Device and method for preparing ethylbenzene from ethylene recovered from refinery dry gas by pressure swing adsorption

A technology for refinery dry gas and ethylbenzene, which is applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc. Complex separation process and other problems, to achieve the effect of reducing follow-up operating costs, saving equipment investment, and reducing benzene absorption towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

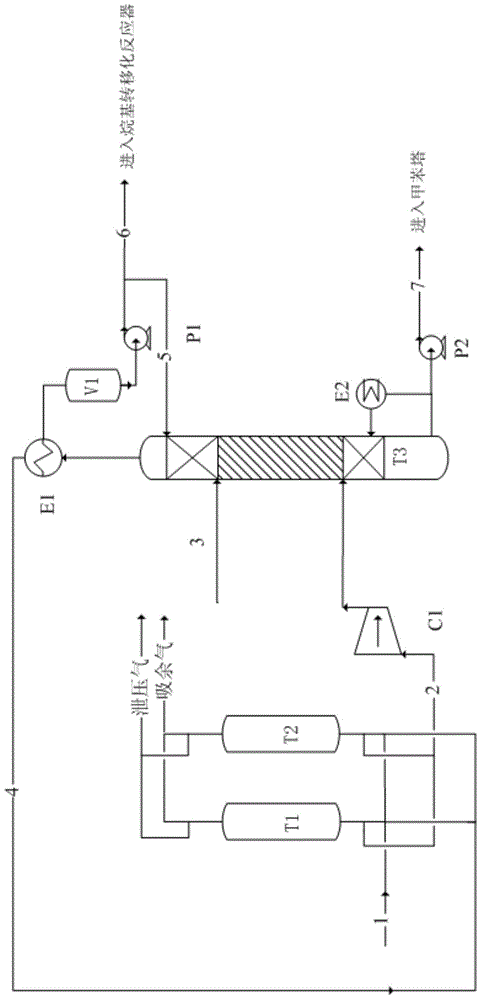

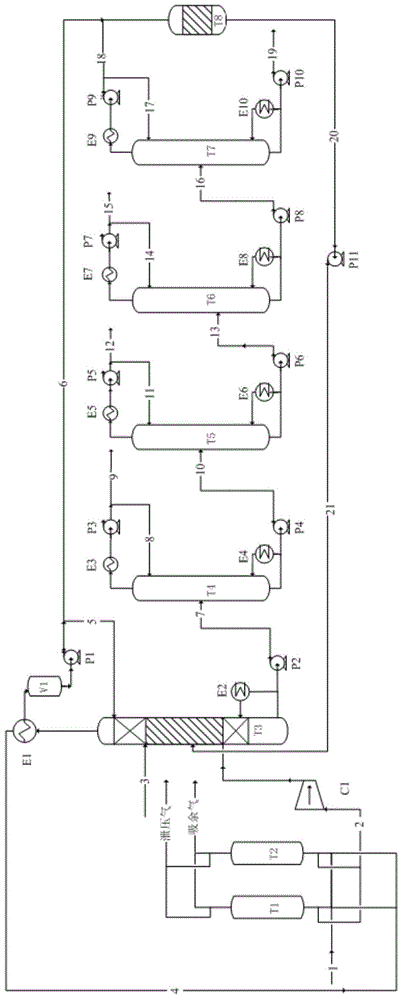

[0024] The method of the present invention is used for refinery dry gas system ethylbenzene and the process of purification, as figure 2As shown, including adsorption tower, catalytic reaction rectification tower, benzene reflux tank, toluene tower, ethylbenzene tower, propylbenzene tower, polyethylbenzene tower, transalkylation reactor, condenser, reboiler, compressor, Pumps and related feed pipelines and pipelines connecting the above equipment; condensers are installed at the top of the catalytic reaction rectification tower, toluene tower, ethylbenzene tower, propylbenzene tower, and polyethylbenzene tower, and reboilers are installed at the bottom of the tower; raw materials The refinery dry gas is connected to the adsorption tower, the material obtained after adsorption and desorption is connected to the inlet of the compressor, the outlet material of the compressor is connected to the lower feed port of the catalytic reaction rectification tower, and the raw material be...

Embodiment 2

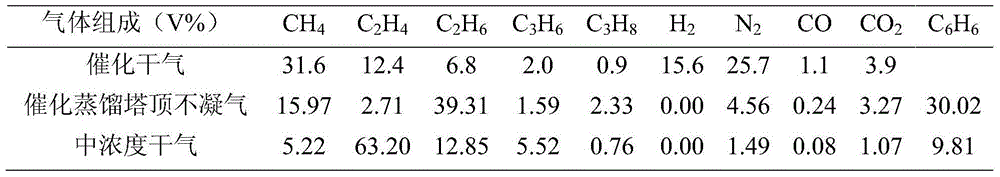

[0032] The method of the present invention is used in the process of refinery dry gas system ethylbenzene, and device is identical with the flow process described in implementation example 1. The temperature during adsorption is 20°C, the adsorption pressure is 0.1MPa, and the volume space velocity is 400 -1 , Desorption adopts the method of vacuuming to 250mmHg; the operating pressure of the catalytic reaction rectification tower is 0.5MPa, the reaction temperature is 250°C, the reflux ratio is 2, and the molar ratio of the total amount of benzene to olefins is 6. The gas composition before and after adsorption and desorption is shown in Table 2.

[0033] Table 2 Gas composition of refinery dry gas before and after adsorption and desorption

[0034]

[0035] After the catalytic dry gas passes through the pressure swing adsorption device, the medium-concentration dry gas is obtained, the concentration of ethylene reaches 53%, and the recovery rate of ethylene reaches 94%. ...

Embodiment 3

[0037] The method of the present invention is used in the process of refinery dry gas system ethylbenzene, and device is identical with the flow process described in implementation example 1. The temperature during adsorption is 50°C, the adsorption pressure is 1MPa, and the volume space velocity is 1500 -1 , Desorption adopts the method of vacuuming to 250mmHg; the operating pressure of the catalytic reaction rectification tower is 1MPa, the reaction temperature is 350°C, the reflux ratio is 10, and the molar ratio of the total amount of benzene to olefins is 7. The gas composition before and after adsorption and desorption is shown in Table 3.

[0038] Table 3 Gas composition of refinery dry gas before and after adsorption and desorption

[0039]

[0040] After the catalytic dry gas passes through the pressure swing adsorption device, the medium-concentration dry gas is obtained, the concentration of ethylene reaches 58.7%, and the recovery rate of ethylene reaches 93.1%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com