Patents

Literature

35results about How to "No recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

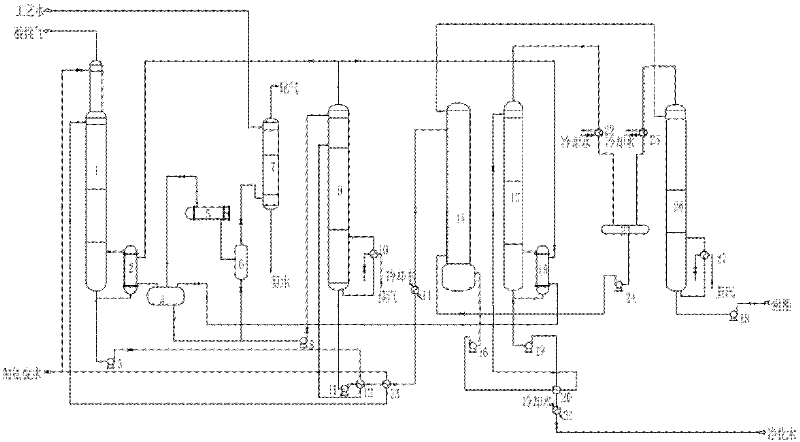

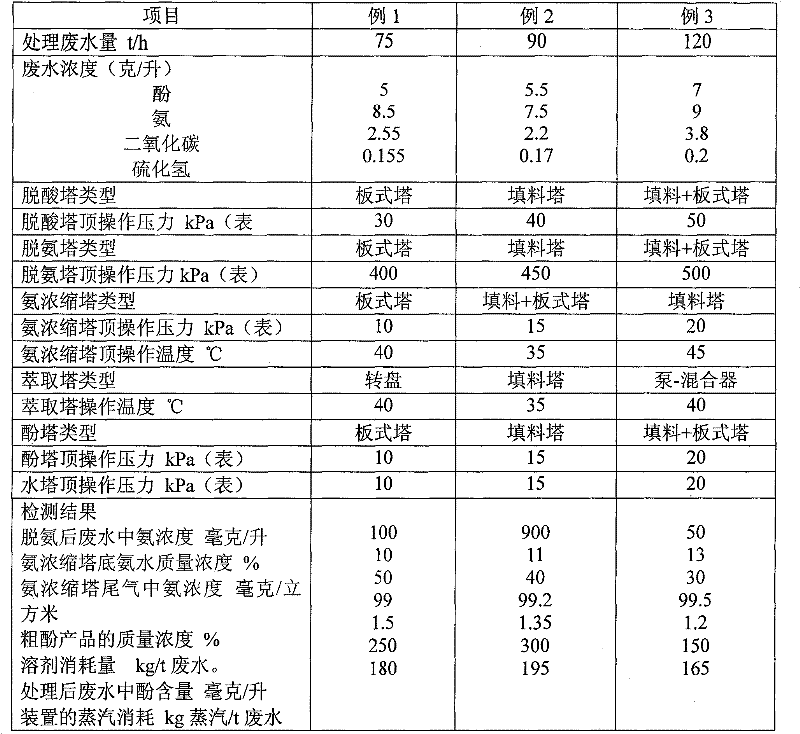

A kind of energy-saving method for recovery and treatment of phenol ammonia wastewater

InactiveCN102259943AEfficient recyclingSolve the technical problems of high energy consumptionChemical industryWater/sewage treatment by heatingCoal gasification wastewaterDifferential pressure

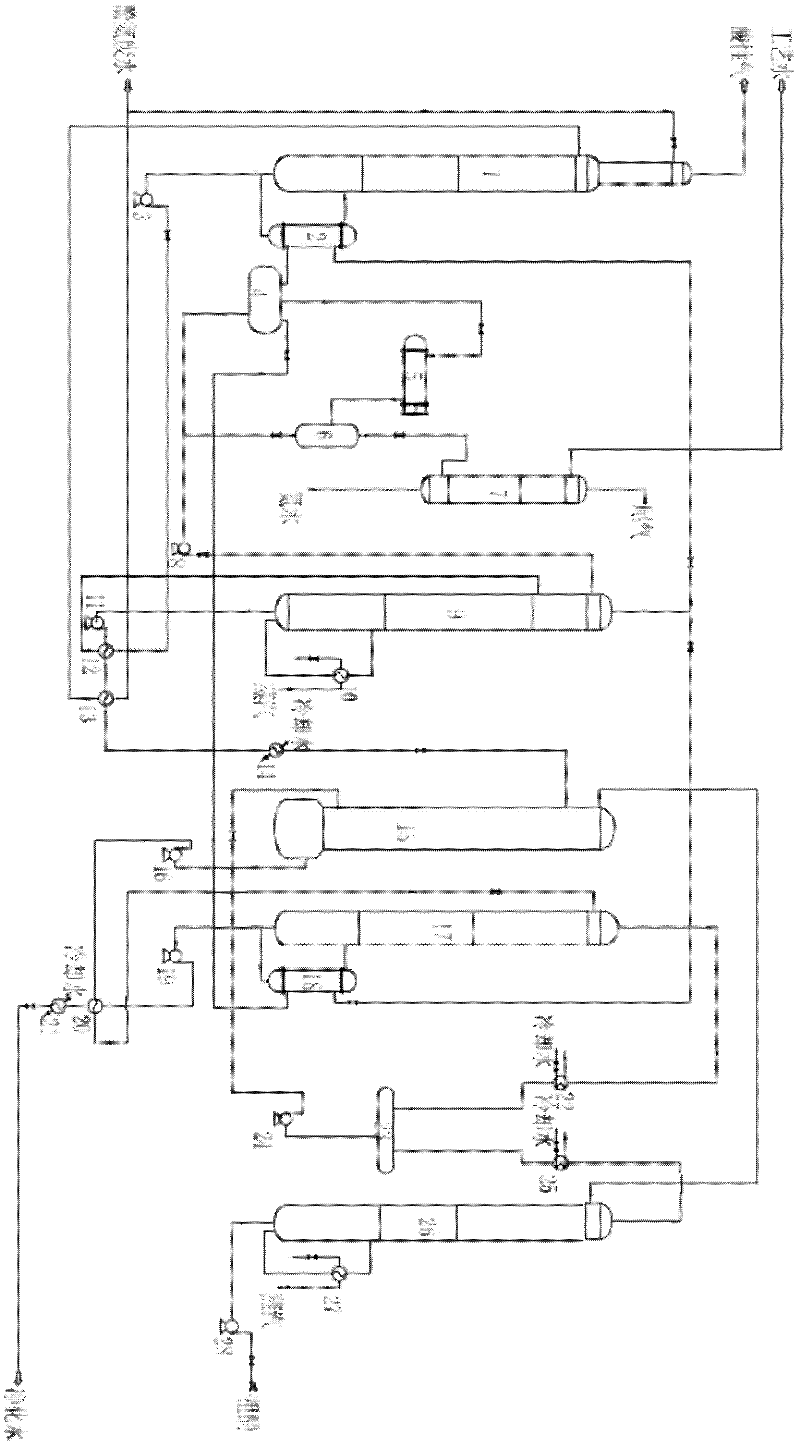

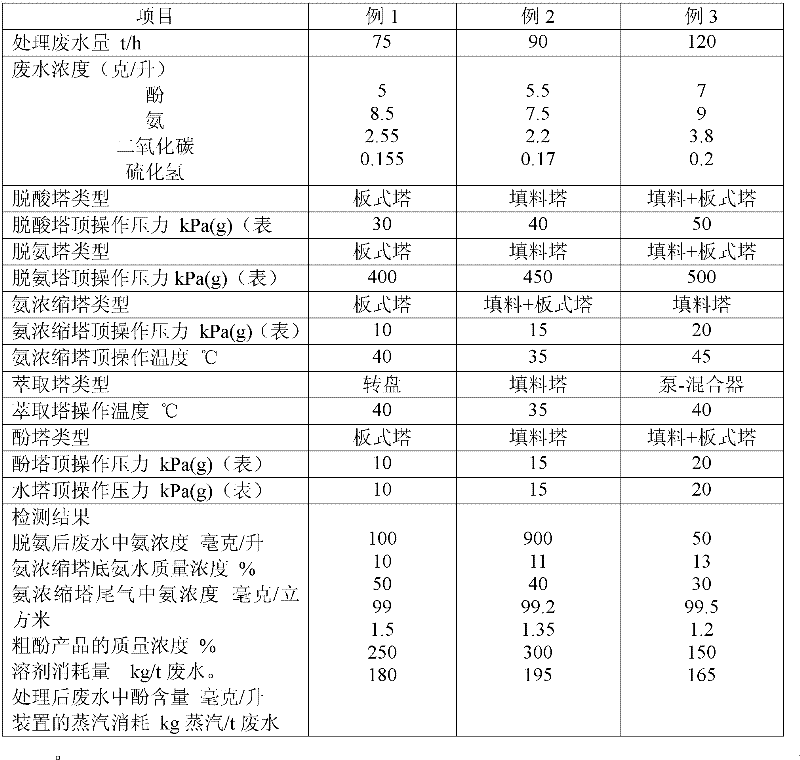

The invention relates to a method for treating wastewater containing phenol and ammonia, in particular to an energy-saving process for recycling the wastewater containing the phenol and the ammonia. Equipment among an acid removing tower, an ammonia removing tower and a water tower is coupled, namely a crude ammonia condenser on the top of the ammonia removing tower is taken as a reboiler of the acid removing tower and the water tower; and a differential pressure rectification technology is utilized, so that the step comprehensive utilization of a heat resource is realized, the energy consumption of wastewater treatment is reduced, and the using amount of steam and circulating water is greatly saved; particularly the equipment is coupled, the differential pressure rectification technologyis utilized and the ammonia and the phenol in the coal gasification wastewater are recycled simultaneously, so that the aims of saving energy and reducing emission in the wastewater treatment and recycling process are fulfilled. The technical problem that the energy consumption is high when the wastewater containing the phenol and the ammonia is recycled in the coal gasification process is solved; and the comprehensive utilization of energy is realized, and the method is high in social value and economic value.

Owner:TIANJIN HAOYONG CHEM TECH

Methyl nitrite regeneration method

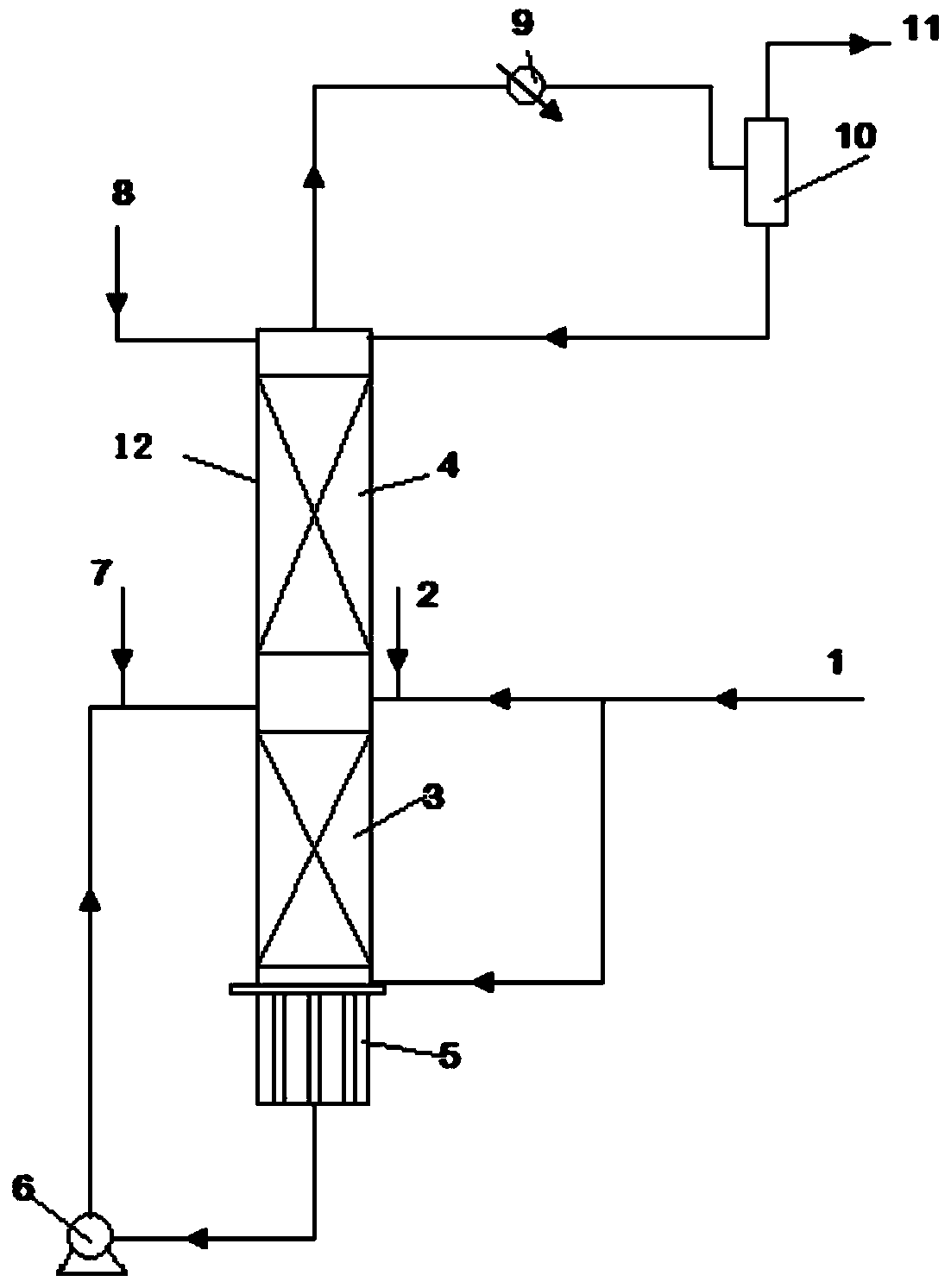

ActiveCN103936591AHigh regeneration rateFull recoveryChemical recyclingNitrous acid preparation ester preparationAlcoholReboiler

The invention discloses a methyl nitrite regeneration method, and is used for solving the problems of low regeneration rate of methyl nitrite, poor operational stability of a system caused by improper side reaction control, increase of operating cost and the like. The methyl nitrite regeneration method comprises the following steps: forming recycled gas containing 5-20% of nitric oxide after synthesis of methyl nitrite and carbon monoxide carbonyl, and entering the recycled gas to a methyl nitrite regeneration reactor in two parts, wherein a small part of recycled gas enters the lower section of the regeneration reactor from the bottom, the rest part of recycled gas and supplementing oxygen gas enter the upper section of the regeneration reactor from the middle part together; spraying fresh methyl alcohol into the tower top of the regeneration reactor, discharging methyl nitrite-containing gas from the tower top, pressurizing tower bottoms led out from the tower by using a pump and entering the tower bottoms to the lower section of the regeneration reactor from the middle part of the regeneration reactor; arranging a reboiler on the tower of the regeneration reactor, filling the lower section of the regeneration reactor with a catalyst, and arranging stuffing and / or a tower plate on the upper section of the regeneration reactor. The methyl nitrite regeneration method is simple in process, low in equipment investment and operating cost and high in regeneration rate of methyl nitrite and can be used for effectively solving the side reaction problem.

Owner:WUHUAN ENG +2

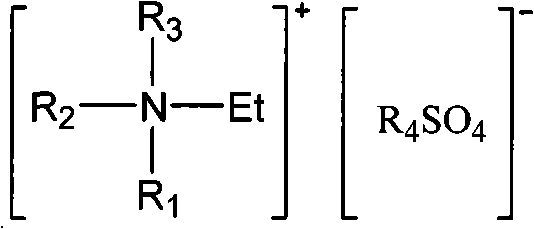

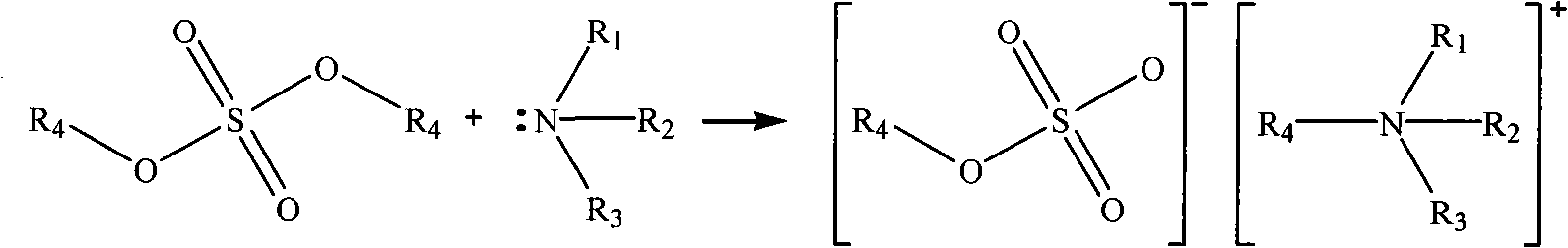

Preparation of sulfuric acid ester ion liquid

InactiveCN101328128AHigh yieldSynthesized in high yieldAmino preparation by functional substitutionAlkyl transferSteam pressure

The invention relates to a method for preparing a sulphuric acid ester ion liquid. The method takes simple amine and sulfuric acid ester as raw materials which are subjected to alkylation in order to synthesize the sulphuric acid ester ion liquid with high selectivity and high yield. The method has the advantages that the raw materials are cheap and available easily, the product has low cost, the synthesizing process is simple, the atom economy is high, the environment protection requirement is met and three wastes are not discharged basically, etc. The sulphuric acid ester ion liquid has the characteristics of the general ion liquid of low steam pressure, good thermal stability, uneasy volatilization, etc. and has industrial application prospect.

Owner:ZHEJIANG UNIV

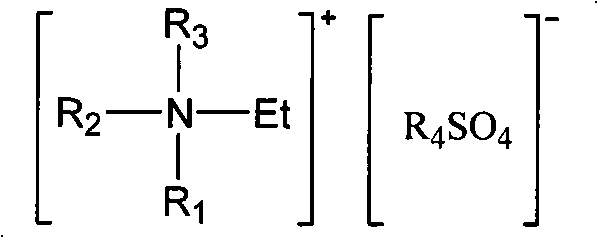

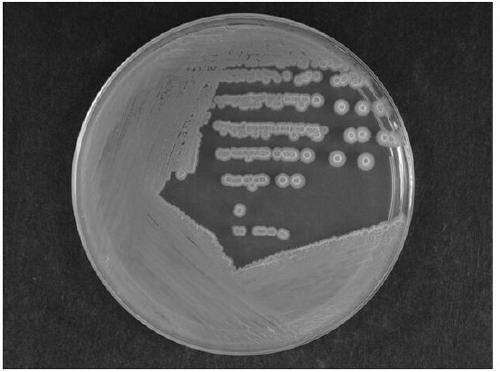

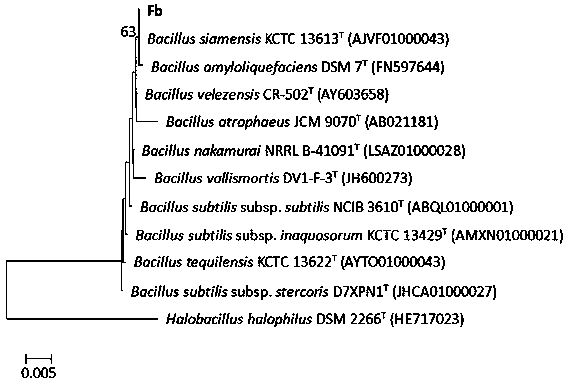

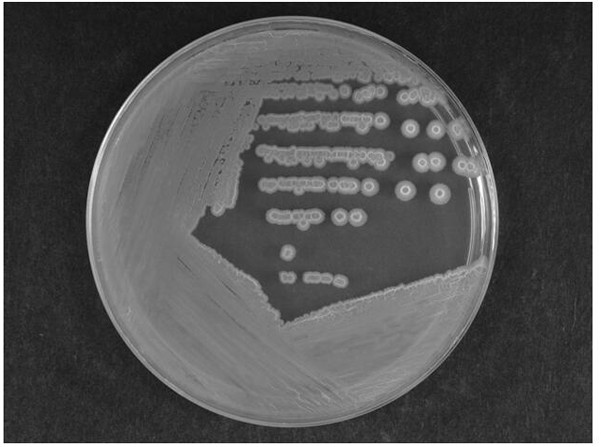

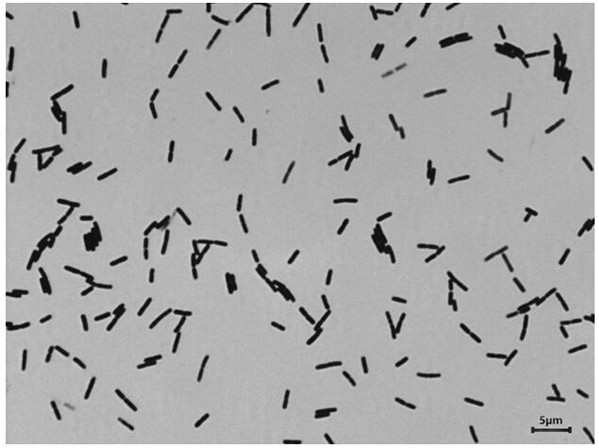

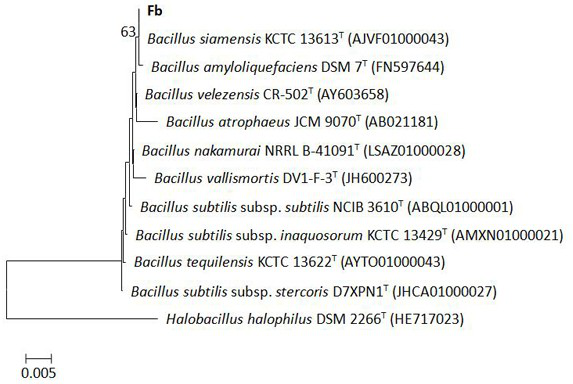

Bacillus velezensis strain and application thereof

ActiveCN111349588AEasy to controlReduce moistureBacteriaMicroorganism based processesBiotechnologyCellulose

The invention discloses a Bacillus velezensis strain and application thereof. The Fb strain is obtained by enrichment culture, primary screening, secondary screening and the like, belongs to the Bacillus velezensis and is gram-positive. The strain is characterized in that: the strain is rod-shaped, 0.4-0.6 microns * 0.9-4.0 microns, and is arranged singly or in pairs; and spores are nearly circular, near-end and cyst is expanded. Through detection, the Bacillus velezensis Fb can resist high temperature of 55 DEG C, the optimal growth temperature is 45 DEG C, and the optimal growth pH value is3.0-7.6. The strain can efficiently degrade tea residues, improve the protein, amino acid and the like of the tea residues and reduce the moisture, cellulose and the like of the tea residues, and thefermented tea residues can be used as a feed raw material; and the strain can realize smokeless, odorless and sewage-free discharge and can realize the cyclic utilization of organic wastes so as to reduce the pollution of the tea residues to the environment, and is a technology which accords with the environmental protection.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

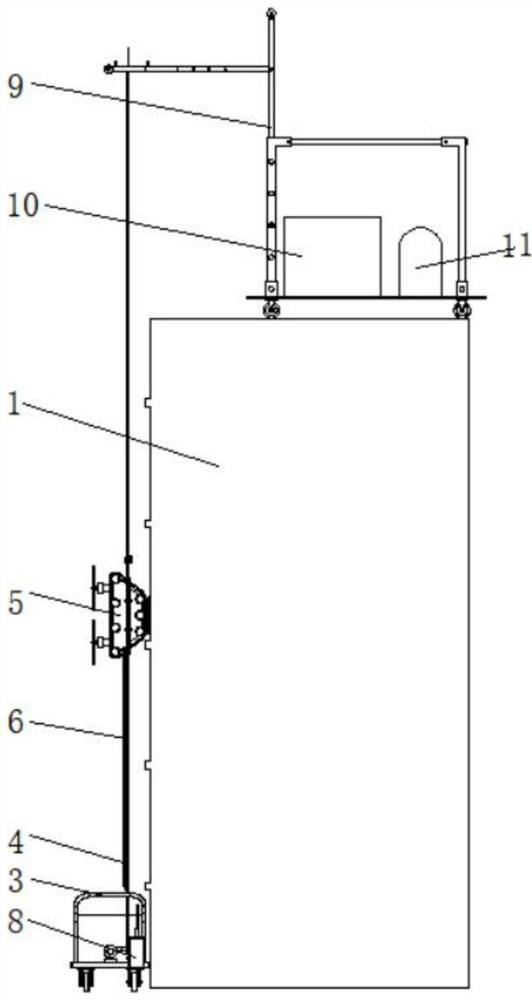

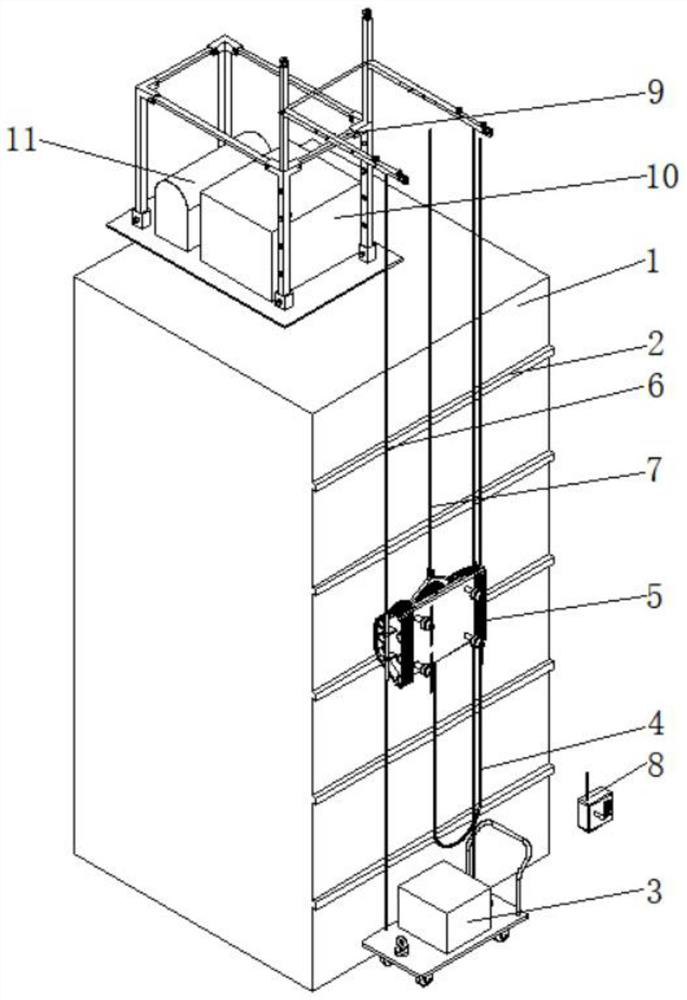

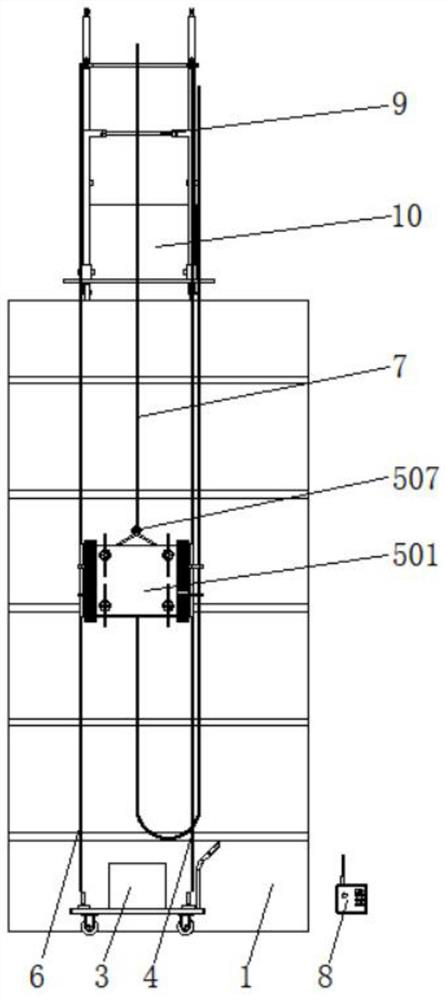

Crawler type obstacle crossing high-rise building external wall cleaning machine

PendingCN111636708ANo recyclingAchieve cleaning effectAutomatic obstacle detectionTravelling automatic controlControl system designArchitectural engineering

The invention relates to the technical field of high-rise building external wall cleaning machines, in particular to a crawler type obstacle crossing high-rise building external wall cleaning machine.The crawler type obstacle crossing high-rise building external wall cleaning machine comprises a high-rise building simplified schematic model and a hand-held remote controller, the front end of theouter wall of the high-rise building simplified schematic model is connected with cross bar obstacles, a building bottom counterweight trolley is mounted at the front ends of the cross bar obstacles,a water and electricity bundled pipe is mounted above the building bottom counterweight trolley, a cleaning machine body is mounted on the upper part of the water and electricity bundled pipe, a steelwire rope lifting rope is connected to the upper part of the cleaning machine body, and nylon rope soft guide rails are mounted on the left side and the right side of the steel wire rope lifting ropecorrespondingly. The crawler type obstacle crossing high-rise building external wall cleaning machine adopts crawler rolling type obstacle crossing, structure and control system design is simple, safety is better achieved during working in the scene with the high-risk environment by adopting the obstacle crossing mode of a mechanical structure, and the practical value and significance are also better achieved; and compared with obstacle crossing realized by a control system and a sensor, the crawler type obstacle crossing high-rise building external wall cleaning machine is more suitable andpractical.

Owner:苏州六翼智能科技有限公司

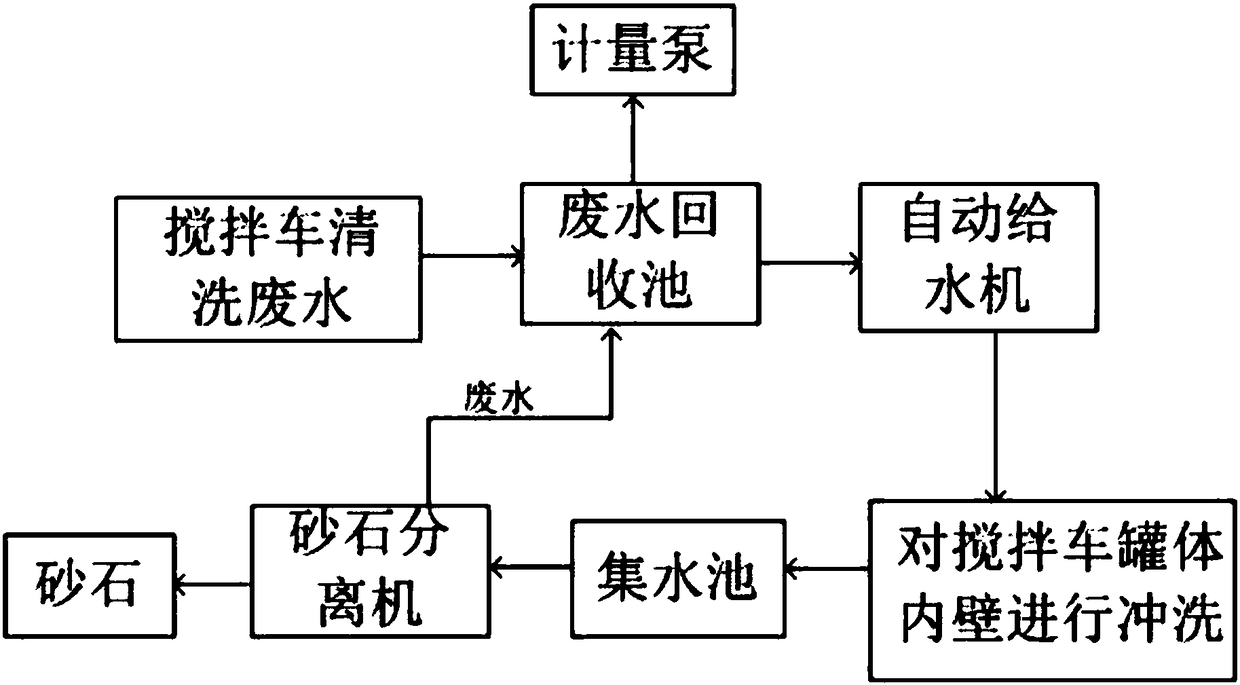

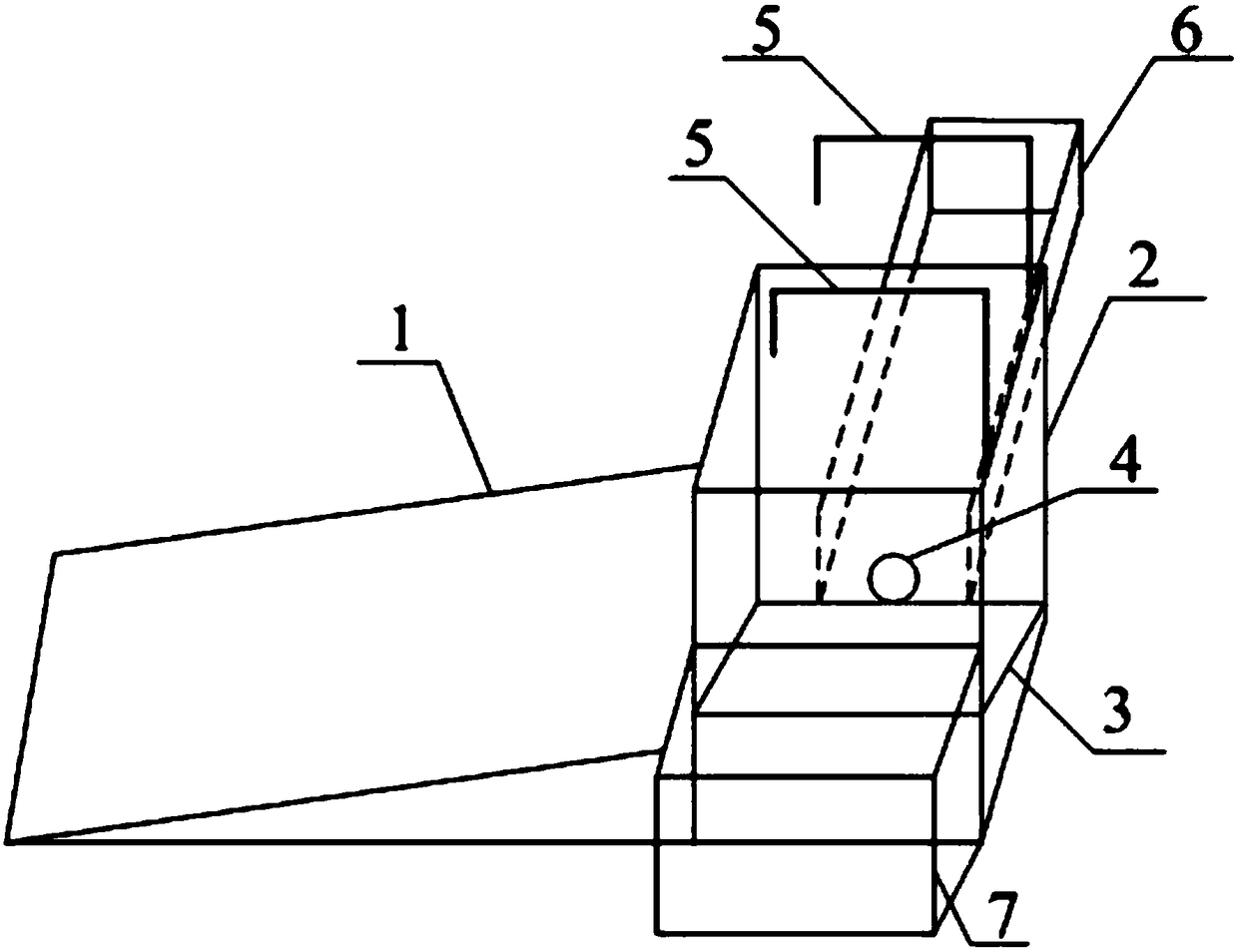

Concrete production system

InactiveCN108212994AImprove production environmentReasonable structural designHollow article cleaningSprayerWater resources

The invention relates to the technical field of concrete, in particular to a concrete production system. The concrete production system is characterized in that the concrete production system comprises a waste water reclaiming pool for collecting the waste water produced after cleaning a concrete mixer, the waste water reclaiming pool is connected with an automatic water feeding machine, the waterfeeding machine is used for cleaning the inner wall of the tank body of the concrete mixer, the waste water produced after cleaning enters a water collection pool, the water collection pool is connected with a sand and stone separator, the separated sand and stones go on to the production working procedure after the waste water is treated by the sand and stone separator, the waste water subjectedto separation enters the waste water reclaiming pool, part of the water in the waste water reclaiming pool enters a metering pump so that the concrete production working procedure can be completed, and the other part of the waste water in the waste water reclaiming pool enters a rinsing sprayer to rinse the inner wall of the tank body of the mixer. With the concrete production system, it can be realized that no waste water or waste residues are emitted, recycling is achieved, the concrete production environment is improved, the waste of water resources and construction raw materials is avoided, the enterprise production cost is reduced, and the concrete production system is suitable for use and promotion.

Owner:嘉兴市旭峰混凝土有限公司

Composting treatment method for waste pig raising fermentation bed

InactiveCN103570392AHigh kill rateNo recyclingBio-organic fraction processingOrganic fertiliser preparationLitterCalcium cyanamide

The invention discloses a composting treatment method for a waste pig raising fermentation bed. The method comprises the following steps of collecting waste fermentation bed litters, mixing the waste litters with straws and weeds, adding calcium cyanamide, laying a layer of straws at the bottom, laying a layer of waste litter mixture, pouring a proper amount of lime water to the waste litter mixture, and covering the waste litter mixture for 10 days by using mud. The composting treatment method for the waste pig raising fermentation bed is free of pollution and odor and high in pest egg and weed seed killing rate, and has high popularization value in the field of modern agriculture; a composting product can be recycled.

Owner:太仓市双凤勤之立生态养殖场

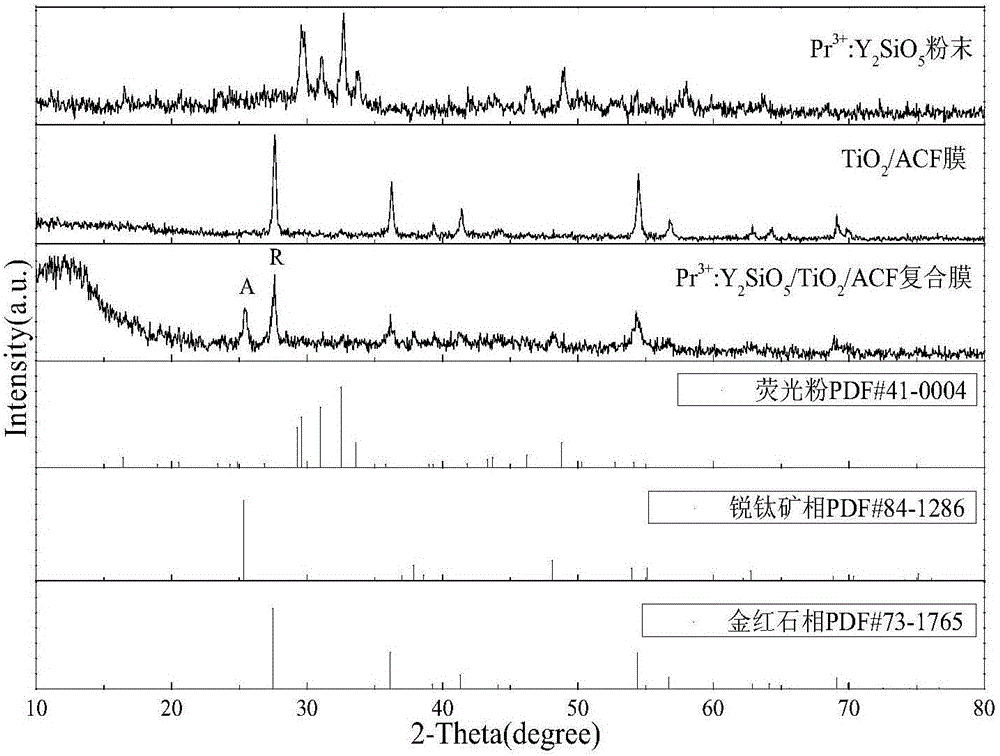

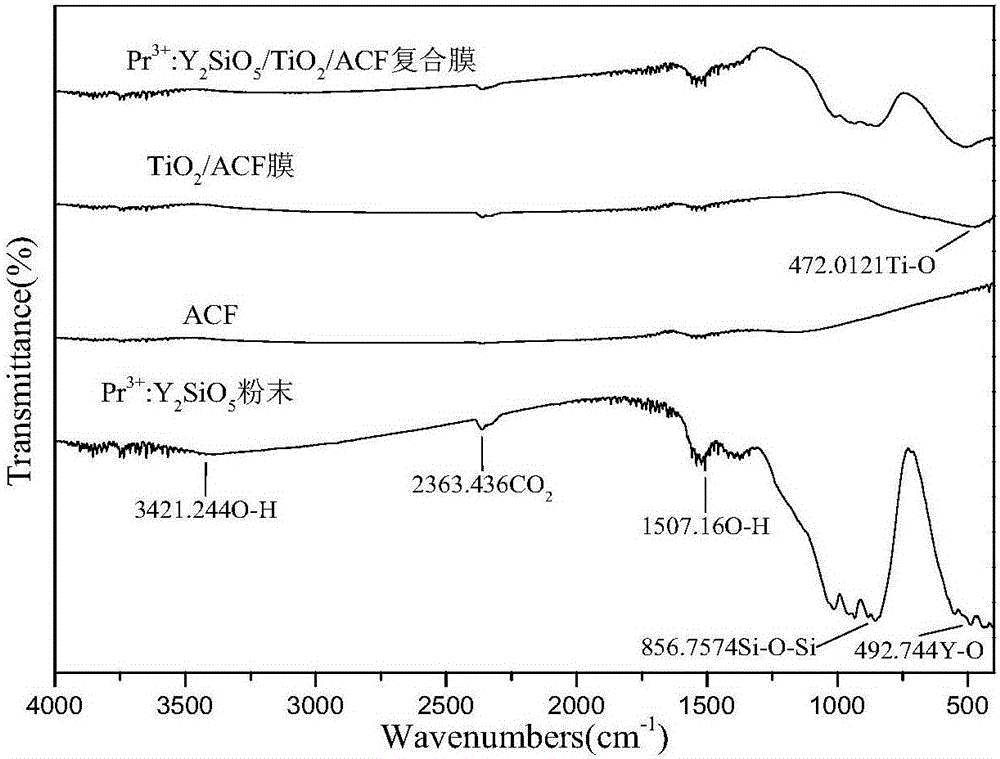

Pr<3+>:Y2SiO5-TiO2-ACF visible-light response type photocatalytic composite membrane and preparation method thereof

InactiveCN106140132AImprove photocatalytic performanceGood chemical stabilityWater/sewage treatment by irradiationWater treatment compoundsChemistryActivated carbon

The invention discloses a Pr<3+>:Y2SiO5-TiO2-ACF visible-light response type photocatalytic composite membrane and a preparation method thereof. The composite membrane is prepared by loading nano-TiO2 doped with Pr<3+>:Y2SiO5 to the surface of an activated carbon fiber. The composite membrane can solve the separating and recycling problems of a catalyst obtained after pollutant treatment and also can reuse the catalyst, and meanwhile a substrate enrichment environment can be generated on the surface of TiO2 through the high adsorption property of the activated carbon fiber, so that the contact chance of the catalyst and the pollutants is increased; accordingly, the prepared Pr<3+>:Y2SiO5-TiO2 composite material based on the activated carbon fiber carrier can achieve a synergistic effect of adsorption and photocatalysis, improve the pollutant removing efficiency and particularly achieves a good effect when the composite material is used for visible-light catalytic degradation on methylene blue.

Owner:NANJING UNIV OF SCI & TECH

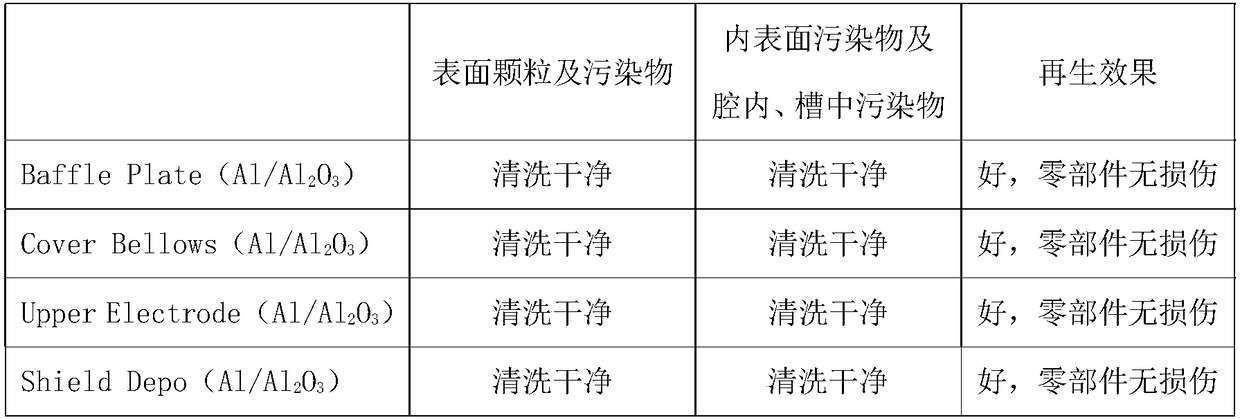

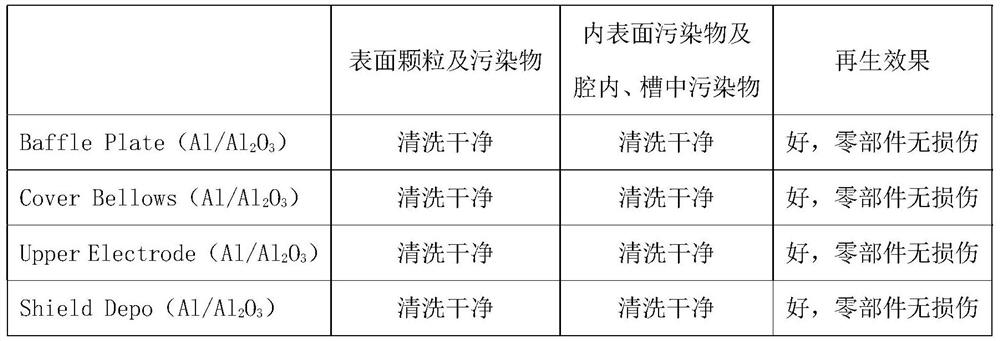

Regenerating method for Al/Al2O3 part of TD/DRM process of semiconductor 8-inch wafer film process

ActiveCN108573855AFast migrationLow viscositySemiconductor/solid-state device manufacturingEnvironmental resistanceThermal energy

The invention relates to a regenerating method for an Al / Al2O3 part of a TD / DRM process of a semiconductor 8-inch wafer film process. The method comprises the steps that dry ice particles are sprayedand cleaned to regenerate the surface of the part; local temperature difference change formed by thermal energy absorption of dry ice during a sublimation process is used to generate a 'shear stress'between a substrate and a cleaned object, and the cleaned object is quickly peeled off from the surface of the substrate; a Venturi nozzle can generate a carbon dioxide gas stream containing more dryice particles; ultrasonic assisted supercritical CO2 cleaning regenerates the inner surface, the chamber and the groove of the part; and supercritical CO2 easily penetrates into the micropores and thechamber or groove of the part to dissolve pollutants, so that the pollutants migrate fast in supercritical CO2 to achieve the purpose of cleaning. Ultrasonic assisting further improves the cleaning effect and efficiency. The regeneration time and cost are shortened. The regenerating method has the advantages of simple process, environmental protection, being pollution-free and good regeneration effect, does not damage the semiconductor part, and has no impact on the performance of the part.

Owner:苏州珮凯科技有限公司

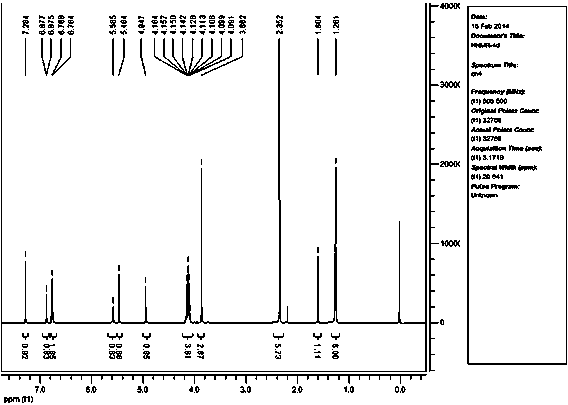

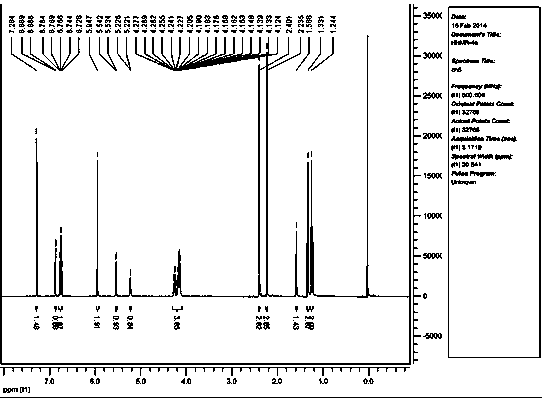

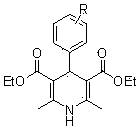

Preparation method of 1, 4-dihydropyridine compound

InactiveCN104030973ASimple operationDoes not pollute the environmentOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEthyl acetateAldehyde

The invention discloses a preparation method of a 1, 4-dihydropyridine compound, the structural formula of which is shown as in the specification, wherein R is -H, 2-OH, 3-NO2, 4-OCH3, 4-CH3, 4-F, 3-OCH3-4-OH or 3, 4-OCH2O. The preparation method comprises the following steps: in the presence of an ionic liquid SiPIPPWO, carrying out a reaction on aromatic aldehyde, ethyl acetoacetate and ammonium acetate for 3-4 hours at 80 DEG C; and after reaction, cooling to room temperature, adding ethyl acetate, filtering to remove the ionic liquid SiPIPPWO, rotatably distilling the filtrate to remove the solvent and recrystallizing by 95% ethanol to obtain the 1, 4-dihydropyridine compound. The preparation method is high in yield which can reach 82-90%, and the ionic liquid is low in cost and easy to obtain, free from environmental pollution, easy to recover and use and simple in post-treatment of products.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

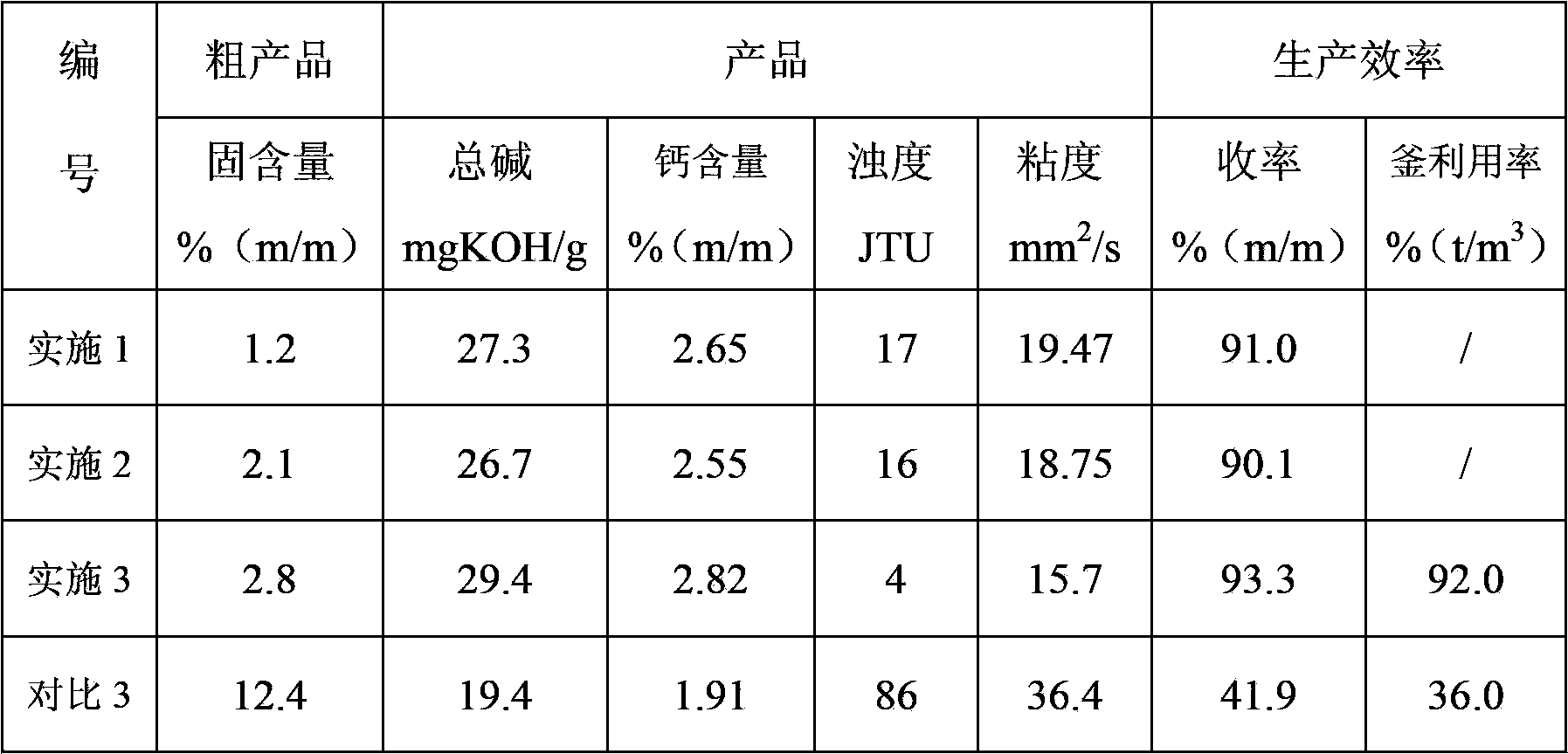

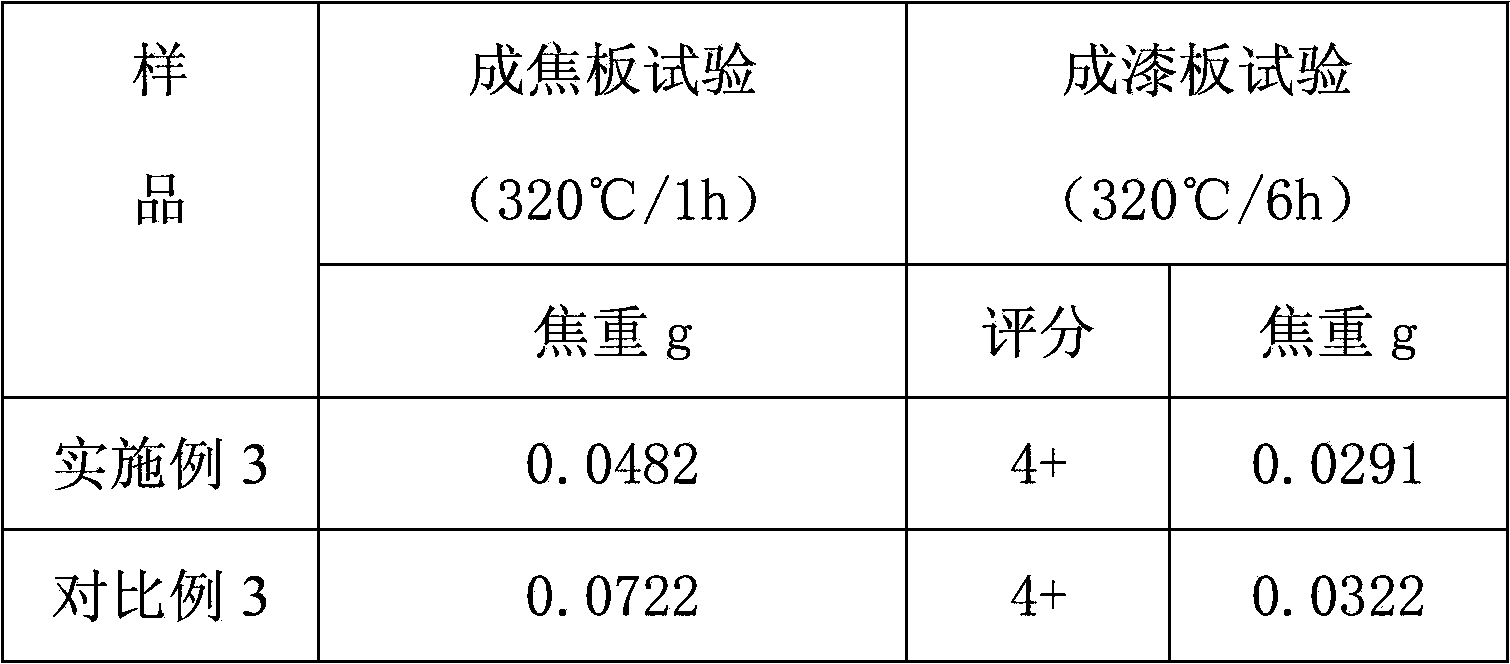

Production method of low-alkali-value sulfonate clearing agent

ActiveCN103694148ANo recyclingEnvironmental protection does not existOrganic compound preparationSulfonic acids salts preparationSulfonateSlag

The invention relates to a production method of a low-alkali-value sulfonate clearing agent. The production method comprises the steps: mixing uniformly 100 parts by weight of sulfonic acid containing 40-60 wt% of a dilute oil, 5 to 10 parts by weight of a metal oxide or 20 to 50 parts by weight of a metal hydroxide and water, carrying out a metallization reaction in the temperature range of the room temperature to 100 DEG C, then carrying out flash evaporation drying, carrying out slag removal and refining, and thus obtaining the low-alkali-value sulfonate clearing agent having transparent appearance and the oily total base value of less than 50 mgKOH / g. The method has simple technological process, not only has no need of a solvent recovery technological step, but also enables the synthetic yield to reach 90% (m / m) or more, enables the single-kettle utilization rate to be up to 90% (t / m<3>) or more, and is an environmental-protection production method for high-efficiency preparation of the low-alkali-value sulfonate clearing agent.

Owner:PETROCHINA CO LTD

Energy-saving method for recycling wastewater containing phenol and ammonia

InactiveCN102259943BNo recyclingAchieve recyclingChemical industryWater/sewage treatment by heatingCoal gasification wastewaterReboiler

The invention relates to a method for treating wastewater containing phenol and ammonia, in particular to an energy-saving process for recycling the wastewater containing the phenol and the ammonia. Equipment among an acid removing tower, an ammonia removing tower and a water tower is coupled, namely a crude ammonia condenser on the top of the ammonia removing tower is taken as a reboiler of the acid removing tower and the water tower; and a differential pressure rectification technology is utilized, so that the step comprehensive utilization of a heat resource is realized, the energy consumption of wastewater treatment is reduced, and the using amount of steam and circulating water is greatly saved; particularly the equipment is coupled, the differential pressure rectification technologyis utilized and the ammonia and the phenol in the coal gasification wastewater are recycled simultaneously, so that the aims of saving energy and reducing emission in the wastewater treatment and recycling process are fulfilled. The technical problem that the energy consumption is high when the wastewater containing the phenol and the ammonia is recycled in the coal gasification process is solved; and the comprehensive utilization of energy is realized, and the method is high in social value and economic value.

Owner:TIANJIN HAOYONG CHEM TECH

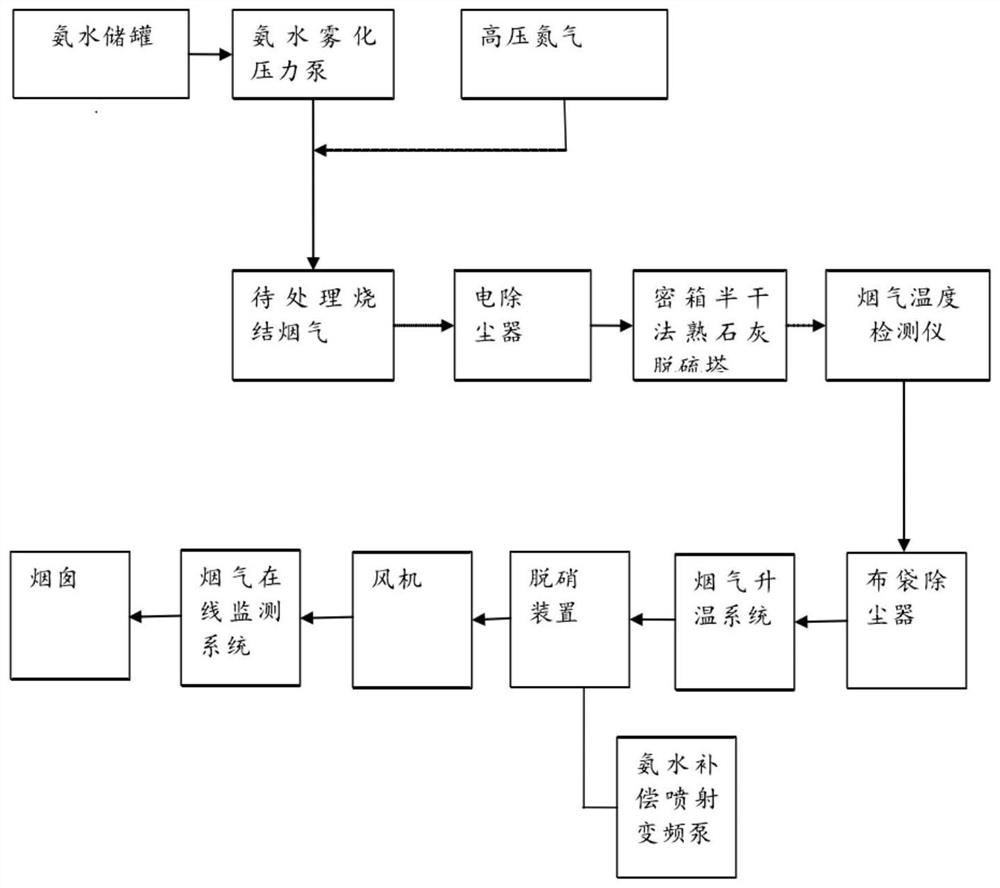

Sintering flue gas treatment method

PendingCN112337281ANo enrichment problemNo recyclingCombination devicesGas treatmentSulfur dioxideFlue gas

The invention provides a sintering flue gas treatment method which comprises the following steps: mixing atomized ammonia water with sintering flue gas to be treated for primary desulfurization to obtain primary desulfurized sintering flue gas; making the primary desulfurized sintering flue gas contact with hydrated slaked lime for secondary desulfurization to obtain secondary desulfurized sintering flue gas; enabling the secondary desulfurization sintering flue gas to enter a first dust removal device for first dust removal; and enabling the secondary desulfurized sintering flue gas subjectedto the first dust removal to enter a denitration device for denitration treatment, and then conducting discharging after reaching the standard. The content of sulfur dioxide discharged into the atmosphere is 10-20 mg / Nm<3>, the content of NOx is 20-30 mg / Nm<3>, the content of dust is 2-3 mg / Nm<3>, ultra-low emission is achieved, and environmental friendliness is achieved.

Owner:BEIJING SHOUGANG CO LTD

Method for removing nonhydratable phospholipid in soybean crude oil with saturated steam

InactiveCN101962597AReduce contentNo recyclingFatty-oils/fats refiningEdible oils/fatsOil and greaseHigh energy

The invention relates to a method for degumming grease by introducing saturated steam into hydrated degummed oil. Liquid-state H2O is changed into gas-state H2O by heating; hydrogen bonds among H2O molecules are damaged to expose H atomic nucleuses and achieve proton similar effect and extremely high energy; metallic ions in nonhydratable phospholipid are damaged to dissociate the phospholipid and divalent metal ions; simultaneously, gas-state water is changed into liquid-stage water due to condensation effect and generated alpha-phospholipid can be removed by a hydration degumming method. The nonhydratable phospholipid is removed by a steaming process by the following steps of: heating the hydrated degummed oil at a certain stirring speed; introducing a certain amount of saturated steam; and performing nonhydration degumming, wherein phosphorus content is 17.9 mg / kg after degumming. Compared with other methods, the method has the advantages that: chemical reagents are not added during steam degumming and residues are not produced.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Dry separation method of waste paper-plastic composite wallpaper

The invention discloses a dry separation method of waste paper-plastic composite wallpaper and relates to the correlated technical field of waste paper recovery. The dry separation method of the wastepaper-plastic composite wallpaper comprises the following steps: (1) sorting the waste paper-plastic composite wallpaper according to the color depth; (2) crushing the waste paper-plastic composite wallpaper by a crushing machine; and (3) performing primary separation, secondary separation and tertiary separation so as to realize thorough separation and efficient recovery. The whole process is completely not in contact with water, subverts the traditional technology and industrial methods, avoids the waste of water resources, and avoids the harm to the environment caused by massive water pollution due to wastewater and sewage discharge, the separation method is simple, the separation equipment is simple in use, the separation process is simple in operation and is not complicated, the investment cost is reduced, and the investment cost for waste paper-plastic product recovery is greatly lowered.

Owner:安徽省昌泰再生资源有限公司

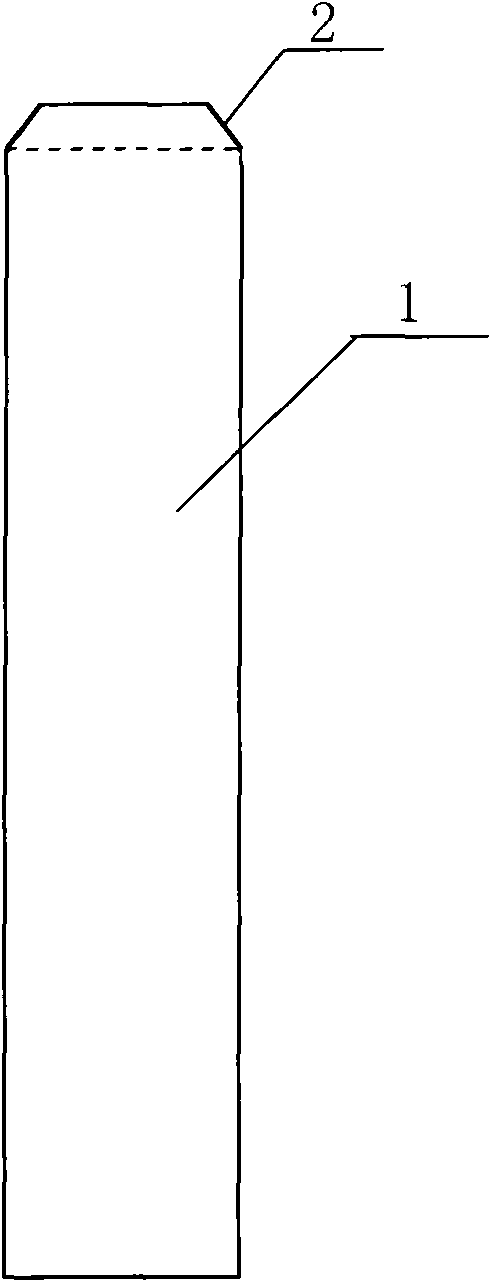

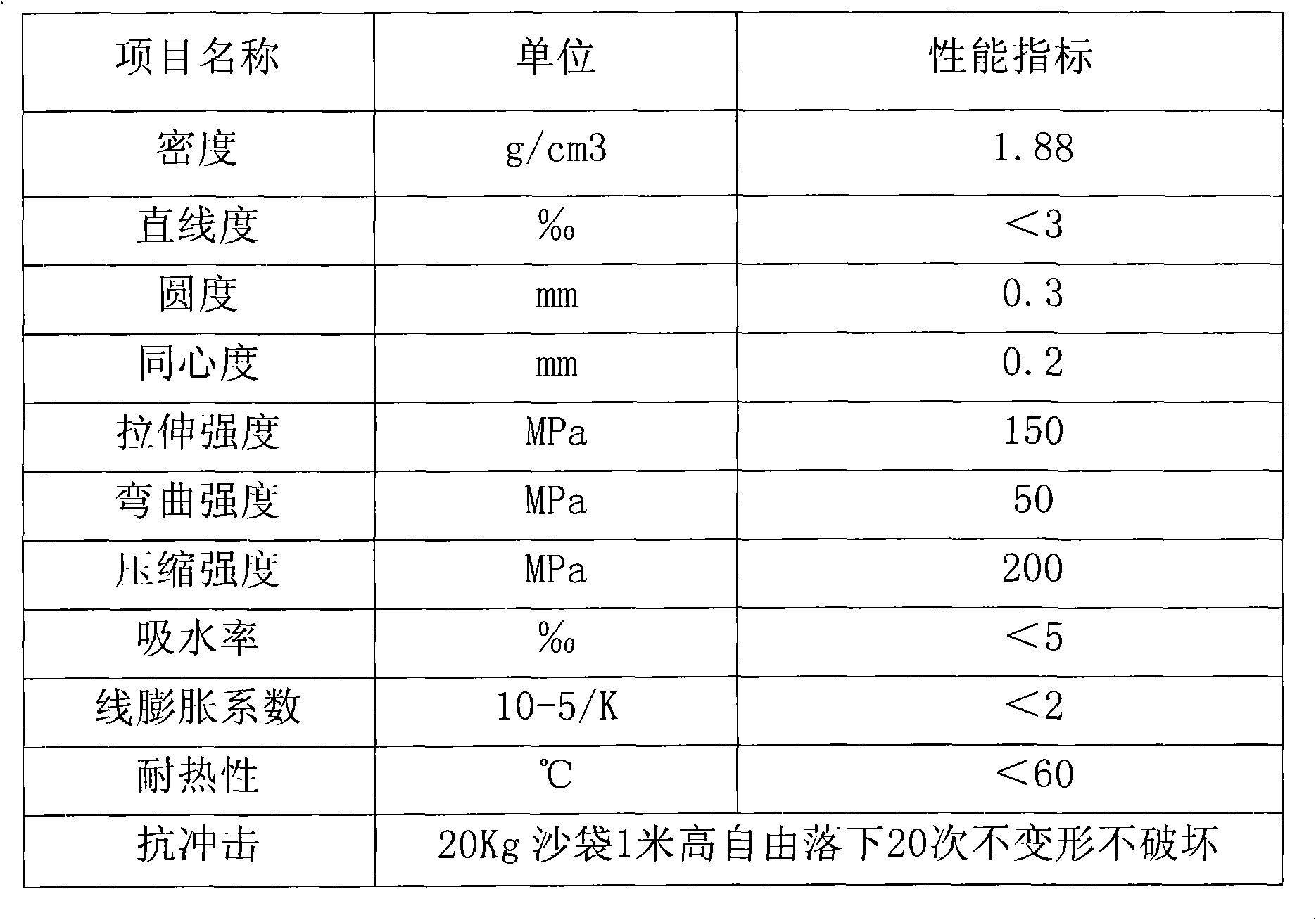

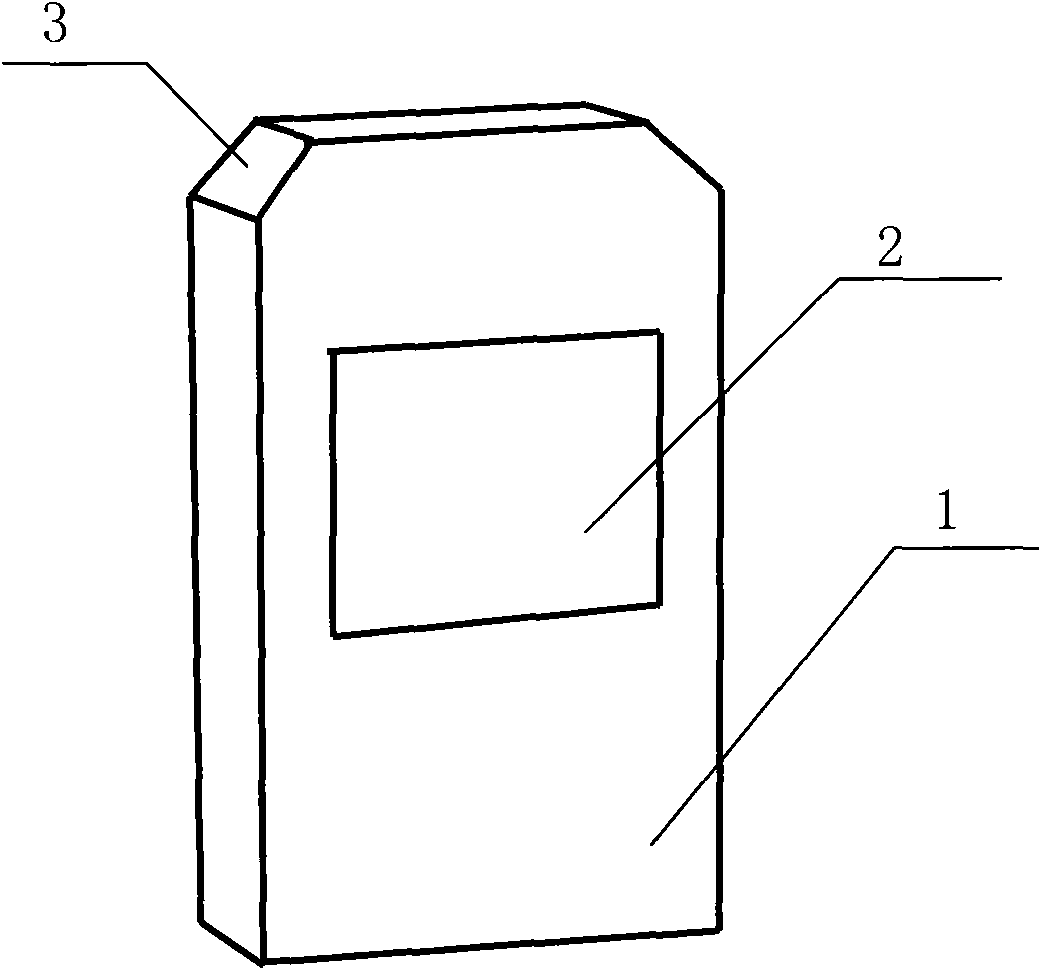

100-meter mark using unsaturated composite epoxy resin materials

The invention discloses a 100-meter mark using unsaturated composite epoxy resin materials, which is of rectangular columnar structure. The four sides at the top of the rectangular columnar structureform a chamfer structure which inclines towards the center of the column. The 100-meter mark is manufactured by the following materials: 18% of special-purpose yarns, 32% of unsaturated resins, 20% oflow profile additives, 20% of fillers and 10% of auxiliary agents. The invention has the characteristics of high brightness, long life, difficult deformation, strong bearing capacity, corrosion resistance, good loss prevention property, rich colors and good capability of beautifying the environment. As the warning mark has the advantages of light weight, high strength and difficult damage, the warning mark can be installed flexibly in a labor and time saving manner. The colors are formed by blending the color paste capable of being compatible with the resins into the resins; therefore, the colors are not shown on the surface, thus keeping the colors lasting.

Owner:天津市津南公路处

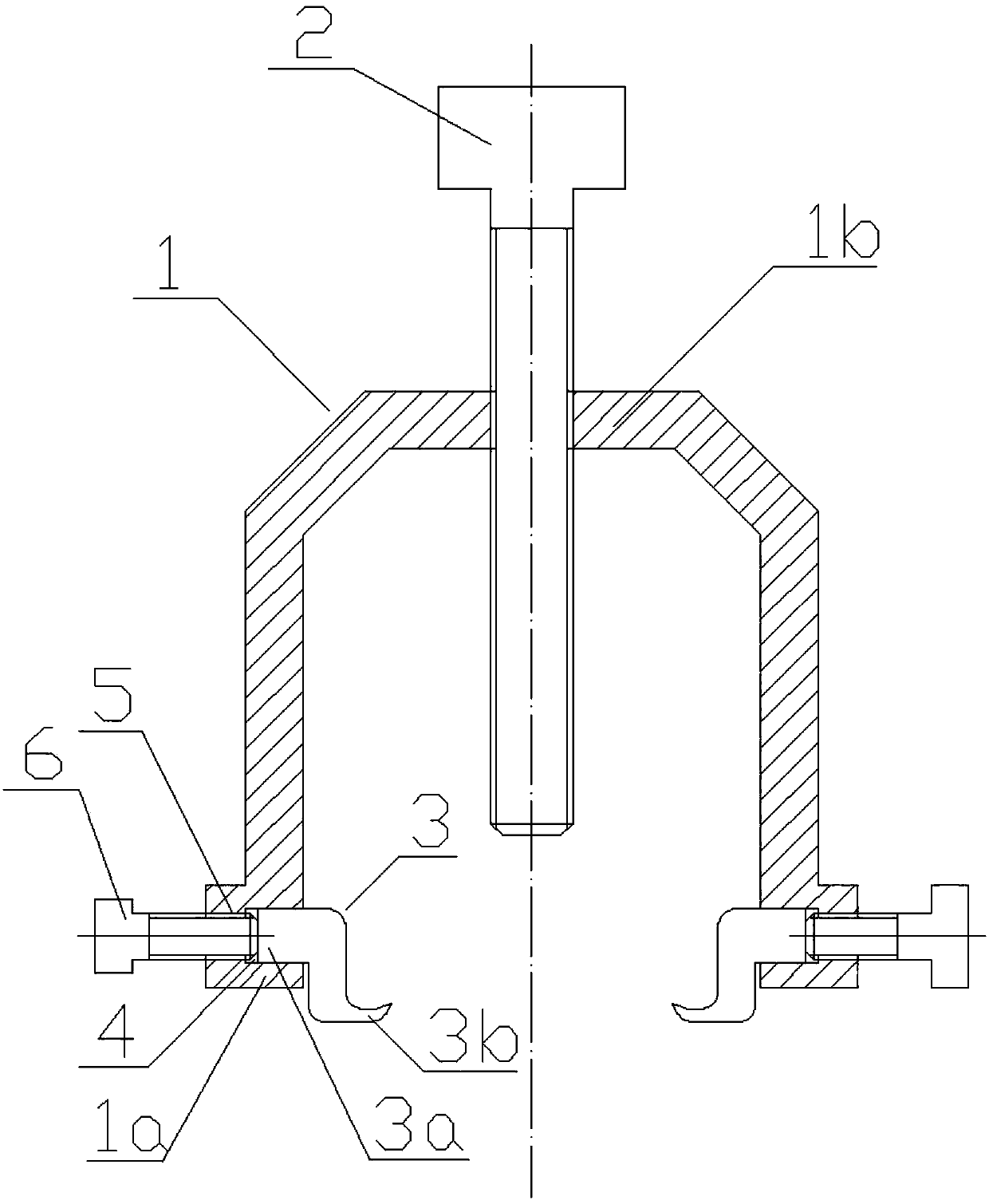

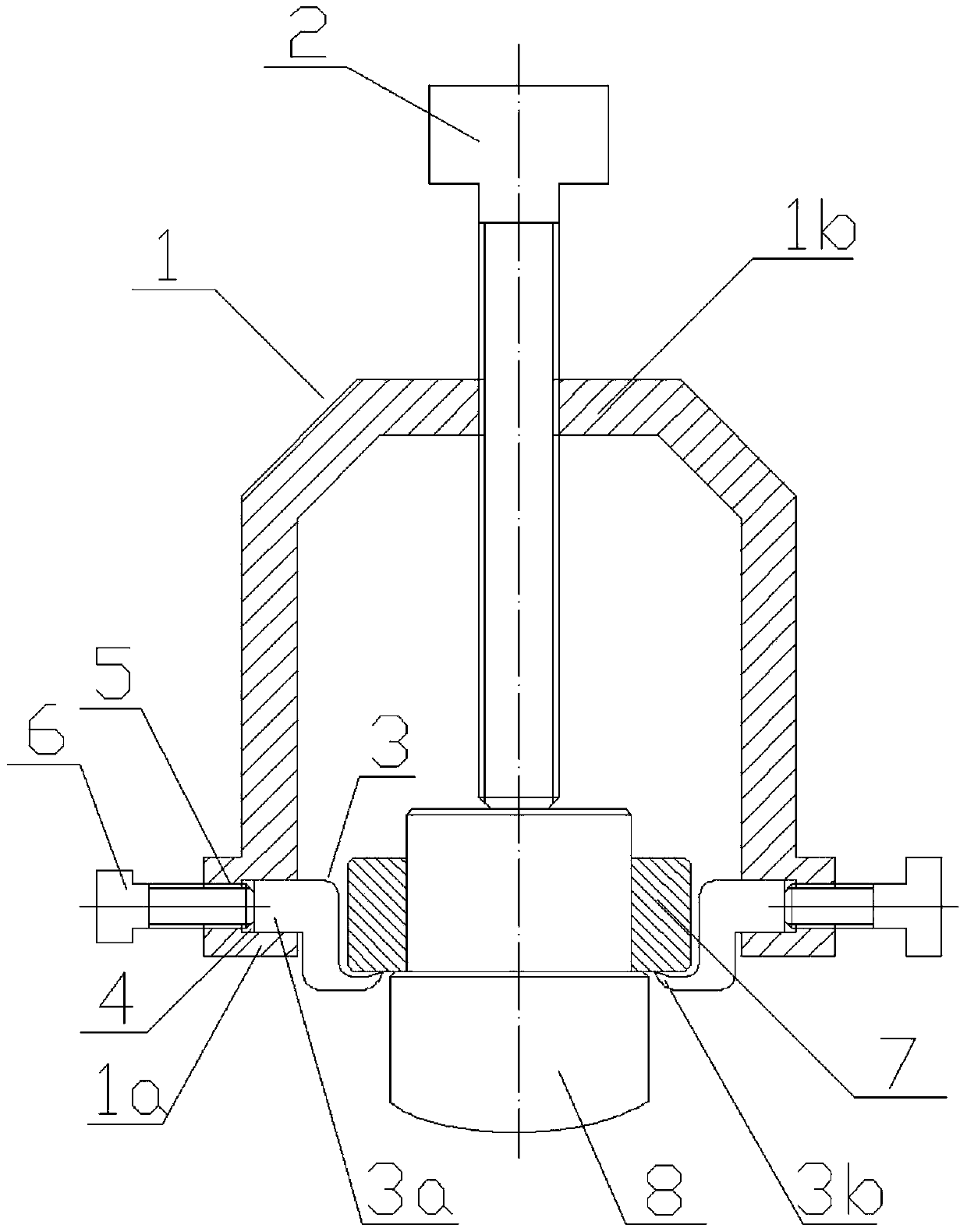

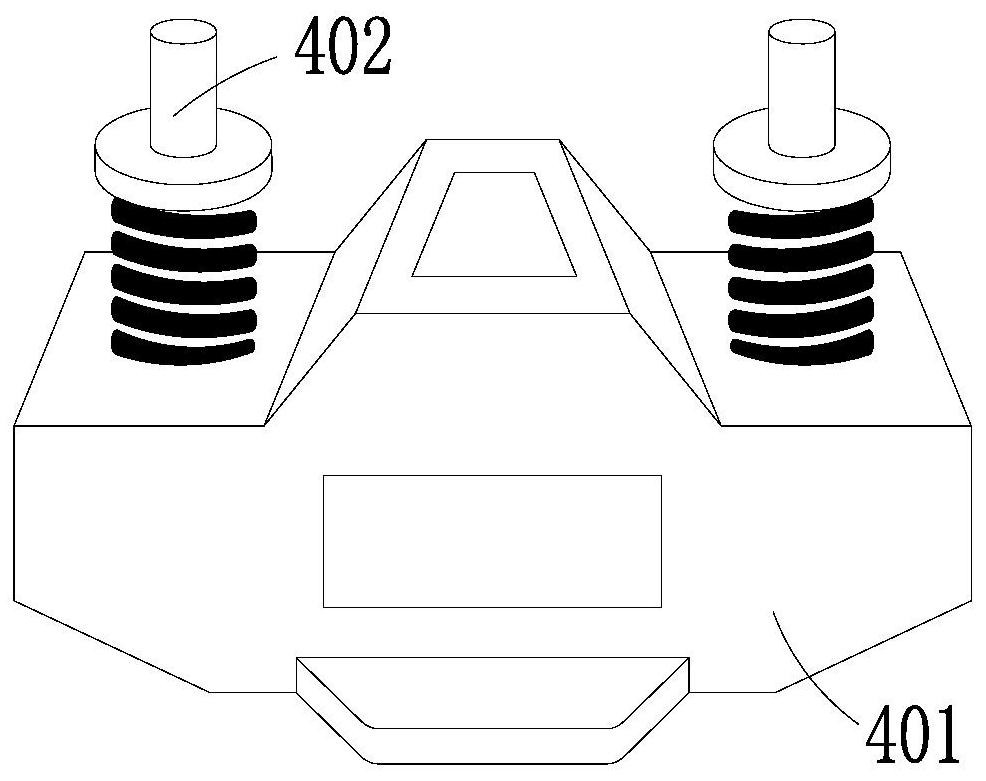

Puller

PendingCN107717856AAdjustable distanceAdapt to disassemblyMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a puller. The puller comprises a body (1) and an extrusion screw (2) which is in threaded connection with the body (1), the body (1) comprises at least two ends (1a), and the ends (1a) are used for hooking an annular workpiece (7). The puller is characterized in that hooking parts (3) are movably connected to the ends (1a), and can move in the axial direction of the workpiece (7). The size of the puller can be adjusted according to the size of the workpiece; meanwhile, the angle of a hooking portion and the workpiece cannot be changed, and the puller is convenient to use and high in reliability.

Owner:SUZHOU TINGYIHUA AUTOMATION EQUIP CO LTD

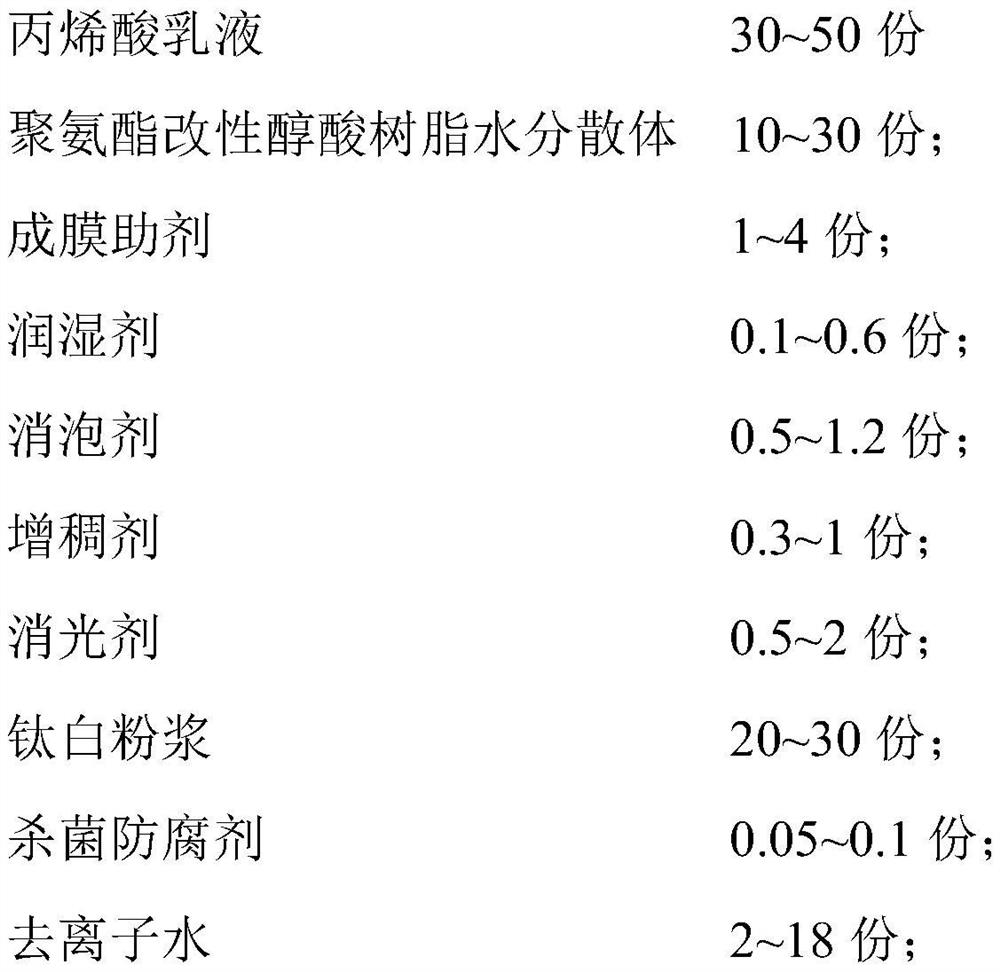

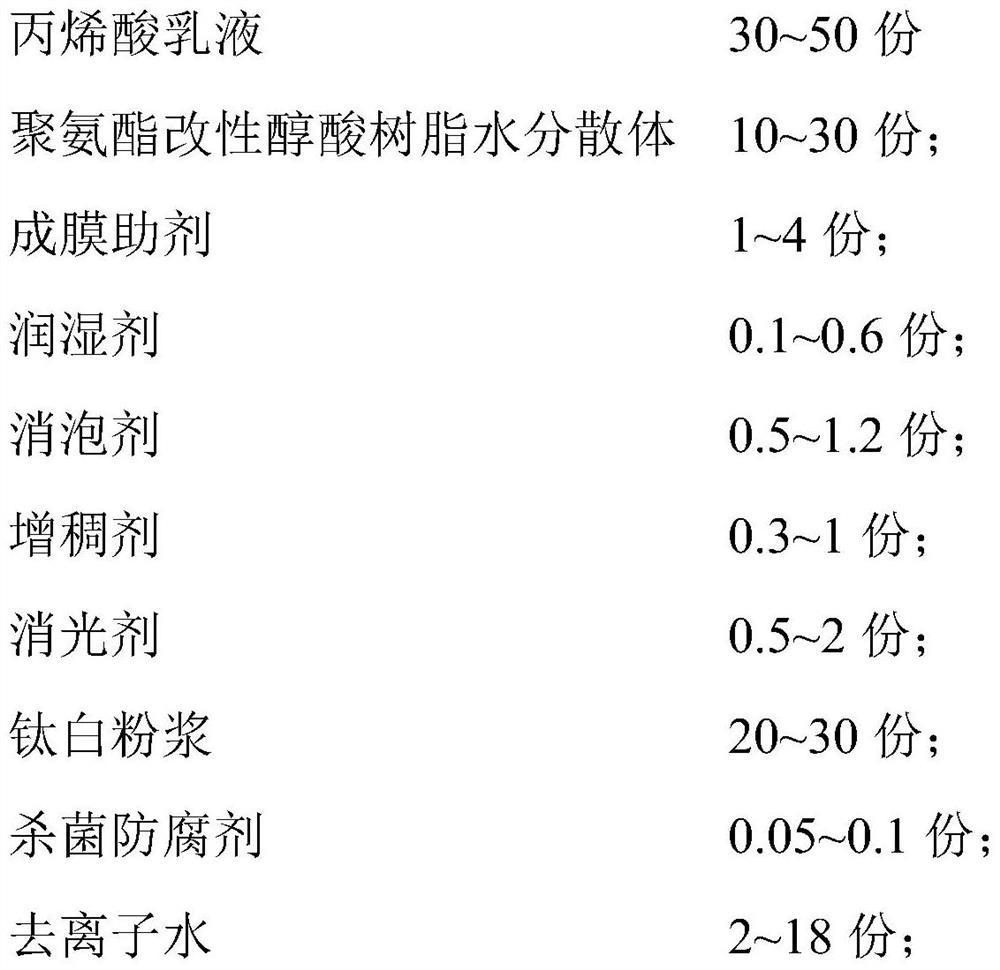

Water-based matte white coating and preparation method thereof

InactiveCN112063250AImprove stabilityImprove construction toleranceAntifouling/underwater paintsPaints with biocidesPolymer scienceColored white

The invention provides a water-based matte white coating and a preparation method thereof.The water-based matte white coating comprises a first component and a second component. The first component comprises, by weight, 30-50 parts of acrylic emulsion, 10-30 parts of a polyurethane modified alkyd resin aqueous dispersion, 1-4 parts of a coalescing agent, 0.1-0.6 parts of a wetting agent, 0.5-1.2 parts of a defoaming agent, 0.3-1 part of thickening agent, 0.5-2 parts of a flatting agent, 20-30 parts of titanium dioxide slurry, 0.05-0.1 parts of an antibacterial preservative and 2-18 parts of deionized water. The second component is hydrophilic modified aliphatic polyisocyanate which does not contain volatile organic compounds. The water-based matte white paint has the advantages of extremely low VOC (Volatile Organic Compound) content, long service life and good comprehensive performance of a coating film.

Owner:珠海展辰新材料股份有限公司

al/al of td/drm process for semiconductor 8-inch wafer thin film process 2 o 3 Regeneration method of parts

ActiveCN108573855BFast migrationLow viscositySemiconductor/solid-state device manufacturingUltrasonic assistedThin membrane

The invention relates to a regenerating method for an Al / Al2O3 part of a TD / DRM process of a semiconductor 8-inch wafer film process. The method comprises the steps that dry ice particles are sprayedand cleaned to regenerate the surface of the part; local temperature difference change formed by thermal energy absorption of dry ice during a sublimation process is used to generate a 'shear stress'between a substrate and a cleaned object, and the cleaned object is quickly peeled off from the surface of the substrate; a Venturi nozzle can generate a carbon dioxide gas stream containing more dryice particles; ultrasonic assisted supercritical CO2 cleaning regenerates the inner surface, the chamber and the groove of the part; and supercritical CO2 easily penetrates into the micropores and thechamber or groove of the part to dissolve pollutants, so that the pollutants migrate fast in supercritical CO2 to achieve the purpose of cleaning. Ultrasonic assisting further improves the cleaning effect and efficiency. The regeneration time and cost are shortened. The regenerating method has the advantages of simple process, environmental protection, being pollution-free and good regeneration effect, does not damage the semiconductor part, and has no impact on the performance of the part.

Owner:苏州珮凯科技有限公司

A method for dry separation of waste paper-plastic composite wallpaper

The invention discloses a dry separation method of waste paper-plastic composite wallpaper and relates to the correlated technical field of waste paper recovery. The dry separation method of the wastepaper-plastic composite wallpaper comprises the following steps: (1) sorting the waste paper-plastic composite wallpaper according to the color depth; (2) crushing the waste paper-plastic composite wallpaper by a crushing machine; and (3) performing primary separation, secondary separation and tertiary separation so as to realize thorough separation and efficient recovery. The whole process is completely not in contact with water, subverts the traditional technology and industrial methods, avoids the waste of water resources, and avoids the harm to the environment caused by massive water pollution due to wastewater and sewage discharge, the separation method is simple, the separation equipment is simple in use, the separation process is simple in operation and is not complicated, the investment cost is reduced, and the investment cost for waste paper-plastic product recovery is greatly lowered.

Owner:安徽省昌泰再生资源有限公司

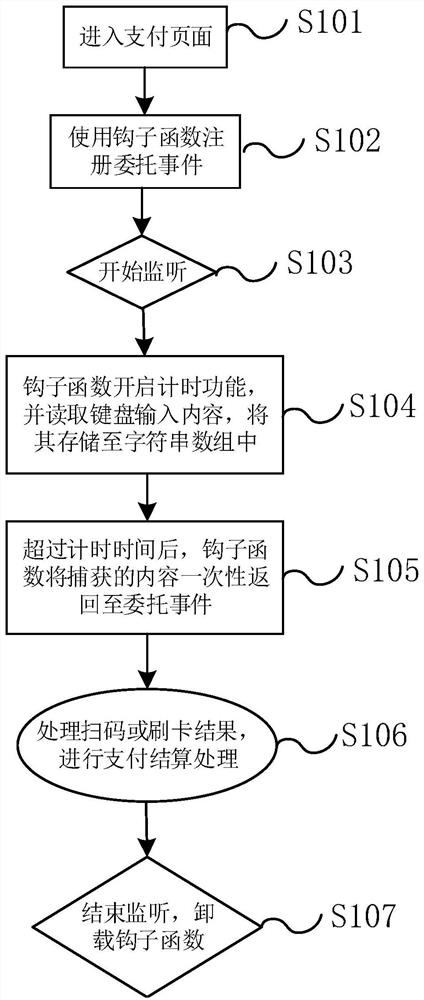

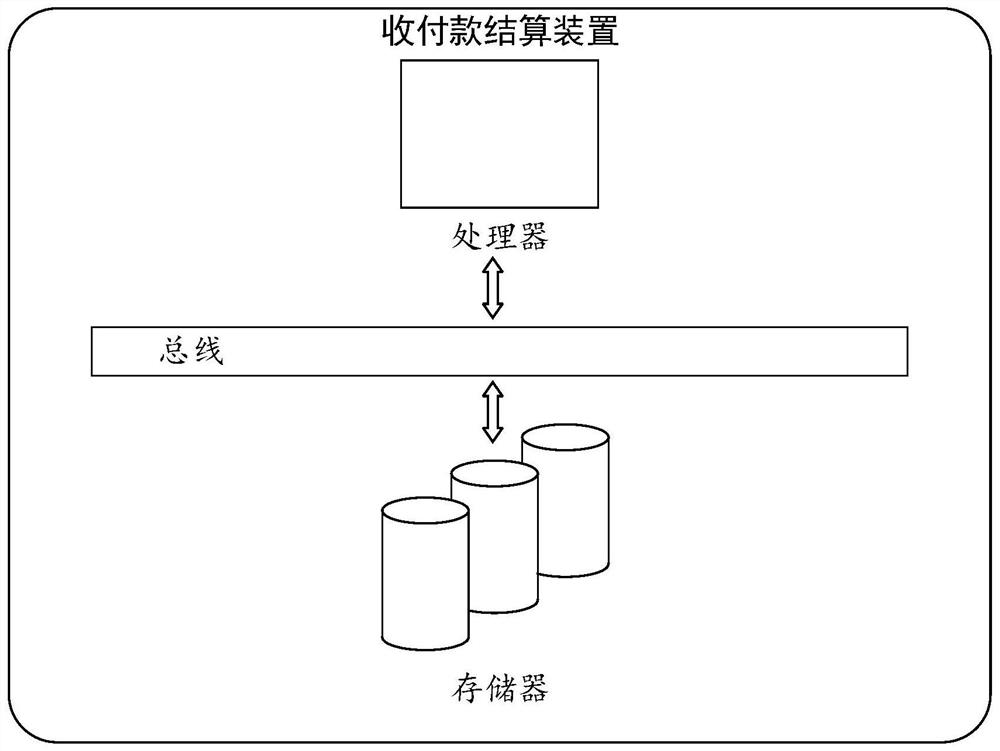

Collection and payment settlement method and device

ActiveCN112184211AFew stepsIncrease flexibilityInterprogram communicationPayment architecturePaymentReliability engineering

The invention discloses a collection and payment settlement method and device, and aims to solve the problems that a payment mode needs to be known in advance in the payment process, and the payment process is complex and inflexible. The method comprises the steps that based on triggering of payment operation, a delegation event related to payment is registered through a hook function HOOK, the payment operation comprises card swiping or code scanning operation, and the delegation event is used for obtaining content captured by the hook function; monitoring content obtained based on triggeringof card swiping or code scanning operation by using a hook function; triggering a timing function by using a hook function when the character is monitored; when the next character is monitored when the timing duration is less than or equal to the first preset duration, resetting the current timing time through a hook function and timing again; and when monitoring that the timing duration is greater than a first preset duration by using the hook function, returning the monitored content to the delegation event through the hook function. Through the method, the payment operation flexibility isimproved, and the payment efficiency is improved.

Owner:山东亚华电子股份有限公司

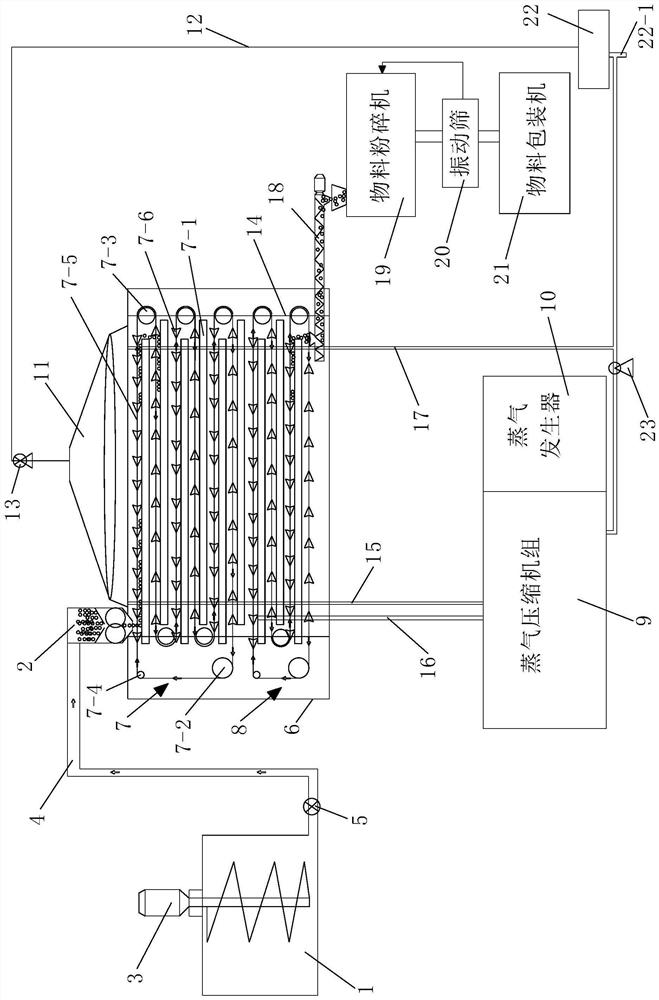

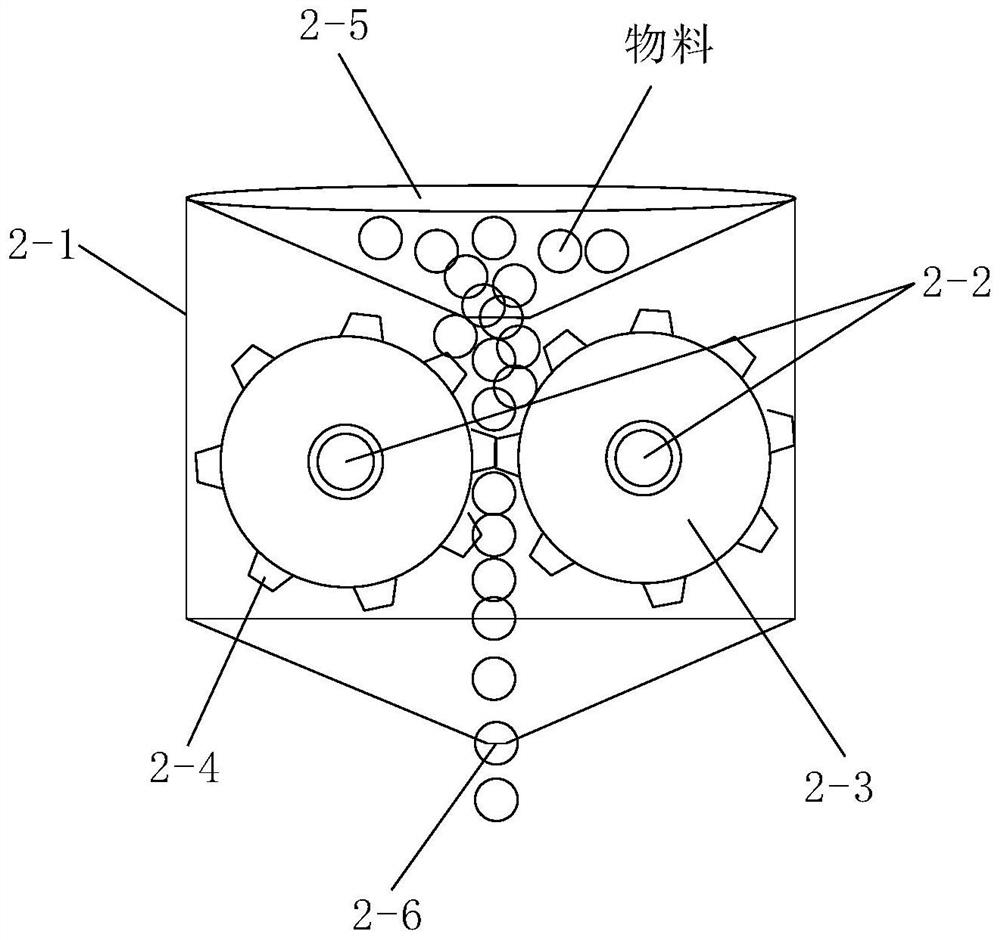

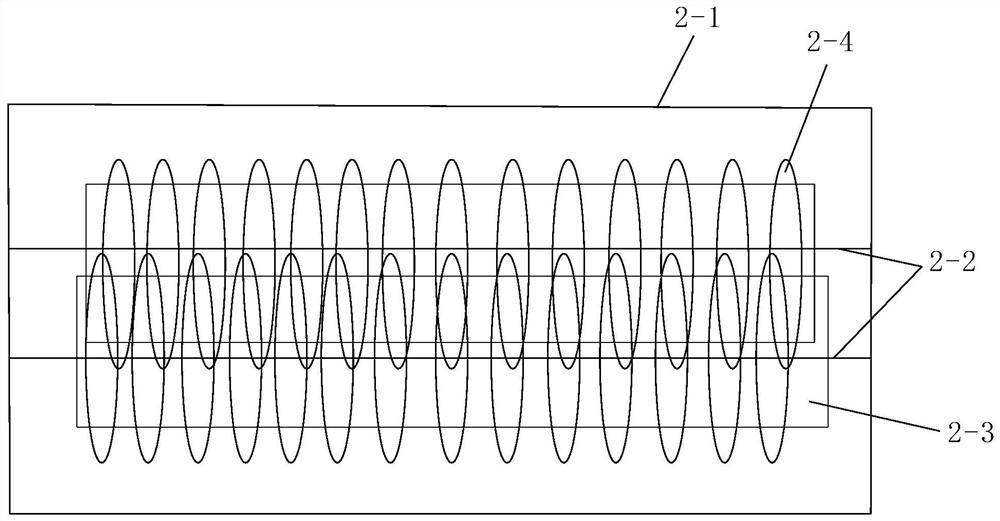

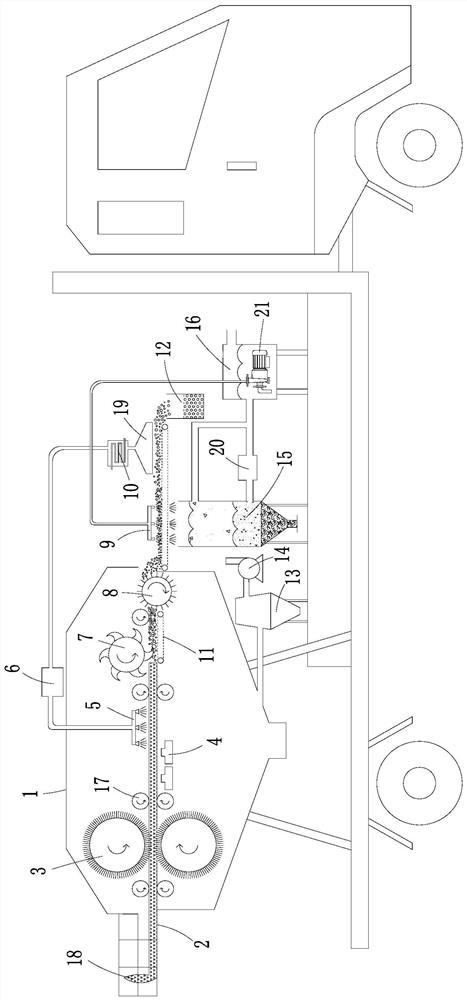

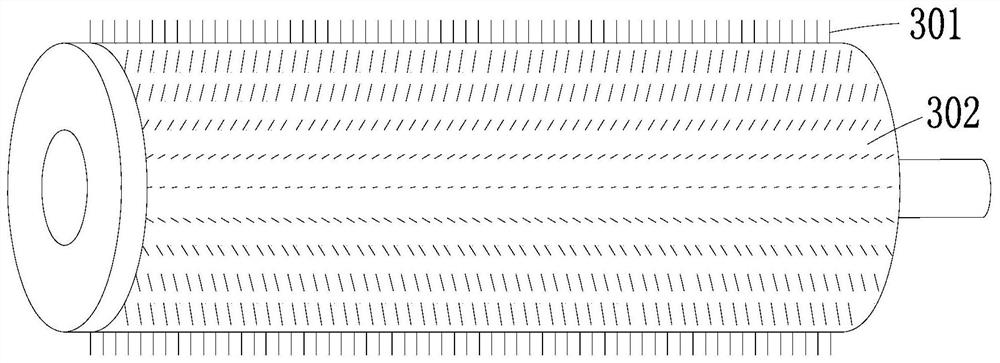

Well drilling waste mud recycling and reusing low-temperature treatment system

PendingCN114590985AKeep aliveOn holdSludge treatment by de-watering/drying/thickeningWell drillingProcess engineering

The invention discloses a well drilling waste mud recycling and reusing low-temperature treatment system which comprises a well drilling waste mud collecting and pumping system, a material distributor, a low-temperature drying mechanism, a steam generating and conveying system and a material post-treatment system. The steam generating and conveying system is connected with the low-temperature drying mechanism; the material post-processing system is arranged at a material outlet of the low-temperature drying mechanism; the well drilling waste mud collecting and pumping system comprises a well drilling waste mud collecting pool, a mud stirrer, a mud conveying pipeline and a single-screw pump, the mud stirrer is installed in the well drilling waste mud collecting pool, one end of the mud conveying pipeline is connected with an outlet of the well drilling waste mud collecting pool, and the single-screw pump is installed on the mud conveying pipeline. The device is simple in structure and convenient to use, the drilling waste mud can keep the original activity of the mud when treated in a low-temperature state, and the device can be reused without waste, has no pollution hidden danger and is low in treatment cost.

Owner:商洛市海蓝科技有限公司

Cleaning device and method for resource recycling of waste filter bag

The invention discloses a cleaning device and method for resource recycling of a waste filter bag. The device comprises a negative-pressure ash chamber, a feeding platform, a double-roller brush, electromagnetic vibrators, compressed air blowing pipes, an air compressor, a cutting and tearing machine, an opener, high-pressure water pipes, an electric heating coil, a net curtain, a fiber collectinghopper, a dust remover, an exhaust fan, a sewage tank and a purified water tank. The method comprises the following steps of: carrying and transferring the waste filter bag through the feeding platform and the net curtain, removing loose and hardened dust on the surface of the filter bag through the powerful brush, removing the dust clamped in a filter material layer in an electromagnetic vibration mode, and blowing off the residual dust on the surface of the filter bag through compressed air; carrying out fragmentation treatment on the whole filter bag through the cutting and tearing machineand the opener, and flushing loose fragment fibers with high-pressure water to effectively remove remaining dust; and finally, heating the compressed air through the electric heating coil, carrying out drying treatment on the fragment fibers through hot air, and obtaining a clean raw material product capable of being recycled as a resource.

Owner:NORTHEASTERN UNIV

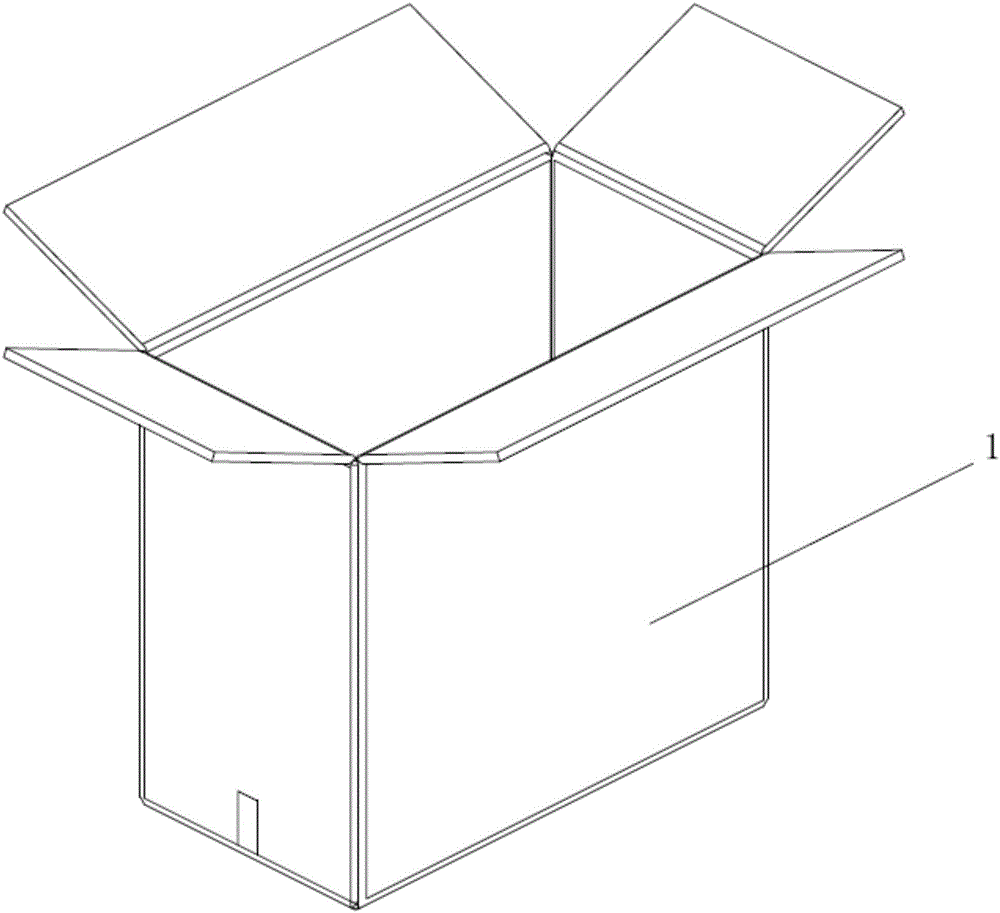

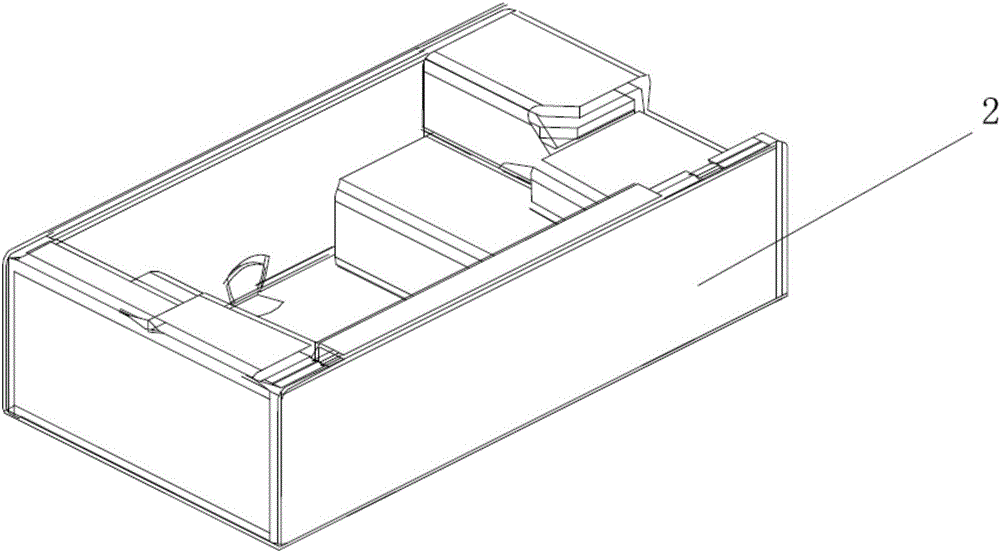

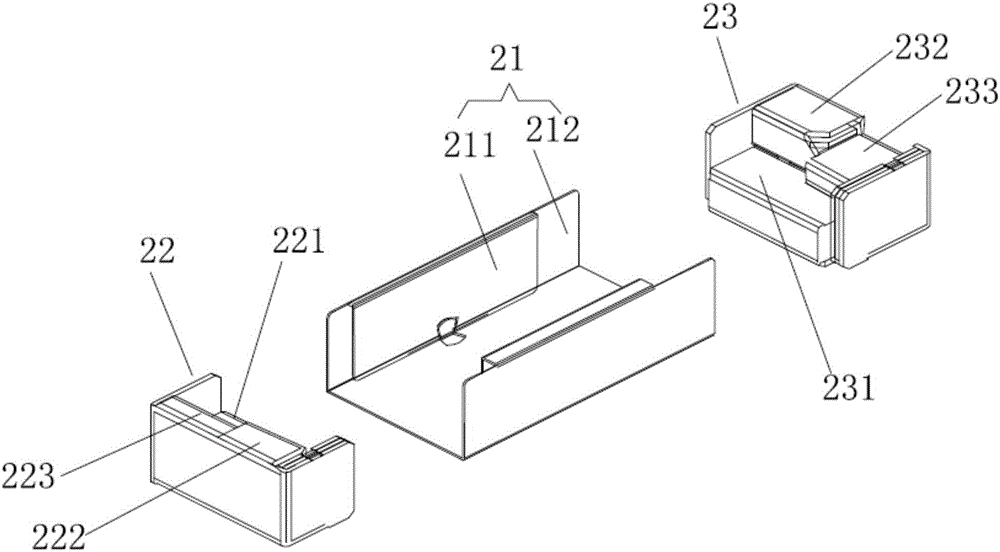

All-paper buffering packing case for medical instrument

The invention relates to the technical field of paper packing, in particular to an all-paper buffering packing case for a medical instrument. The packing case comprises a case body. The case body of the packing case is of a common case structure. The packing case is easy and convenient to operate and not damaged when being used for a long time. A lower support for supporting the medical instrument is arranged at the bottom of the inner side of the case body. An upper support for covering the medical instrument is arranged at the top of the inner side of the case body. The upper support and the lower support are stable in structural performance and good in buffering performance. The case body, the upper support and the lower support are each formed by arranging folding marks on corrugated paper according to the required shape and folding the corresponding corrugated paper according to the folding marks. Corrugated paper package has the beneficial effects of being low in cost and good in machining property. When being used, the all-paper buffering packing case is nuisanceless, free of pollution, convenient to recycle, small in global mass and easy to transport and handle.

Owner:MYS GRP CO LTD

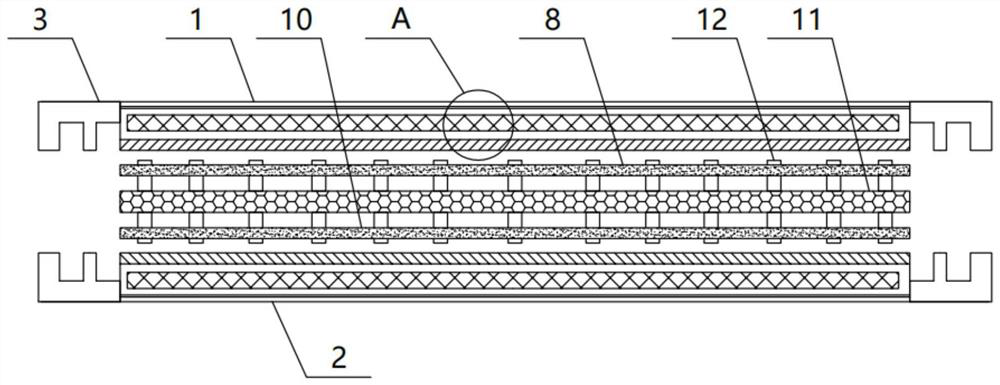

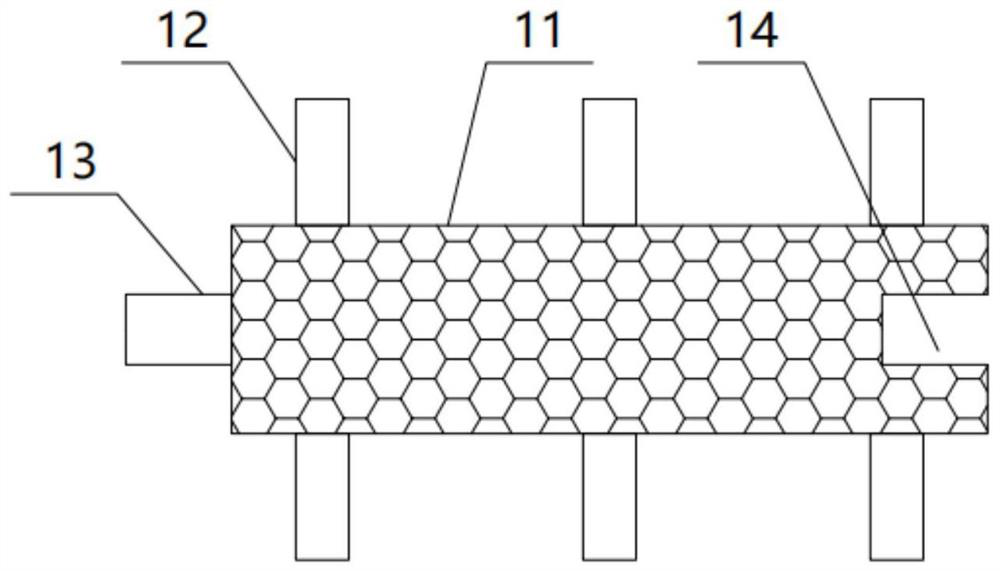

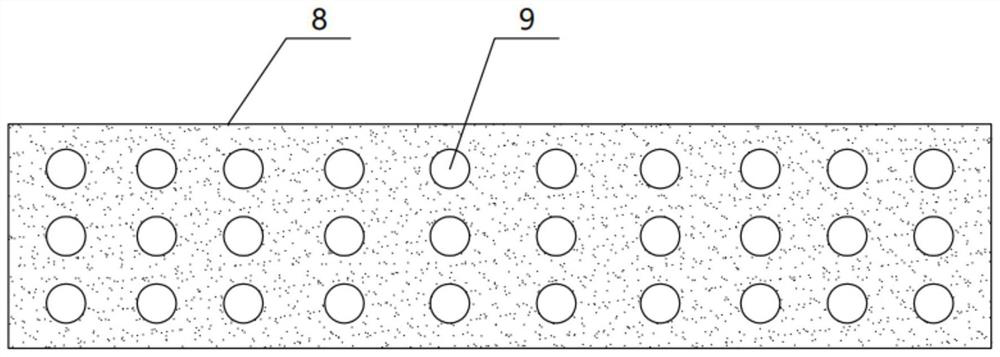

Multifunctional negative ion carbon composite board and manufacturing process thereof

InactiveCN114103290AHigh hardnessEffective absorptionGas treatmentDispersed particle separationCarbon compositesHoneycomb

The multifunctional negative ion carbon composite board comprises an upper carbon base plate, a lower carbon base plate, an upper bamboo charcoal plate layer, a lower bamboo charcoal plate layer and a honeycomb bamboo charcoal layer, fixing connecting pieces are arranged on the two sides of the upper carbon base plate and the two sides of the lower carbon base plate correspondingly, and mounting cylinders are evenly arranged on the upper face and the lower face of the honeycomb bamboo charcoal layer; a protruding block is arranged on the left side of the honeycomb bamboo charcoal layer, and a groove is formed in the right side of the honeycomb bamboo charcoal layer. During use, the honeycomb bamboo charcoal layer, the upper bamboo charcoal plate layer and the lower bamboo charcoal plate layer are installed and fixed through the installation cylinders and the connection through holes; the upper charcoal base plate and the lower charcoal base plate are connected with the mounting cylinders arranged on the honeycomb bamboo charcoal layer in an inserting manner through the circular holes, so that the contact area between the honeycomb bamboo charcoal layer and air is increased, the firmness is improved, and through the arrangement of the convex blocks and the grooves on the honeycomb bamboo charcoal layer and the fixed connecting pieces on the upper charcoal base plate and the lower charcoal base plate, the firmness is improved; and the carbon composite plate is more convenient to mount and dismount.

Owner:苏州零号元素新材料科技有限公司

Mileage mark using unsaturated composite epoxy resin materials

The invention discloses a mileage mark using unsaturated composite epoxy resin materials. The highway mileage mark is a rectangular milestone body and chamfer structures are formed at both sides at the top of the rectangular milestone body. Concave surfaces for marking kilometers are formed on the front and rear surfaces of the rectangular milestone body. The mileage mark is manufactured by resinmatrix composite materials including 30% of unsaturated polyester resin materials, 30% of glass fiber materials, 30% of SiO2 fillers and 10% of auxiliary agents. The invention has the characteristicsof high brightness, long life, difficult deformation, strong bearing capacity, corrosion resistance, good loss prevention property, rich colors and good capability of beautifying the environment. As the warning mark has the advantages of light weight, high strength and difficult damage, the warning mark can be installed flexibly in a labor and time saving manner. The colors are formed by blendingthe color paste capable of being compatible with the resins into the resins; therefore, the colors are not shown on the surface, thus keeping the colors lasting.

Owner:天津市津南公路处

A Strain of Bacillus Veles and Its Application

ActiveCN111349588BEasy to controlReduce moistureBacteriaMicroorganism based processesBiotechnologyCellulose

The invention discloses a strain of Bacillus Velez and its application. The Fb strain is obtained through enrichment culture, primary screening, re-screening, etc., belongs to Bacillus Velez, and is Gram-positive. The morphological characteristics of the strain are as follows: the bacterium is rod-shaped, 0.4-0.6 μm×0.9-4.0 μm, arranged singly or in pairs, the spores are nearly round, proximal, and the cysts are enlarged. It has been tested that the Bacillus Velez Fb can withstand a high temperature of 55°C, and the optimum growth temperature is 45°C, and the optimum growth pH value is 3.0-7.6. The strain of the present invention can efficiently degrade tea dregs, increase tea dregs protein, amino acid, etc., reduce tea dregs moisture and cellulose, etc., and the fermented tea dregs can be used as feed raw materials; it can realize smokeless, odorless, and sewage discharge, and It can realize the recycling of organic waste, thereby reducing the environmental pollution caused by tea dregs, which is a technology in line with environmental protection.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

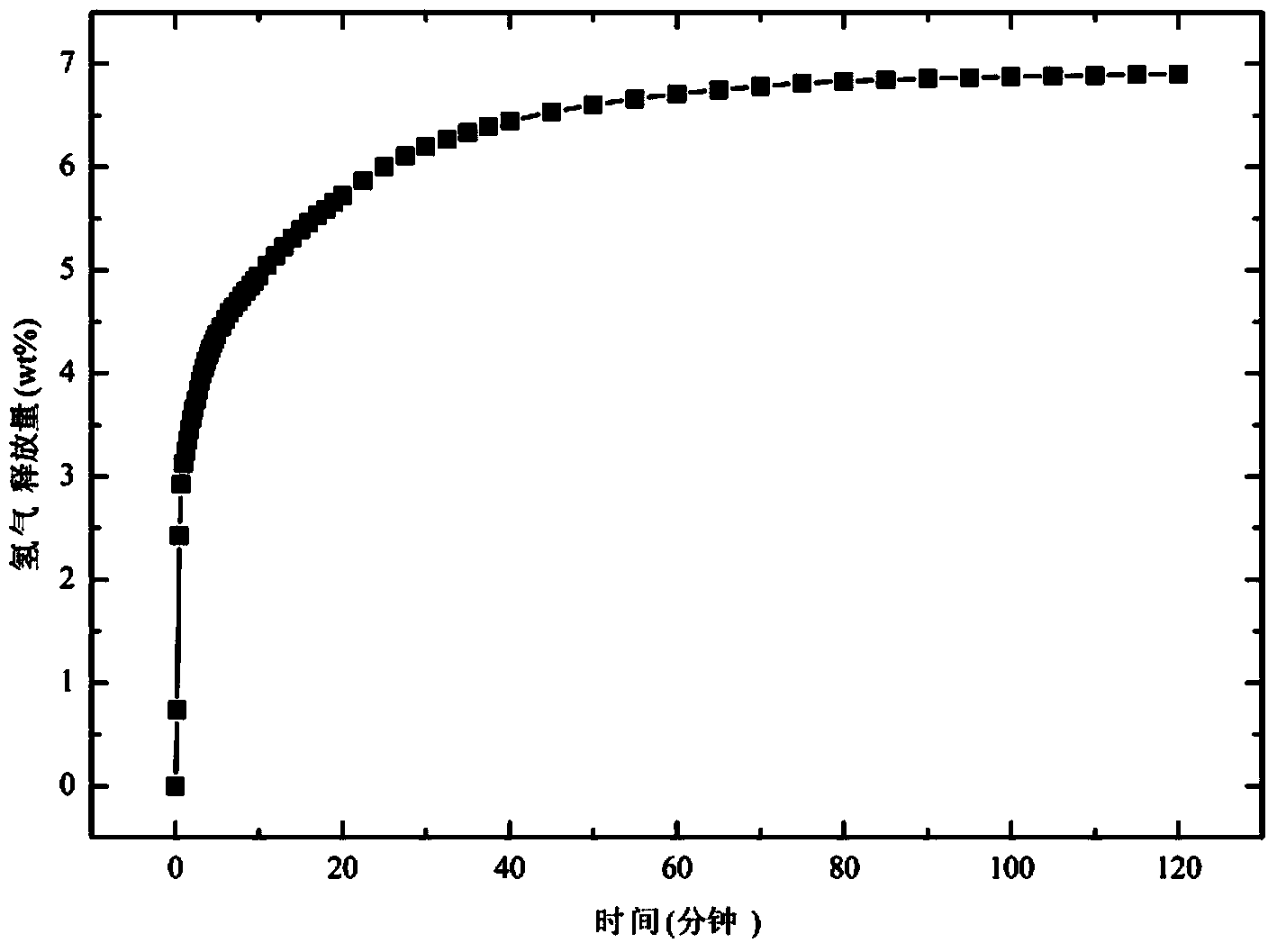

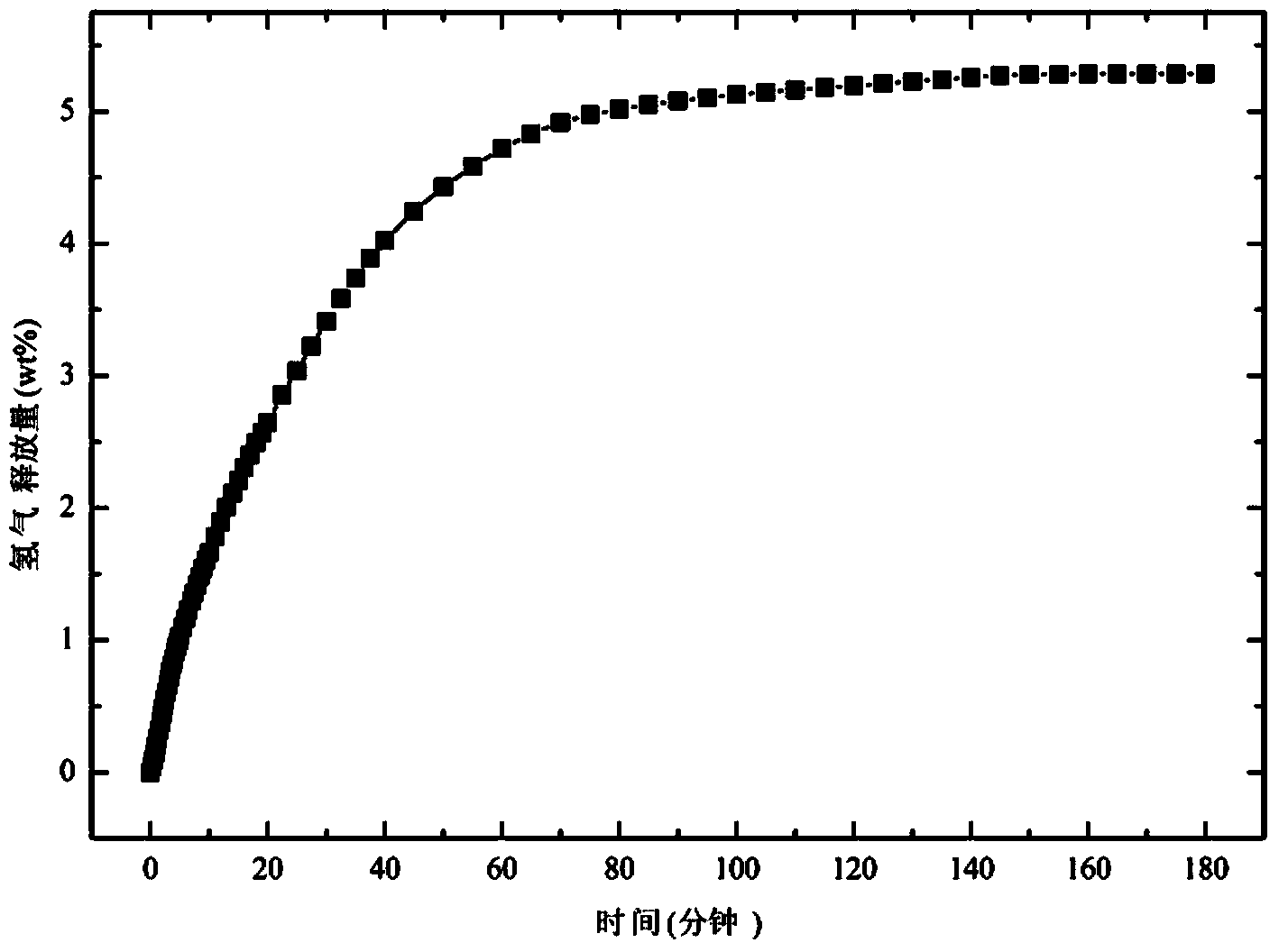

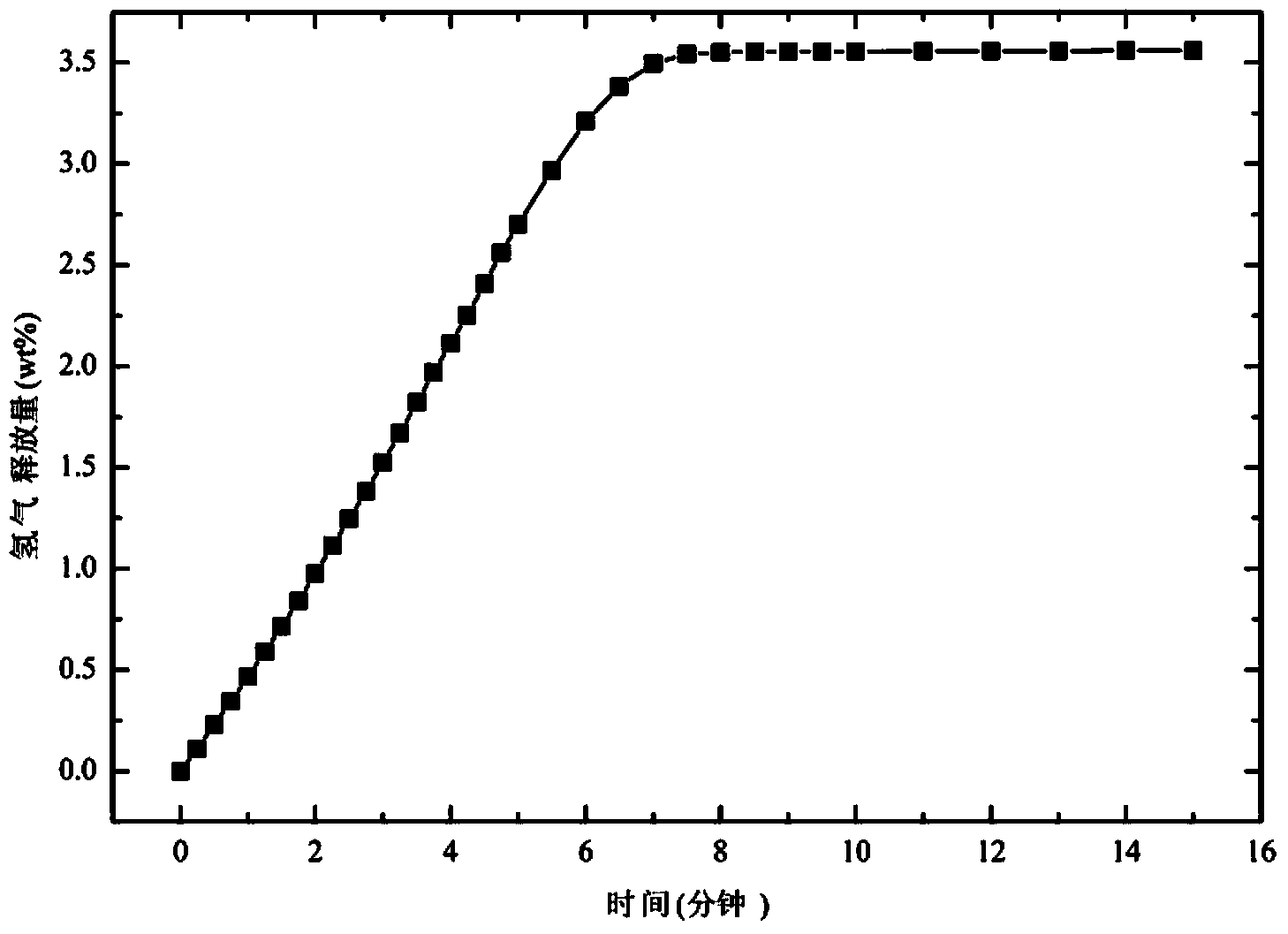

Method of promoting coordinate alanate and ammonium salt to react by solvent to prepare hydrogen

The invention relates to a method of promoting coordinate alanate and ammonium salt to react by a solvent to prepare hydrogen. The chemical formula of the coordinate alanate is M(AlH4)m, wherein M is an alkali metal or alkaline earth capable of forming coordinate hydride, and m is the valence of the alkali metal or alkaline earth; the chemical formula of ammonium salt is (NH4)nX, wherein X is an acidic group and n is the valence of the acidic group. The method comprises the following steps: adding the coordinate alanate, the ammonium slat and the solvent into a reactor to be mixed, thus accelerating reaction of the coordinate alanate and the ammonium slat by the solvent, wherein the molar ratio of the coordinate alanate to the ammonium slat is (0.38-4.55):1, and the use level of the solvent is 0.4-100L / mol of the coordinate alanate. According to the method, the coordinate alanate is just contacted with the ammonium salt without heating, and the solvent provides the reaction environment, so that reaction can be carried to generate hydrogen. The method can efficiently release hydrogen under a condition of not providing extra energy sources.

Owner:SICHUAN UNIV

Environment-friendly packaging box for precision instrument

InactiveCN107640397ALight in massEasy to transportPackage recyclingRigid containersPulp and paper industryMachining

The invention relates to the technical field of paper packaging, in particular to an environment-friendly packaging box for a precision instrument. The environment-friendly packaging box comprises a packaging shell with a common box structure, the packaging shell is simple and convenient to operate and enduring, a lower supporting frame for supporting the precision instrument is arranged at the bottom of the inner side of the packaging shell, an upper supporting frame covering the precision instrument is arranged at the top of the inner side of the packaging shell, the upper supporting frame and the lower supporting frame are stable in structural performance and good in buffer performance, wavy folding paper is provided with fold according to needed shapes and folded according to the foldto form the packaging shell, the upper supporting frame and the lower supporting frame, wavy folding paper packaging has the advantages of low cost and good machining property, public hazards and pollution are avoided in use, and the packaging box is conveniently recycled and reused, light in total weight and easy to transport and carry.

Owner:南通富强纸业有限公司

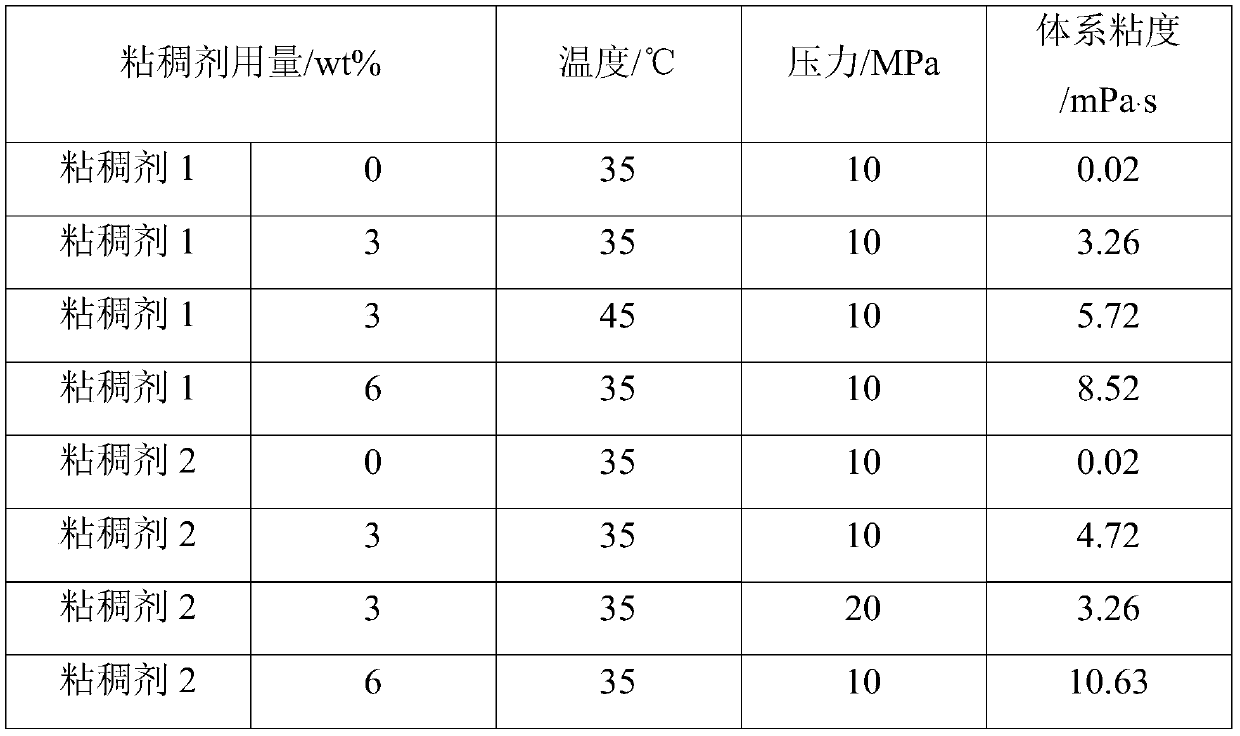

A kind of supercritical carbon dioxide thickener and its preparation method and application

ActiveCN107236091BImprove cooling effectEasy transferDrilling compositionBulk chemical productionOrganic chemistryPolydimethylsiloxane

The invention provides a supercritical carbon dioxide thickener and its preparation method and application. The thickener contains the following components: (a) polydimethylsiloxane; (b) acrylate compounds; (c) benzene Vinyl compounds; (d) initiators; (e) emulsifiers; wherein, the component (a) is polydimethylsiloxane with a viscosity of 50-3000mPa·s. The thickener prepared by the method of the invention can thicken supercritical carbon dioxide more than 100 times. The supercritical carbon dioxide fluid thickened by the thickener can suspend 1%-10% (volume ratio) proppant. The supercritical carbon dioxide fracturing fluid thickened by the thickener can effectively realize oil layer stimulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com