Method of promoting coordinate alanate and ammonium salt to react by solvent to prepare hydrogen

An aluminum hydride and coordination technology, applied in the production of hydrogen, etc., to achieve the effects of energy saving, mature production technology, great practicability and commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

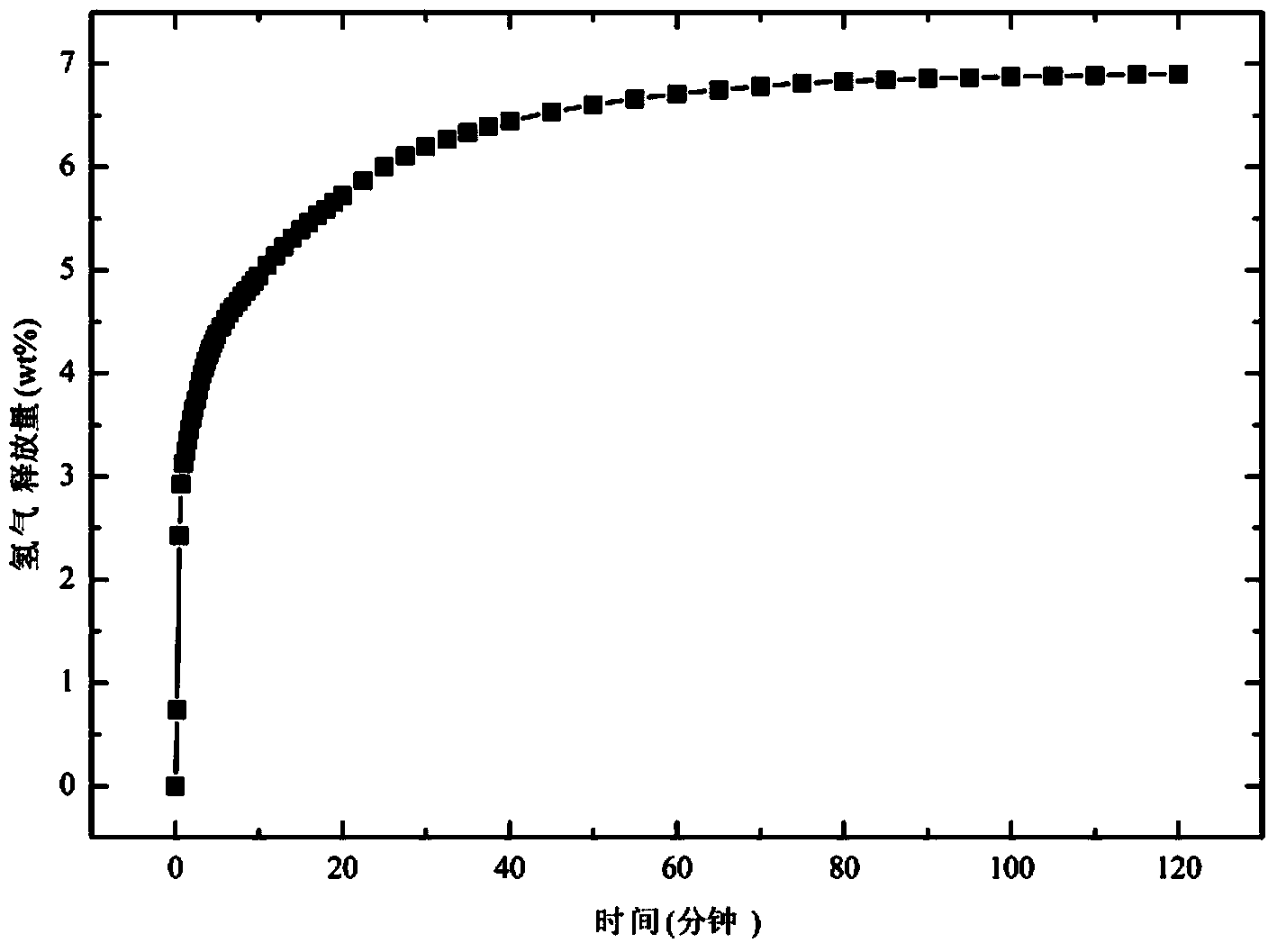

Embodiment 1

[0033] Add 0.005mol LiAlH 4 And 0.005mol NH 4 F (LiAlH 4 With NH 4 The molar ratio of F is 1:1). Put into the flask, add 10mL DME (the amount of solvent is 2L / mol LiAlH 4 ), react under stirring at 85°C, and collect hydrogen by drainage gas collection method. Such as figure 1 As shown, the reaction produces about 6.71 wt% hydrogen in 60 minutes, and about 6.90 wt% hydrogen in 120 minutes.

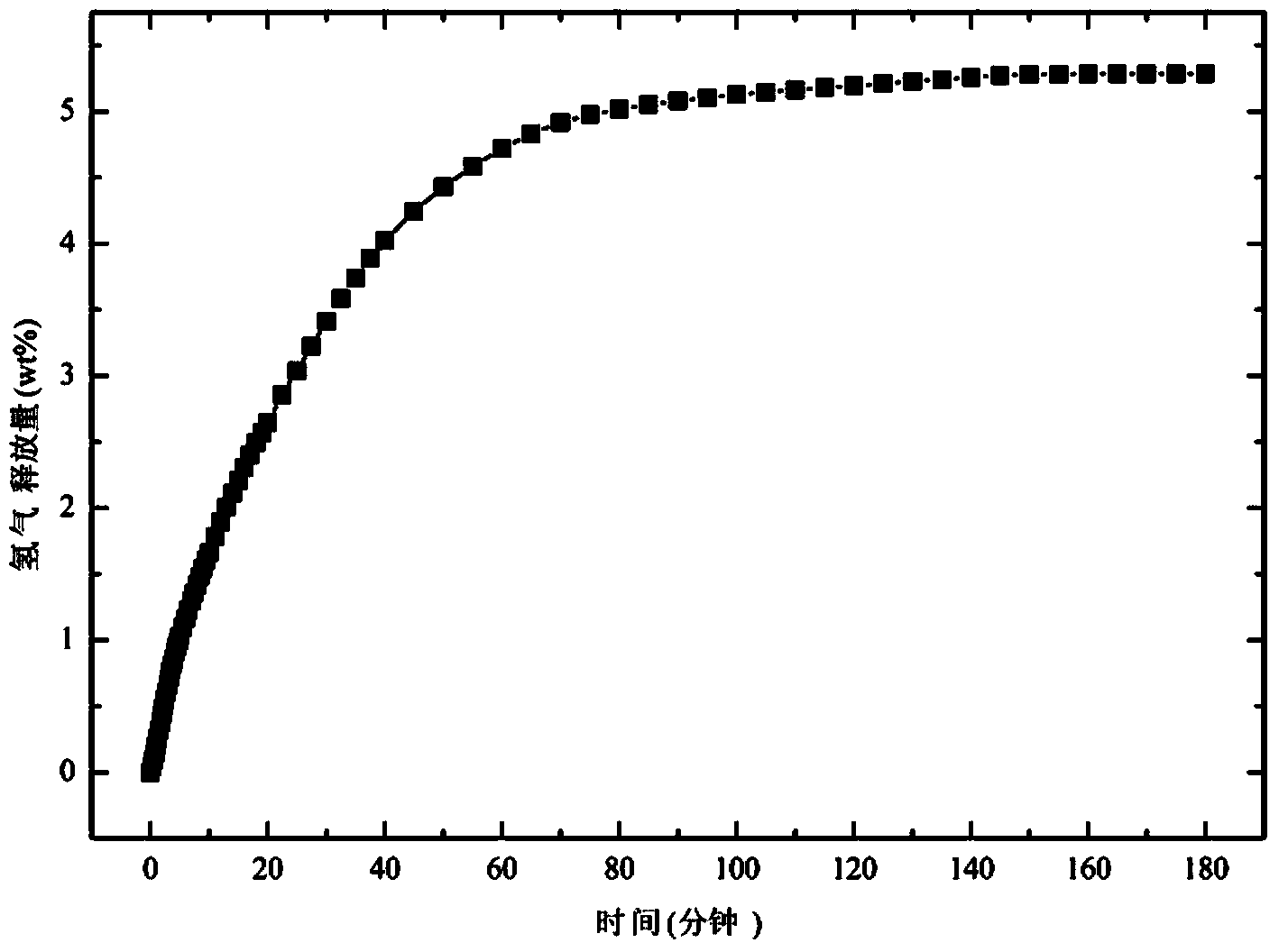

Embodiment 2

[0035] Add 0.005mol LiAlH 4 And 0.005mol NH 4 Cl (LiAlH 4 With NH 4 The molar ratio of Cl is 1:1) Put it into the flask and add 10mL Et 2 O (the amount of solvent is 2L / mol LiAlH 4 ), react under stirring at 25°C, and collect hydrogen by drainage gas collection method. Such as figure 2 As shown, the reaction produces about 5.08 wt% hydrogen in 90 minutes, and a total of about 5.29 wt% hydrogen in 180 minutes.

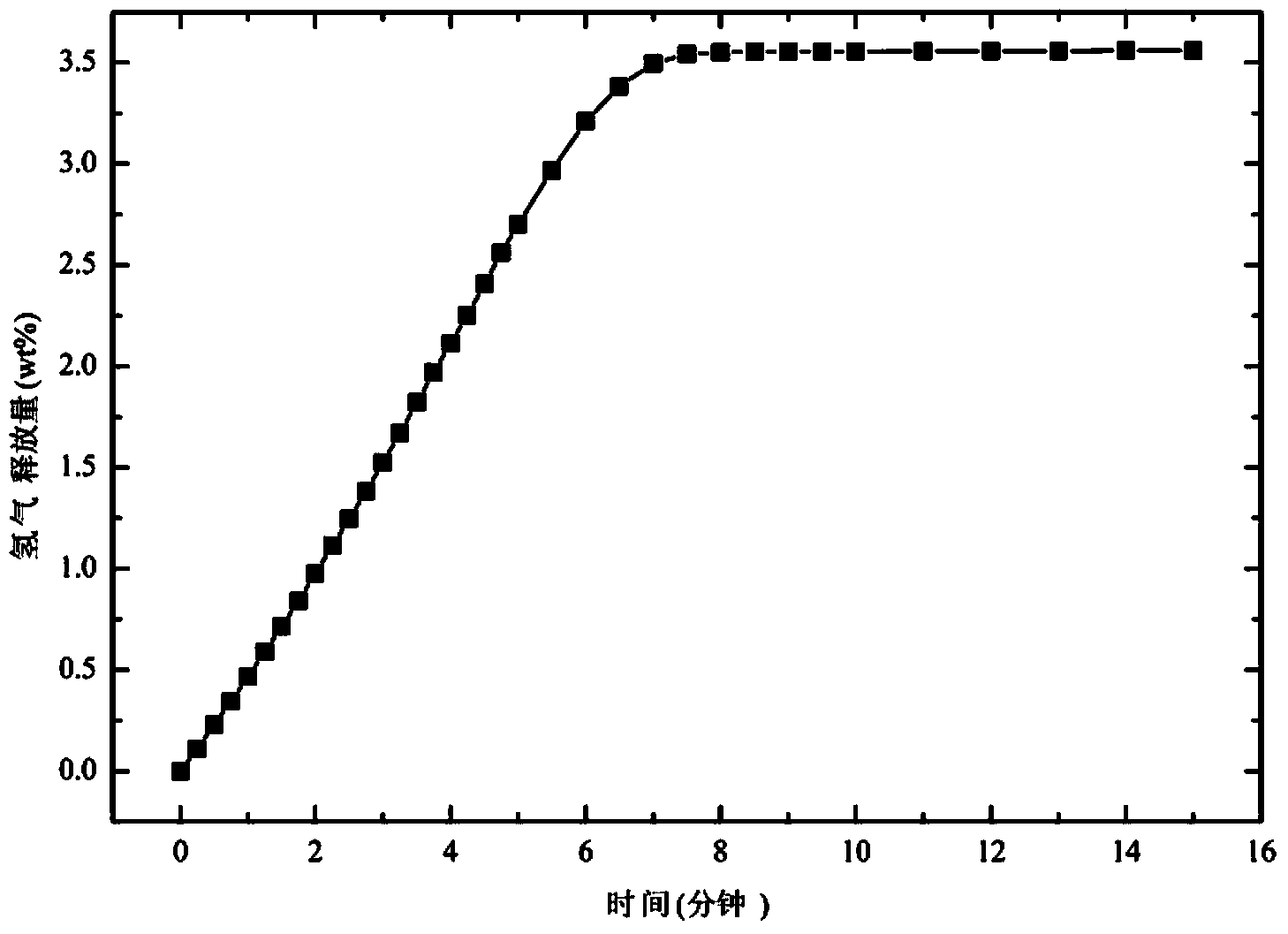

Embodiment 3

[0037] Add 0.005mol LiAlH 4 And 0.005mol(NH 4 ) 2 SO 4 (LiAlH 4 With (NH 4 ) 2 SO 4 The molar ratio is 1:1) into the flask, add 10mL THF (the amount of solvent is 2L / mol LiAlH 4 ), react under stirring at 25°C, and collect hydrogen by drainage gas collection method. Such as image 3 As shown, about 3.56% by weight of hydrogen is produced within 15 minutes, and basically no hydrogen is produced after the reaction continues.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com