Pr<3+>:Y2SiO5-TiO2-ACF visible-light response type photocatalytic composite membrane and preparation method thereof

A composite film and visible light technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of separation and recovery of suspended nano-catalysts, powders are easy to agglomerate and settle, Reduce the photocatalytic effect and other problems, achieve good visible photocatalytic performance, improve photocatalytic performance, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] PR 3+ :Y 2 SiO 5 / TiO 2 Preparation of Photocatalytic Composite Films

[0043] (1) Preparation of Pr by sol-gel method 3+ Pr content of 1.0% (mol) 3+ :Y 2 SiO 5 Up-conversion material powder. First take a certain amount of Y 2 o 3 Add dilute HNO 3 (dilute nitric acid and water 1:1) to configure Y(NO 3 ) 3 Solution, accurately measure a certain amount of Pr(NO 3 ) 3 Join Y(NO 3 ) 3 Solution, heating and boiling in an electric furnace to crystallize, drying in an oven at 110°C for several hours to obtain white anhydrous nitrate; Stir for 30 minutes, then heat in a water bath at 80°C to form a gel; dry the gel in an oven at 110°C for 12 hours, and grind the xerogel into a powder, place it in a muffle furnace for calcination at 900°C for 3 hours, and cool to obtain 1.0% (mol )Pr 3+ :Y 2 SiO 5 Phosphor.

[0044] (2) Using the sol-gel method, prepare a certain viscosity titanium dioxide sol with tetrabutyl titanate, glacial acetic acid, absolute ethanol, ...

Embodiment 2

[0048] Material Performance Characterization Testing

[0049] 1. X-ray diffraction analysis (XRD)

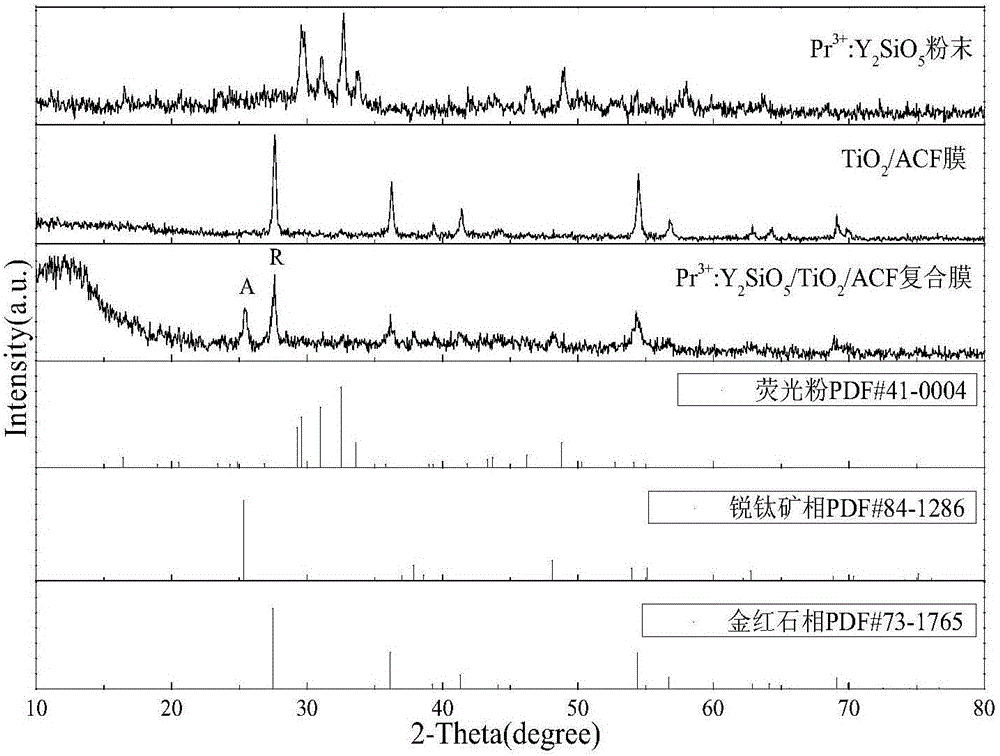

[0050] X-ray diffraction analysis such as figure 2 As shown, the sample was analyzed by D8 ADVANCE X-ray diffractometer (XRD) produced by German Bruker Company; the test conditions were: graphite monochromator, Cu-Kα radiation, radiation wavelength λ=0.15418 nm, tube voltage 40 kV, tube current 40 mA, scan speed 8~10 o min -1 , scanning angle range 2θ=10~80 o . Observed figure 2 It can be seen that the XRD of the phosphor powder after calcination at 900°C, the corresponding PDF standard library number of the spectrum is PDF#41-0004, indicating that the main component of the prepared sample is Y 2 SiO 5 . TiO after 800℃ treatment 2 The XRD diffraction pattern of / ACF diaphragm has the strongest diffraction peak at 2θ=27.5°, and the prepared TiO 2 / ACF film TiO 2 Mainly rutile phase, the corresponding PDF card number is #73-1765. After high temperature treatment at ...

Embodiment 3

[0060] Degradation performance test under visible light

[0061] 1. Pr in the composite film 3+ :Y 2 SiO 5 with TiO 2 best mass ratio

[0062] First prepare methylene blue solutions with concentrations of 1mg / L, 3mg / L, 5mg / L, 10mg / L, 15mg / L, and 20mg / L, and then use an ultraviolet spectrophotometer to measure its absorbance at a wavelength of 665nm. The concentration is the abscissa, and the absorbance is the ordinate to make a standard curve.

[0063] Using 500ml of 15mg / L methylene blue solution as the target degradation solution, under the irradiation of trichromatic light at 140W intensity, take composite films of the same size (wherein Pr 3+ :Y 2 SiO 5 with TiO 2 According to the mass ratio (5%, 7%, 9%, 11%, 13%) into the solution to be degraded, turn on the stirring device, and then turn on the light source to carry out the degradation experiment for 12 hours. The change curve of the removal rate with time is as follows: Figure 7 shown by Figure 7 It can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com