Patents

Literature

45results about How to "Reduce follow-up costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

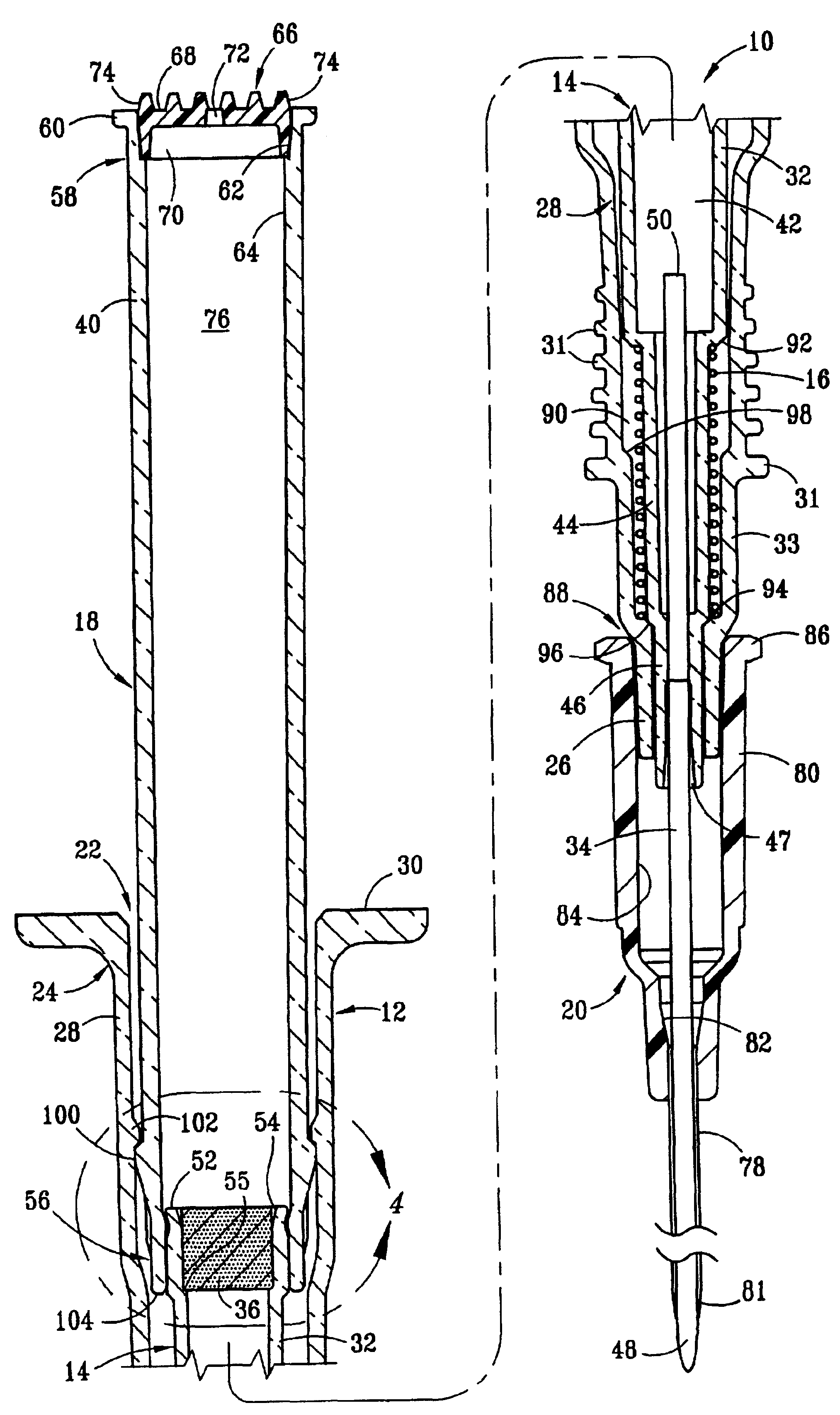

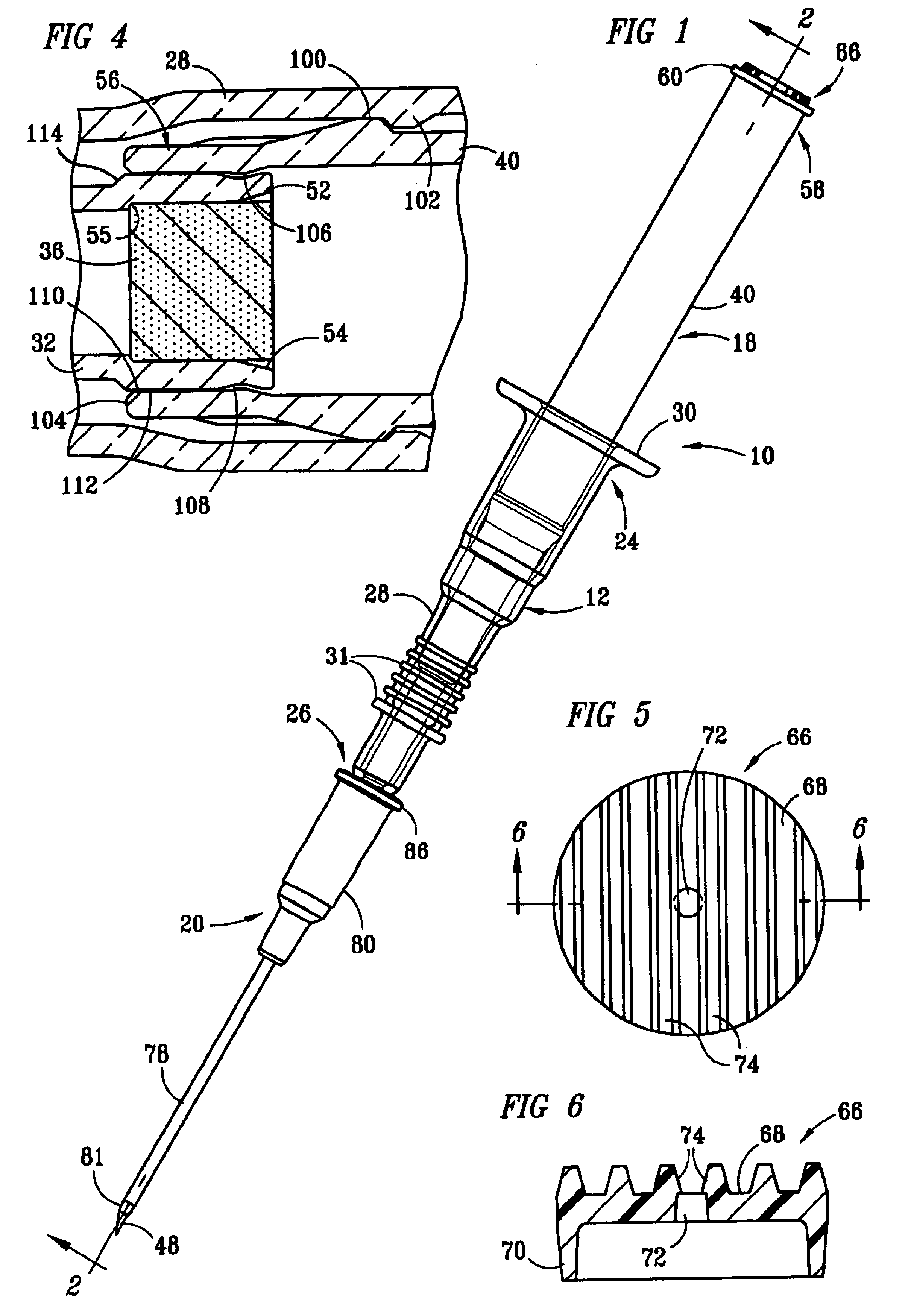

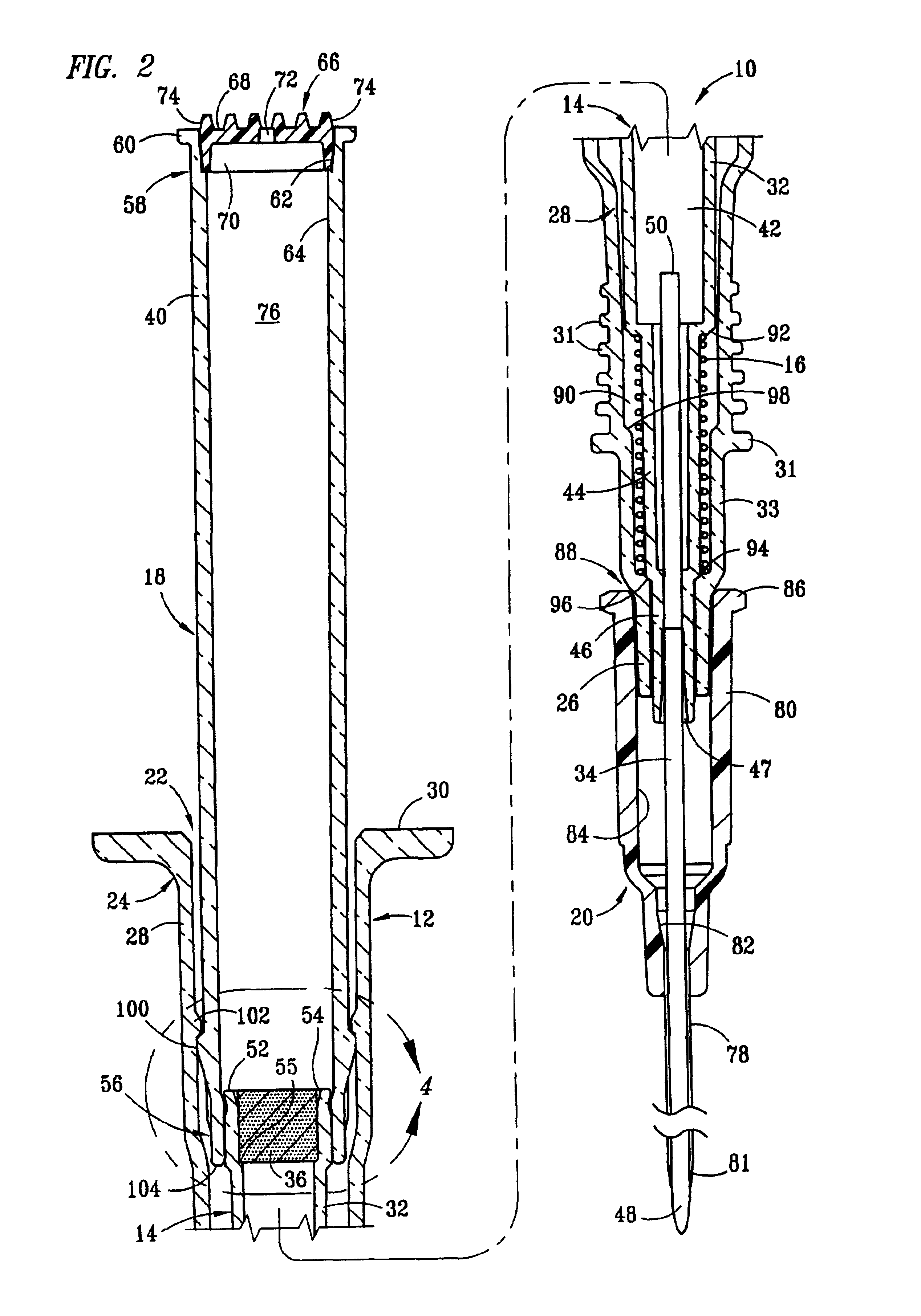

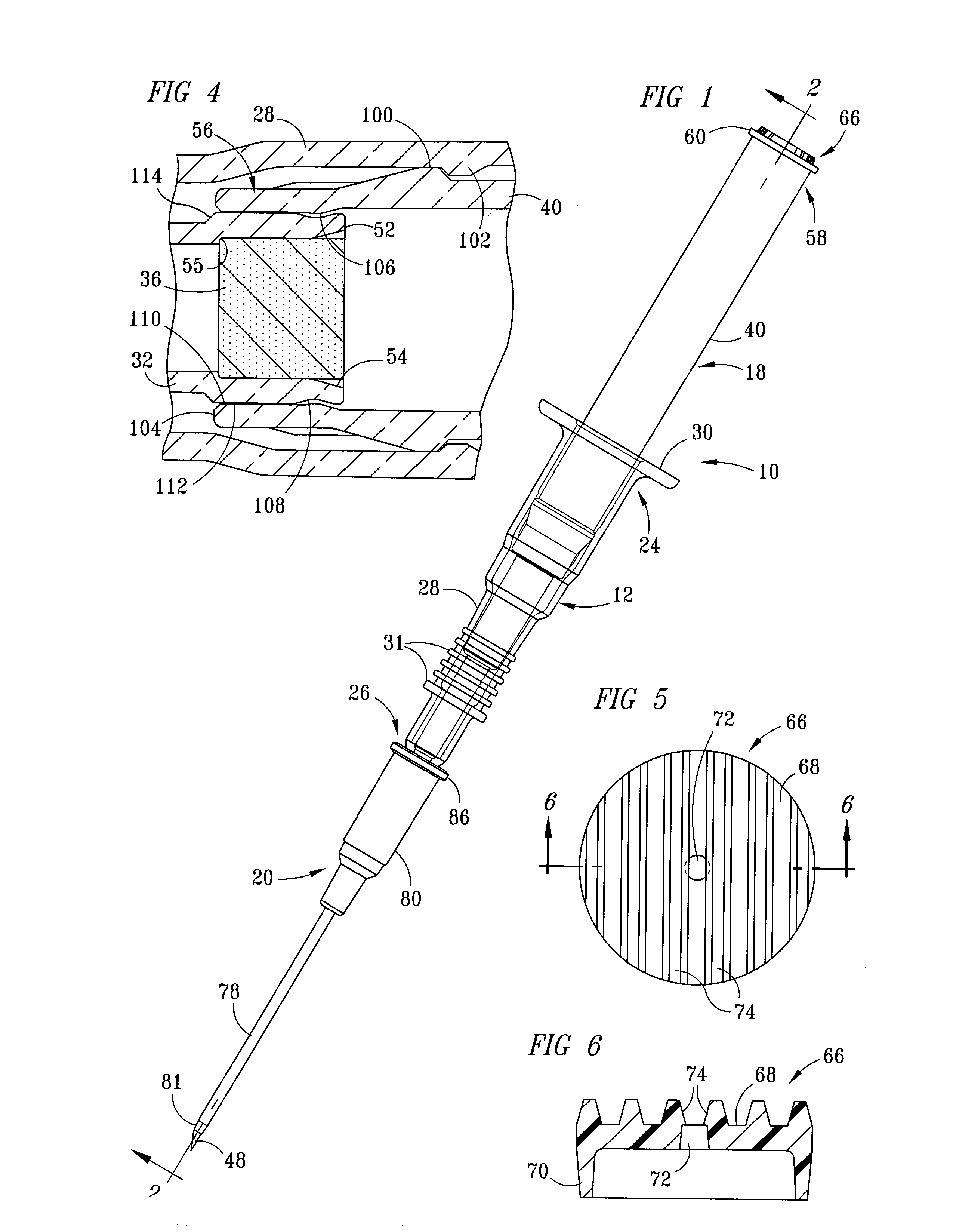

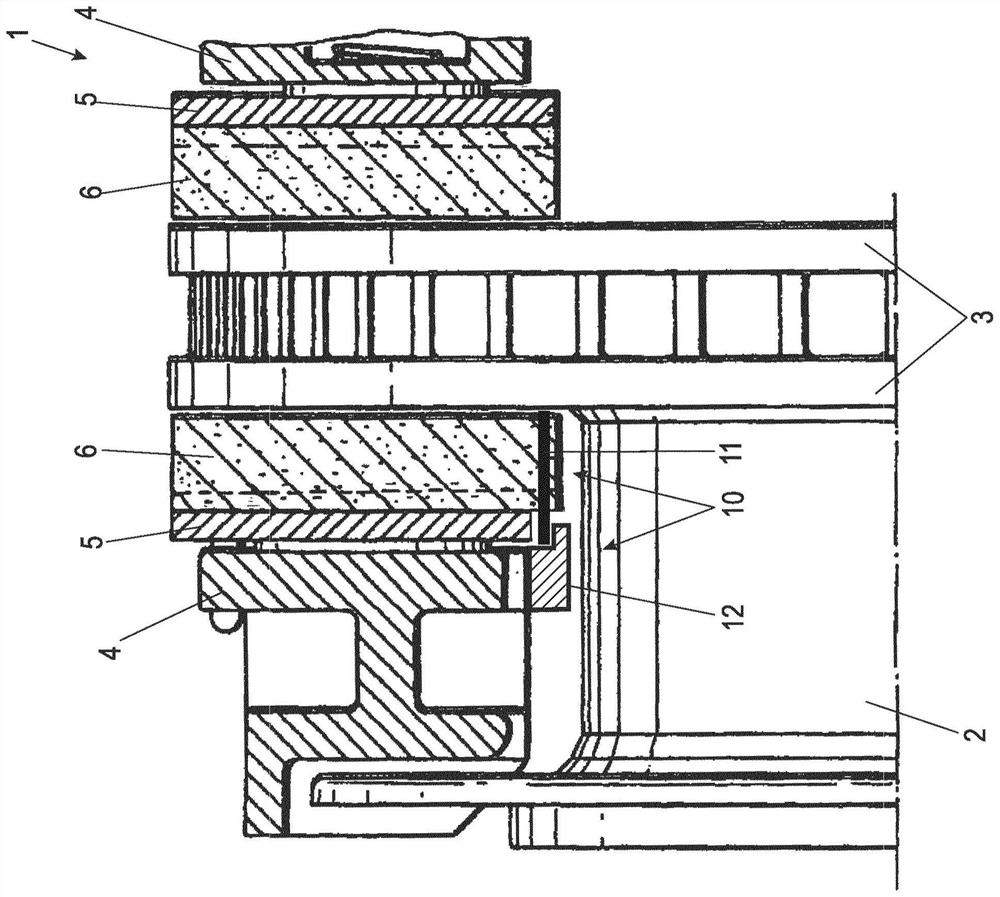

IV catheter introducer with retractable needle

InactiveUS6872193B2Reliable and reliableEasy to use with one handGuide needlesInfusion syringesDetentCatheter introducer

An IV catheter introducer having a retractable needle holder and a tubular plunger that are held by a detent structure in a preferred positional relationship prior to and during insertion of the catheter. Following insertion, the plunger is pushed past the detent structure, permitting a compressed spring to force the needle holder upwardly into the plunger. A vented end cap in the plunger permits rapid venting of air displaced during retraction of the needle holder. The needle holder includes a flash chamber that is easily viewable through a clear plastic housing. Wings are provided on the housing to facililate one-handed operation of the device. A method for assembling the subject catheter introducer is also disclosed.

Owner:RETRACTABLE TECH INC

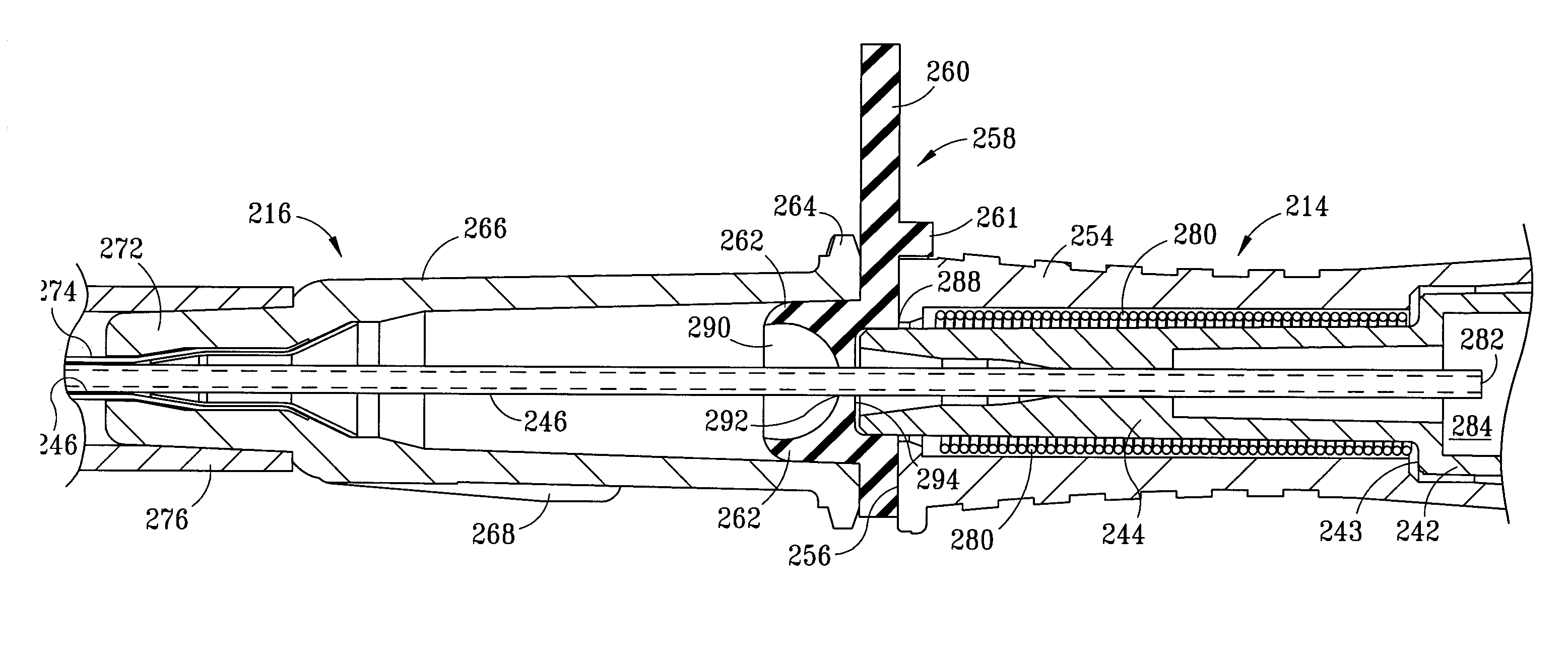

IV Catheter Introducer

ActiveUS20100168674A1Reduce the possibilityEasy to useInfusion syringesInfusion devicesCatheter hubCatheter introducer

An IV catheter introducer having an elastomeric grommet disposed between the housing and the IV catheter assembly that helps avoid unintentional separation of IV catheter assembly from the housing during shipping and handling prior to use, that acts as a needle guide, that helps align the housing and IV catheter assembly coaxially, that indicates that top side of the catheter introducer, that provides proper rotational alignment between the grommet and housing, that wipes blood off the needle during withdrawal of the needle from the catheter assembly and grommet, that impedes blood flow out of the catheter hub after needle withdrawal, and that assists the user in separating the housing from the IV catheter assembly following insertion of the catheter and withdrawal of the needle.

Owner:RETRACTABLE TECH INC

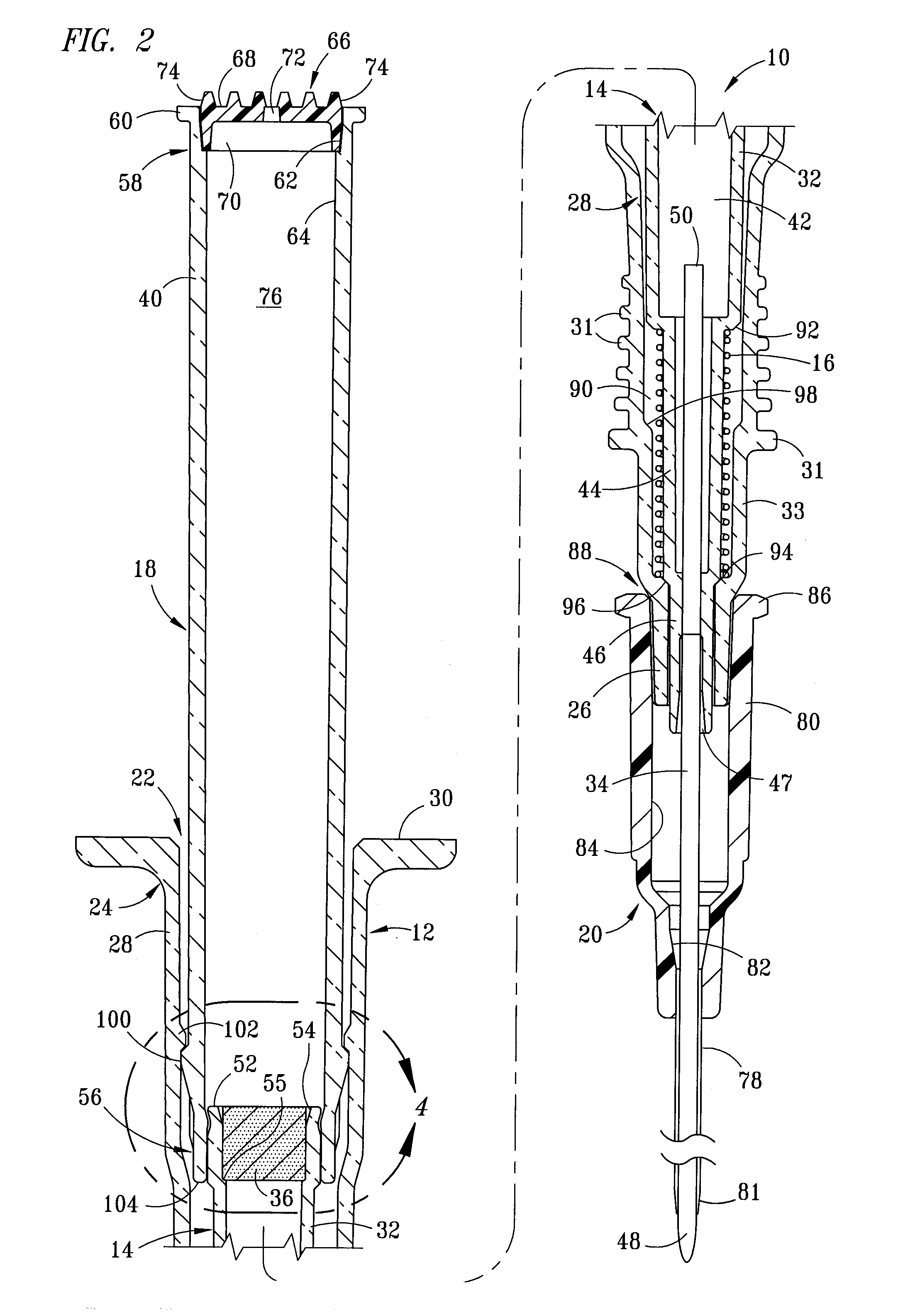

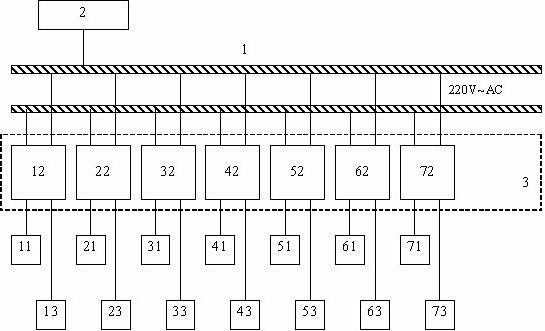

Method and system for intelligent centralized monitoring and management of photovoltaic power station

InactiveCN103812217ADisplay power generationShow Power Station PRPhotovoltaic monitoringCircuit arrangementsData transformationTransformer

The invention discloses a method and a system for intelligent centralized monitoring and management of a photovoltaic power station. The method includes the steps: acquiring and analyzing meteorological data of the photovoltaic power station; acquiring signals of an inverter, a circuit breaker and a transformer of the photovoltaic power station and receiving remote control signals to control related modules; acquiring voltage, current and component temperature data of each sub-module of the photovoltaic power station; converting the data into proper protocols, transmitting the protocols to a network switch through a network and finally transmitting the protocols to a monitoring computer and a server; displaying the data. Operation, maintenance and management of the distributed power station are realized by the centralized monitoring and management method, the data of the photovoltaic power station are deeply analyzed, the problem of shortage of data statistics of the photovoltaic power station is solved, and the operation and maintenance management mode of the photovoltaic power station is optimized.

Owner:CHINA MERCHANTS NEW ENERGY SHENZHEN

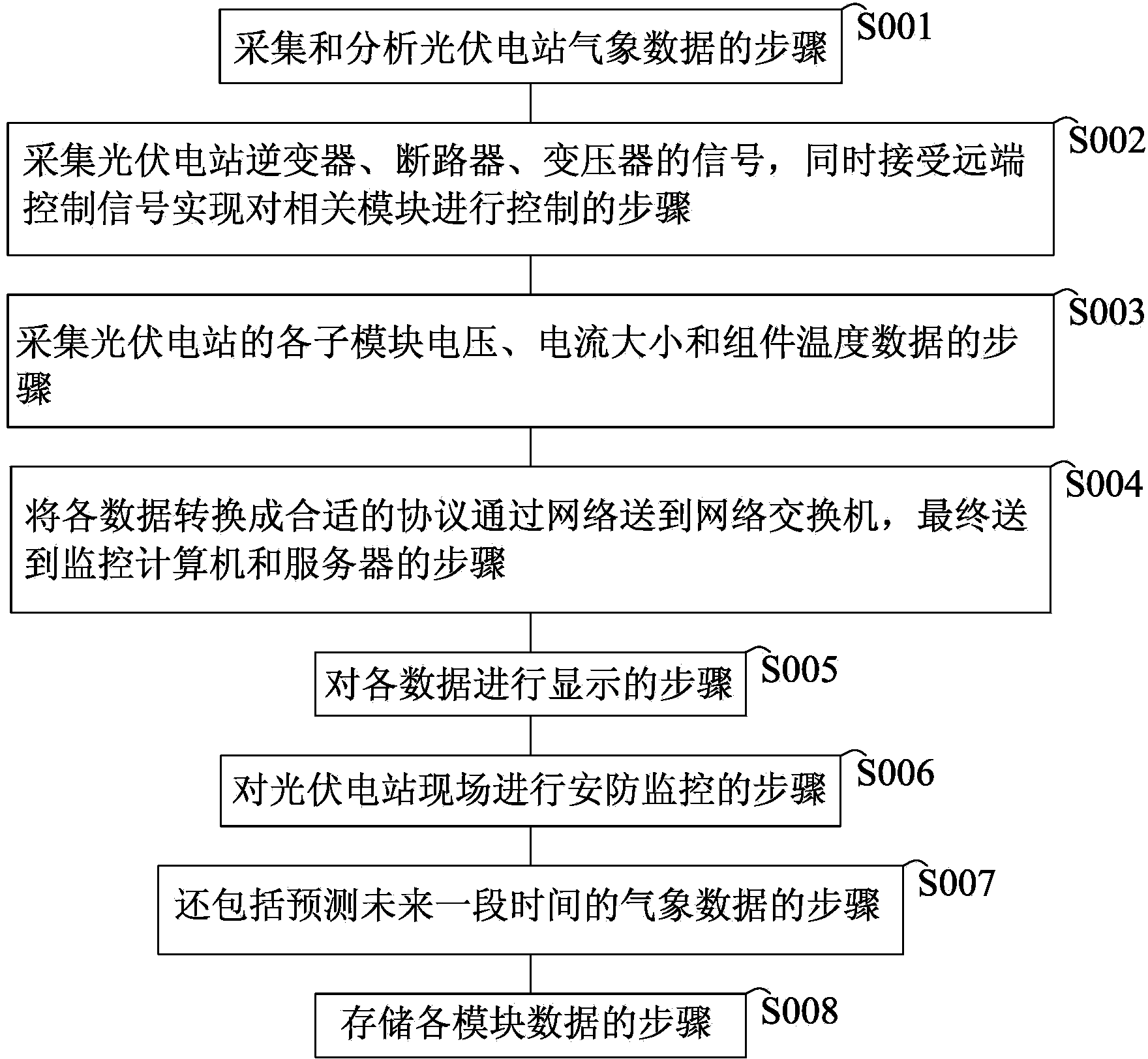

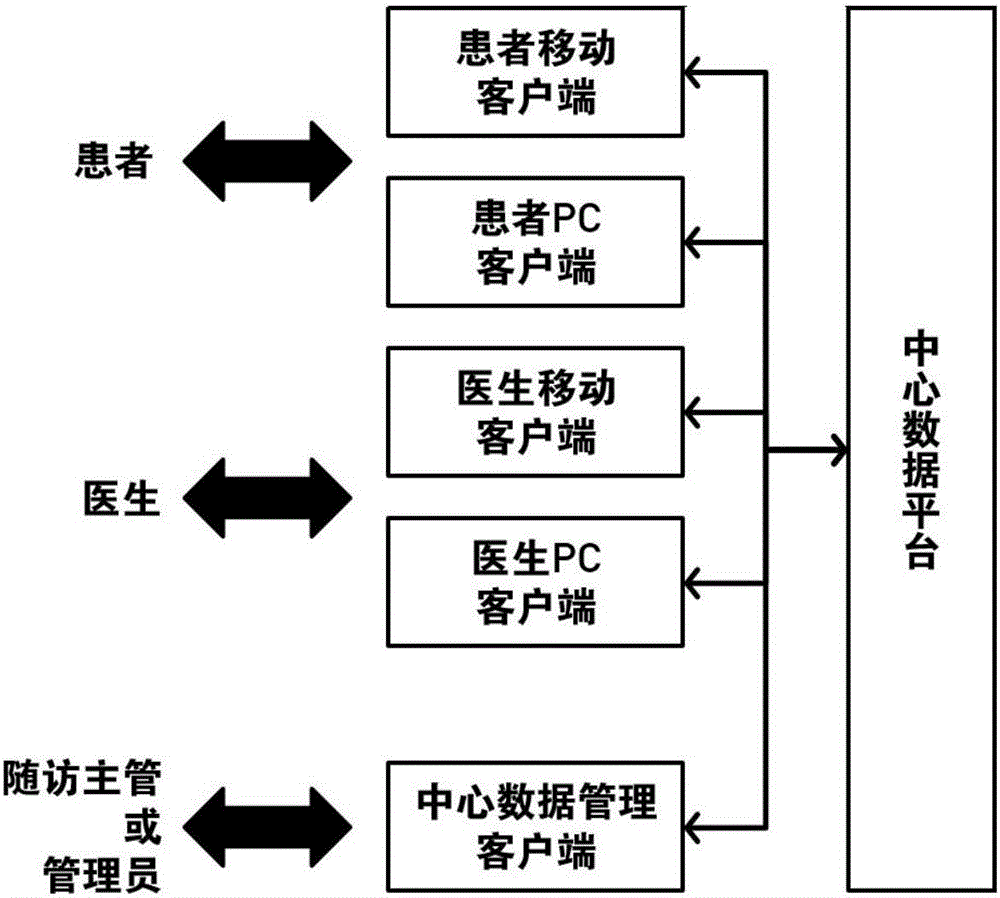

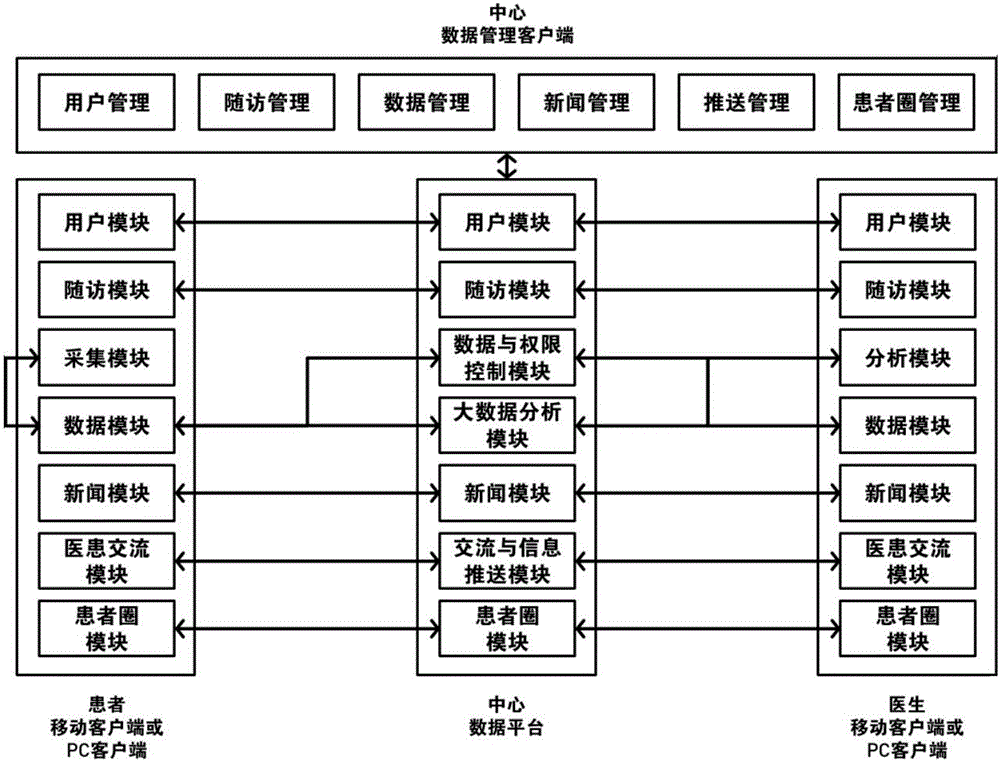

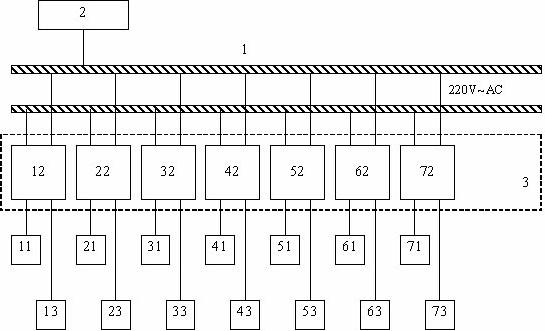

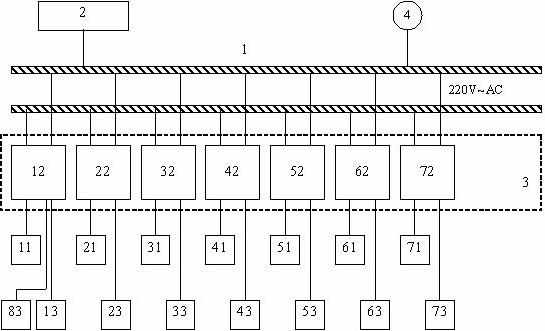

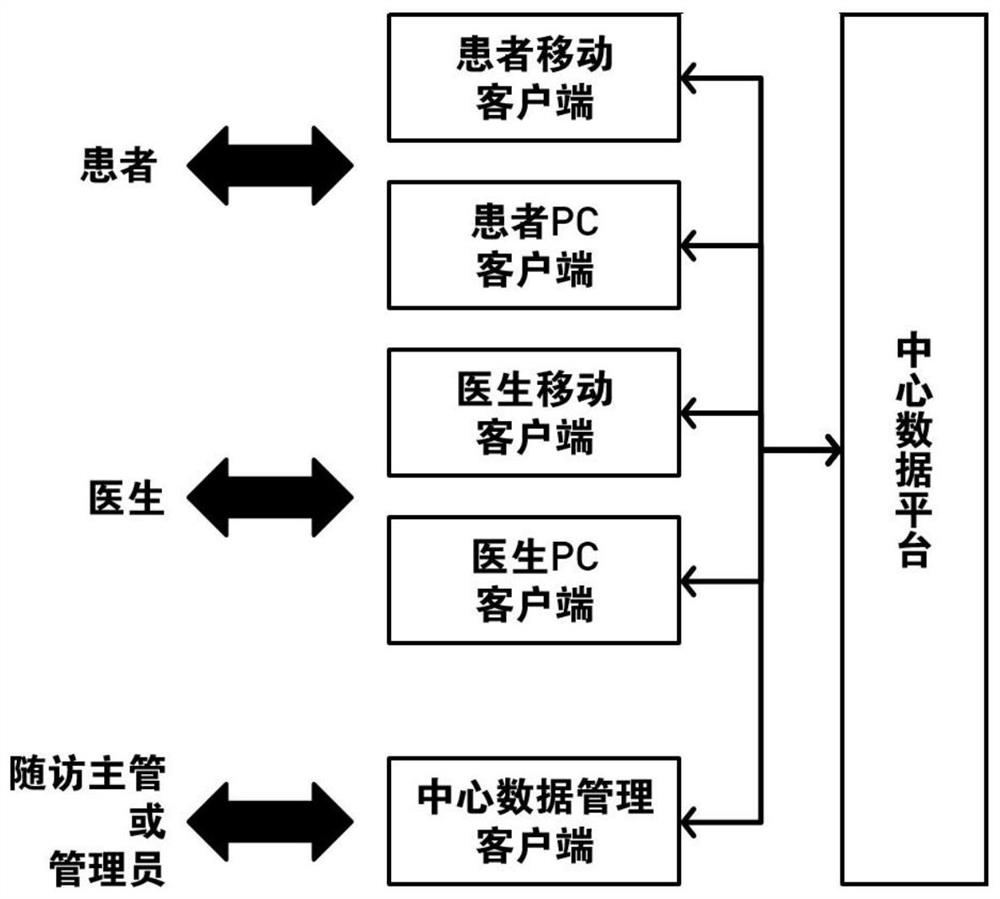

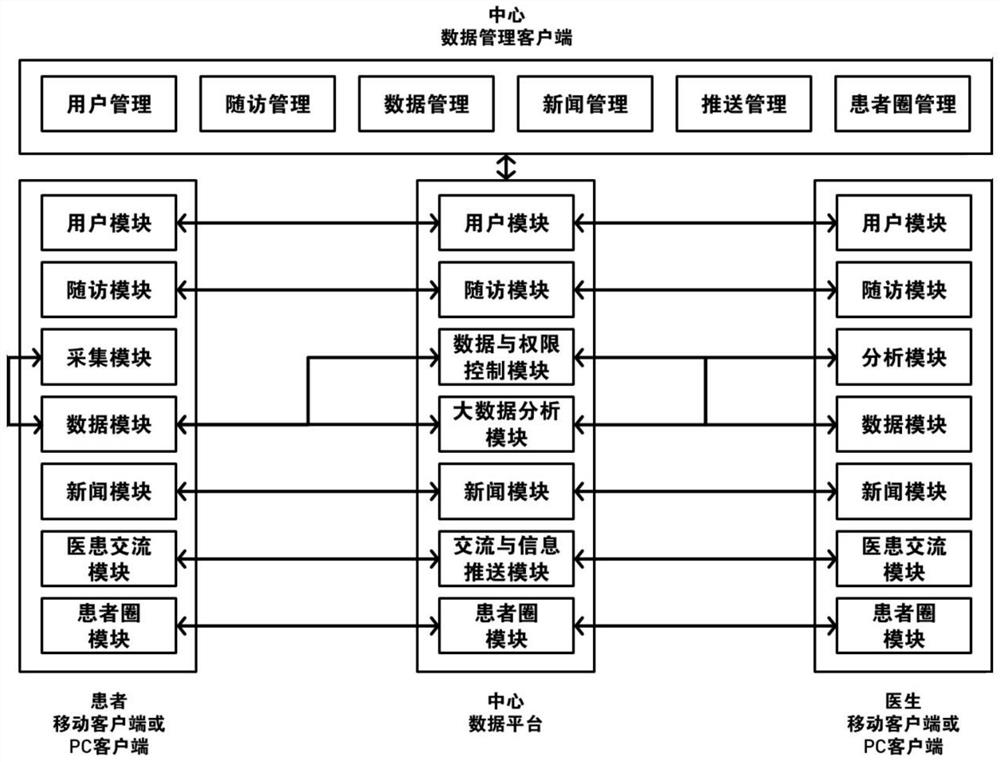

Intelligent cardiovascular disease follow-up system based on network

ActiveCN106453619AImprove efficiencyImprove accuracyData processing applicationsDatabase distribution/replicationData platformNetwork connection

The invention relates to an intelligent cardiovascular disease follow-up system based on a network. The intelligent cardiovascular disease follow-up system is characterized by comprising a patient client side, a doctor client side, a centre data management client side and a centre data platform; the patient client side and the doctor client side are connected together with the centre data platform through the network; the follow-up relationship between the patient client side and the doctor client side is established through the centre data platform; furthermore, a follow-up function is implemented; and the centre data management client side and the centre data platform are connected, so that a follow-up management function is realized. By means of the intelligent cardiovascular disease follow-up system disclosed by the invention, the patient client side and the doctor client side are connected together with the centre data platform through the network; therefore, the follow-up relationship can be established rapidly; functions, such as rapid and automatic input of all kinds of patient data, targeted transmission of the patient data between a patient and a doctor, which the patient belongs to, and generation of an automatic message template replied to the patient by the doctor, can be realized; therefore, the follow-up efficiency and the accuracy are increased; the follow-up cost is reduced; and the follow-up application scene is enlarged.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

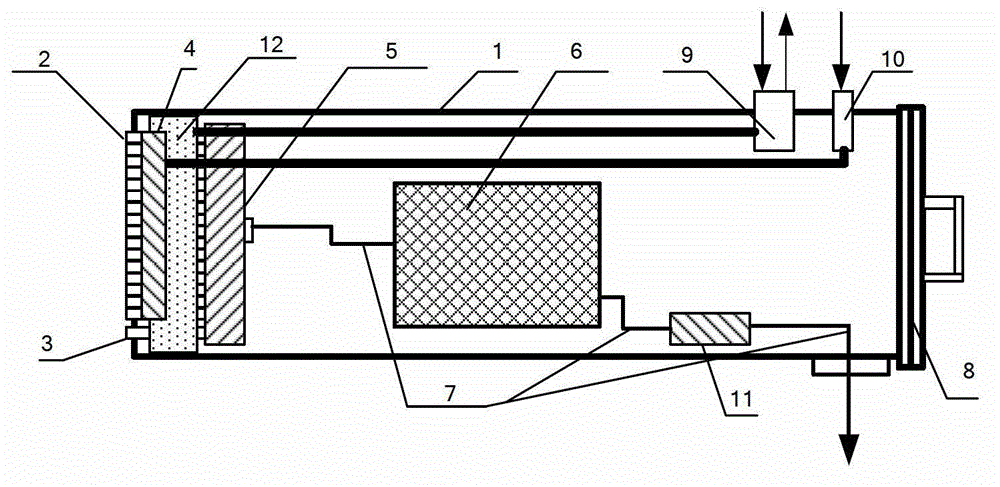

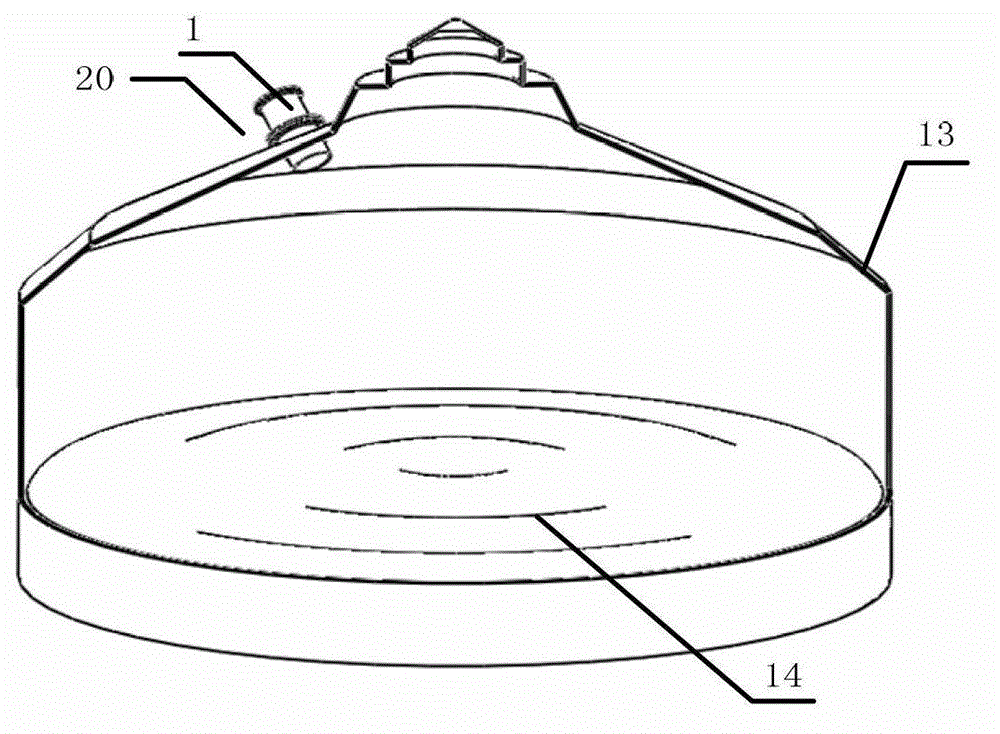

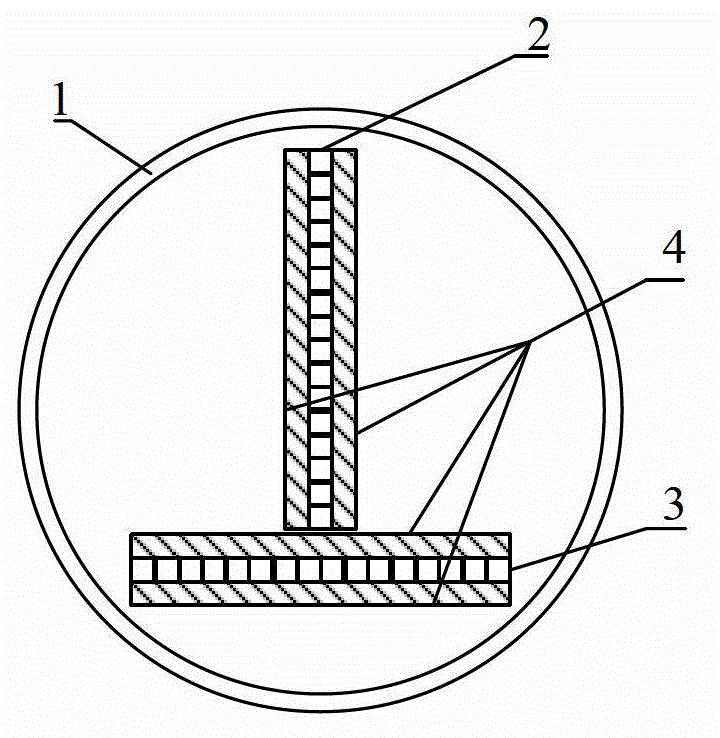

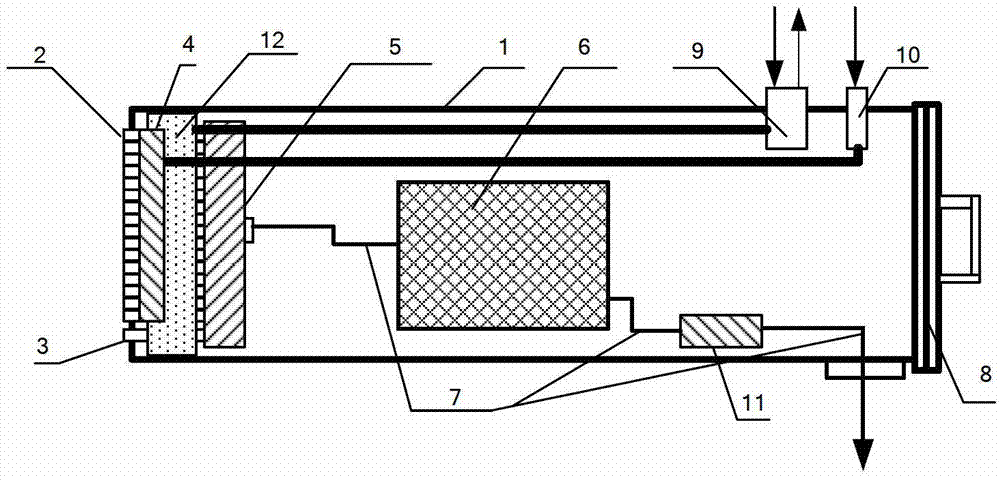

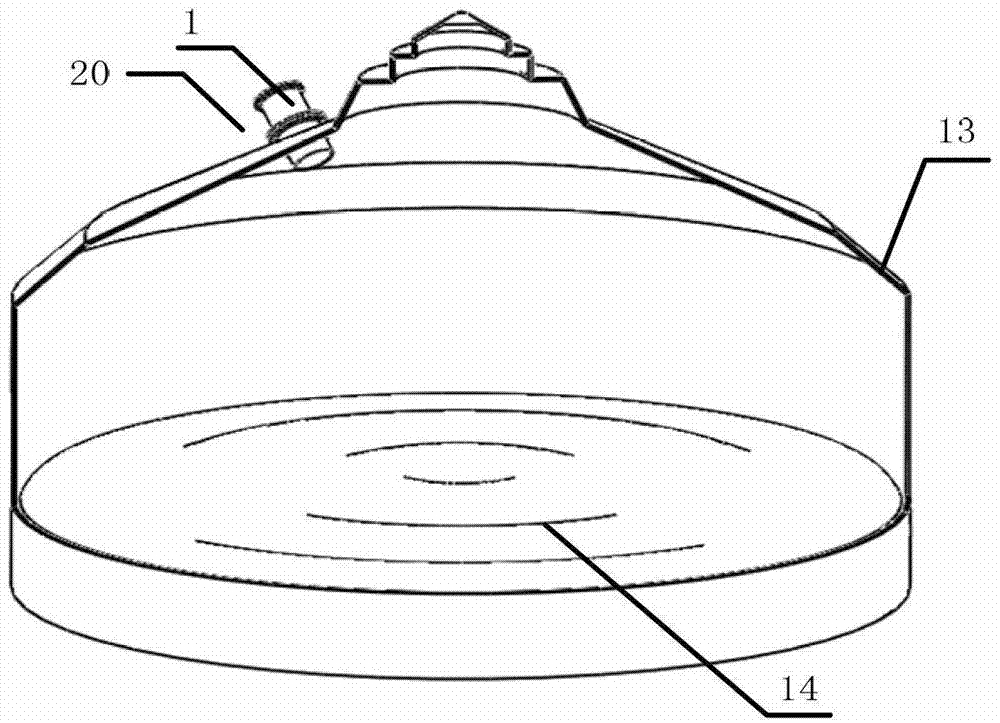

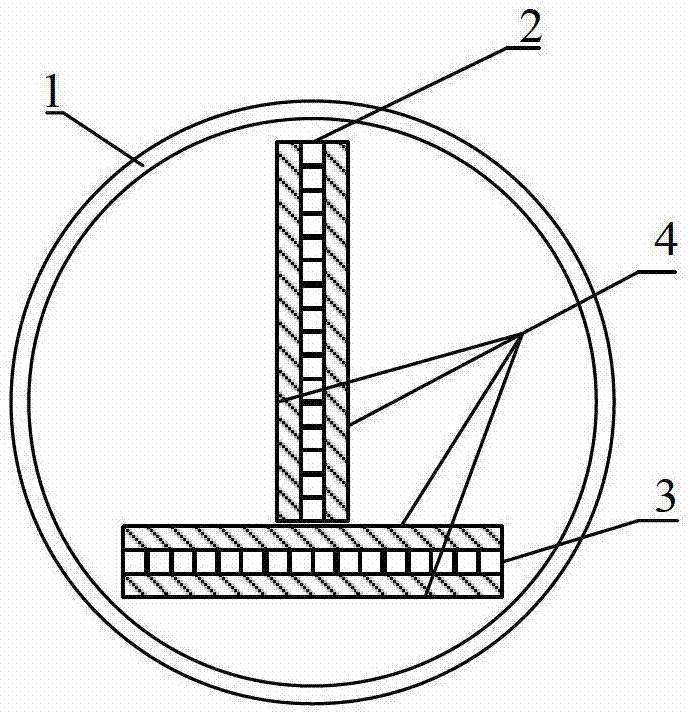

Device for measuring material surface by using blast furnace based on multiple input multiple output (MIMO) radar

InactiveCN102912054AHigh resolutionHigh precisionChecking devicesHigh resolution imagingRadar imaging

The invention relates to a device for measuring a material surface by using a blast furnace based on an MIMO radar. The device is a set of system composed of an MIMO radar, antenna arrays, an antenna protection casing, a cooling blowing unit and the like. Three-dimensional information of a whole bacterial surface in the blast furnace is obtained by using sparse array high resolution characteristics of the MIMO radar and a near field high resolution imaging algorithm, costs of electronic control scanning array imaging radars are decreased greatly simultaneously, and on-line dynamic monitoring capacity of three-dimensional material surfaces under bad conditions of industrial sites is provided by a dust and high temperature resistance technology.

Owner:BEIHANG UNIV

Machining method of complex casting with non-circular cross section

InactiveCN103831579AReduce scrap rateQuantitative Inspection RequirementsThree levelMachined surface

The invention discloses a machining method of a complex casting with a non-circular cross section. In the casting machining surface, through setting and machining of process margin and removal of the machining margin, the size and shape relationship between complex surfaces is established; through the measurement of wall thickness, a machined outer surface is used as a standard, layout inspection is conducted on the casting, and whether the size accuracy of a non-machined surface of the casting meets the requirements of subsequent machining or not is judged; a special tool is used for reducing heat treatment deformation of the casting; a rough machining standard of the casting is determined according to heat treatment detection data, and subsequent machining is conducted; analysis is conducted on the deformation trend and the deformation amount of all processes for casting manufacturing, anti-deformation design is conducted on the casting in advance, and the pass percent of the sizes of castings is improved. The machining method belongs to the field of casting, is high in universality and suitable for complex castings manufactured through various materials and various methods; the casting accuracy of the machining method is improved by one to three levels on the basis of an original casting method, the machining finished product rate is increased, energy consumption and the part manufacturing cost are lowered, and the manufacturing cycle is shortened.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

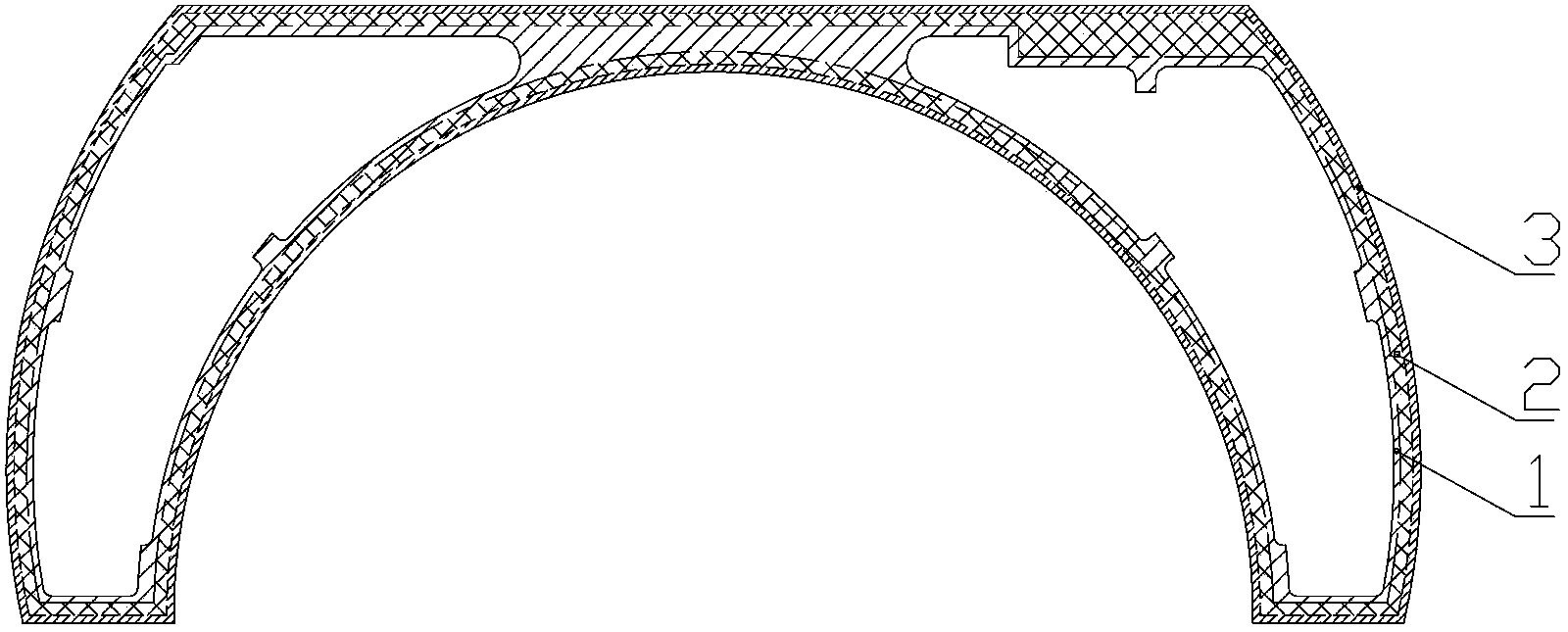

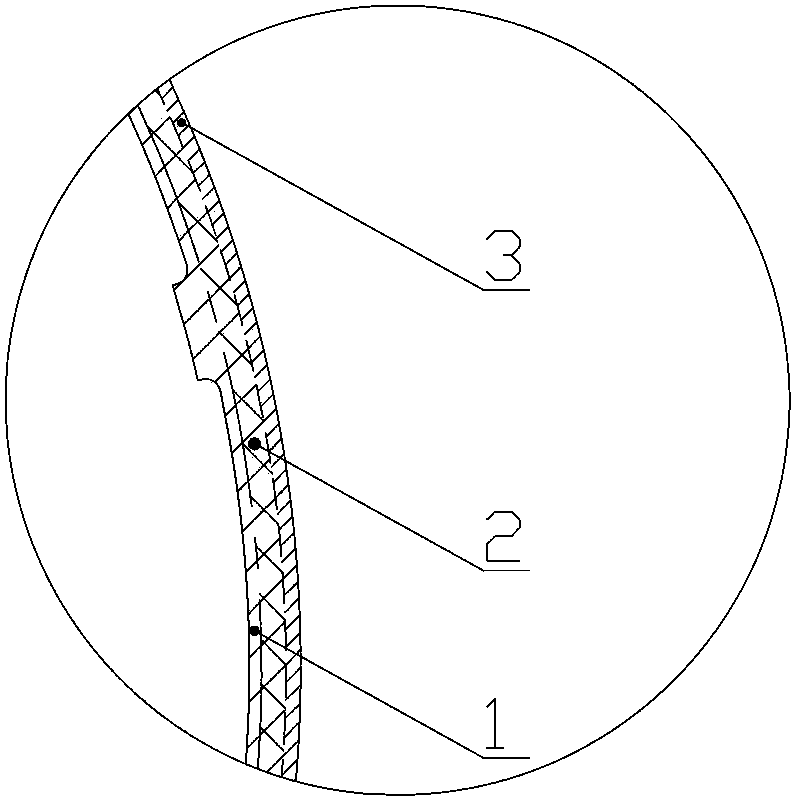

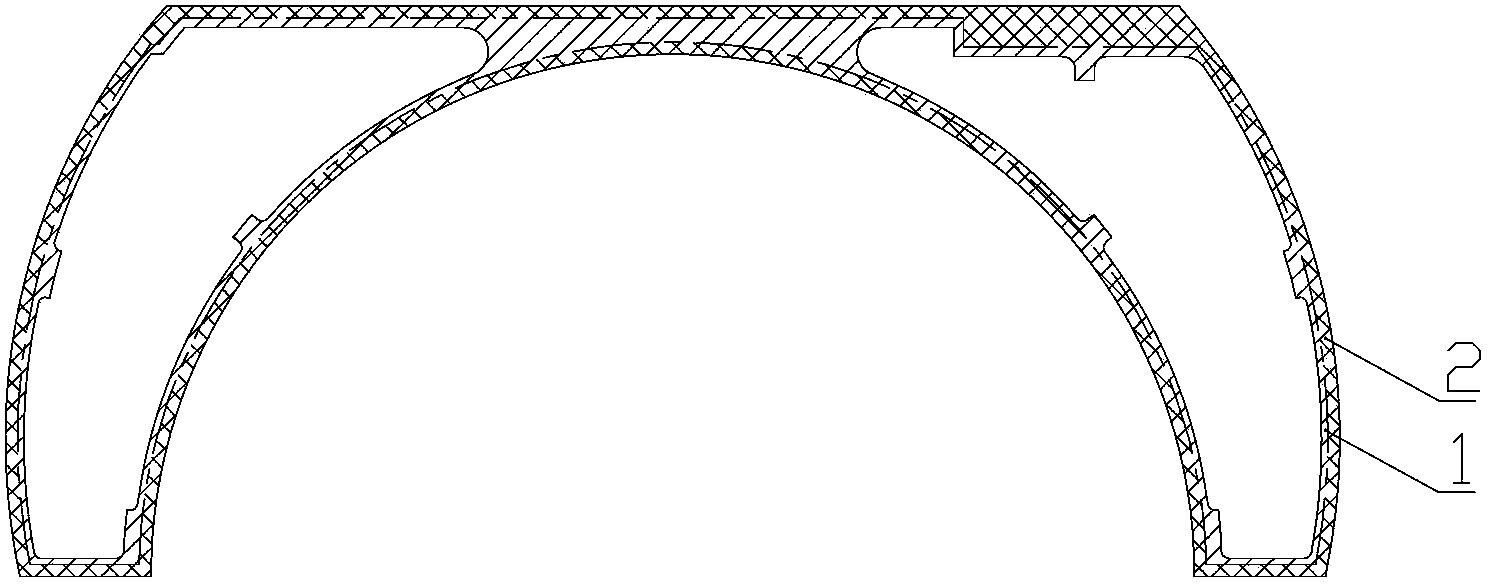

Mold pressing production process for SMC (sheet molding compound) insulators

The invention discloses a mold pressing production process for SMC (sheet molding compound) insulator, and relates to a production process for insulators. The process includes using different matrix resin, packing and auxiliaries; manufacturing an SMC sheet with high insulating performance and flame retardant property by processes of mixing, paste scraping and doffing, impregnating and thickening; and then carrying out mold pressing and solidifying for the SMC sheet and an insulator core to obtain an SMC insulator product. The insulators produced by the method have the advantages of high product strength, good electric insulating performance, convenience in construction, excellent flame retardant property and ageing resistance and low cost.

Owner:SHANDONG JINGUANG COMPOSITE MATERIALS

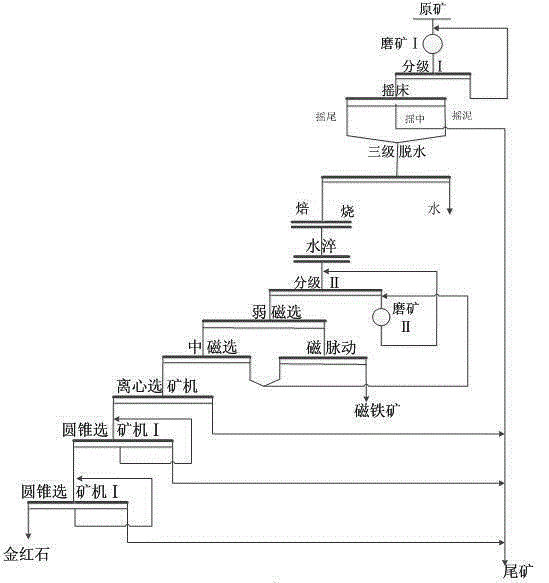

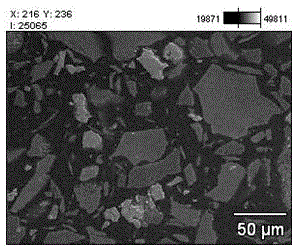

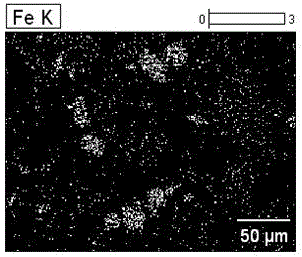

Processing method for fine-grained disseminated rutile ore difficult to separate

ActiveCN105057086AIncrease added valueReduce follow-up costsMagnetic separationWet separationFluidized bedMagnetite

The invention relates to a processing method for fine-grained disseminated rutile ore difficult to separate, and belongs to the technical field of mineral processing. The method is characterized in that under the operating conditions of primary grinding, a shaking table is adopted for primary separation so as to remove coarse-grained disseminated gangue, so that subsequent operating cost is reduced. Fluidized bed tube type calcination is adopted for reducing hematite into magnetite, so that nature difference between the hematite and the rutile is enhanced, separation between the hematite and the rutile is promoted, and influences on the rutile recovery effect from iron are reduced. The magnetite is recovered after calcination, so that the additional value of rutile ore utilization and processing is increased; ideal separation indexes of the fine-grained rutile obtained by monomer separation are achieved through level flow separation devices, namely, suspension vibration cone separators.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

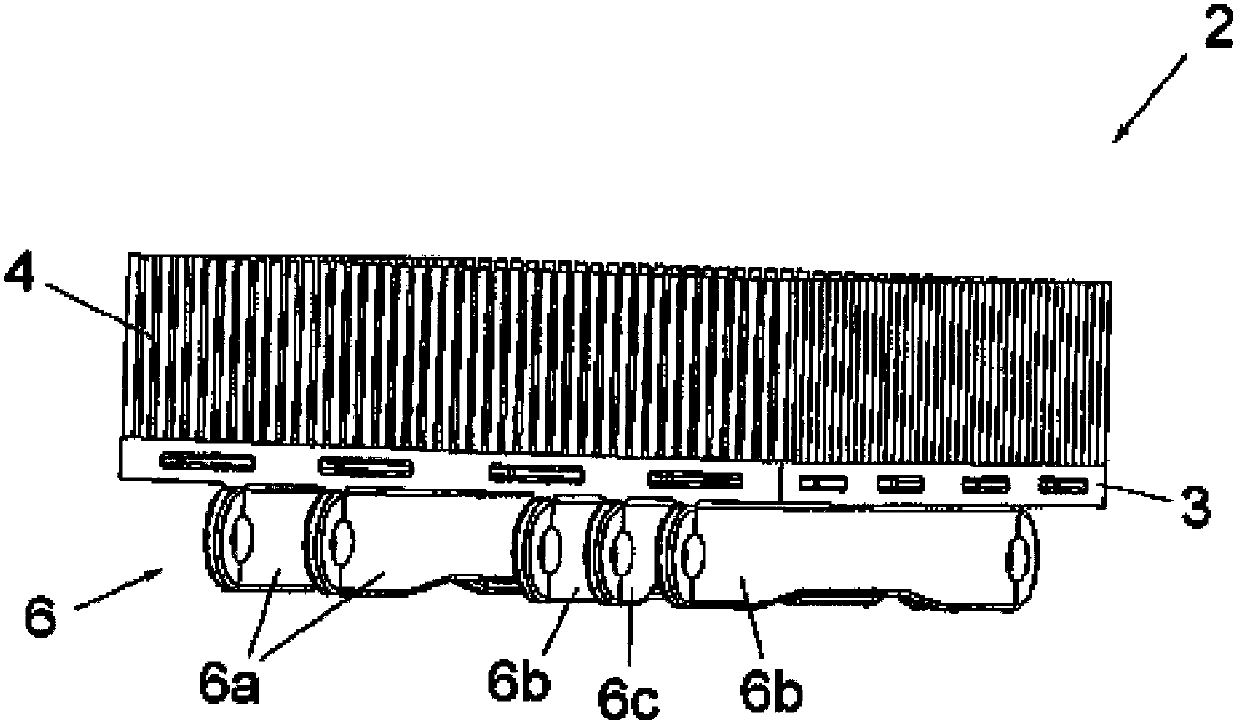

Plastic, modular and self-engaging bristle brush

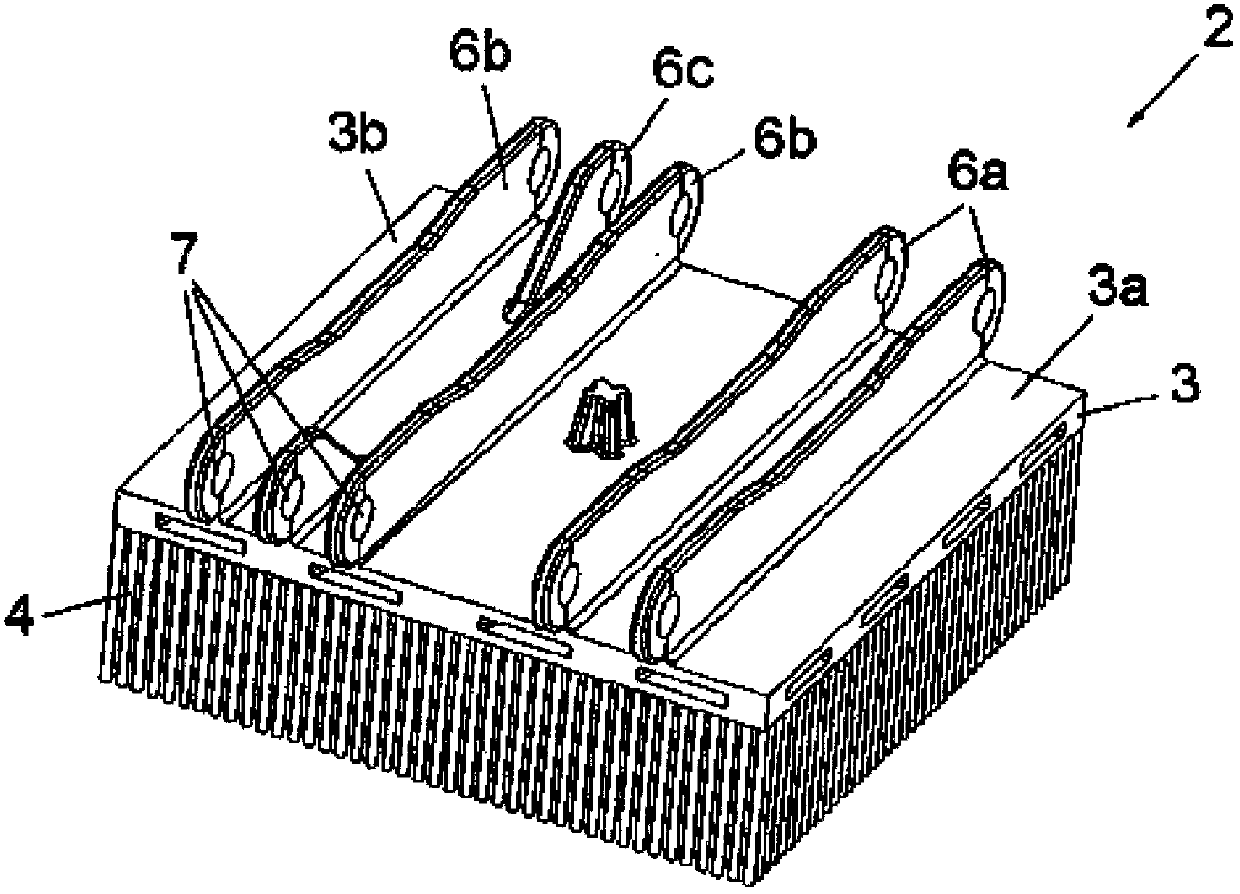

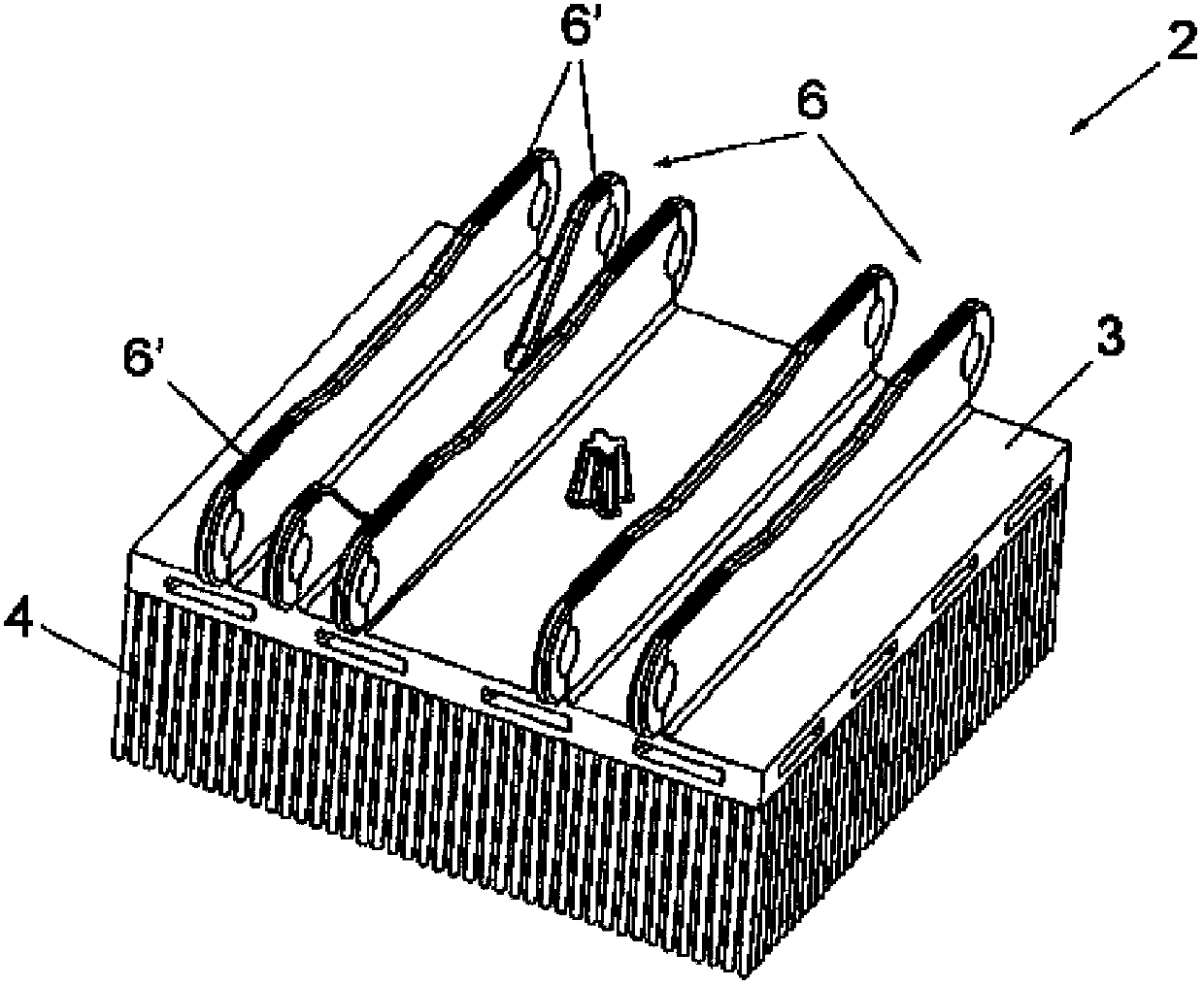

The present invention relates to a plastic, modular and self-engaging bristle brush (2), comprising a set of runners (6) including a pair of opposing guiding and self-centering ends projecting from the perimeter of the brush (2), said runners (6) being distributed such that the ends of runners (6) of contiguous brushes (2) can be fitted together by overlapping one another, and in that said runners (6) include at their guiding and self-centering ends articulated attachment means (7) for the articulated attachment of contiguous brushes (2) for self-engagement, turning the set of multiple brushes (2) into a cutting mat (1) which in turn forms an endless conveyor belt, said articulated attachment means in turn being provided with articulating drive shafts (8) that can engage drive elements (9) housed in multiple positions of a support table (5).

Owner:MFR Y TRANSFORMADOS AB

House intelligent control device based on European installation bus

ActiveCN102436220ASimplify the indoor environmentReduce wire consumptionProgramme total factory controlEmbedded systemControl mode

The invention relates to the field of electric digital data processing equipment for interconnection or transmission of information or other signals among memories, input / output equipment or central processors, in particular to a house intelligent control device based on a European installation bus. The house intelligent control device based on the European installation bus comprises an illuminating lamp (11), a curtain (21), a common antenna control module (72) and the like, and is characterized in that the device additionally comprises the European installation bus (1), a bus control panel (2), a common antenna distribution sensor (73) and the like. The house intelligent control device based on the European installation bus has the advantages of high real-time performance, high automation level, flexible control method, wide application scope and low cost.

Owner:SHANGHAI BAOYE GRP CORP

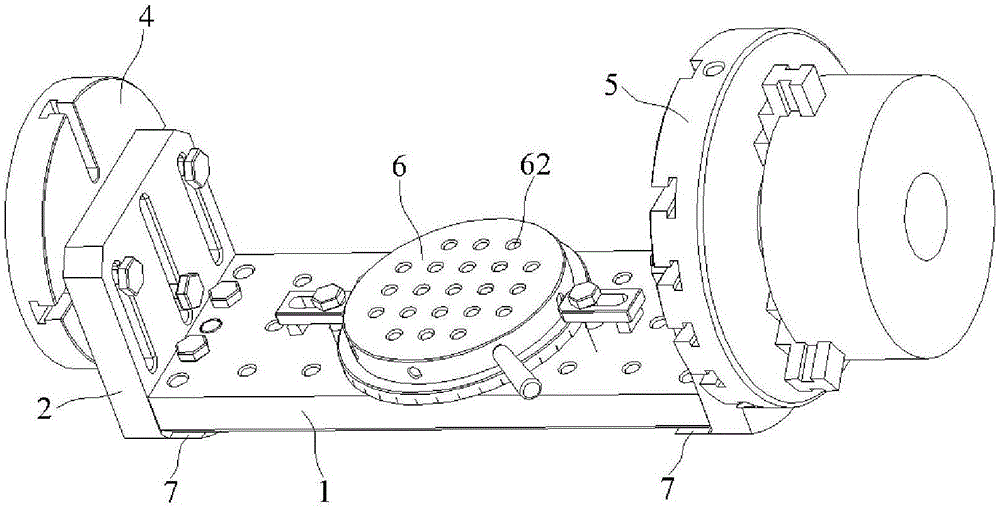

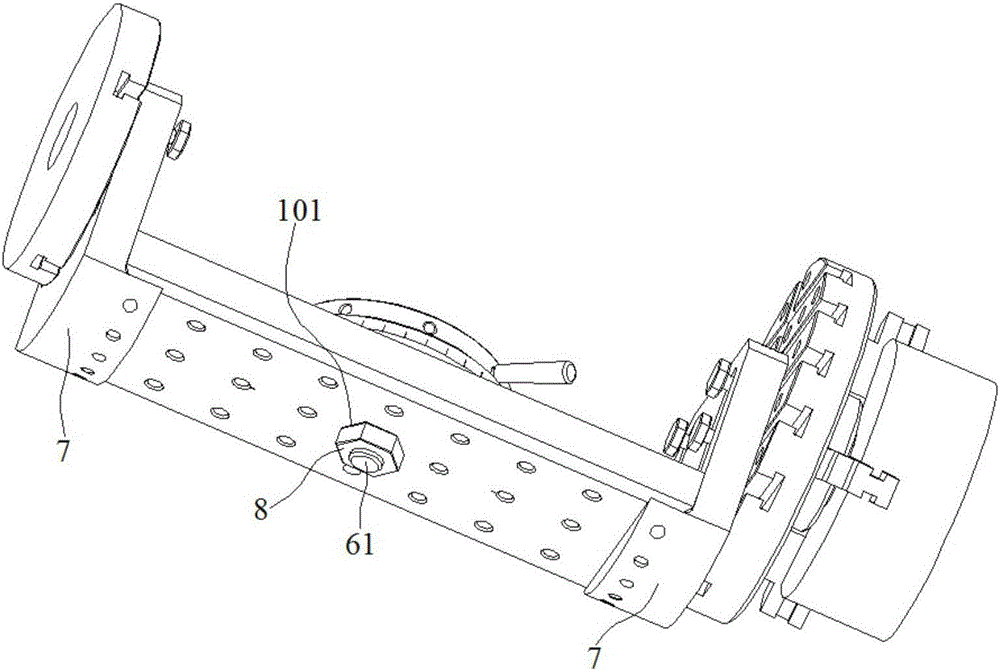

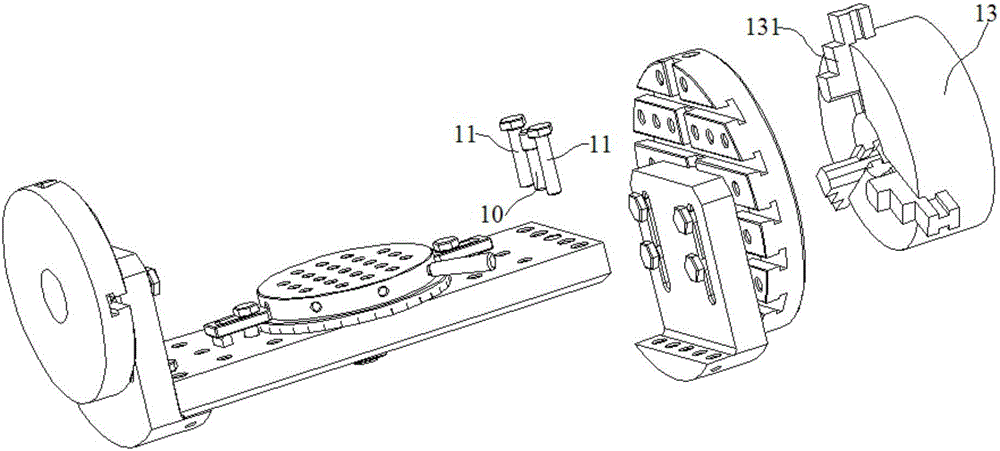

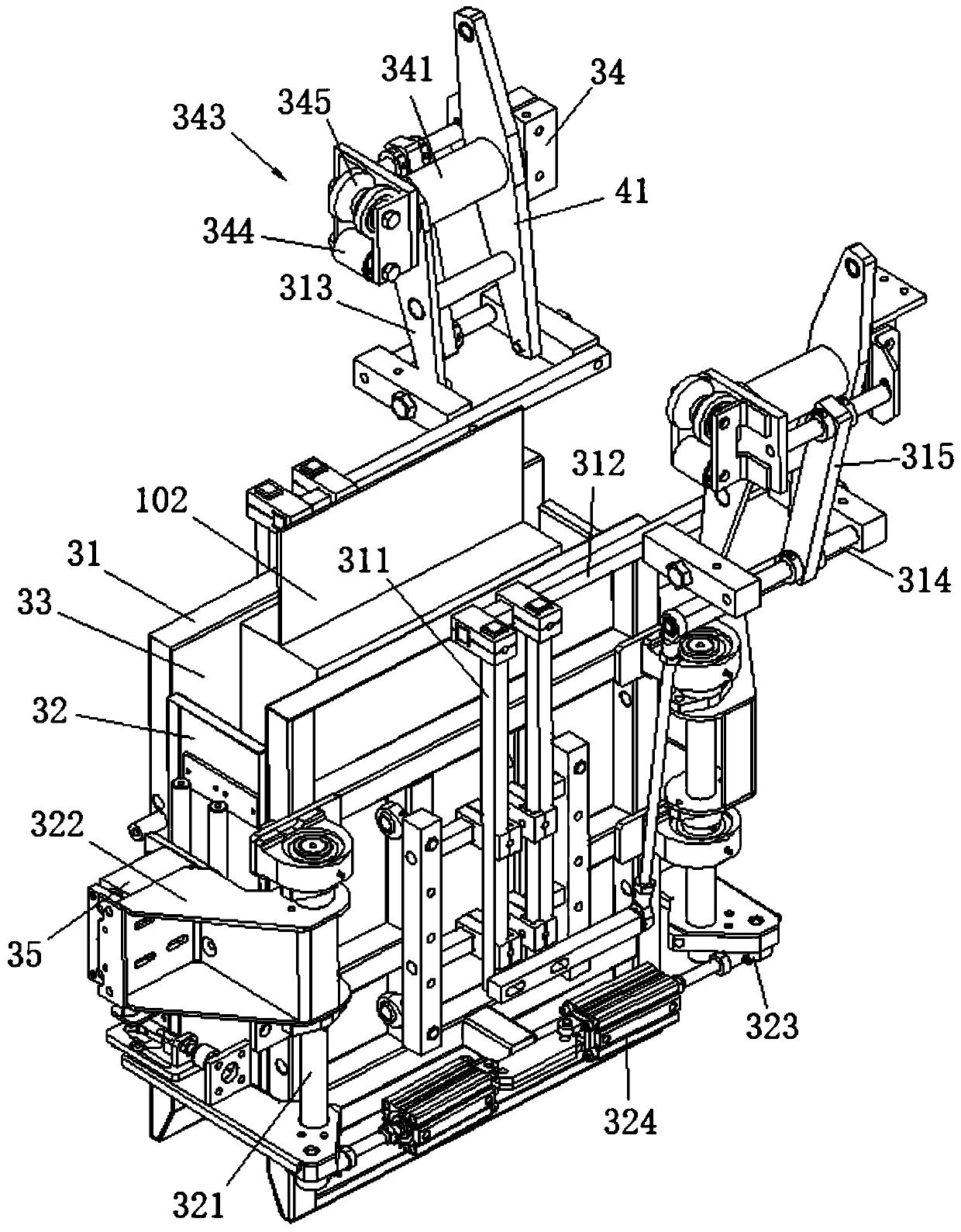

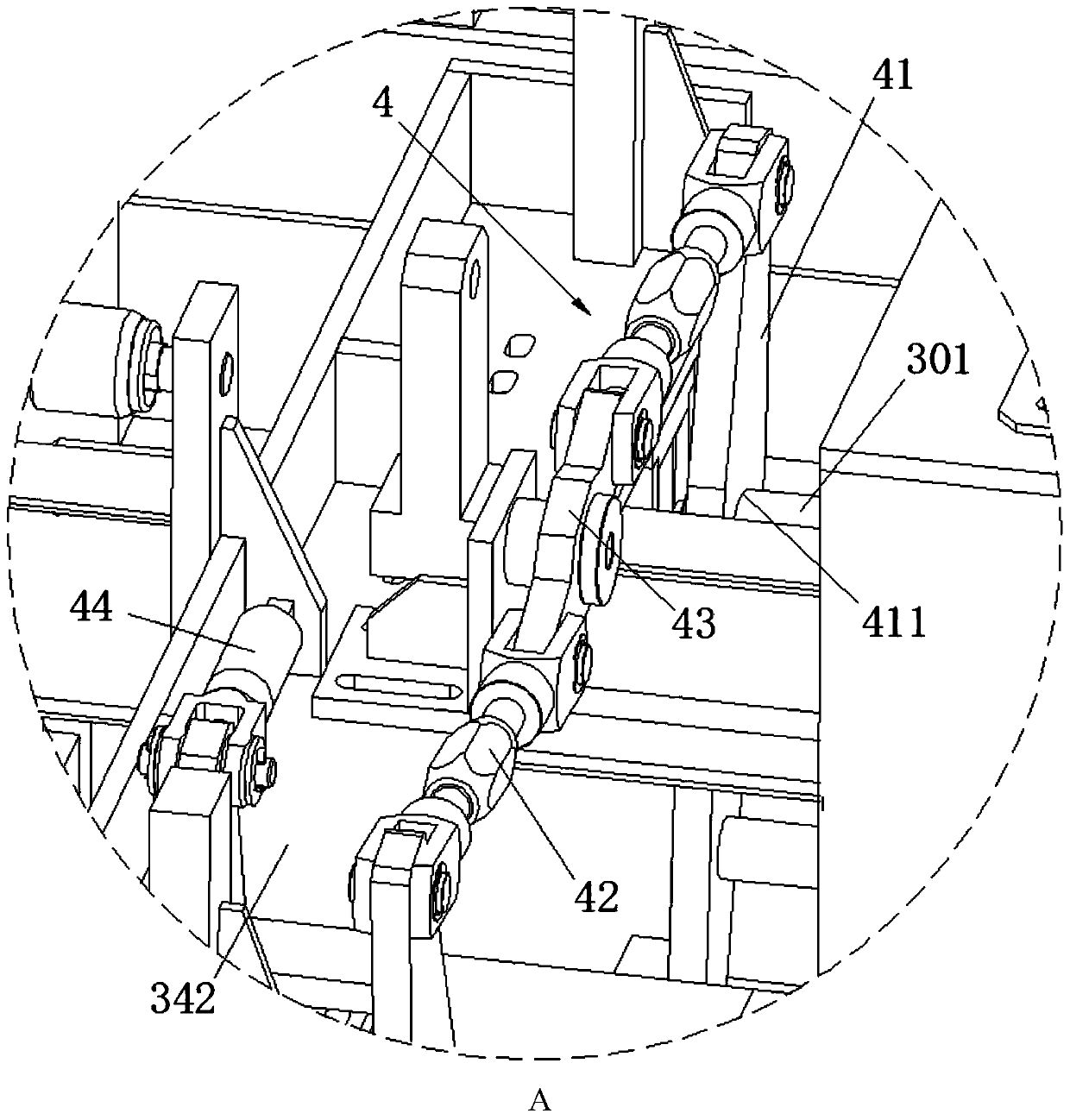

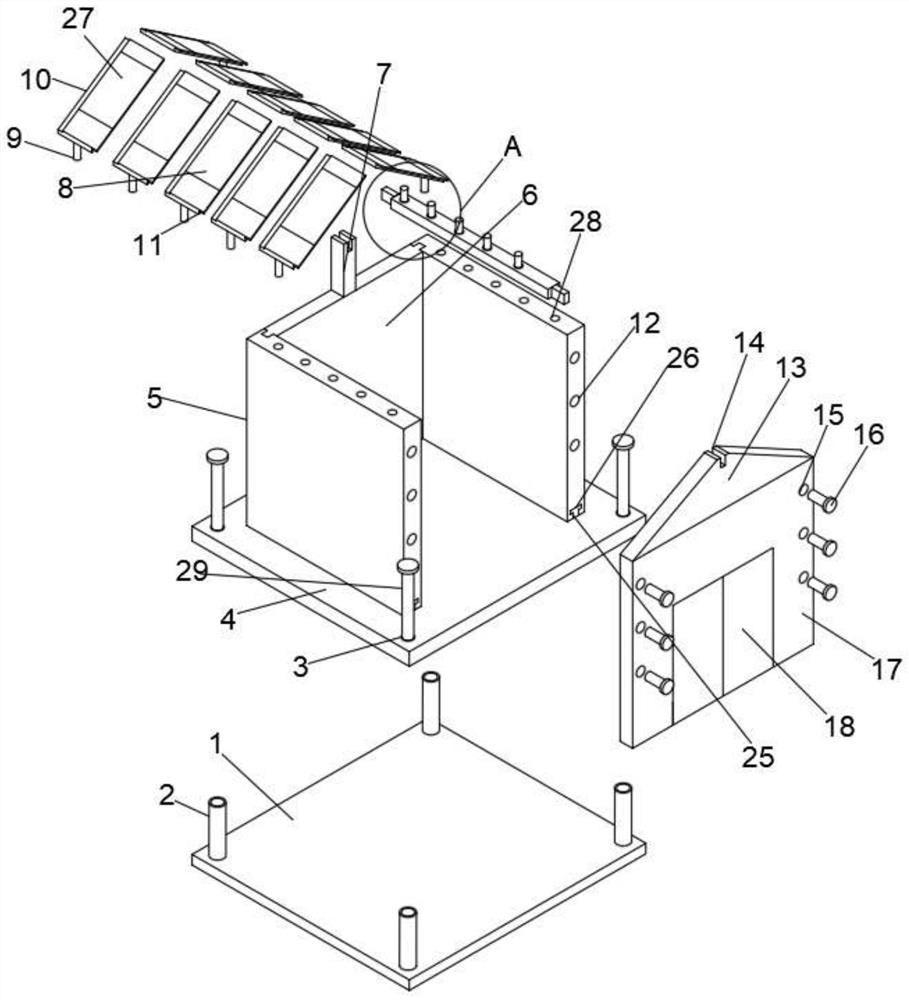

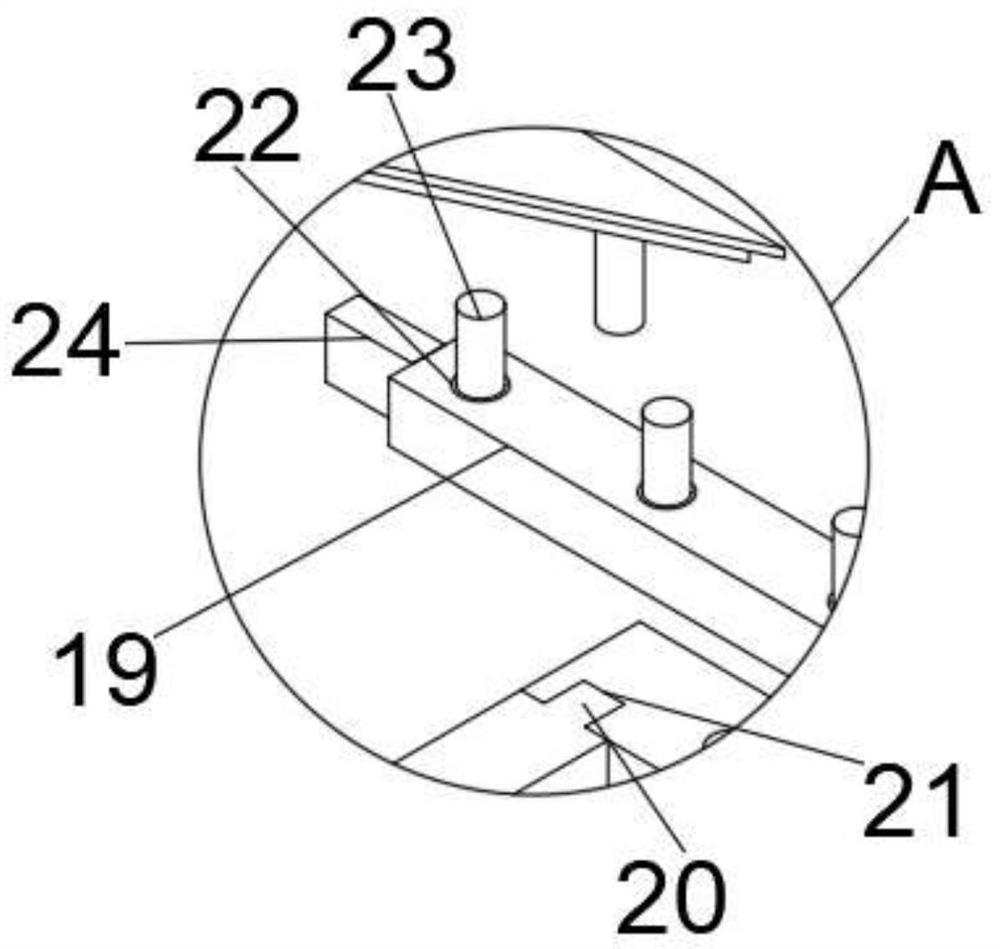

Workpiece fixture for numerically-controlled machine tool

InactiveCN106392702AExpand the scope of processingFlexible and changeable clamping schemePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a workpiece fixture for a numerically-controlled machine tool. A center bolt is fixed to the bottom of a flange plate of the workpiece fixture. A center through hole is formed in a center area of a base plate. The center bolt on the flange plate is embedded into the center through hole of the base plate. A nut is located on the lower surface of the base plate and is installed at the tail end of the center bolt. A ball lock clamping mechanism is installed on the upper surface of the flange plate and further comprises a bottom plate, a base plate body, a left positioning plate, a right positioning plate, a U-shaped elastic sheet, a wedge block with a first through hole, a left to-be-machined workpiece and a right to-be-machined workpiece. The U-shaped elastic sheet is located between the left workpiece and the right workpiece. The wedge block is embedded into the U-shaped elastic sheet. The left positioning plate and the right positioning plate are each parallelly provided with at least two strip-shaped grooves. The left positioning plate is installed on the base plate body through at least two plug pins embedded into the strip-shaped grooves in the left positioning plate. According to the workpiece fixture for the numerically-controlled machine tool, a flexible and changeable clamping scheme and machining of various angles are achieved, the multiple surfaces of a product can be machined through one-time clamping, and precise positioning and fixing are also achieved.

Owner:昆山西诺巴精密模具有限公司

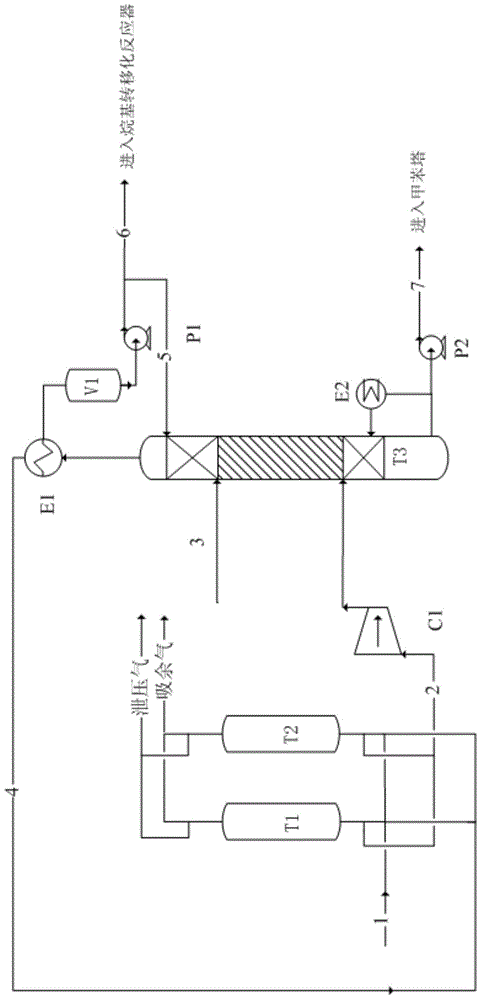

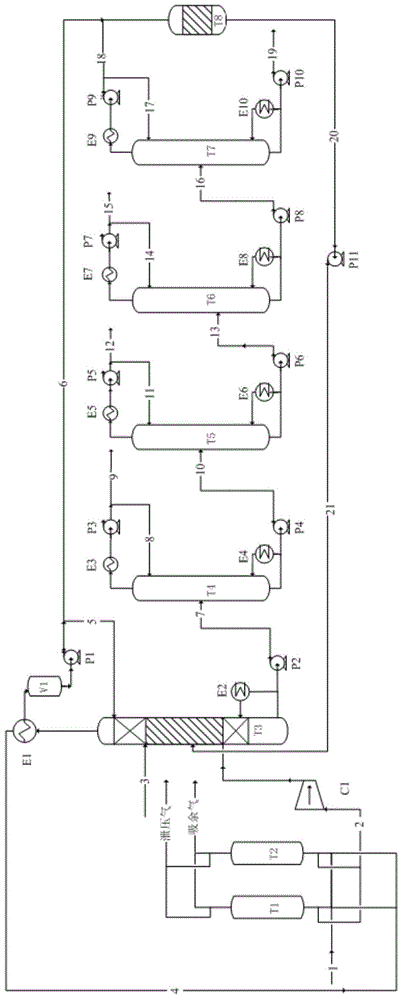

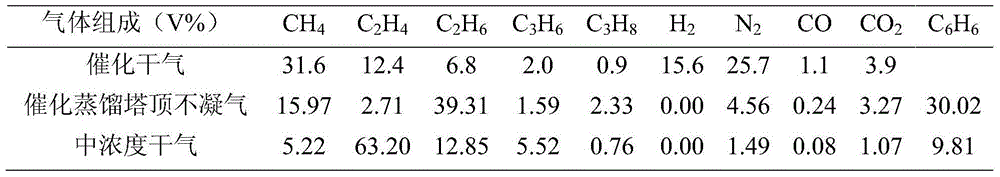

Device and method for preparing ethylbenzene from ethylene recovered from refinery dry gas by pressure swing adsorption

ActiveCN104860790ASmall sizeReduce follow-up costsHydrocarbonsHydrocarbon preparationDesorptionGas phase

The invention relates to a device and a method for preparing ethylbenzene from ethylene recovered from refinery dry gas by pressure swing adsorption. The refinery dry gas and non-condensable gas at the top of a catalytic reaction rectification tower enter an adsorption tower loaded with an adsorbent, adsorbed residual gas is directly discharged from the device, pressure relief gas is directly discharged from the system when adsorption saturation is reached, and medium-concentration dry gas is obtained through desorption operation and enters the lower part of the catalytic reaction rectification tower after being pressurized through a compressor. Raw material benzene enters the upper part of the catalytic reaction rectification tower, the non-condensable gas at the top of the catalytic reaction rectification tower after a gas phase is condensed through a condenser part returns to the adsorption tower, a condensed liquid phase enters a benzene return tank, one part of the liquid phase is returned, the other part of the liquid phase serves as benzene feed liquid of a transalkylation reactor, and liquid obtained through an extraction pump of a tower kettle at the bottom of the catalytic reaction rectification tower enters a toluene tower for subsequent separation. The size of the alkylation reactor can be greatly reduced; benzene and a generated product are separated while a reaction is produced, so that conventional benzene tower and crude separation tower devices are reduced and the equipment investment is reduced.

Owner:TIANJIN UNIV

Black fungus liquid fermentation quick-producing high-yield melanin culture medium

InactiveCN104357484AIncrease productionEasy to separateMicroorganism based processesFermentationBiotechnologyTyrosine

The invention relates to a black fungus liquid fermentation quick-producing high-yield melanin culture medium. The formula of the culture medium comprises the following raw materials: 17.27 g / L of a yeast extract, 1.92 g / L of tyrosine, 3.84 g / L of lactose, 1 g / L of NaCl, 2 g / L of MgSO4, 0.5 mg / L of biotin, and 1 g / L of KH2PO4, wherein the pH value is 6. According to the invention, the melanin is produced by black fungus liquid fermentation; with optimization of the fermentation conditions, the melanin production by fermentation can be ahead of time, and the yield of melanin can be increased. Under the optimized conditions, the yield of melanin can be up to 2.97 g / L, which is 2.14 times more than that of the existing culture medium; melanin can be produced on the third day during the culture process. The formula of the culture medium provided by the invention aims to shorten the melanin production time; the mycelial growth amount is less, and the melanin yield is high; the culture medium is more favorable to separate out and extract melanin, so as to reduce the follow-up working cost.

Owner:FUJIAN AGRI & FORESTRY UNIV

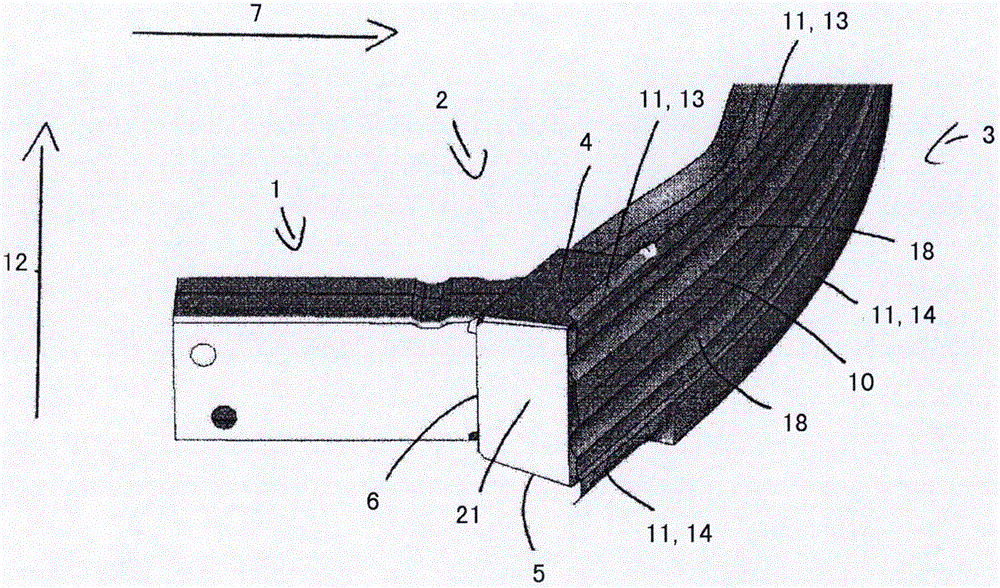

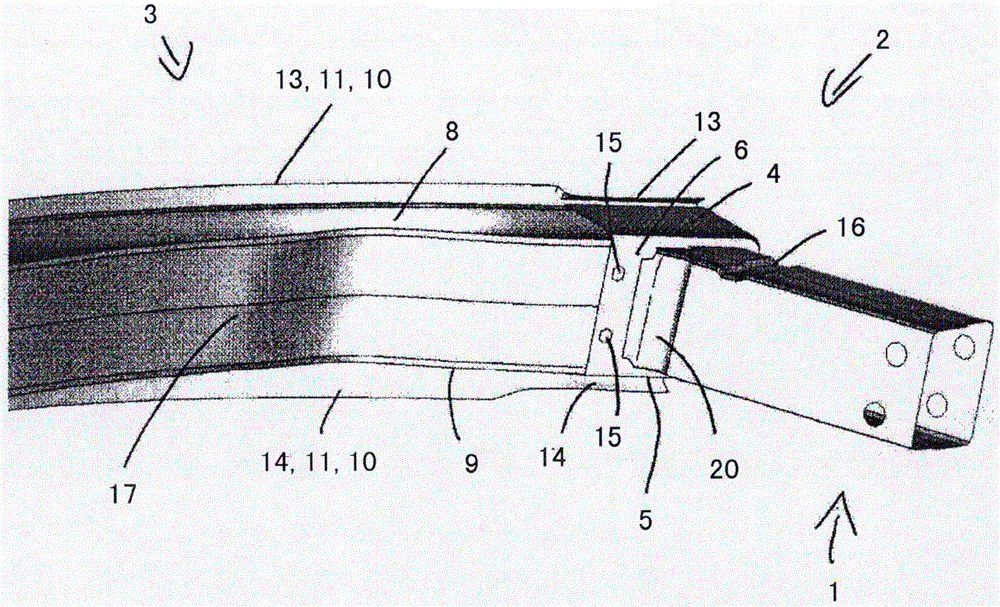

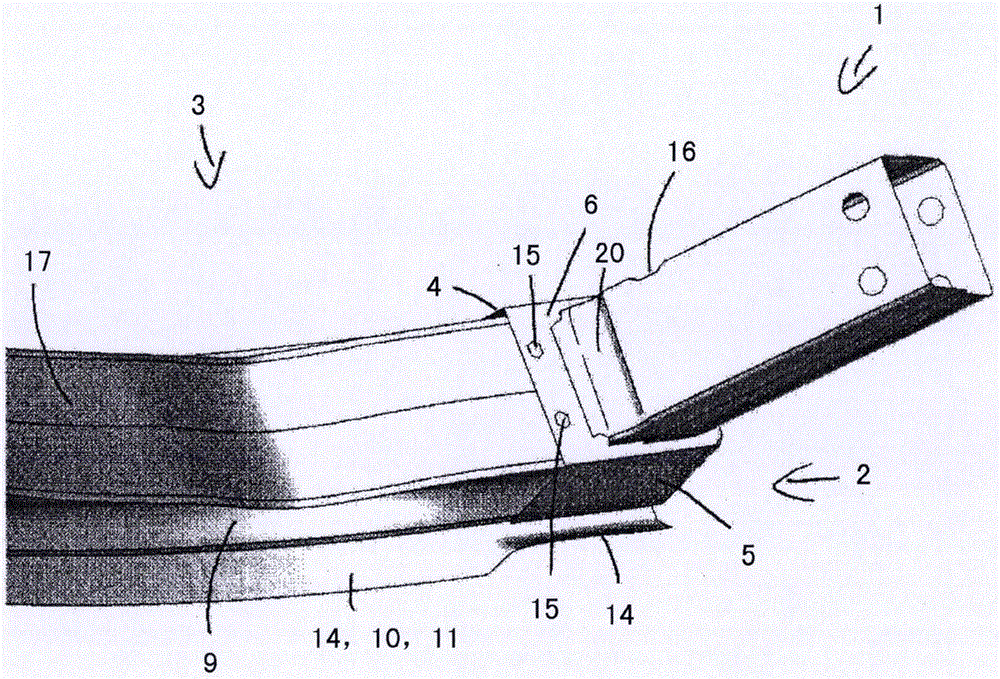

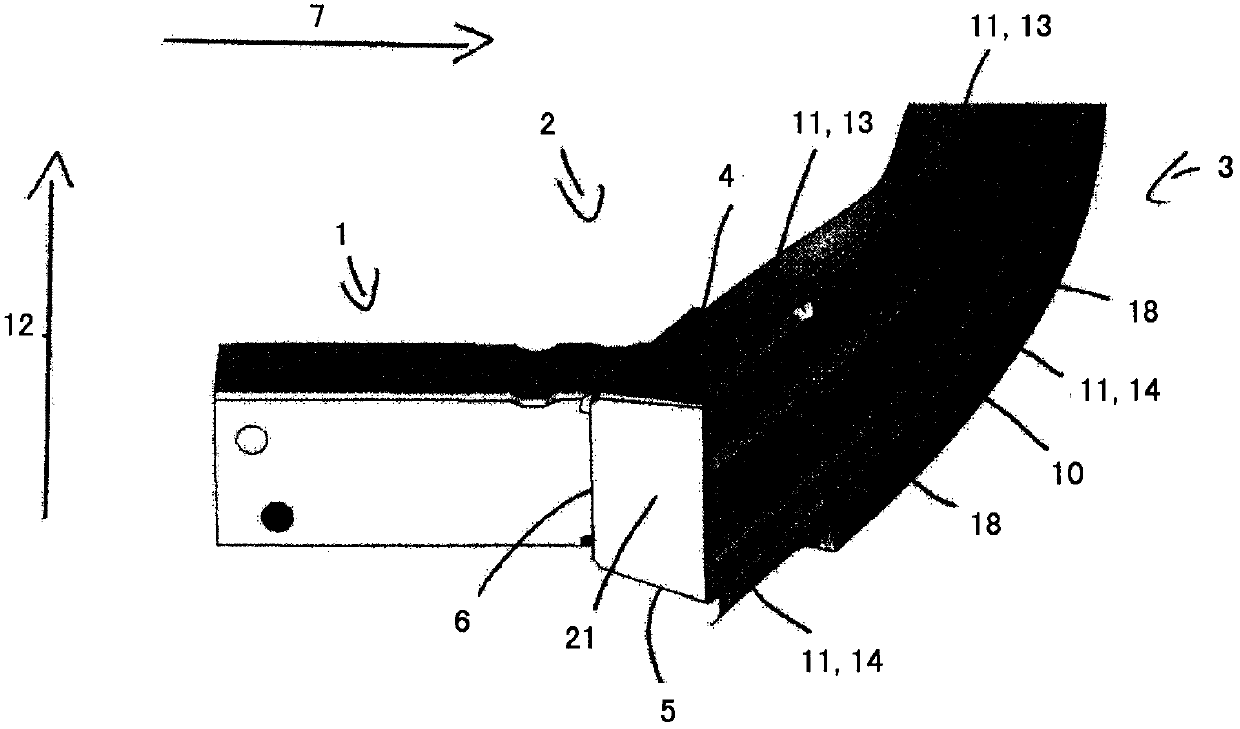

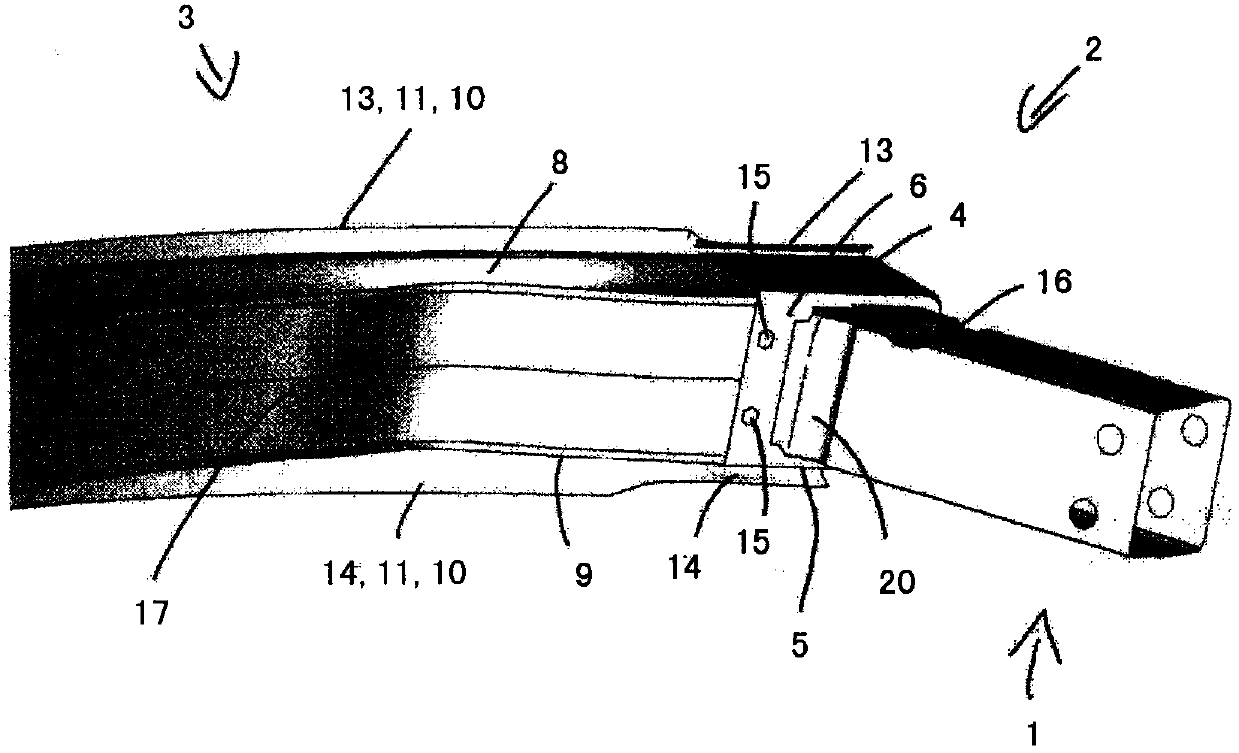

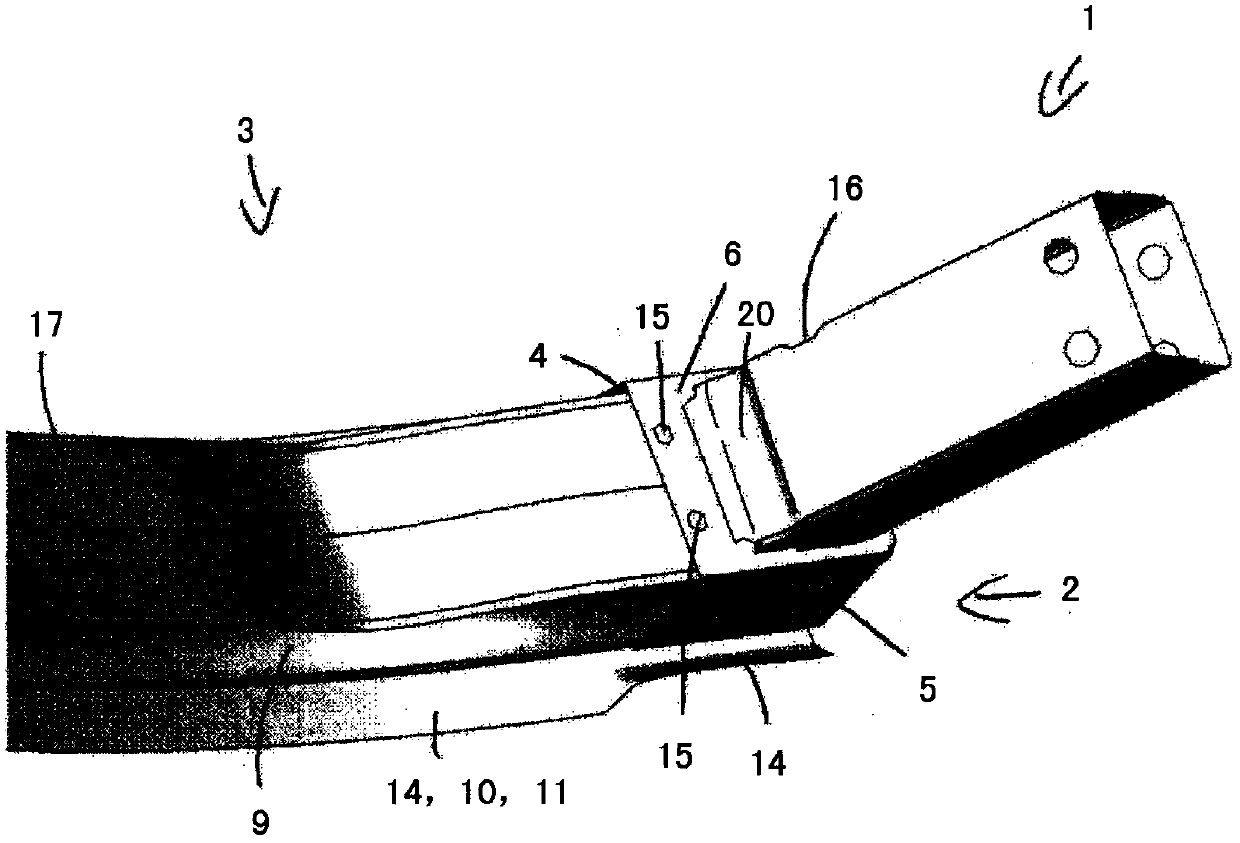

Bumper system for motor vehicle

The invention relates to a bumper system for a motor vehicle with at least one crashbox, which is arranged by means of a bracket on a bumper cross member, wherein the bracket is provided with a first bracket plate and a second bracket plate, while the first bracket plate bears at least partly against a first limiting element and the second bracket plate against a second limiting element of the bumper cross member, wherein the bumper cross member is taken up in the bracket such that the first bracket plate and / or the second bracket plate extends in the direction of the vehicle longitudinal axis over at least 3 4 preferably over 9 / 10 of the bumper cross member in the direction of a bumper cross member front wall, especially preferably entirely up to the bumper cross member front wall.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

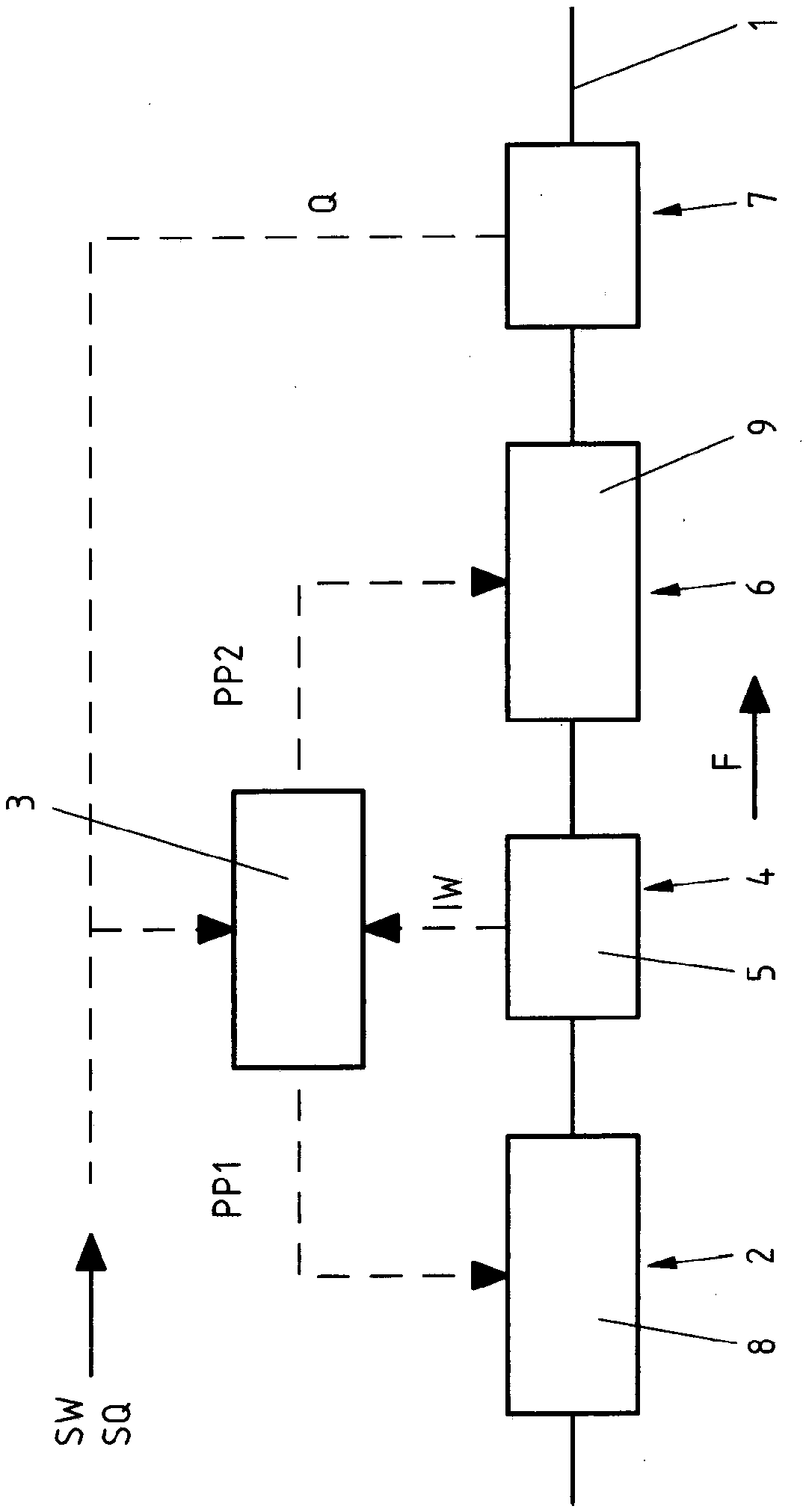

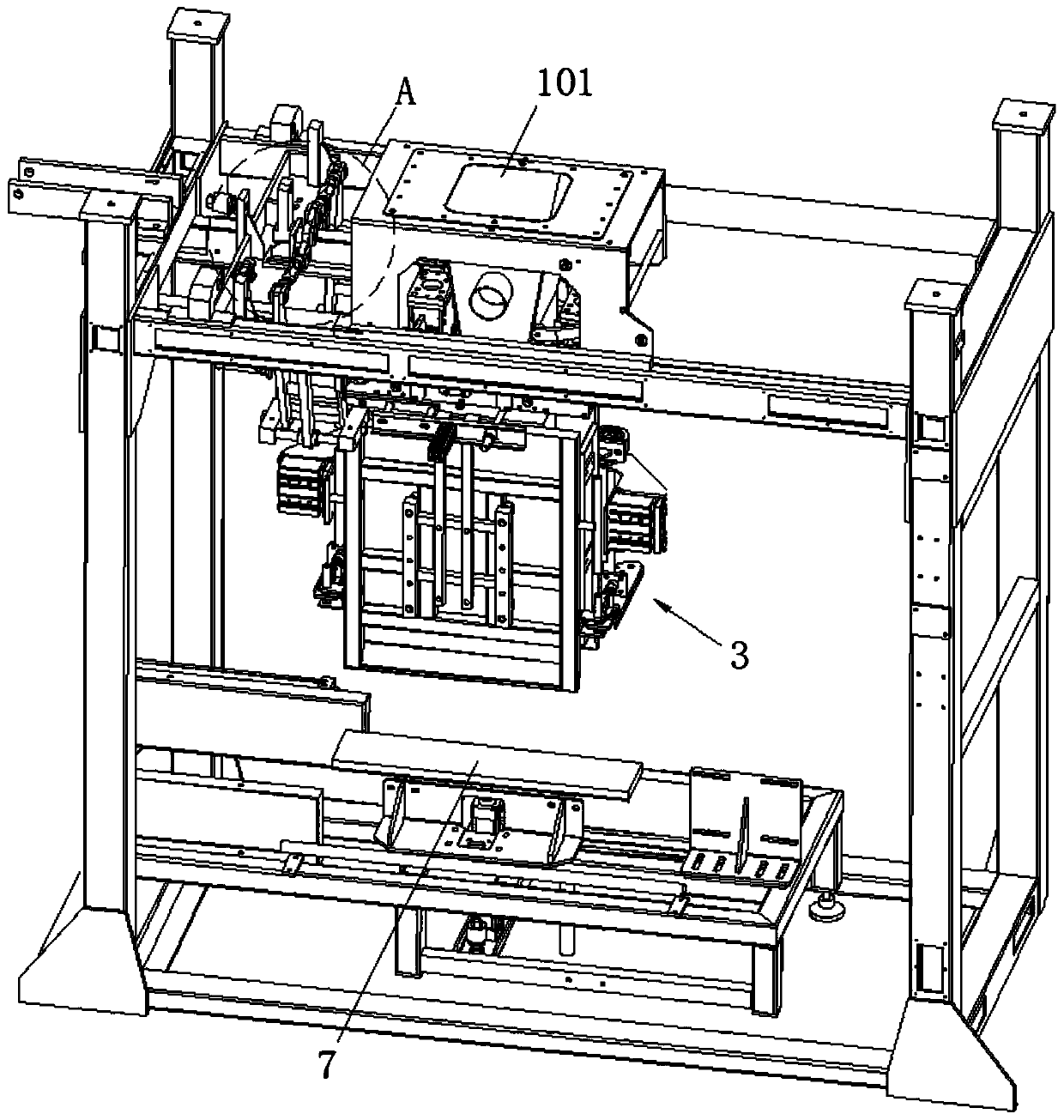

Method for rolling and/or heat treating a metal strip

ActiveCN108779508AEasy to controlEasy to adjustProgramme controlHot-dipping/immersion processesEngineeringProcess engineering

The invention relates to a method for rolling a metal product (1), wherein the metal product is subjected to a rolling operation at a first station (2), which rolling operation is controlled by a control device (3), wherein the product (1) is subjected to a measurement at a second station (4), wherein the product (1) is subjected to a further processing operation at a third station (6), and wherein the product (1) is in a specified quality at a fourth station (7). In order to increase the quality of the produced strip, the invention provides that the method has the following steps: a) measuring the value of a material property (IW) at the second station (4); b) feeding the value measured at the second station (4) to the control device (3), comparing the measured value with a value (SW) stored in the control device (3), and adjusting a parameter (PP1) if the measured value deviates from the stored value (SW), c) measuring a value of a quality material property (Q) at the fourth station(7); d) comparing the measured value with a stored value, and initiating a measure to influence the quality material property (Q) if the measured value deviates from the stored value beyond a permissible tolerance.

Owner:SMS GRP GMBH

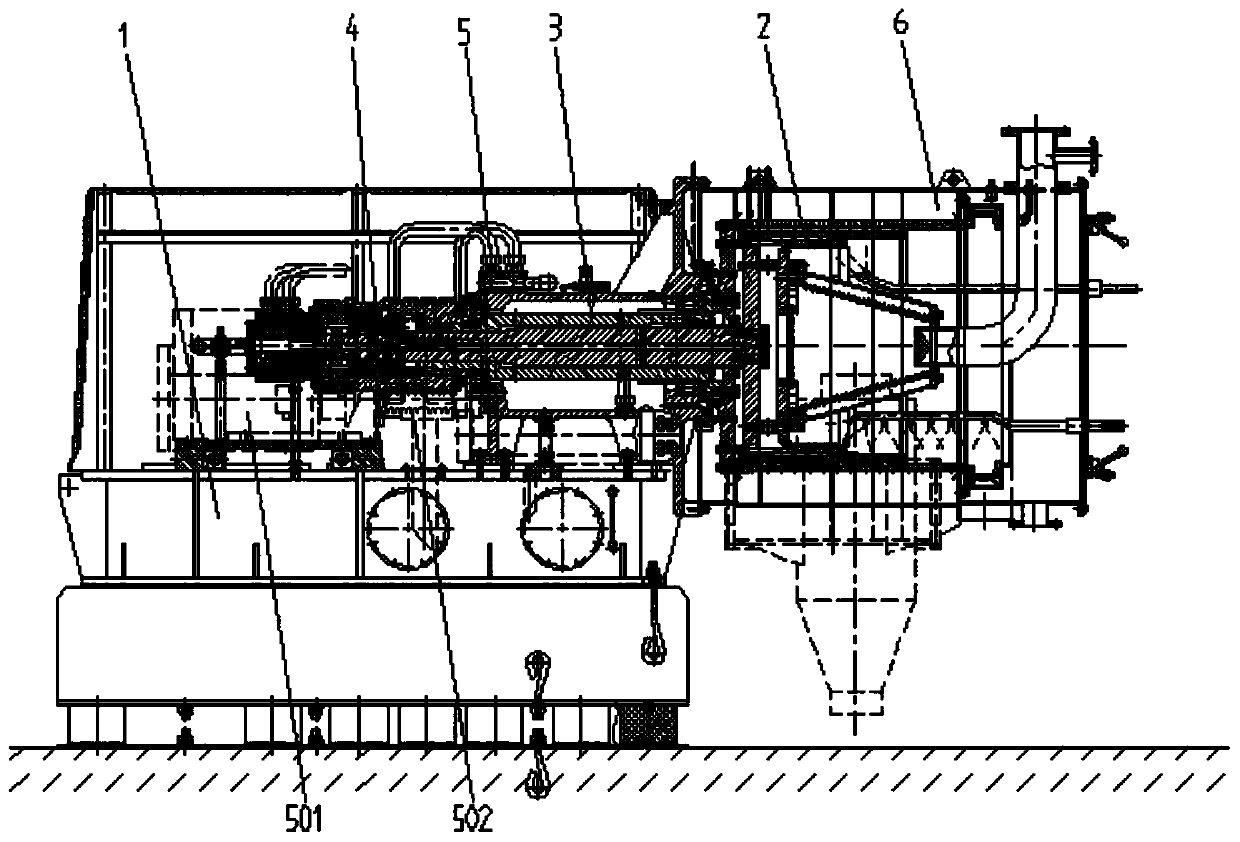

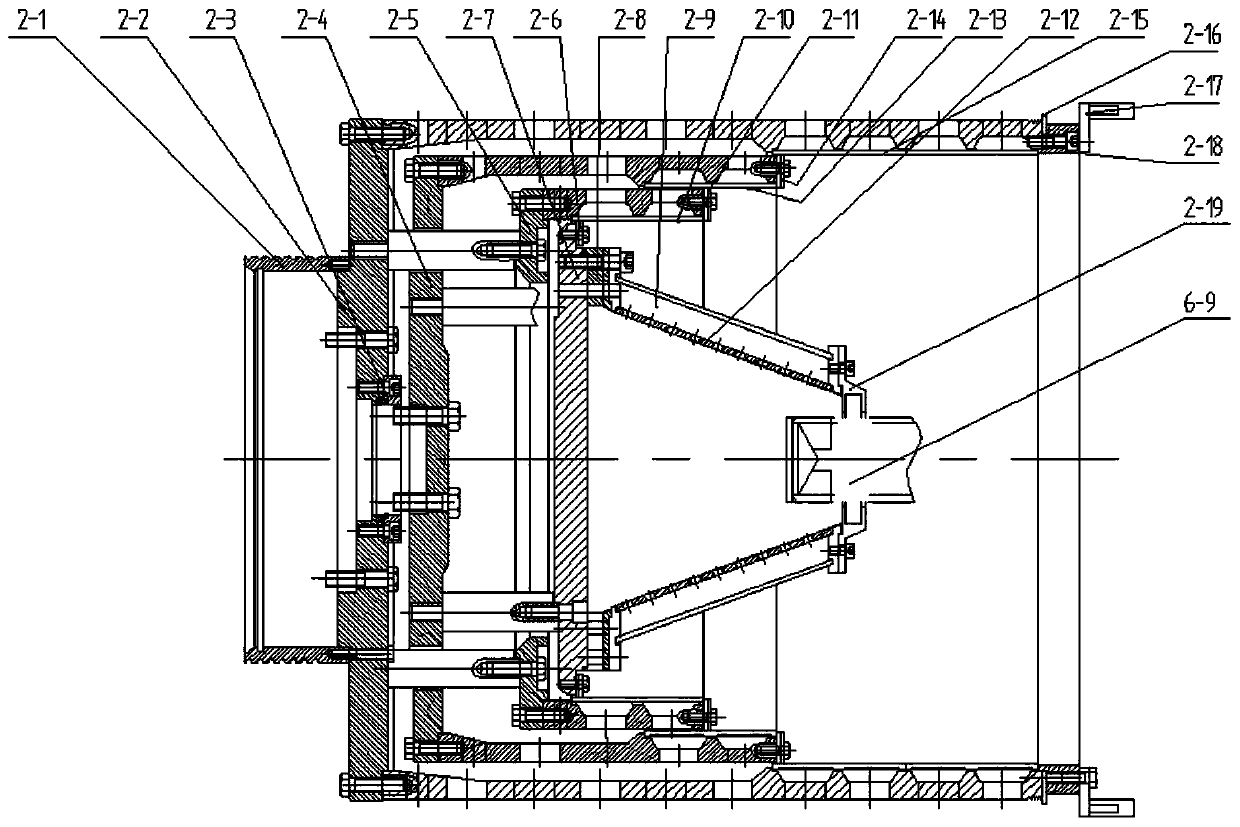

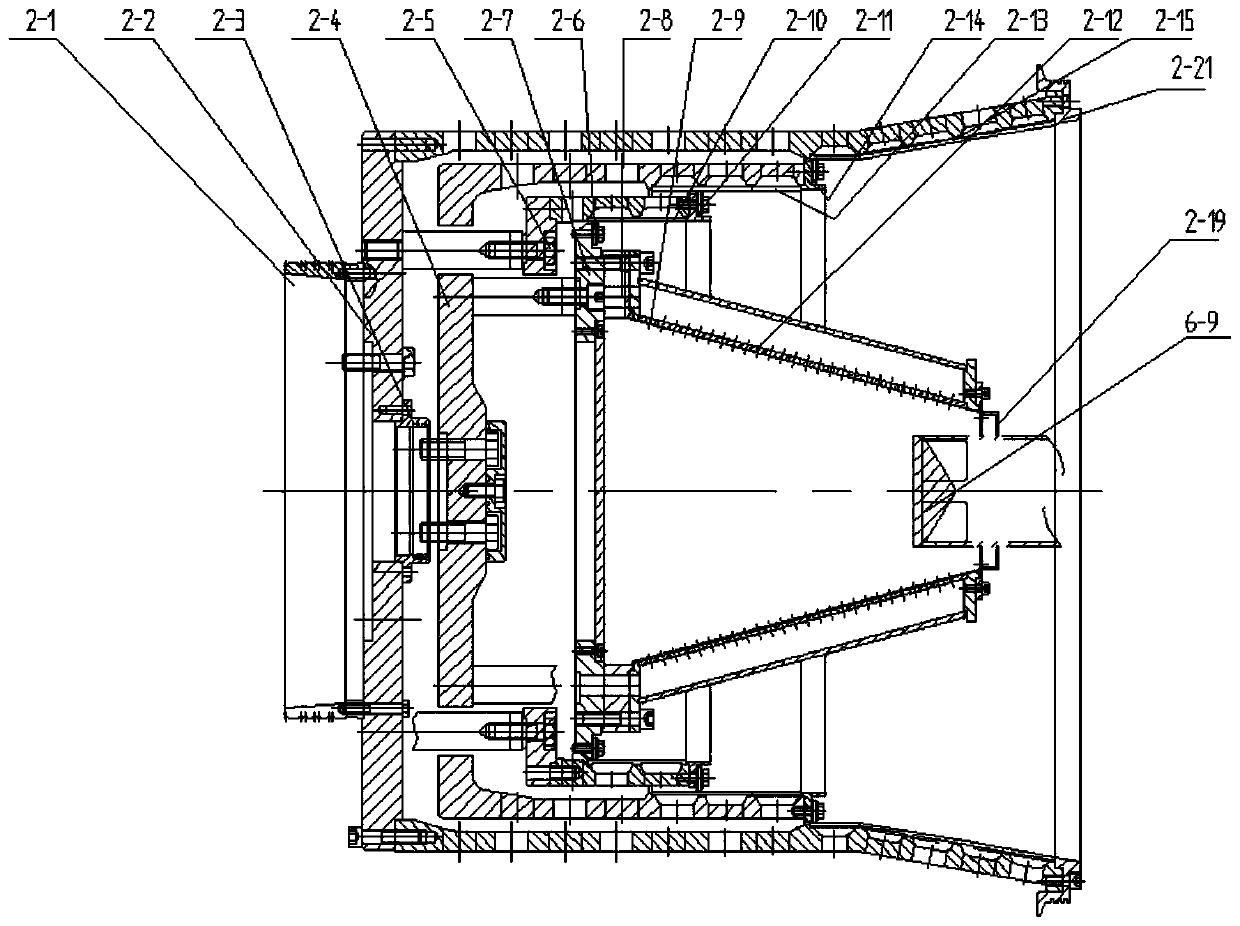

Pushing type centrifugal machine

The invention discloses a pushing type centrifugal machine which comprises a machine base, a drive device, a composite cylinder assembly, a shaft and bearing assembly, a rotary drum assembly and a housing assembly; the rotary drum assembly comprises a water stop ring and a third-stage rotary drum, a second-stage rotary drum is arranged at the inner circumference of the third-stage rotary drum, a first-stage rotary drum is arranged at the inner circumference of the second-stage rotary drum, a pushing disc is arranged at the inner circumference of the first-stage rotary drum, a distributing opening is formed in the circumference of the side end of the pushing disc, a centrifugal distributor is arranged at the circumference of the side end of the distributing opening, a centrifugal mesh pressing ring is arranged at one end of the centrifugal distributor, and a feeding pipe alternately penetrates through the centrifugal mesh pressing ring; a first-stage screen cloth is arranged on the first-stage rotary drum, a second-stage screen cloth is arranged on the second-stage rotary drum, and a third-stage screen cloth is arranged on the third-stage rotary drum; a first-stage pushing piece, asecond-stage pushing piece and a third-stage pushing piece are arranged on the pushing disc, the first-stage rotary drum and the second-stage rotary drum respectively. The pushing type centrifugal machine is convenient to use and maintain, due to the unique design of the rotary drum device, the material dehydration effect is good, the pushing type centrifugal machine is applicable to a low-concentration suspension, and the service life is long.

Owner:XIANGTAN HUIBO CENTRIFUGE

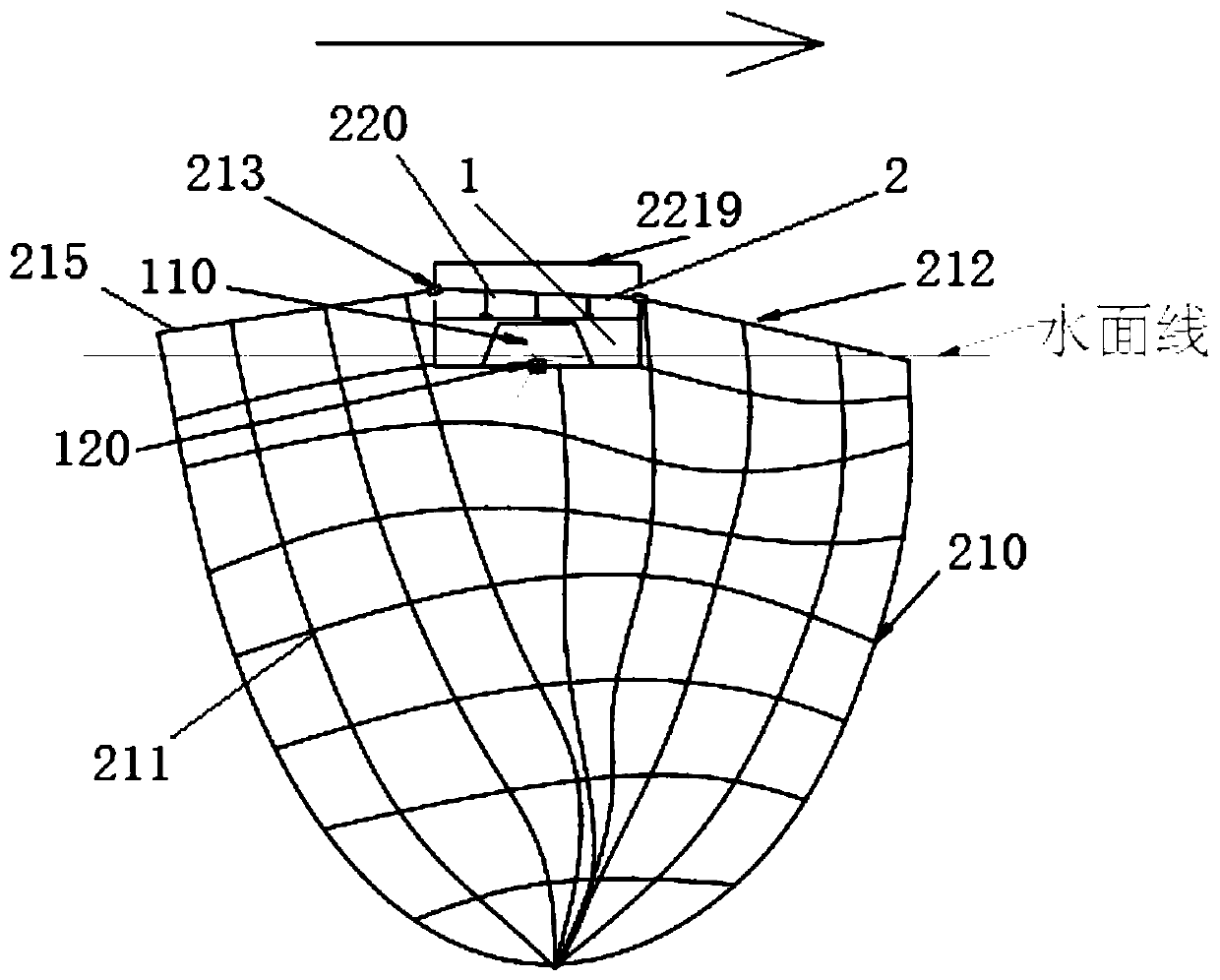

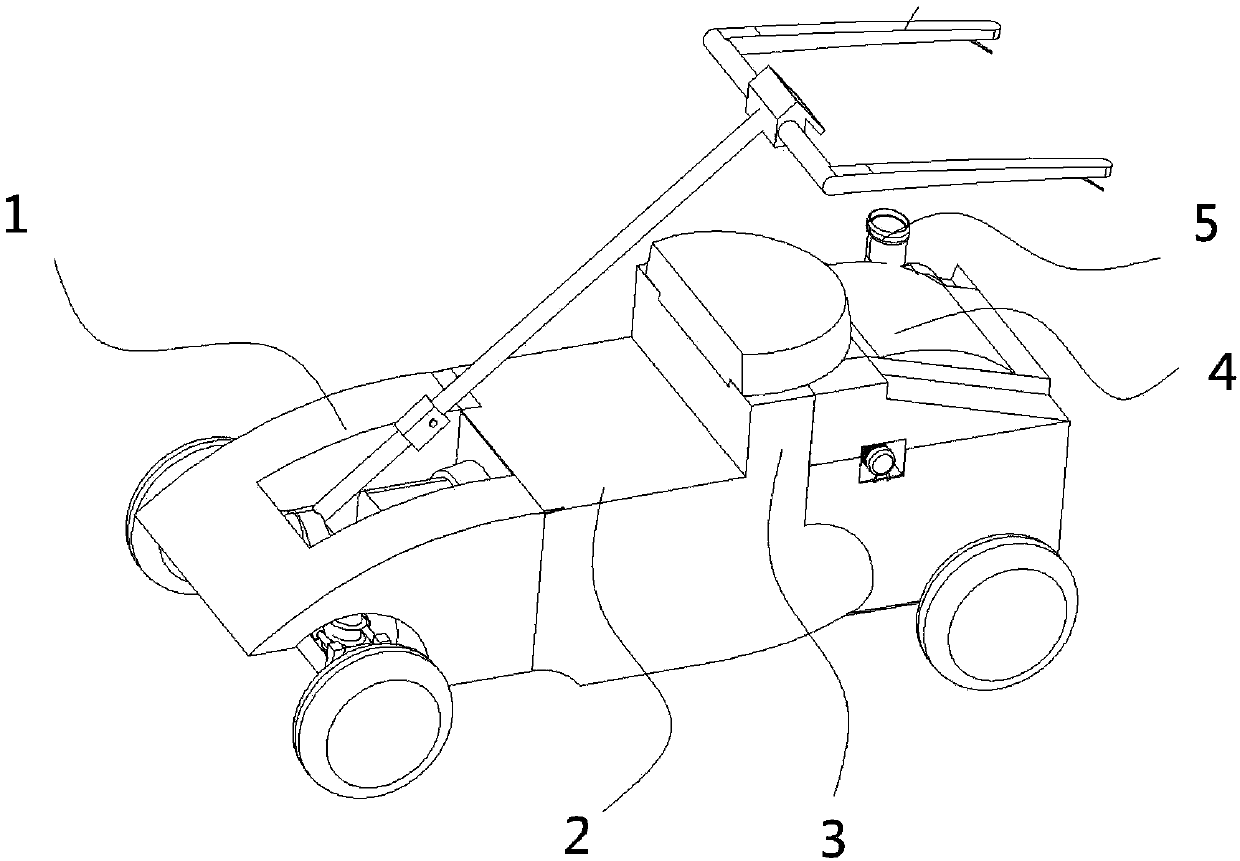

Automatic duckweed fishing device

PendingCN110106849AImprove fishing efficiencyRealize automatic and intelligent salvageWater cleaningElectricityImpeller

The invention relates to an automatic duckweed fishing device. The automatic duckweed fishing device comprises a floating body, a speed measurement assembly, a control assembly and a fishing assembly,wherein the speed measurement assembly, the control assembly and the fishing assembly are arranged on the floating body, the floating body is provided with a first impeller assembly for pushing the floating body to move frontwards and backwards in water, the floating body is provided with a second impeller assembly for pushing the floating body to move leftwards and rightwards in the water, and the speed measurement assembly, the first impeller assembly and the second impeller assembly are electrically connected with the fishing assembly correspondingly. The automatic duckweed fishing devicehas the beneficial effects that after the automatic duckweed fishing device encounters a large obstruction or is in contact with the bank side, the automatic duckweed fishing device can perform translation in the direction perpendicular to the current fishing direction automatically, then line-feed fishing is carried out, non-repetitive fishing is ensured, the duckweed fishing efficiency is improved, and the automatic and intelligent fishing is realized.

Owner:CAMCE WHU DESIGN & RES CO LTD

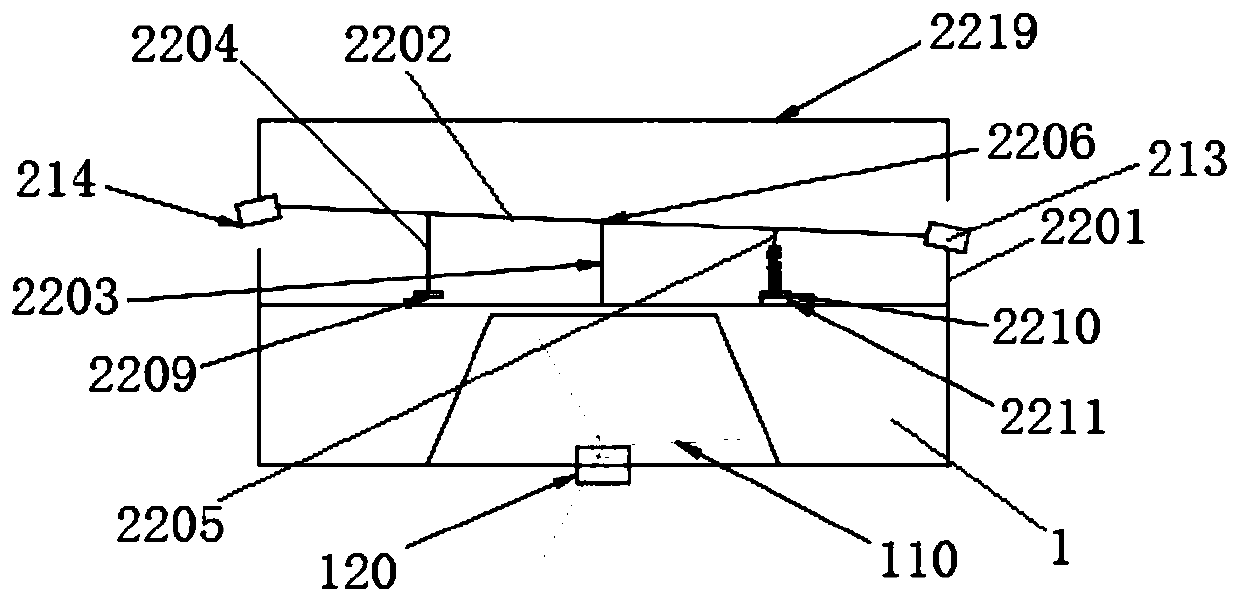

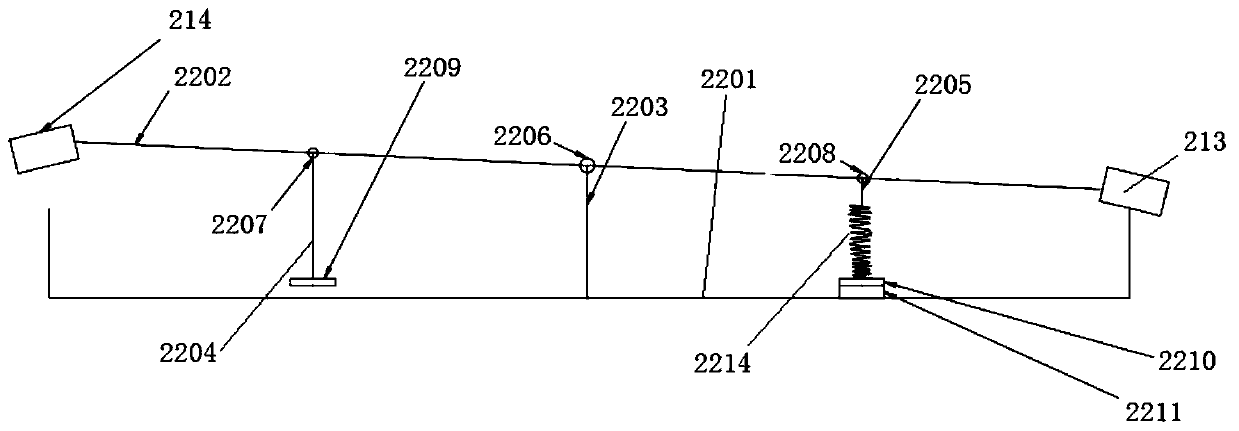

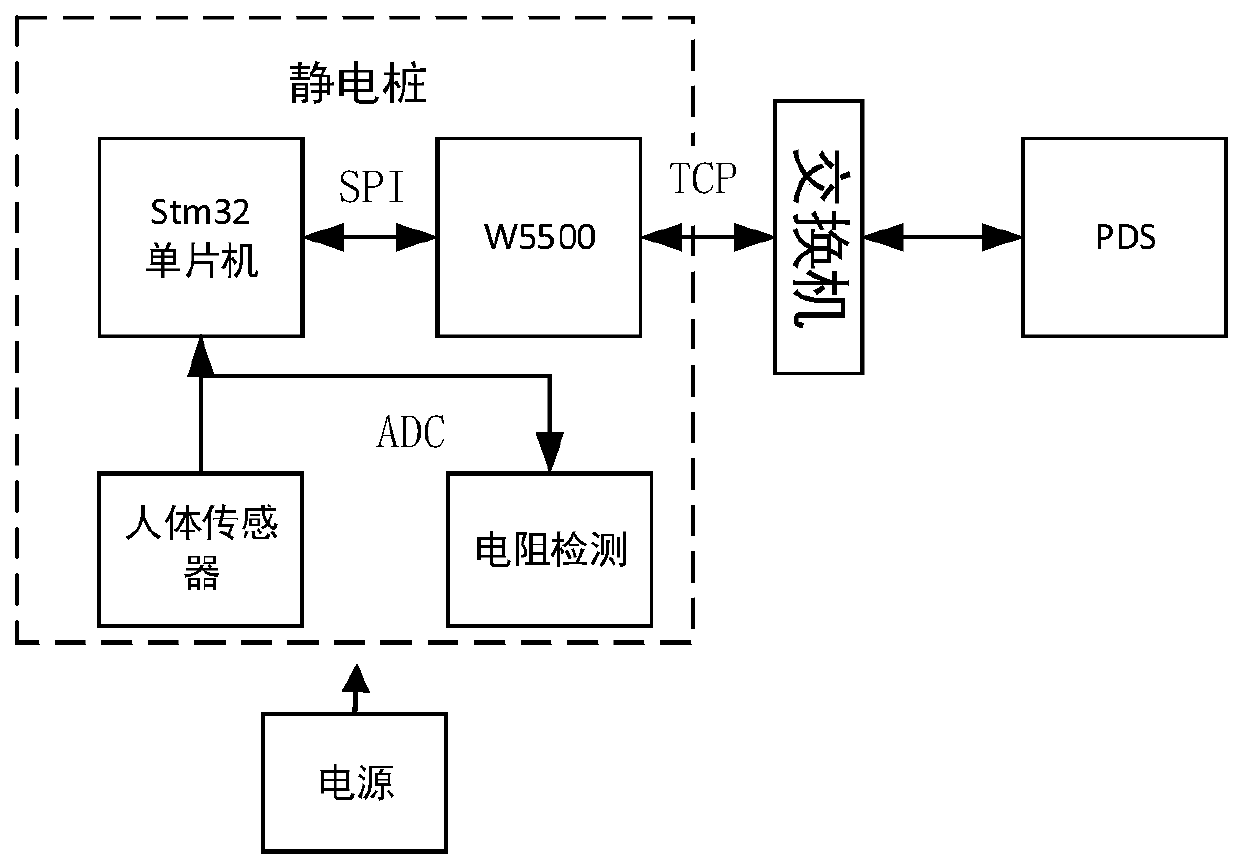

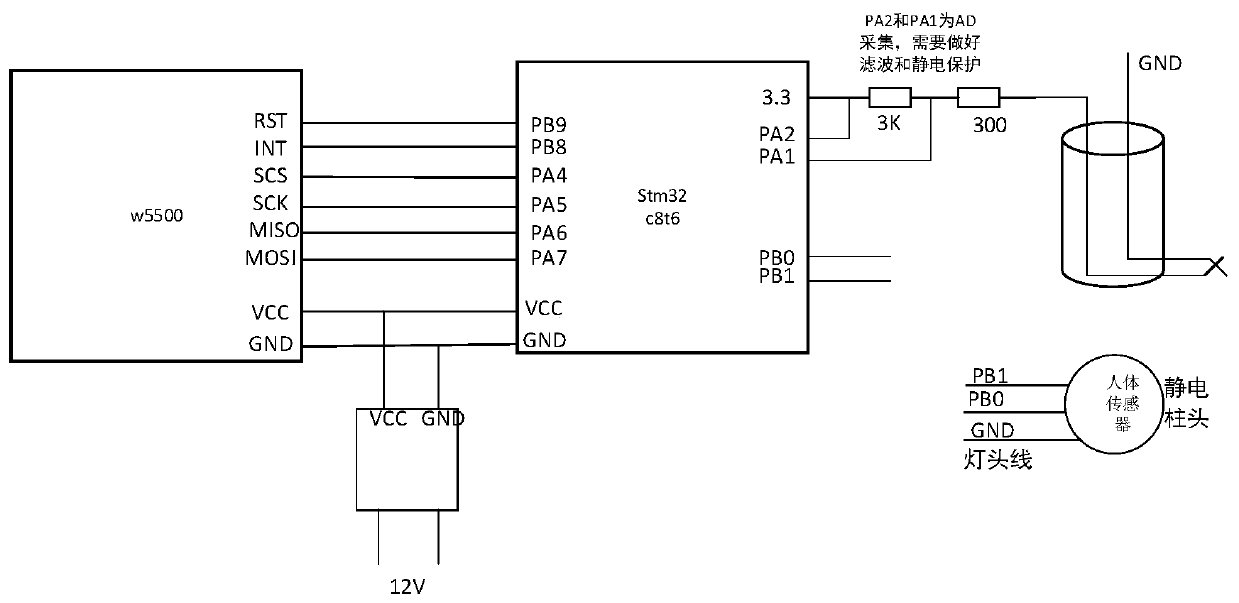

Electrostatic discharge device

InactiveCN110368578ANormal data transferFeedback statusElectrotherapyElectrical resistance and conductanceIp address

The invention discloses an electrostatic discharge device. The electrostatic discharge device comprises an electrostatic pile and a power supply and is characterized in that an electrostatic pile headat the top of the electrostatic pile is made of a subconductor material, a single-chip microcomputer is mounted inside the electrostatic pile, the input end of the single-chip microcomputer is electrically connected with the output end of a human body sensor, a resistance detecting circuit is electrically connected to the single-chip microcomputer, the resistance detecting circuit is connected tovoltage of 3.3V and the 2-way ADC of the single-chip microcomputer to perform detection, the resistance detecting circuit performs resistance calculation by using a voltage dividing manner, the single-chip microcomputer and a network module adopt SPI communication, and the network module is electrically connected with PDS through a switch. The electrostatic discharge device has the advantages that the device supports online upgrading, ground resistance detecting and touch alarm on whether the electrostatic discharge is completed or not, each electrostatic pile has an independent IP address, the electrostatic pile can be directly controlled through PDS to modify the internal IP address, cost caused by follow-up equipment upgrading can be reduced, and follow-up cost can be reduced greatly.

Owner:北京中安信合科技有限公司

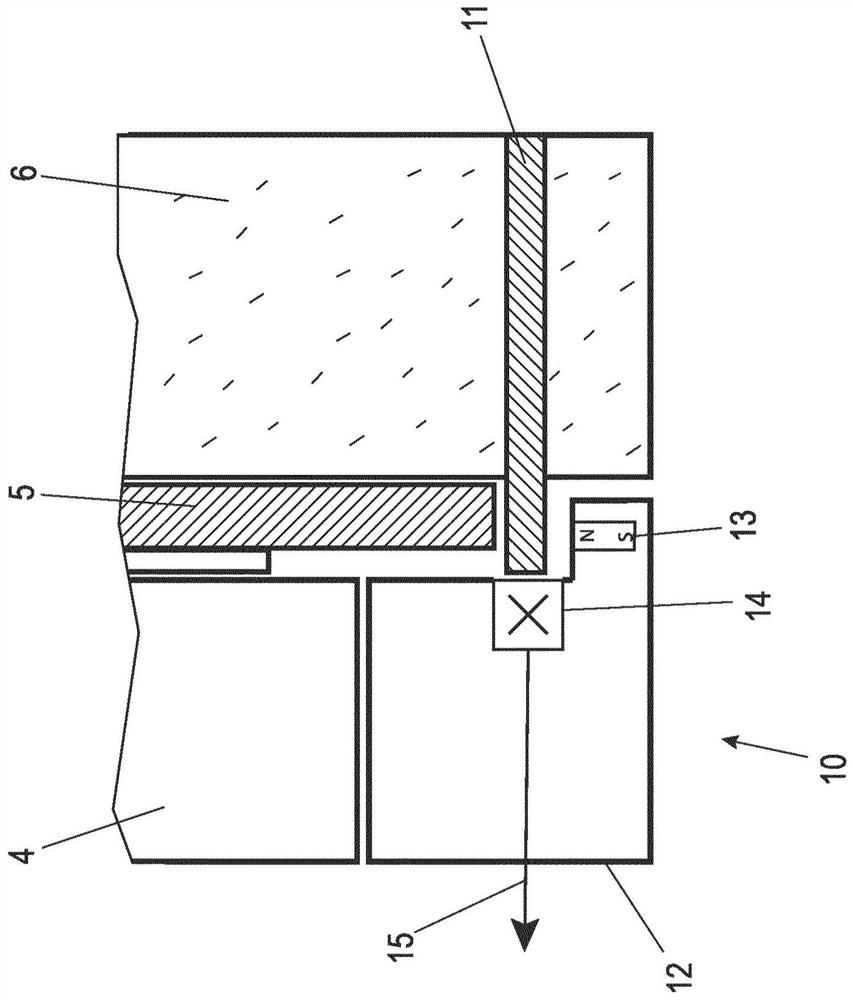

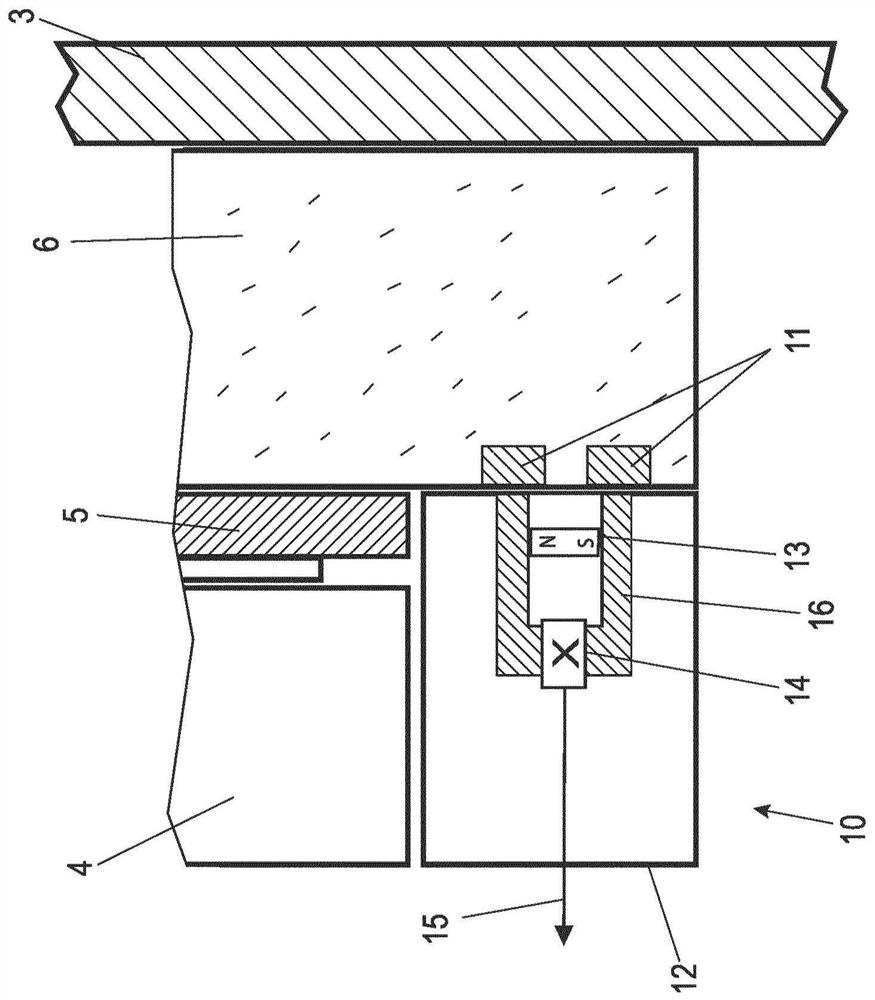

Measuring system and measuring method for determining wear of brake lining of friction brake

The invention relates to a measuring system for determining the wear of a brake lining (6) of a friction brake, wherein a wear element (11) is integrated into the brake lining (6), the wear of which wear element is determined to represent the brake lining (6) or by means of which wear of the brake lining (6) is detected. The wear element (11) is ferromagnetic and the measuring system has a permanent magnet (13) and a magnetic field sensor which are arranged such that the wear element (11) lies in the field of the permanent magnet (13), and the magnetic field sensor detects a magnetic field intensity influenced by the wear of the wear element (11) or the brake lining (6).

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

Packaging equipment for cable sheath material

ActiveCN110667943AAvoid irregular accumulationReduce transition spaceSolid materialStructural engineeringElectric cables

The invention discloses packaging equipment for a cable sheath material. A forming mechanism located below a hopper comprises two first forming plates, two second forming plates and a guide rail. Thefirst forming plates and the second forming plates are mounted on the guide rail through a connecting seat, the second forming plates are located between the two first forming plates, the first forming plates and the second forming plates encircle a forming cavity where a packaging bag is formed, two ends of a rotating plate are separately connected to a driving assembly and the first forming plates, a rotating hole where the guide rail penetrates through is formed in the rotating plate, second rotating rods are mounted on two sides of the first forming plates, the second forming plates are mounted on a second rotating rod, and the second forming plates are mounted on a second connecting plate through a first extrusion air cylinder. The packaging equipment not only can prevent a material from being accumulated irregularly at a corner to affect the regularity of a packaging structure, but also is convenient for staff to adjust and replace the first and second forming plates and adjust the thickness and width of the forming cavity so as to fit packaging demands of different specifications.

Owner:SUZHOU HENGLI COMM MATERIAL +1

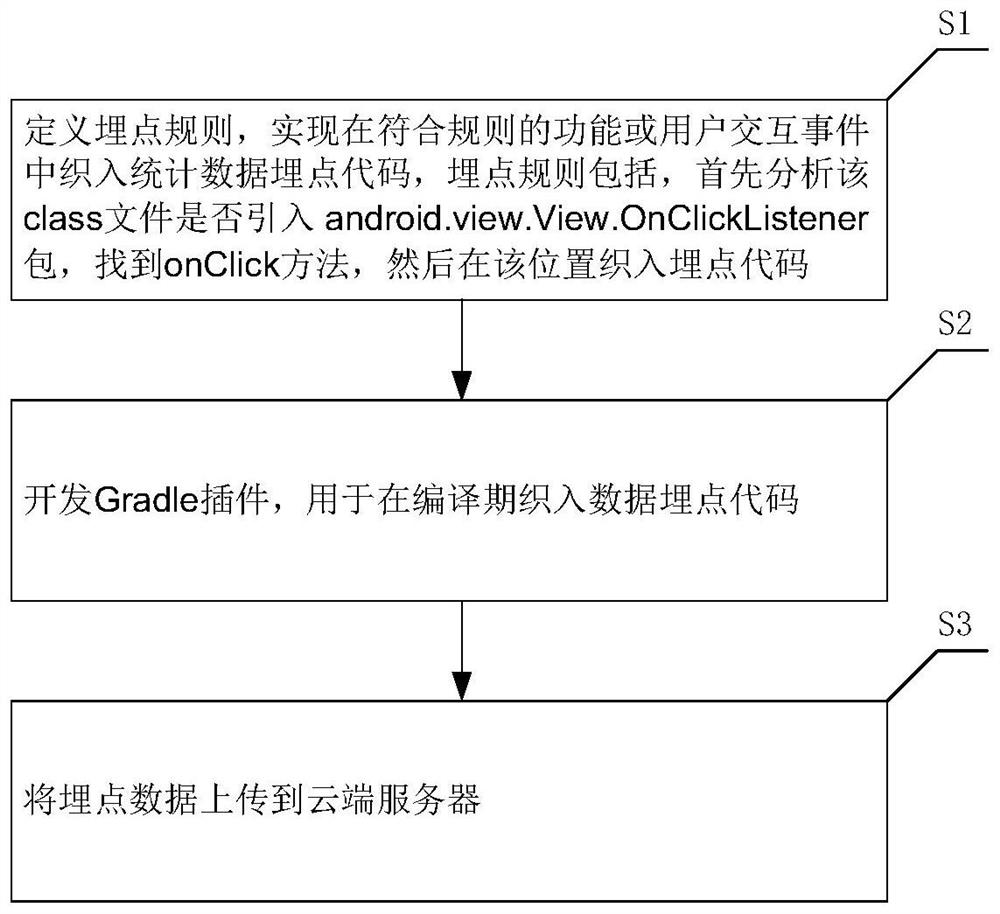

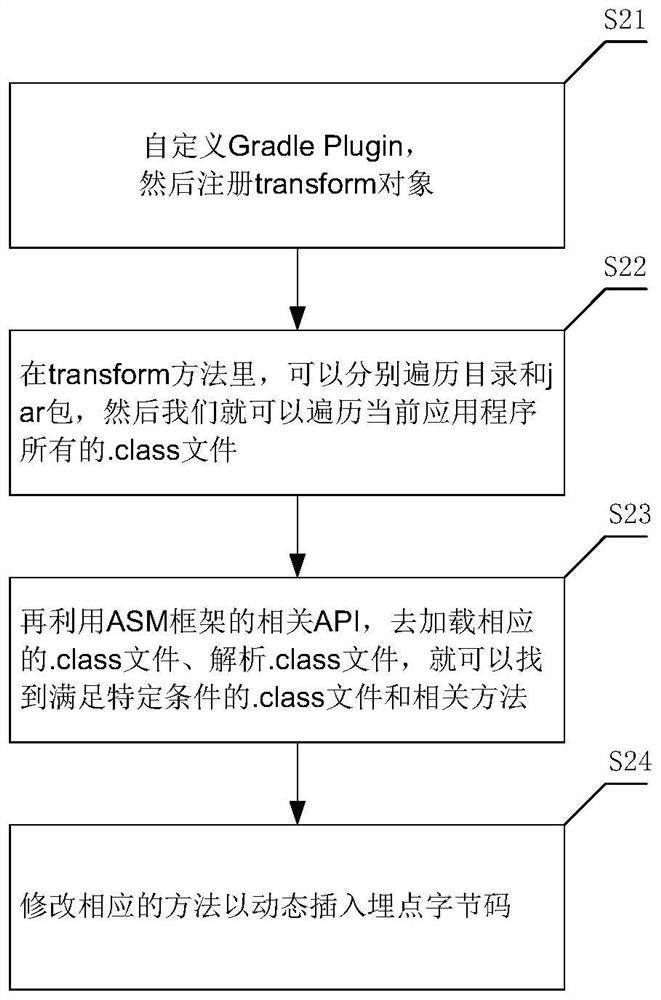

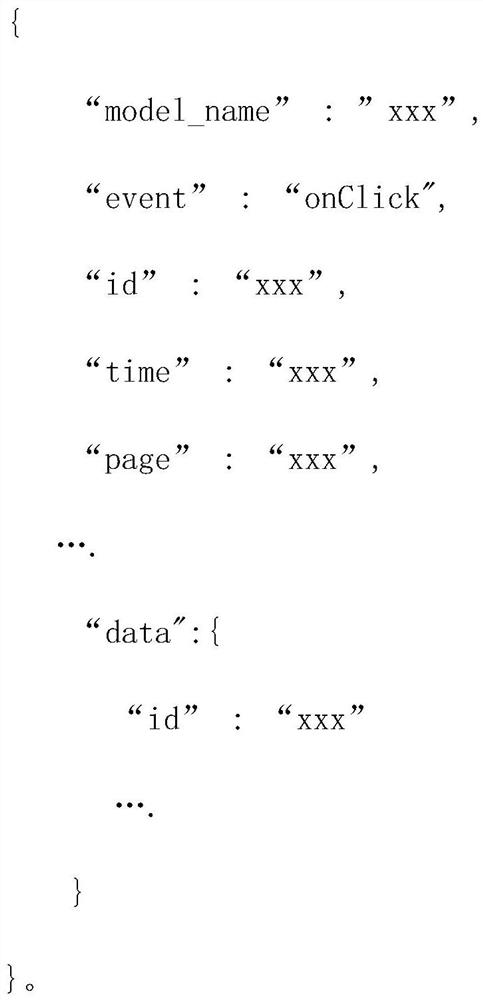

Android automatic data point burying method

PendingCN112130818ARealize automatic burialSave development costSoftware designProgram loading/initiatingSoftware engineeringData error

The invention discloses an Android automatic data point burying method, which comprises the following steps of: defining a point burying rule, and weaving a statistical data point burying code into afunction meeting the rule or a user interaction event; developing a Gradle plug-in, wherein the Gradle plug-in is used for weaving a data burying point code in a compiling period; uploading the burying point data to a cloud server; full-automatic point burying is achieved on the premise that app running period performance is not affected, development resources consumed by data point burying are saved, burying missing caused by manual factors is avoided, data reporting errors caused by manual point burying due to manual factors in the development process are avoided, more comprehensive data isprovided for data analysis of the cloud. The buried point code and the service code of the program are separated and do not influence each other, so that the stability of the program is improved, andthe subsequent cost of the program is reduced.

Owner:北京值得买科技股份有限公司

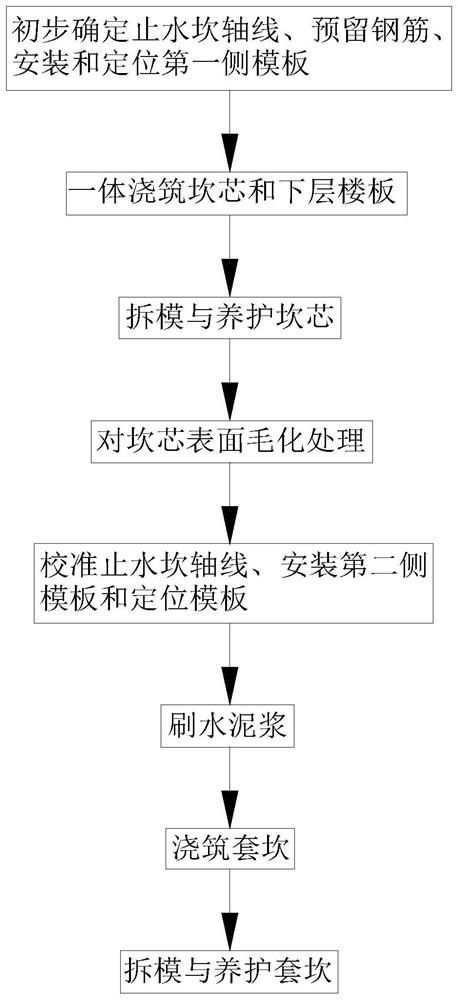

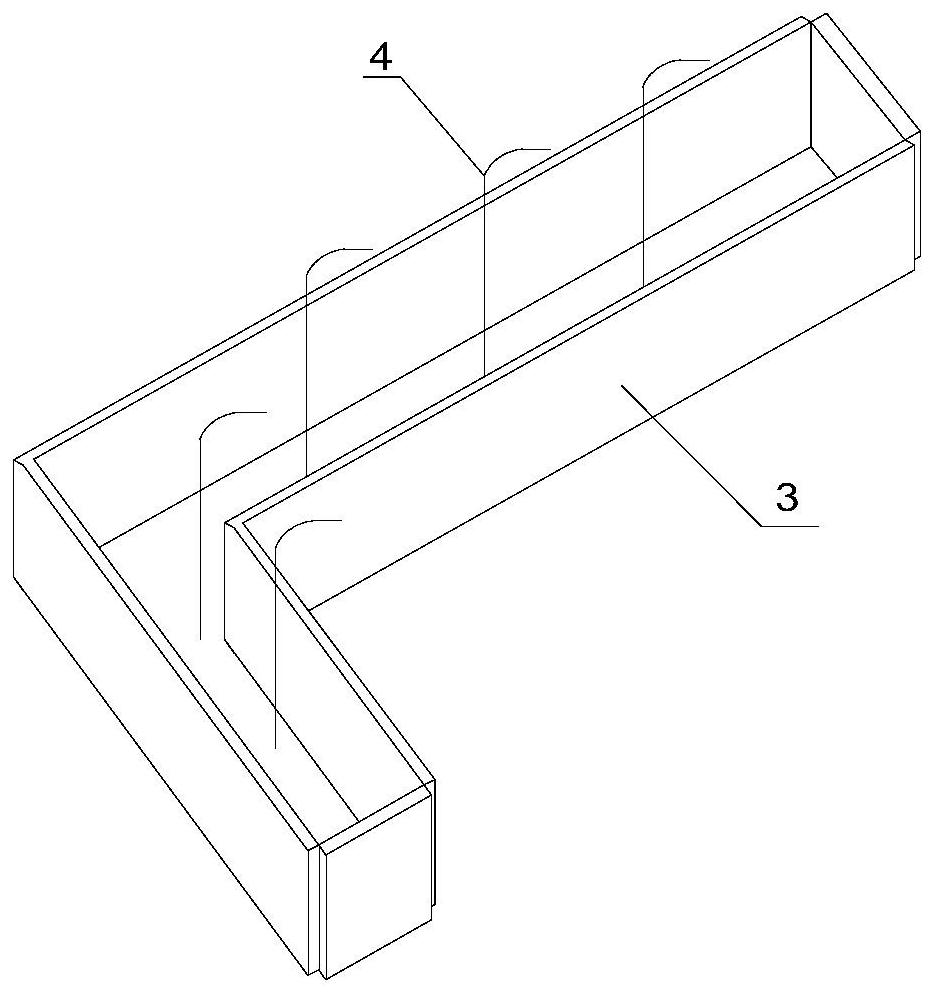

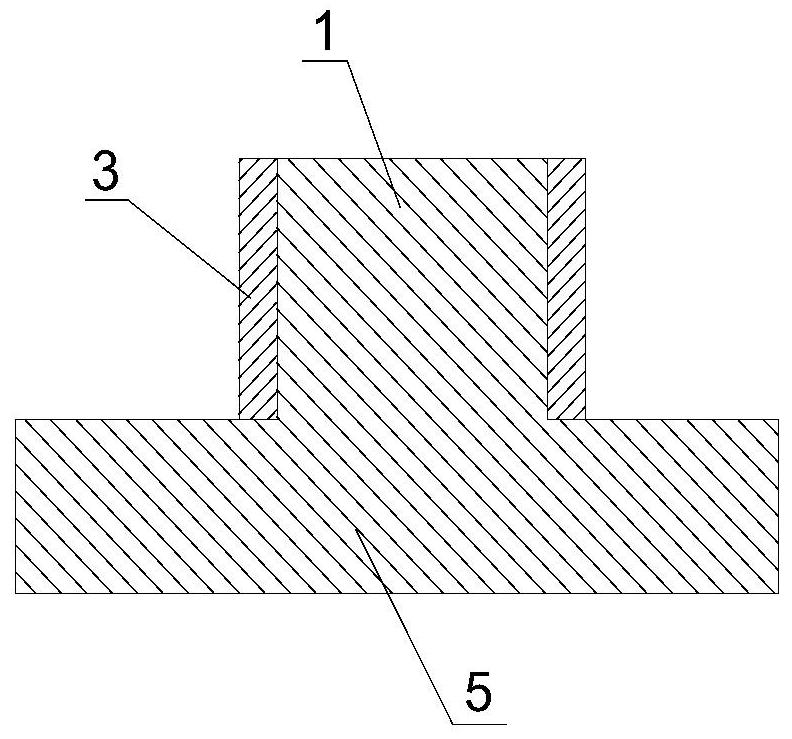

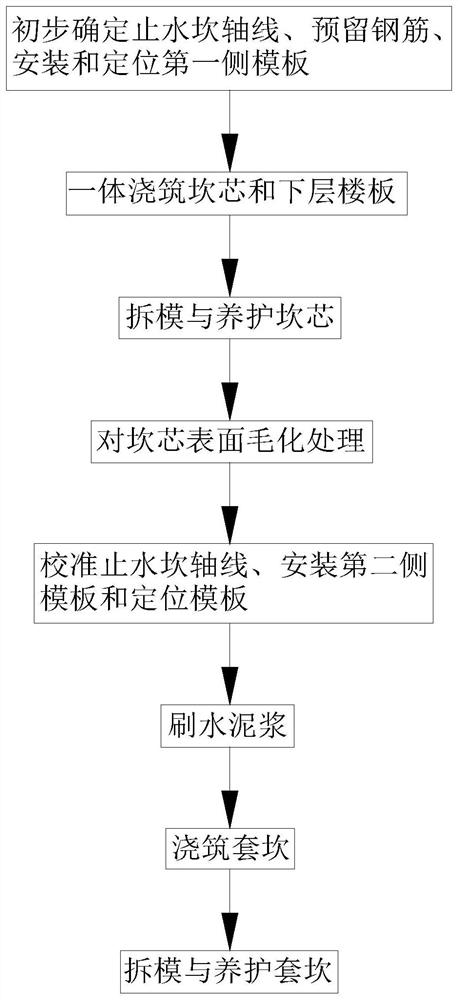

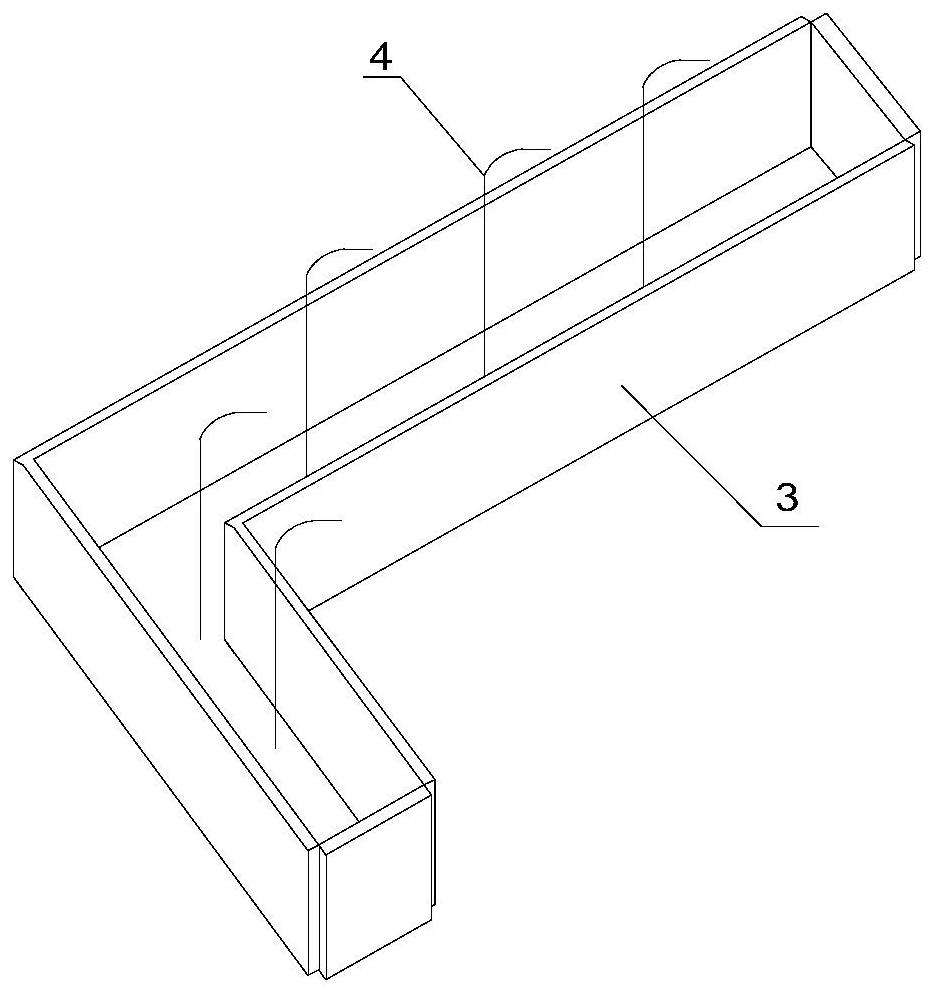

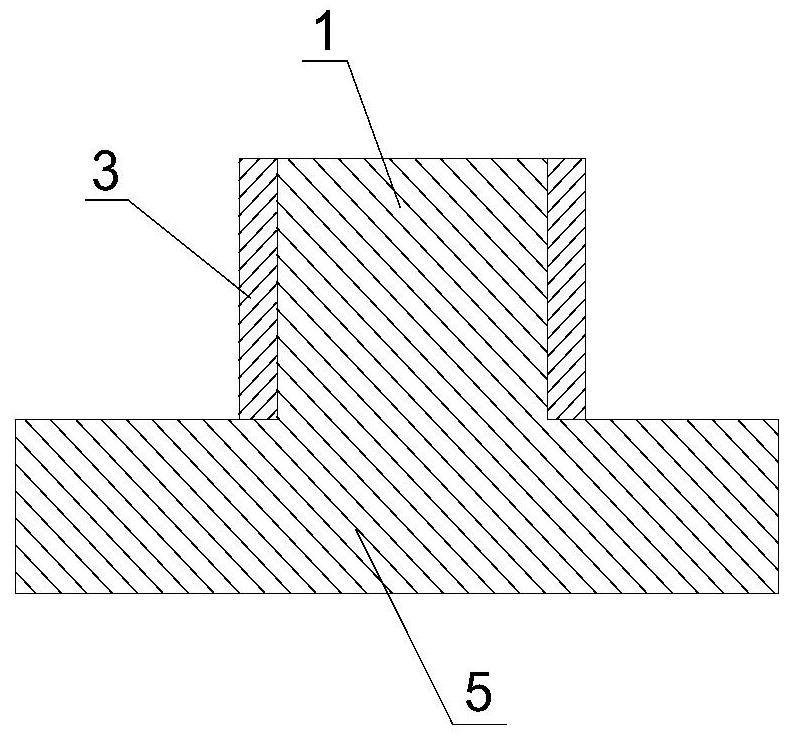

Sleeve sill type water stop sill construction method

ActiveCN111926928AAvoid construction gapsImprove waterproof and anti-seepage performanceSills/thresholdForms/shuttering/falseworksWater stopFloor slab

The invention discloses a sleeve sill type water stop sill construction method, and relates to the technical field of water stop sill construction. The sleeve sill type water stop sill construction method comprises the following steps that steel bars are embedded in a preset position, two first side forms are arranged at the preset position in parallel, the steel bars are located between the two first side forms, a portion below the embedded position corresponds to a lower-layer floor slab pouring space, and a space between the two first side forms and the lower-layer floor slab pouring spacejointly form a first to-be-poured space; first concrete is poured into the first to-be-poured space, and the first concrete between the two first side forms forms a sill core; the two first side formsare dismantled, and the sill core is cured; the surface of the sill core is roughened; second side forms are arranged on the two sides of the sill core, the inner sides of the second side forms are aligned with an edge line of the water stop sill, and the two second side forms are reinforced through positioning forms; second concrete is poured between the two second side forms to form a sleeve sill; and the two second side forms and the positioning forms are dismantled, and the sleeve sill is cured. By means of the arrangement, the waterproof and anti-seepage capacity is high, calibration ofthe axis position can be achieved, and axis positioning is accurate.

Owner:NANTONG SIJIAN CONSTR GRP

A network-based intelligent follow-up system for cardiovascular diseases

ActiveCN106453619BImprove efficiencyImprove accuracyData processing applicationsDatabase distribution/replicationData connectionData platform

The invention relates to an intelligent cardiovascular disease follow-up system based on a network. The intelligent cardiovascular disease follow-up system is characterized by comprising a patient client side, a doctor client side, a centre data management client side and a centre data platform; the patient client side and the doctor client side are connected together with the centre data platform through the network; the follow-up relationship between the patient client side and the doctor client side is established through the centre data platform; furthermore, a follow-up function is implemented; and the centre data management client side and the centre data platform are connected, so that a follow-up management function is realized. By means of the intelligent cardiovascular disease follow-up system disclosed by the invention, the patient client side and the doctor client side are connected together with the centre data platform through the network; therefore, the follow-up relationship can be established rapidly; functions, such as rapid and automatic input of all kinds of patient data, targeted transmission of the patient data between a patient and a doctor, which the patient belongs to, and generation of an automatic message template replied to the patient by the doctor, can be realized; therefore, the follow-up efficiency and the accuracy are increased; the follow-up cost is reduced; and the follow-up application scene is enlarged.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

Device for measuring material surface by using blast furnace based on multiple input multiple output (MIMO) radar

InactiveCN102912054BAchieve full coverageMeet measurement accuracy requirementsChecking devicesHigh resolution imagingRadar imaging

The invention relates to a device for measuring a material surface by using a blast furnace based on an MIMO radar. The device is a set of system composed of an MIMO radar, antenna arrays, an antenna protection casing, a cooling blowing unit and the like. Three-dimensional information of a whole bacterial surface in the blast furnace is obtained by using sparse array high resolution characteristics of the MIMO radar and a near field high resolution imaging algorithm, costs of electronic control scanning array imaging radars are decreased greatly simultaneously, and on-line dynamic monitoring capacity of three-dimensional material surfaces under bad conditions of industrial sites is provided by a dust and high temperature resistance technology.

Owner:BEIHANG UNIV

Bumper systems for motor vehicles

The invention concerns a bumper system for a motor vehicle with at least one crashbox, which is arranged by means of a bracket on a bumper cross member, wherein the bracket is provided with a first bracket plate and a second bracket plate, while the first bracket plate bears at least partly against a first limiting element and the second bracket plate against a second limiting element of the bumper cross member, wherein the bumper cross member is taken up in the bracket such that the first bracket plate and / or the second bracket plate extends in the direction of the vehicle longitudinal axis over at least ¾ preferably over 9 / 10 of the bumper cross member in the direction of a bumper cross member front wall, especially preferably entirely up to the bumper cross member front wall.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

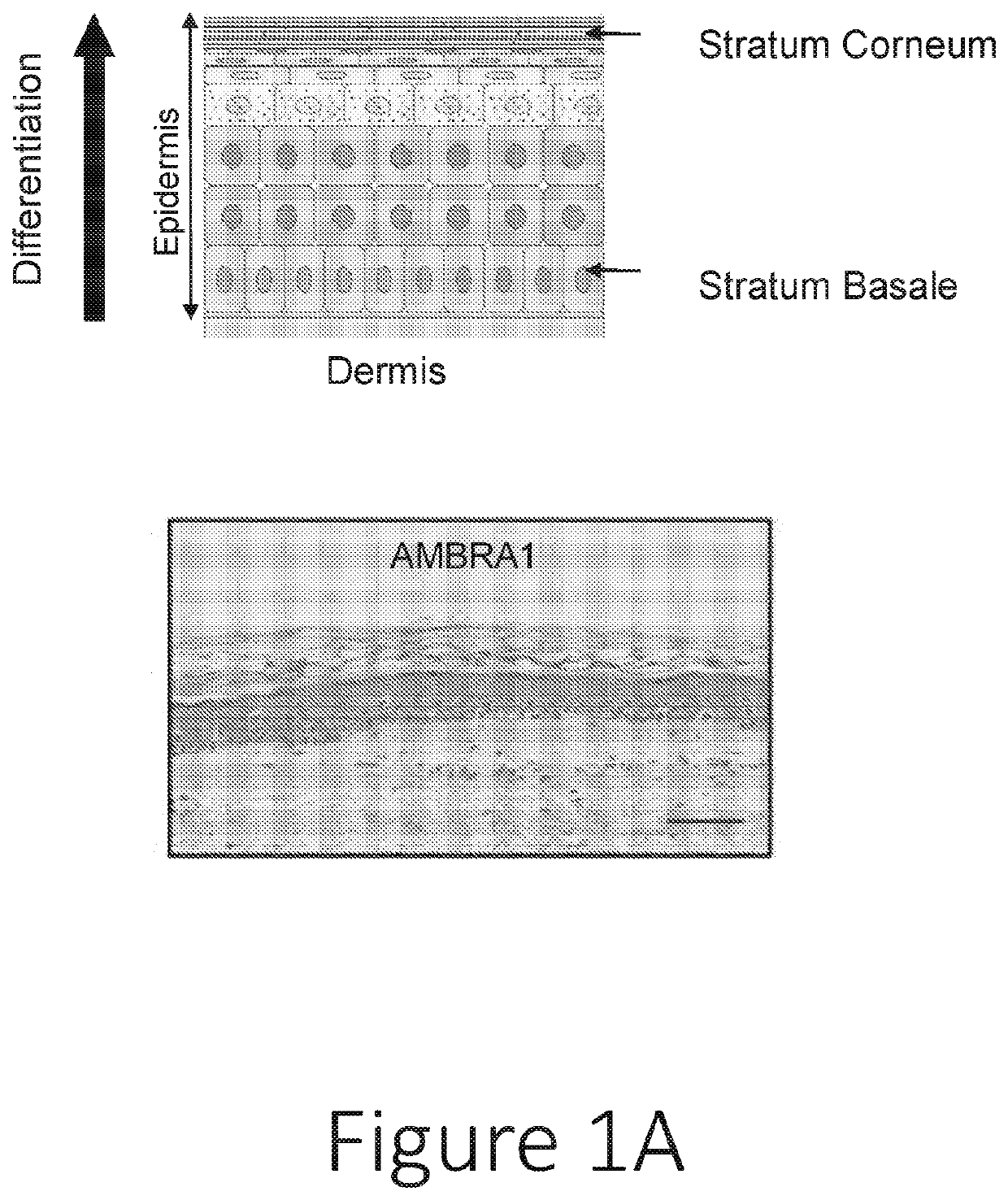

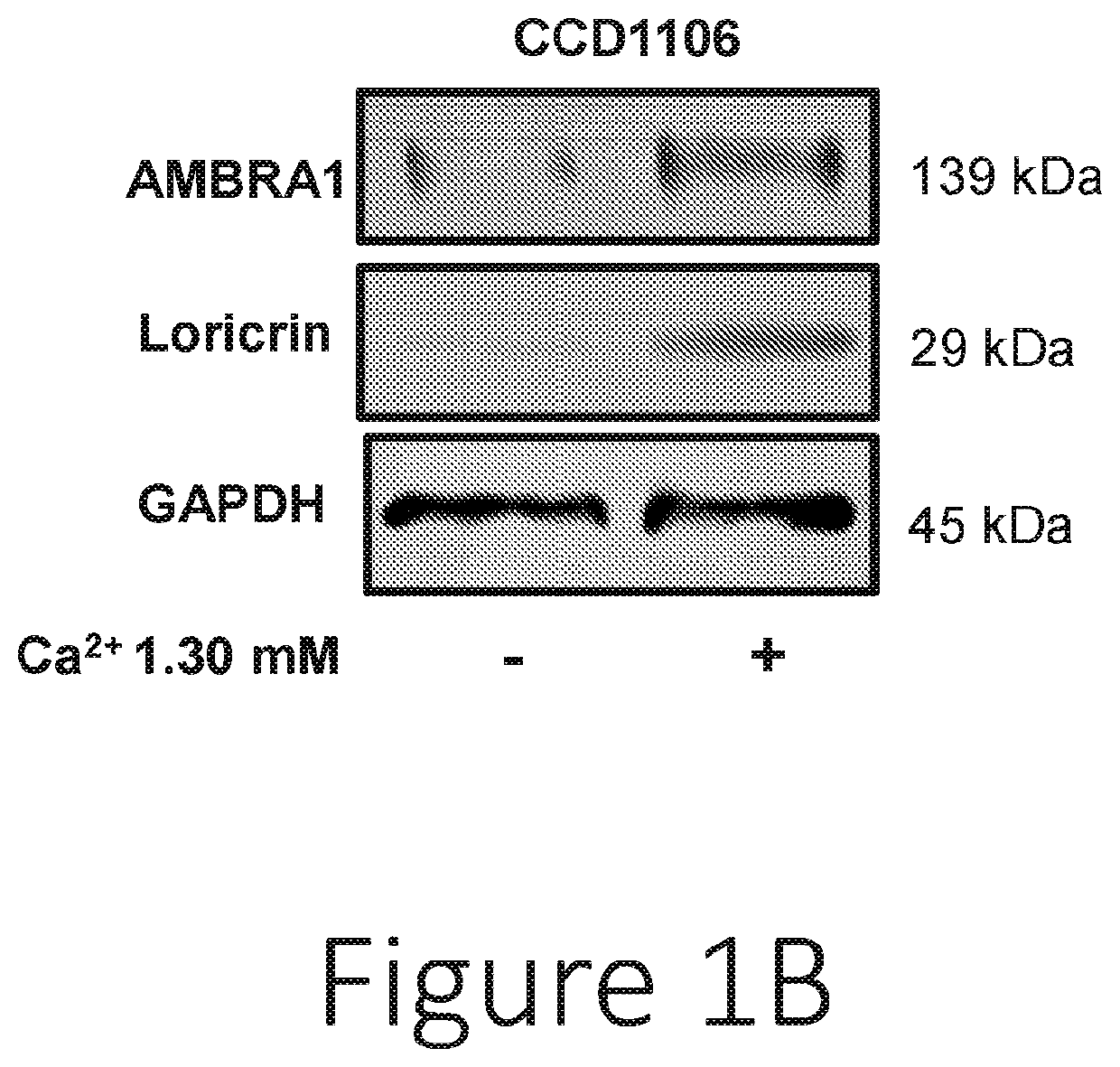

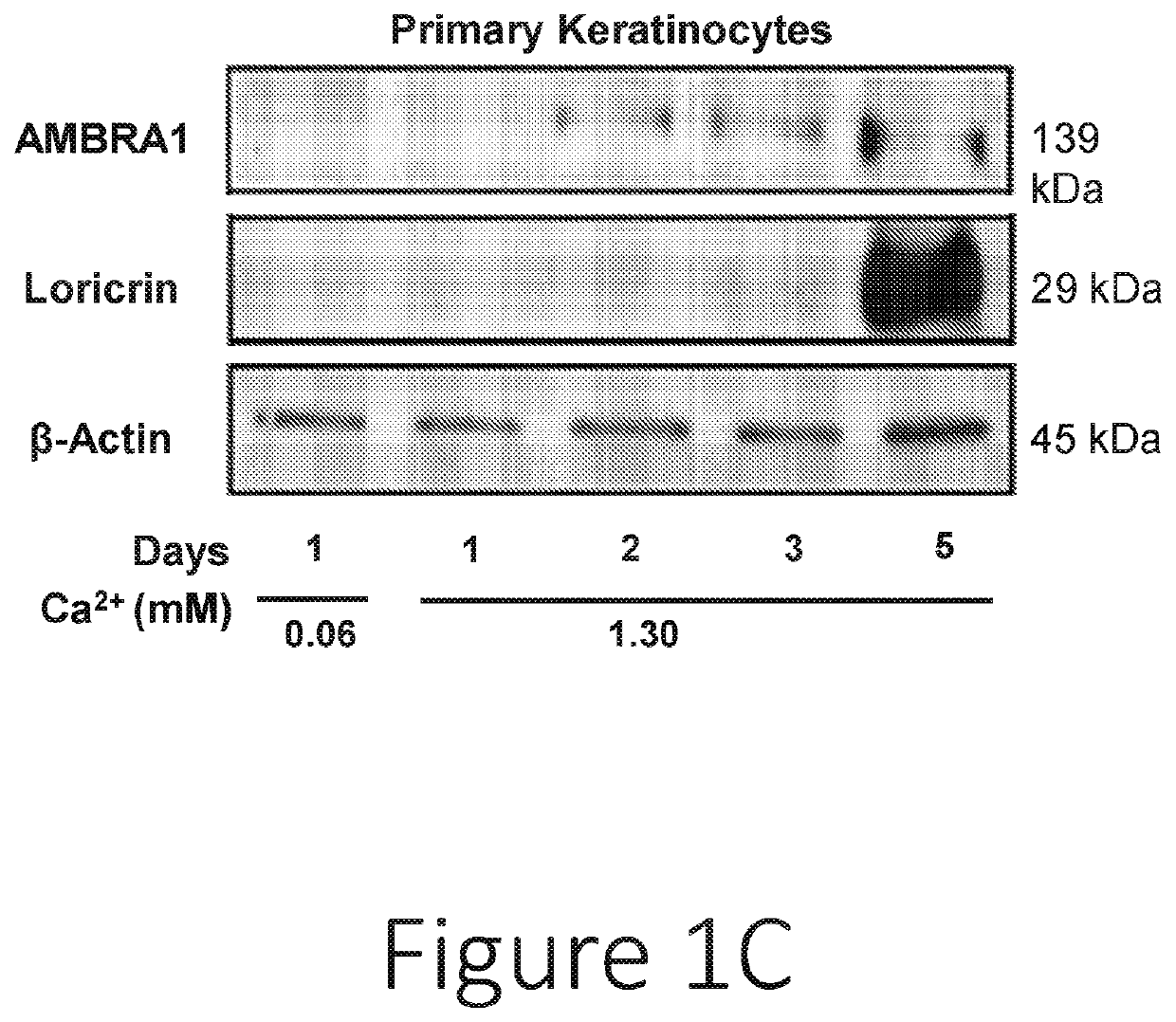

Biomarkers for disease progression in squamous cell carcinoma

PendingUS20220308059A1Accurate predictionPromote resultsImmunoglobulins against cell receptors/antigens/surface-determinantsDisease diagnosisAssaySquamous Carcinomas

The present invention relates inter alia to methods for determining whether a subject with squamous cell carcinoma (SCC) has an increased risk of metastasis. The invention further relates to methods of treating such subjects, diagnostic assays and kits. In certain embodiments, the invention relates to identifying whether a subject suffering from SCC has an increased risk of metastasis by determining the expression of Ambra-1 and p62 in a SCC tissue sample obtained from the subject.

Owner:AMLO BIOSCI LTD

Greenhouse

InactiveCN105123335ASuitable temperature and humidityEasy to controlAgricultural buildingsClimate change adaptationFloor slabBrick

The invention relates to a greenhouse. The technical problems that indoor temperature of an existing mushroom planting greenhouse is high and hard to control, the ventilating effect is poor, and maintenance cost is high are solved. The greenhouse comprises a house body and a greenhouse arch center. The house body comprises four reinforced concrete stand columns, a brick wall is arranged between every two adjacent reinforced concrete stand columns, and three brick walls are arranged totally. A floor slab is arranged at the top of the house body and connected with a heat preservation layer. The greenhouse arch center is connected with the house body, and space below the greenhouse arch center is communicated with space in the house body. The greenhouse arch center is covered and connected with plastic paper, the greenhouse arch center is connected with a curtain winder, and the curtain winder is connected with a grass curtain. A glass window is arranged on one brick wall of the house body, and provided with an exhaust fan. The greenhouse is widely applied to the technical field of planting of edible mushrooms and other crops.

Owner:苏延利

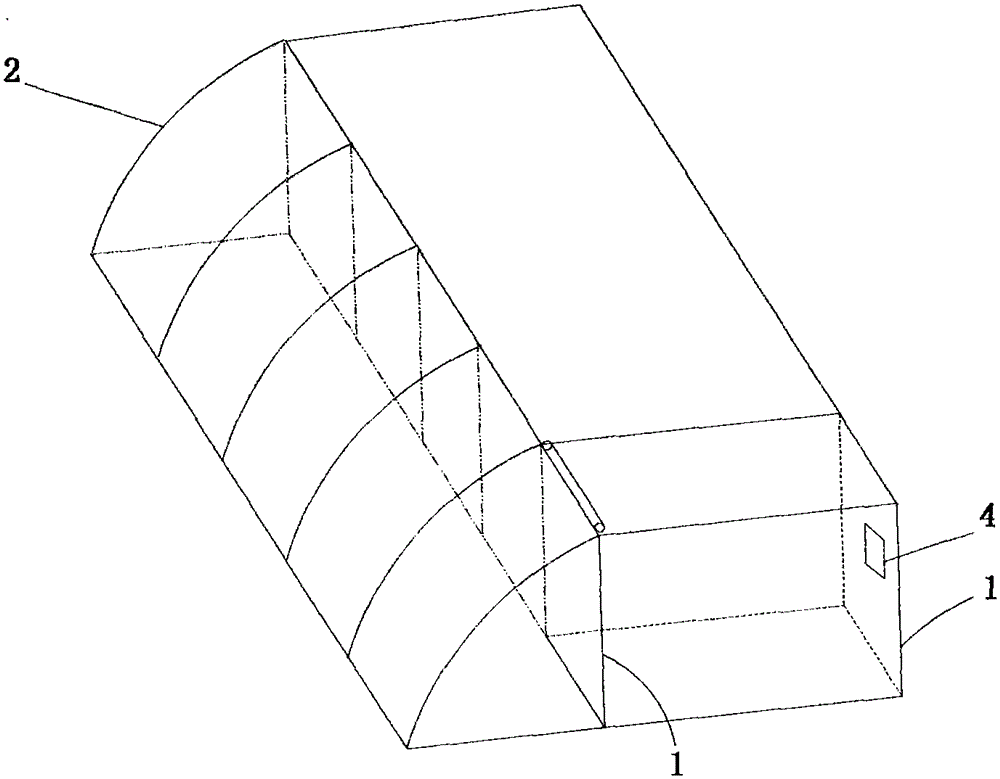

Novel building house structure and installation and construction technology

PendingCN113789852AEasy to installEasy to transportRoof covering using slabs/sheetsRoof covering using tiles/slatesRoof tileArchitectural engineering

The invention relates to the technical field of building houses, and discloses a novel building house structure and an installation and construction technology. The novel building house structure comprises a base and a ground platform, the ground platform is arranged on the base, two side plates are arranged on the upper wall surface of the ground platform, a back plate is arranged between the two side plates, a front plate is arranged on the front sides of the two side plates, a rectangular opening is formed in the middle of the front plate, two movable doors are hinged into the rectangular opening through hinges, a stand column is fixedly arranged at the top of the back plate, a check block is fixedly arranged at the top of the front plate, the cross section of the check block is trapezoidal, a cross beam is arranged between the check block and the stand column, roof tiles connected with the side plates on the two sides are arranged above the cross beam, the number of the roof tiles is set according to the length and size of the house, the roof tiles are in a V shape, and glass is installed in the gaps between the stand columns and the roof tiles on the two sides. The house is of an assembled structure, so that the purposes of convenient installation and convenient transportation are effectively achieved.

Owner:浙江双堰建设有限公司

Construction method of sill-type water-stop sill

ActiveCN111926928BAvoid construction gapsImprove waterproof and anti-seepage performanceSills/thresholdForms/shuttering/falseworksWater stopFloor slab

The invention discloses a construction method for a set-up type water stop, which relates to the technical field of water stop construction, comprising: pre-embedding steel bars in preset positions and arranging two first side formwork side by side, the steel bars are located on the two first side formworks Between, the lower part of the embedded position corresponds to the lower floor slab pouring space, the space between the two first side formwork and the lower floor slab pouring space together constitute the first space to be poured; pour the first concrete into the first space to be poured, two The first concrete between the first side formwork forms the sill core; the two first side formwork and the curing sill core are removed; the surface of the sill core is textured; the second side formwork is arranged on both sides of the sill core, and the second side formwork The inner side is aligned with the edge line of the water stop sill, and the two second side formwork is reinforced by the positioning formwork; the second concrete is poured between the two second side formwork to form the sill; the two second side formwork, the positioning formwork and the curing sleeve are removed Hom. This setting has strong waterproof and impermeability, can calibrate the axis position, and accurately locate the axis.

Owner:NANTONG SIJIAN CONSTR GRP

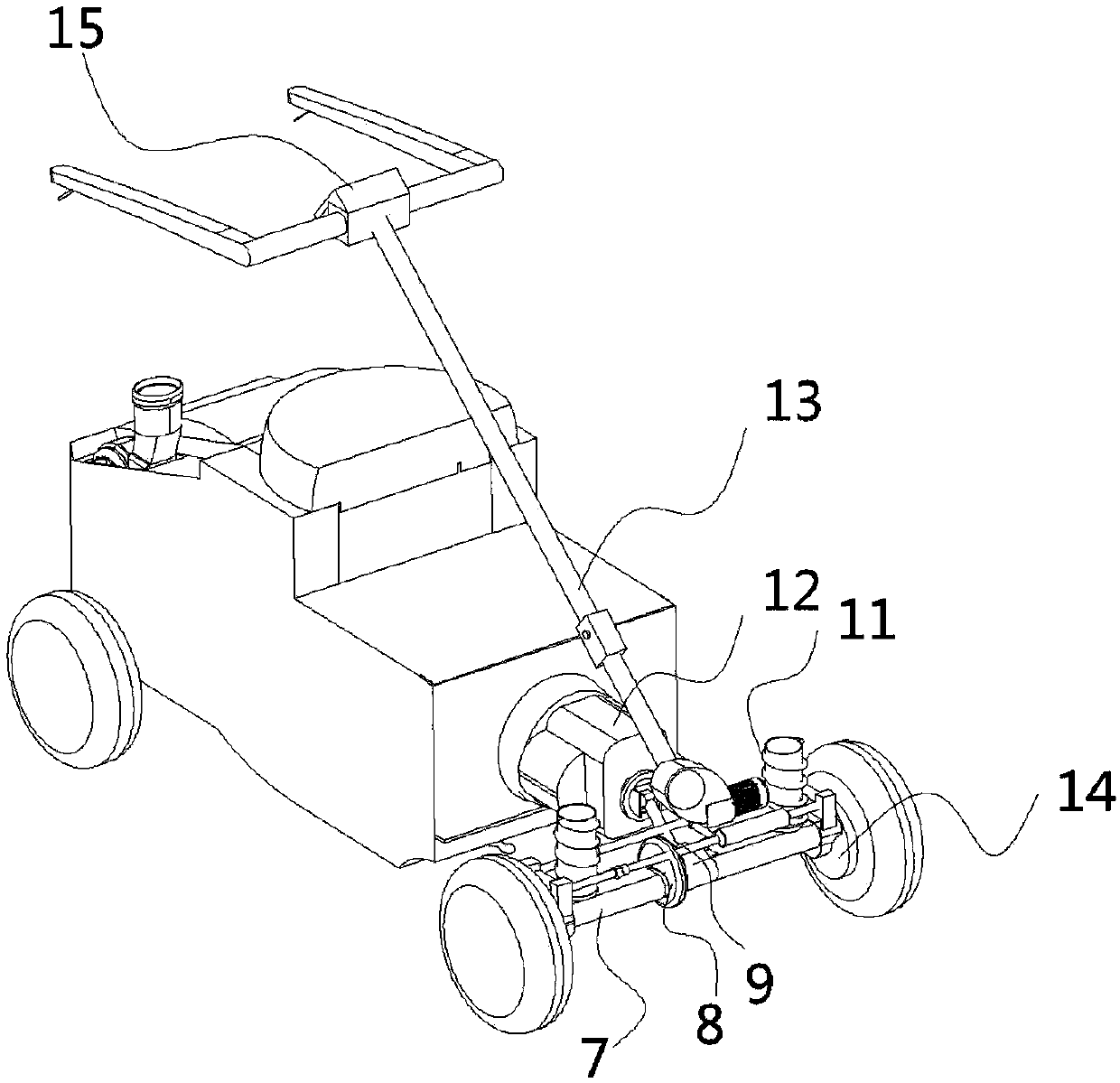

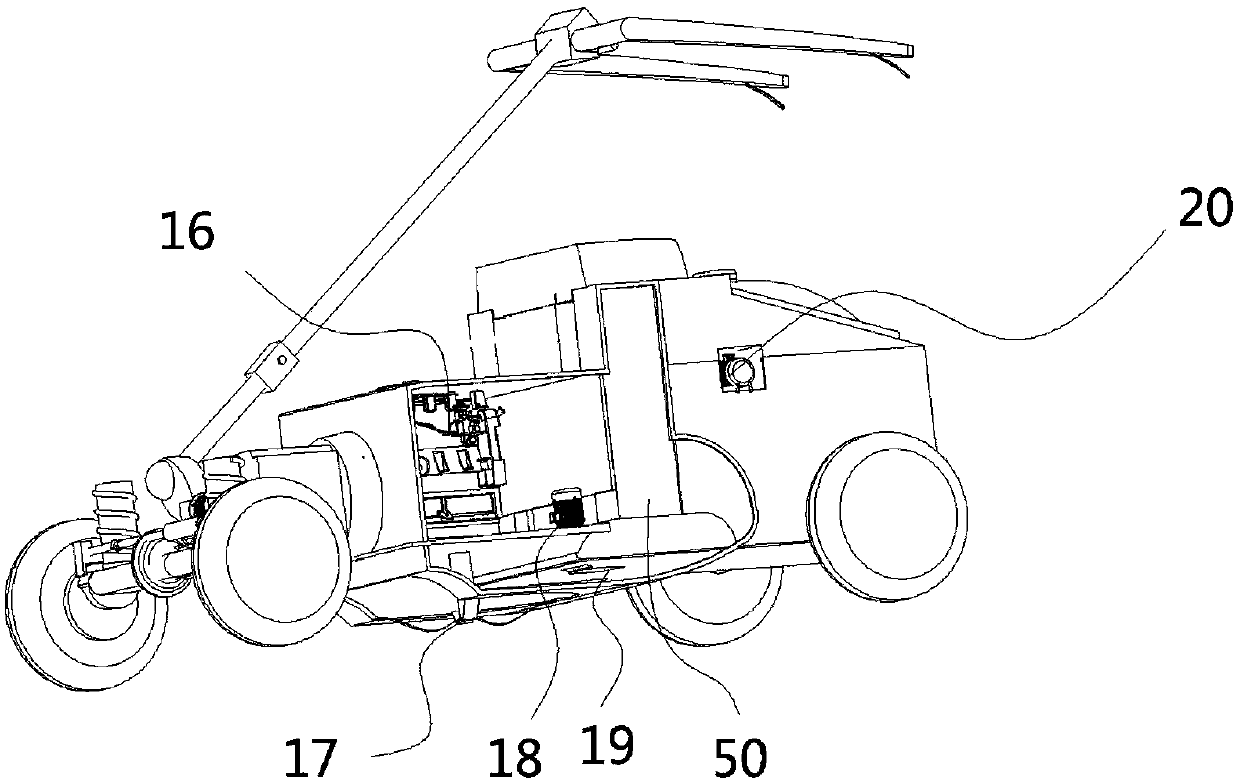

Garden weeding device

Owner:XIAMEN LUBAN ENVIRONMENT ART ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com