Device for measuring material surface by using blast furnace based on multiple input multiple output (MIMO) radar

A technology of radar and material surface, applied in the direction of inspection devices, etc., can solve the problems of multiple laser rangefinders, high cost, and large difference in material surface shape, and achieve high anti-interference ability, high reliability, and high resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

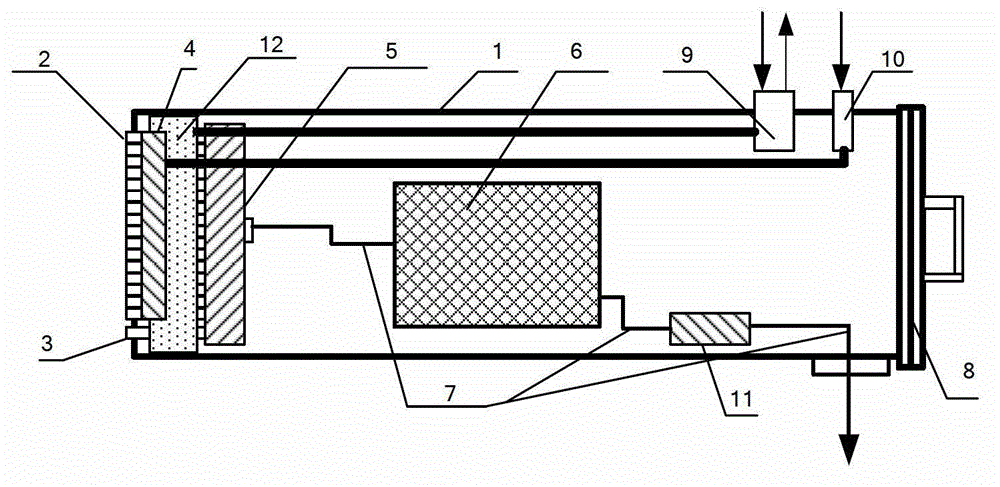

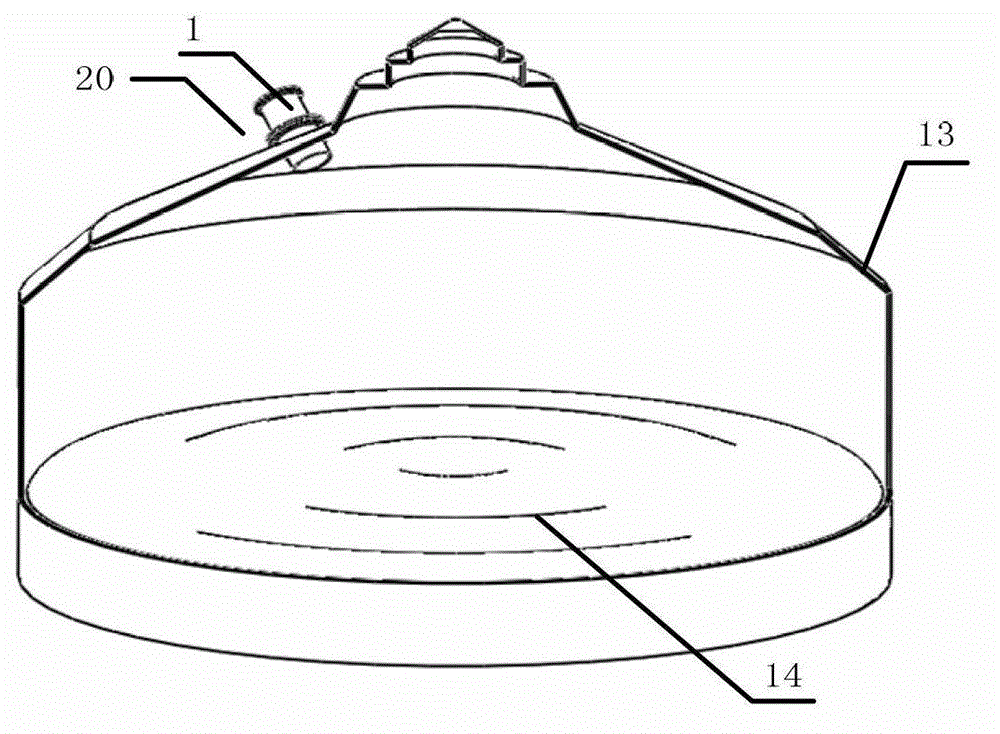

[0040] Examples of the present invention will be described below in conjunction with the accompanying drawings.

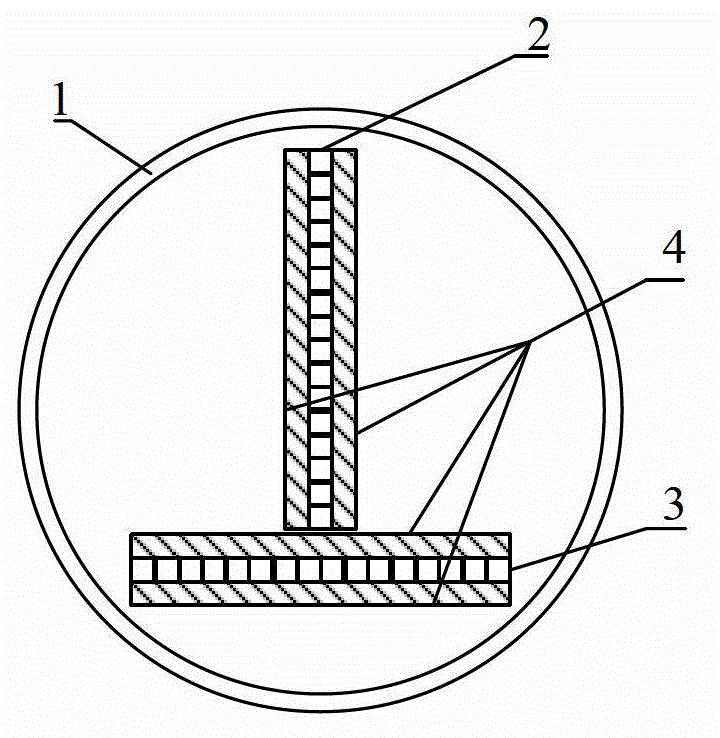

[0041] figure 1 It is a schematic cross-sectional side view of the device of the present invention, wherein the radar protection sleeve 1 of the device of the present invention plays an integral role in protecting the MIMO radar, preventing high temperature and dust and rain impact. In the embodiment of the present invention, the radar sleeve is made of stainless steel. The front end of the barrel is covered with high temperature resistant ramming material to insulate the high temperature in the furnace and protect the sleeve. The main body of the MIMO radar includes a transmitting antenna array 2 and a receiving antenna array 3. The transmitting antenna array 2 and the receiving antenna array 3 form a MIMO array through a T-shaped array or a cross-shaped array. In the embodiment of the present invention, the antenna unit adopts a special high-temperature resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com