Water-based matte white coating and preparation method thereof

A white, water-based technology, applied in the field of coatings, can solve problems such as high VOC content and short pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The second aspect of the embodiment of the present application provides a kind of preparation method of water-based matte white paint, and the preparation method of the first component comprises the steps:

[0048] S01. The acrylic emulsion and the polyurethane-modified alkyd resin aqueous dispersion are subjected to the first mixing treatment to obtain the first mixture;

[0049] S02. The wetting agent, the defoamer and the first mixture are subjected to a second mixing treatment to obtain a second mixture;

[0050] S03. Carrying out the third mixing treatment of the film-forming aid and the deionized water to obtain the third mixture;

[0051] S04. The second mixture, the third mixture, the thickener, the matting agent, the titanium dioxide slurry, and the bactericidal preservative are subjected to a fourth mixing treatment to obtain the first component.

[0052] The preparation method of the first component in the water-based matte white paint provided by the second...

Embodiment 1

[0062] A water-based matte white paint

[0063] The water-based matte white paint comprises a first component and a second component, wherein the first component comprises the following components in parts by weight:

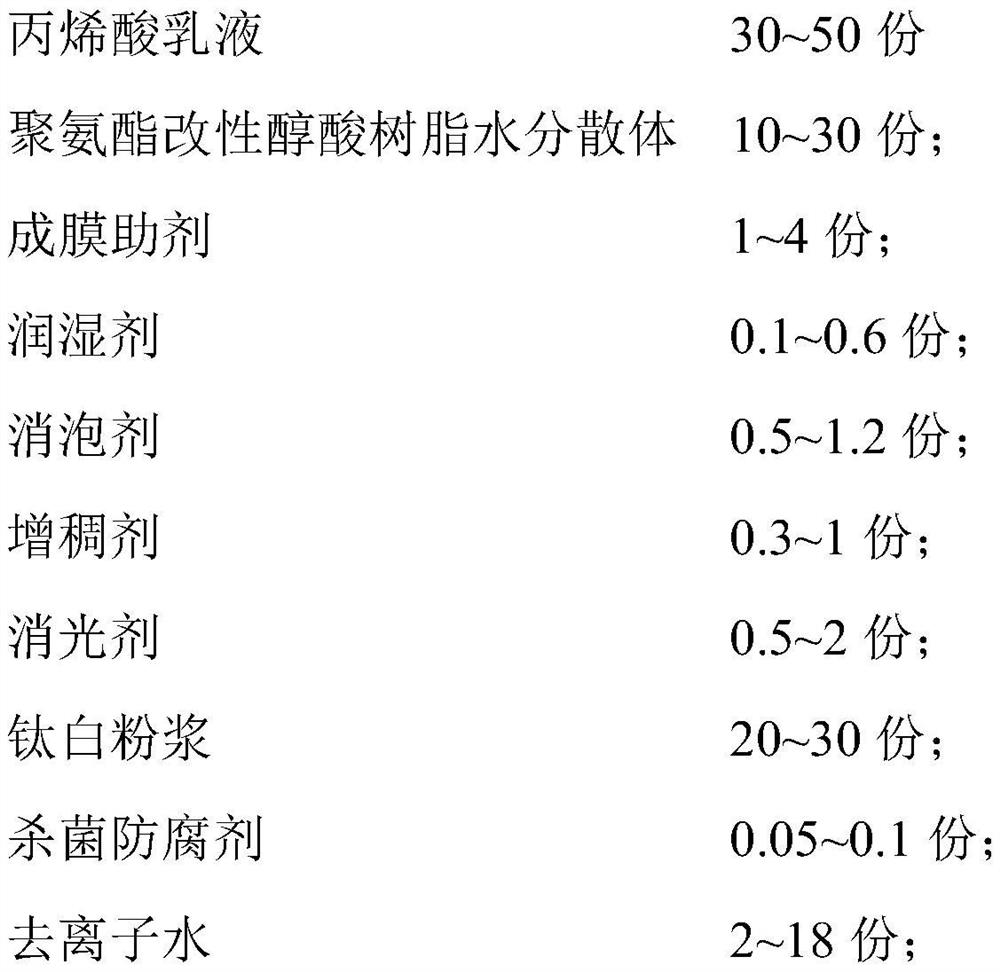

[0064]

[0065] The second component is selected from the hydrophilic aliphatic polyisocyanate curing agent Bayhydur ultra 307;

[0066] The mass ratio of the first component to the second component is 100:10.

[0067] Among them, the mass percentage of hydroxyl group in the acrylic emulsion is 1.6%, and the minimum film-forming temperature is 40°C;

[0068] Polyurethane modified alkyd resin aqueous dispersion is AKD 2734 provided by French ECOAT company, oil degree 36, hydroxyl mass percentage content 1%;

[0069] The wetting agent is BYK346;

[0070] The defoamer is a mixture of TEGO Foamex 810, BYK 024, and TEGO Airex 902W, and the ratio of the three is 3:2:3;

[0071] The film-forming aid is used in a 1:1 mixture of DPM and DPnB;

[0072] The thickene...

Embodiment 2

[0083] A water-based matte white paint

[0084] The water-based matte white paint comprises a first component and a second component, wherein the first component comprises the following components in parts by weight:

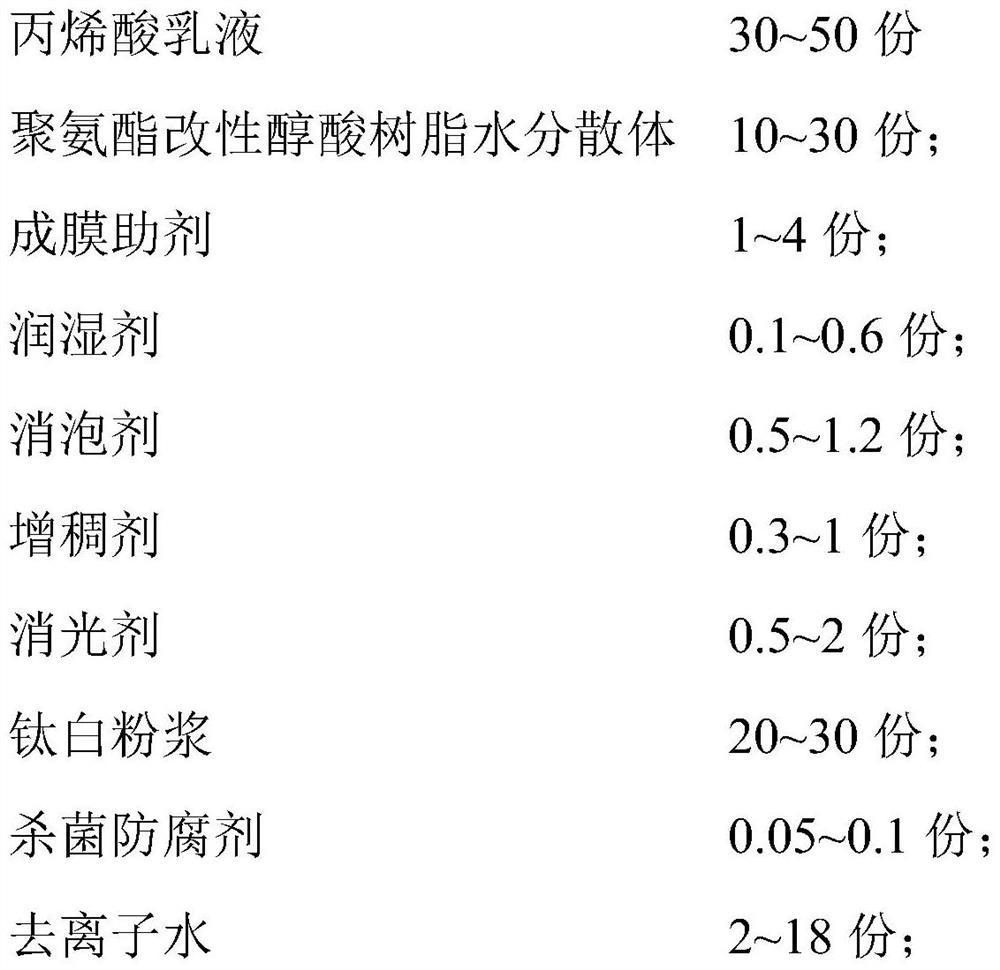

[0085]

[0086] The second component is selected from the hydrophilic aliphatic polyisocyanate curing agent Bayhydur ultra 307;

[0087] The mass ratio of the first component to the second component is 100:8.

[0088] Among them, the mass percentage of hydroxyl group in the acrylic emulsion is 1.6%, and the minimum film-forming temperature is 40°C;

[0089] Polyurethane modified alkyd resin aqueous dispersion is AKD 2734 provided by French ECOAT company, oil degree 36, hydroxyl mass percentage content 1%;

[0090] The wetting agent is BYK346;

[0091] The defoamer is a mixture of TEGO Foamex 810, BYK 024, and TEGO Airex 902W, and the ratio of the three is 3:2:3;

[0092] The film-forming aid is used in a 1:1 mixture of DPM and DPnB;

[0093] The thicken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com