Electron beam cold hearth single melted TC4 titanium alloy cast ingot head feeding process

A titanium alloy and electron beam technology, which is applied in the field of titanium alloy ingot feeding technology, can solve the problems of Al volatilization loss of alloying elements, ingot chemical composition failing to meet the standard, and ingot yield decline. The effect of yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0028] An electron beam cooling bed single-melting TC4 titanium alloy ingot head feeding process, comprising the following steps:

[0029] Step 1: Determine the head of the TC4 titanium alloy ingot that needs to be fed in a single smelting of the electron beam cooling bed. The method of determination is to define the head of the ingot within 100mm from the start of the casting surface to the length of the ingot;

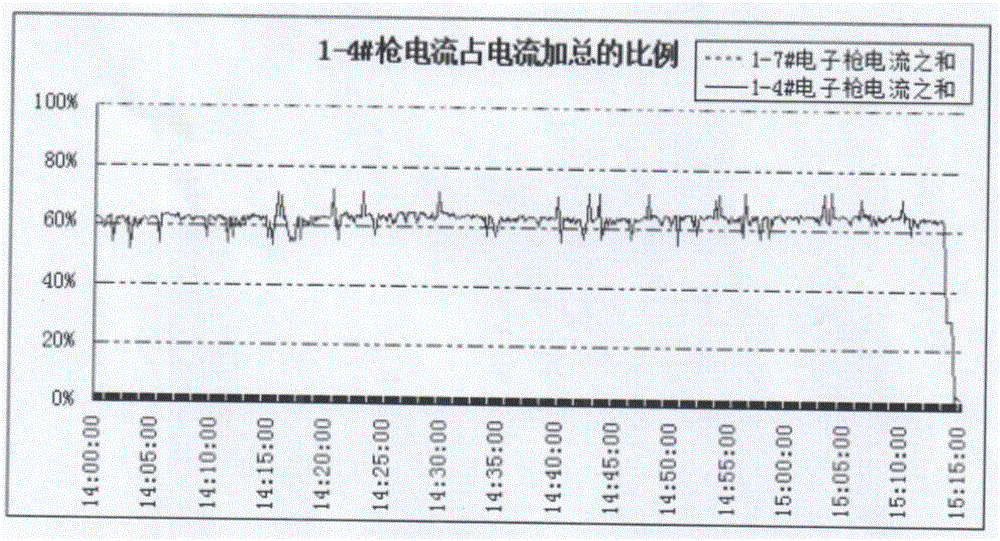

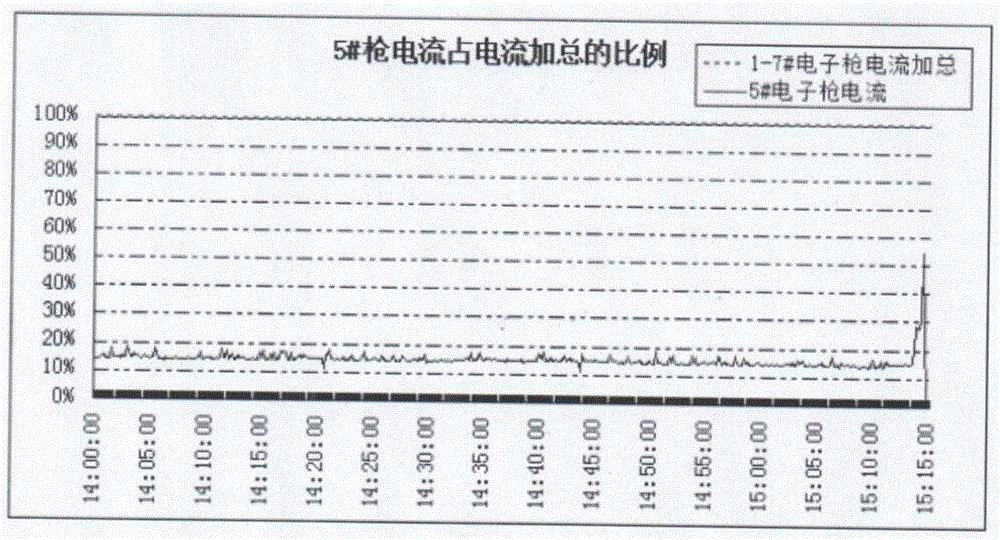

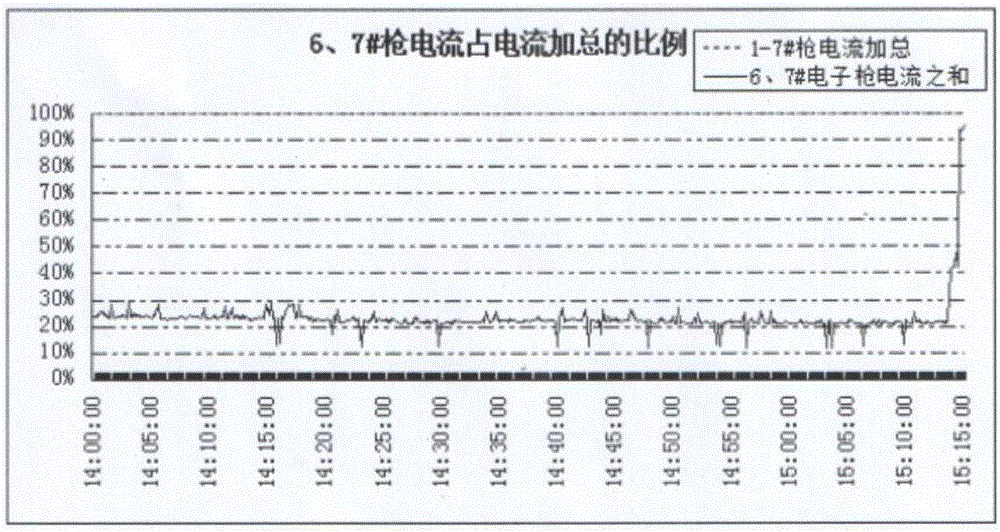

[0030] Step 2: Number the electron guns responsible for scanning the melting area, refining area and casting area of the electron beam cooling hearth furnace. 1-4# is responsible for scanning the melting area of the electron beam cooling hearth furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com