Bumper systems for motor vehicles

A technology for bumpers and motor vehicles, which is applied in the field of bumper systems, can solve the problems that the force level cannot be fully predicted, the energy introduction cannot be fully predicted, and cannot be realized, so as to minimize subsequent costs, save resources, and reduce damage. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

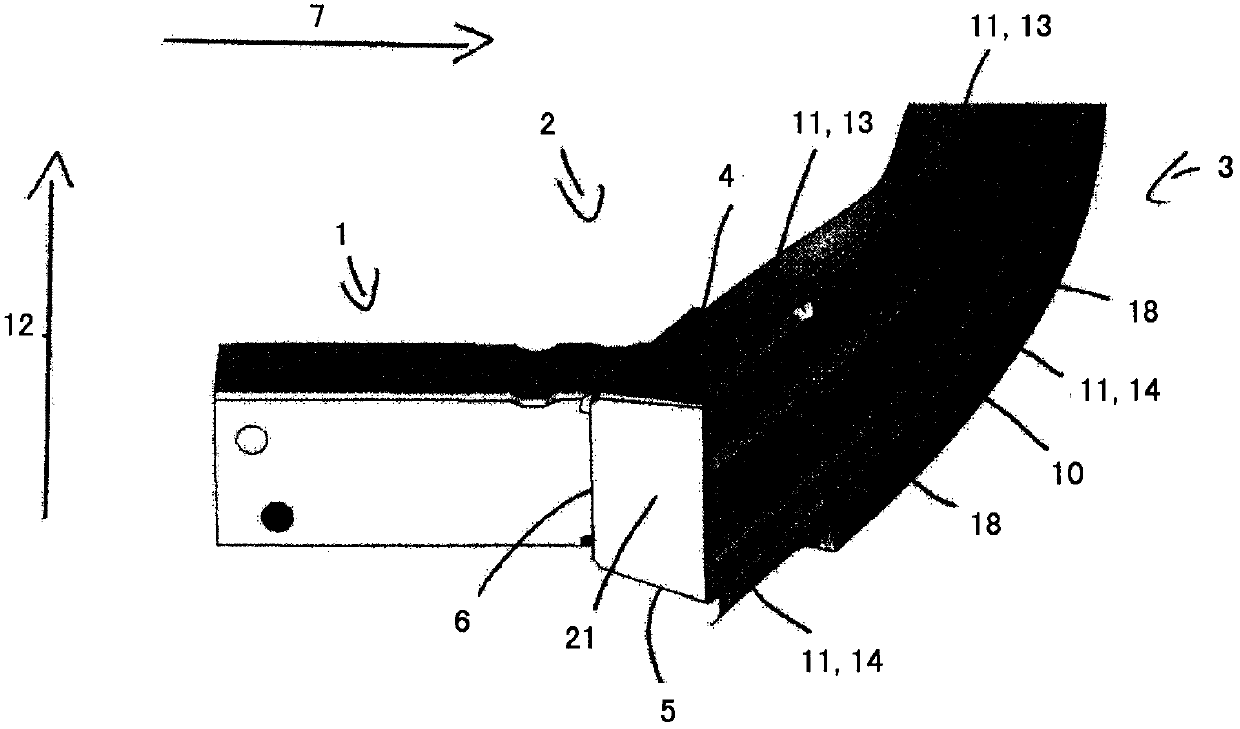

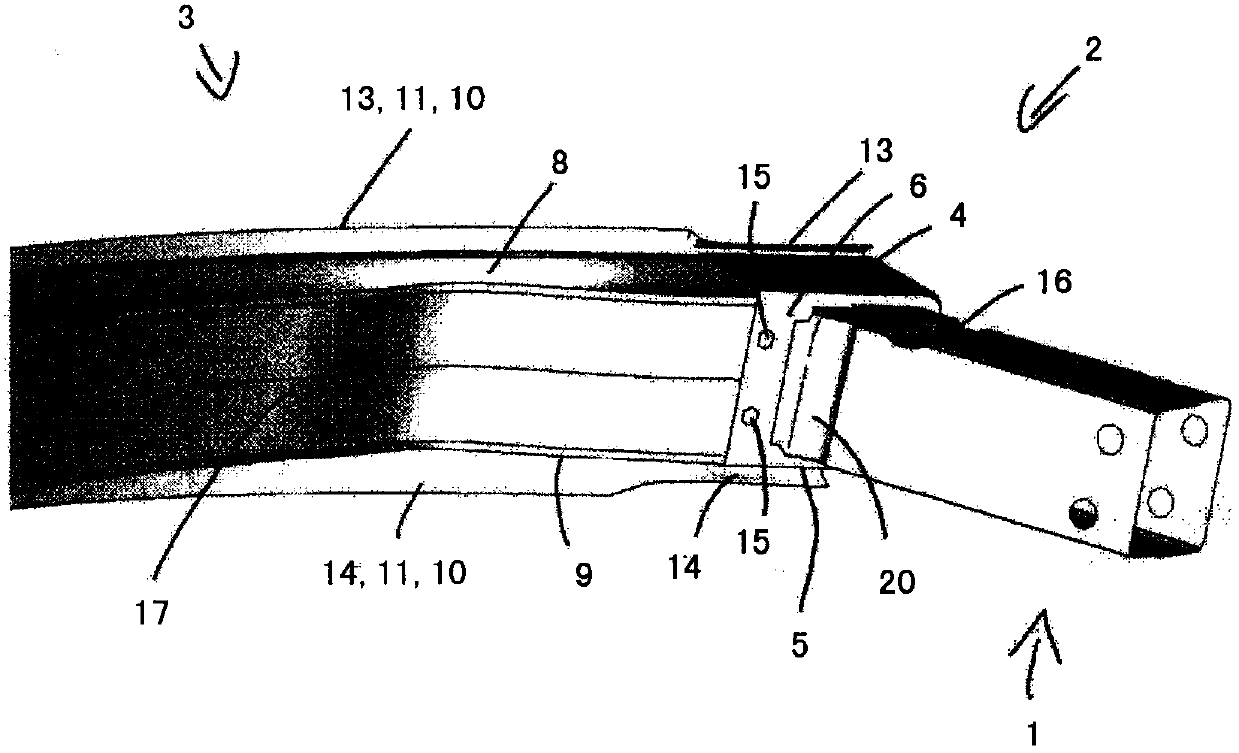

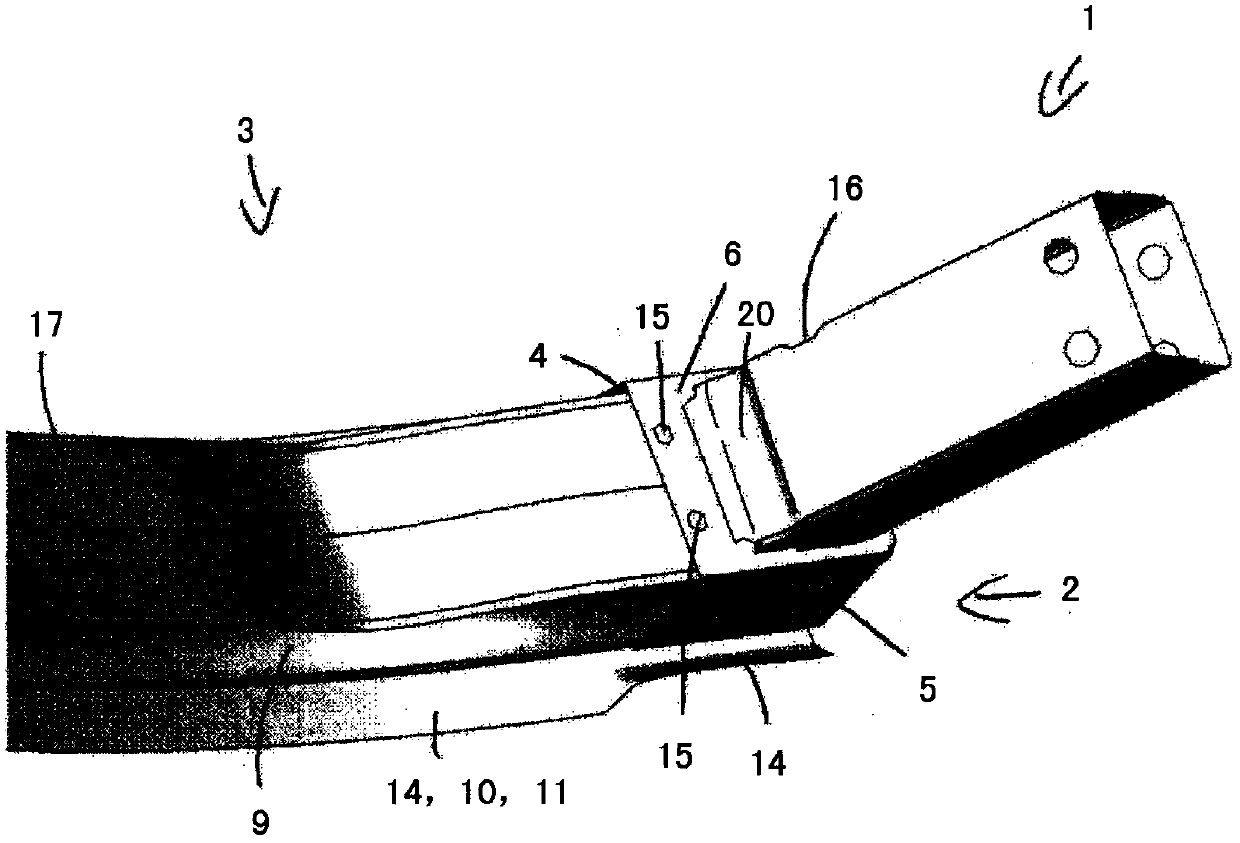

[0028] exist Figure 9 and 10 An exemplary embodiment of a bumper system for a motor vehicle according to the invention is shown in a wireframe model, wherein the bumper system here has a bumper beam 3 which is designed as a multi- Cavity parts. The bumper beam 3 here has an upper boundary wall 8 , a lower boundary wall 9 as well as a bumper beam front wall 10 and a bumper beam rear wall 17 .

[0029] The bumper cross member 3 is here substantially rectangular and is bent or curved over its longitudinal extent. In this case, inside the bumper beam 3 , which is designed as a multi-chamber profile, a corrugated intermediate wall 19 is arranged, which connects the bumper beam front wall 10 to the bumper beam rear wall 17 . In this case, the intermediate wall 19 is arranged in the center of the bumper cross member 3 .

[0030] The bumper beam front wall 10 here has two continuous grooves 18 over its entire longitudinal extent, which increase the stability of the bumper beam 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com