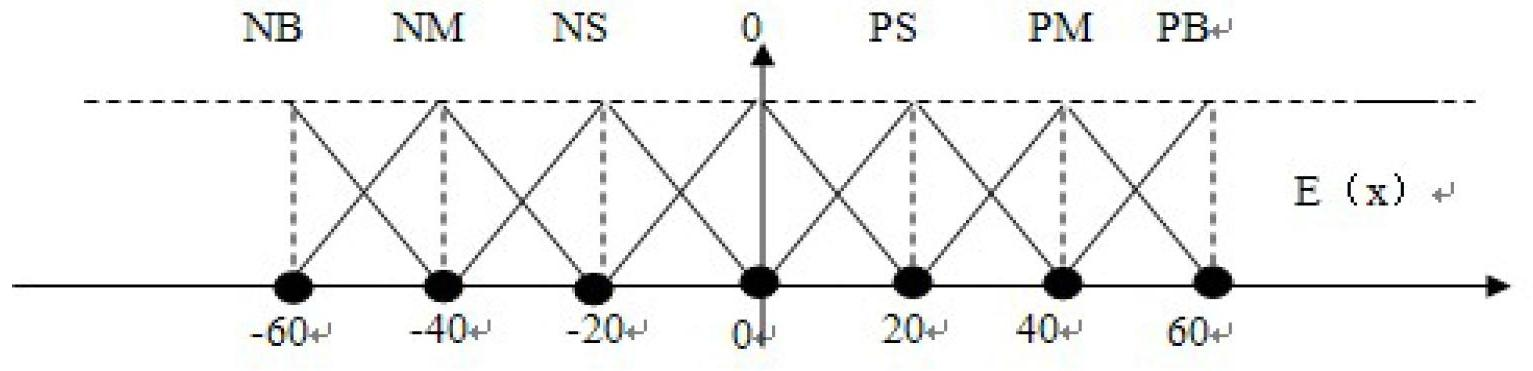

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com