Machining method of complex casting with non-circular cross section

A technology of non-circular cross-section and processing method, which is applied in the field of casting processing, can solve problems such as affecting the use of parts, low part yield, and part weight exceeding the design index, so as to reduce product manufacturing costs, improve processing yield, and reduce follow-up cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preferred feasible embodiment is now described in detail in conjunction with the accompanying drawings as follows:

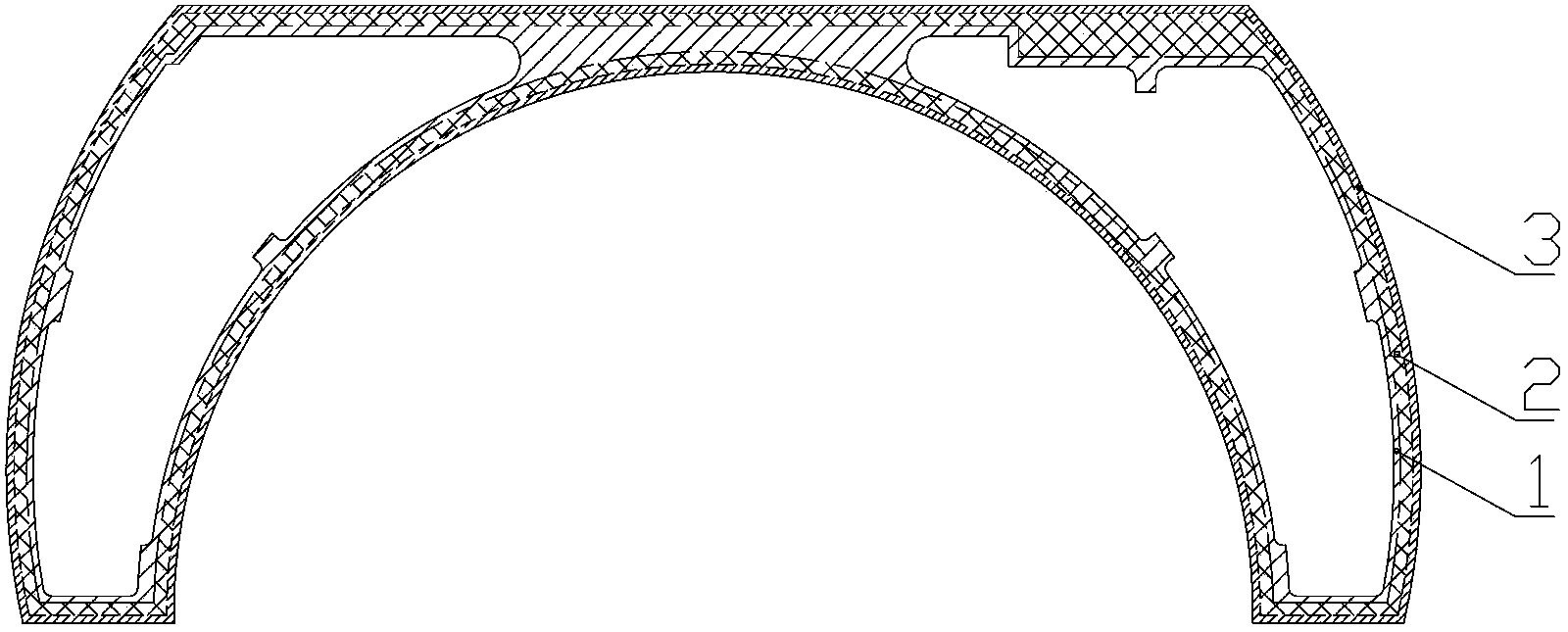

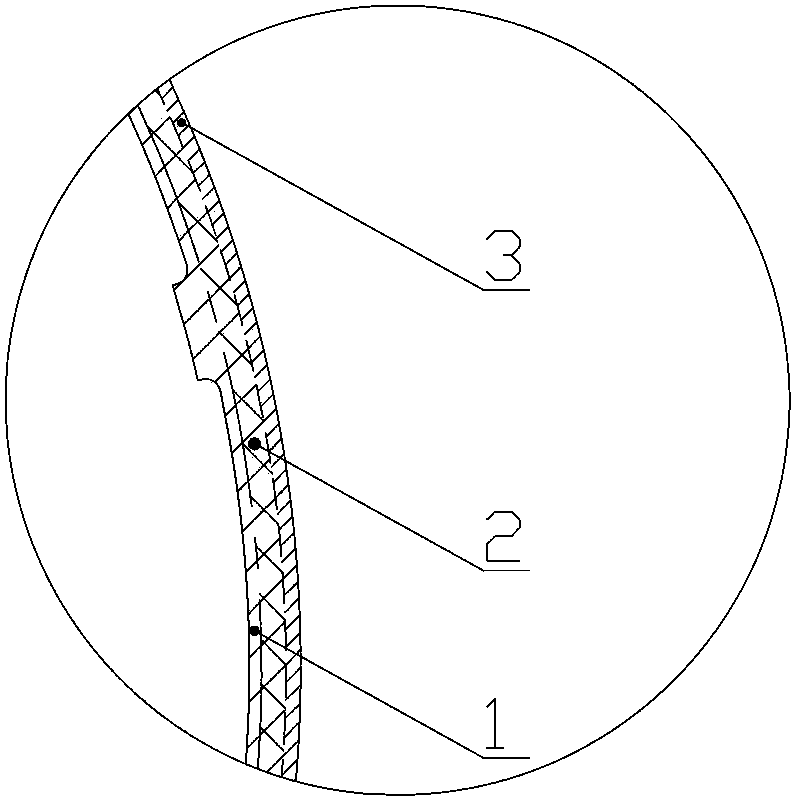

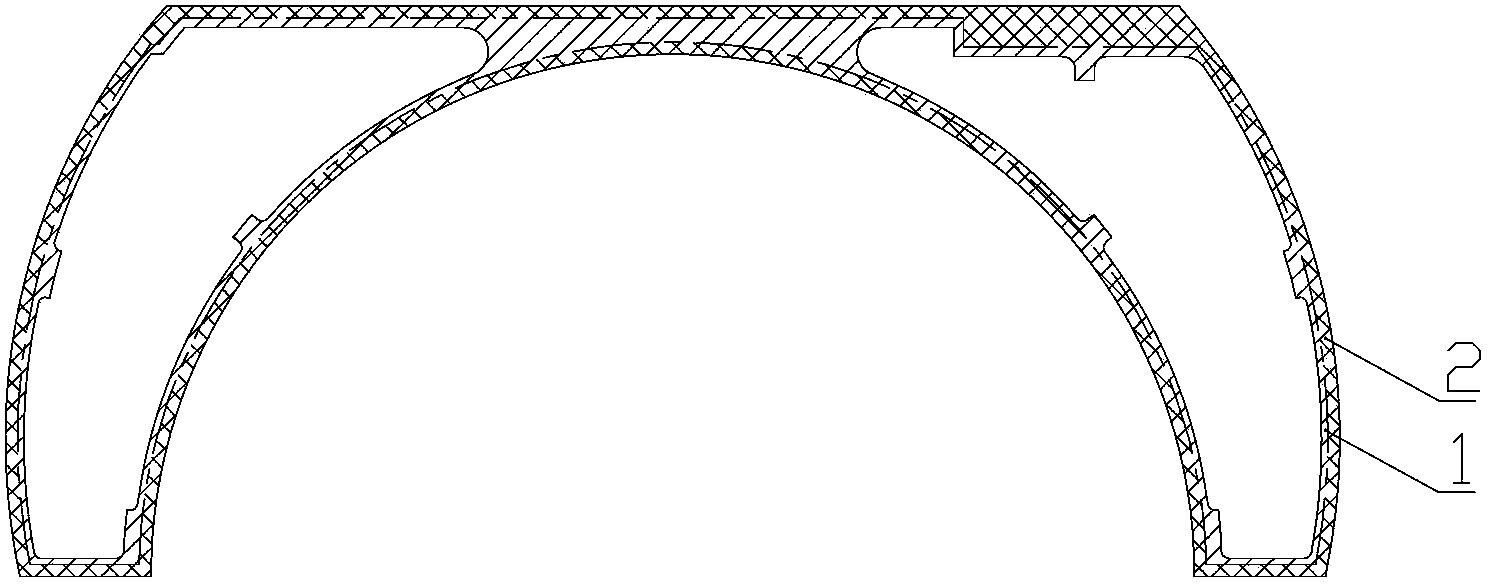

[0032] Take the saddle-shaped aluminum alloy part as a typical part, the material is ZL114A, T6 heat treatment, the length is 1100mm, the typical cross-sectional size is as follows figure 1 As shown, the part is composed of two inner and outer arcs and three planes. The inner cavity is narrow and long, the skin wall thickness is 2.5±0.5mm, the small plane wall thickness is 2.5±0.5mm, the large plane wall thickness is 4±0.5mm, and the outer diameter is R270mm. The inner diameter is R220mm, and the inner and outer arcs are not concentric. Due to the large size of the casting structure and the irregular cross-section, it is easy to shrink the arc surface and twist the plane during casting, heat treatment and subsequent processing. Out-of-tolerance leads to the scrapping of parts, and the qualified rate of parts processing is low.

specific Embodiment approach

[0033] The specific embodiment is carried out according to the following process steps:

[0034] (1) Process margin design: the inner cavity of the part is too small to be machined, the inner cavity surface is directly formed by casting, and the outer surface is all machined surface, such as figure 1 As shown, in addition to increasing the machining allowance +5mm according to the conventional design on the outer surface of the part, a +2mm thick process allowance layer is also added. Theoretical dimensions of the casting: outer diameter R277mm, inner diameter R213mm, skin and facet wall thickness 9.5mm, large plane wall thickness 11mm; according to the casting design drawing, carry out the casting process and casting tooling design, and organize the casting production after the tooling is complete.

[0035] (2) Removal of process allowance: After the casting is cast, there is a certain deviation between the actual size of the casting and the theoretical size. Process margin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com