Metal die for coining super-hydrophobic micro-nanometer surface and laser manufacturing method thereof

A micro-nano surface and metal mold technology, applied in laser welding equipment, metal processing equipment, nanotechnology, etc., to achieve the effects of wide practicability, high efficiency, great flexibility and designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

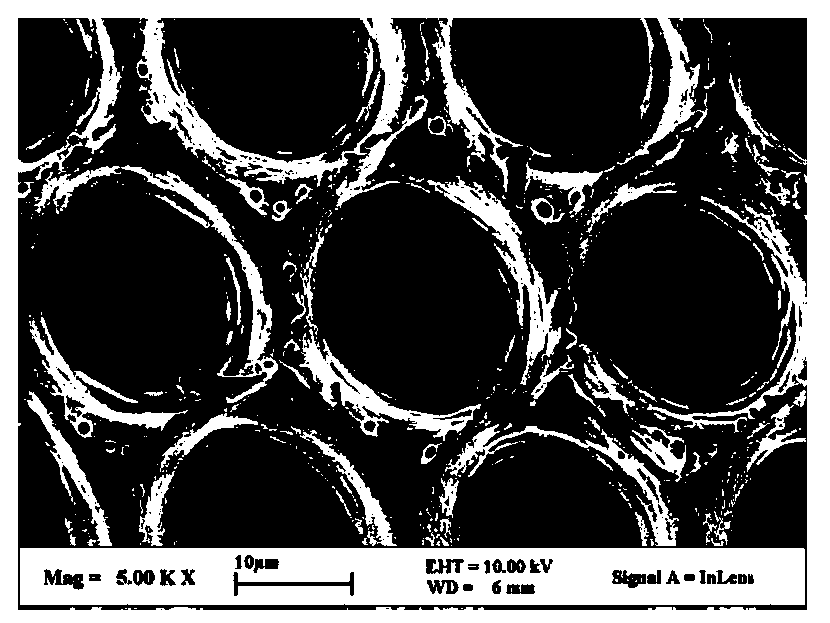

[0040] Example 1. Preparation of high-power picosecond laser die steel mold with imprinting superhydrophobic micro / nano surface

[0041] In this embodiment, a high-power picosecond laser is used to prepare H13 hot work die steel molds with superhydrophobic micro / nano surfaces, including the following steps:

[0042] 1) Preparation of the metal substrate: firstly, the surface of the H13 hot mold steel substrate is polished by mechanical processing, and then polished with a grinding and polishing machine, ultrasonically cleaned with alcohol, and dried for later use;

[0043] 2) Laser processing: using high-power picosecond laser, near-infrared with a laser wavelength of 1.06 microns, laser beam with Gaussian distribution, pulse width of 15 picoseconds, repetition frequency of 4M, average power of 100W, and ablation threshold exceeding The laser energy density is 3.0J / cm 2 , With the XY scanning galvanometer, ablate the surface of the H13 hot-worked die steel to form a symmetrical negat...

Embodiment 2

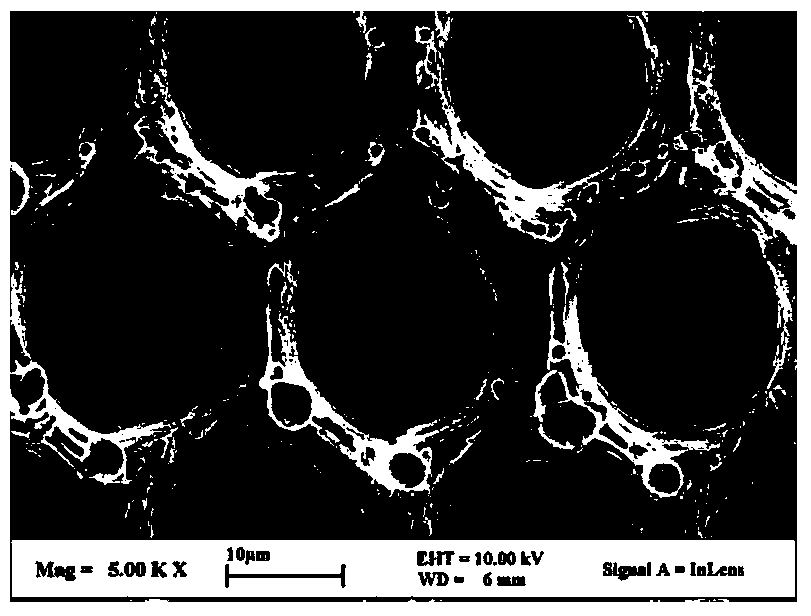

[0045] Example 2. Preparation of high-speed steel mold with superhydrophobic micro / nano surface imprinted by high-power picosecond laser

[0046] In this embodiment, using a high-power picosecond laser to prepare a mold steel mold for imprinting super-hydrophobic micro / nano surfaces includes the following steps:

[0047] 1) Preparation of the metal substrate: first, the surface of the high-speed steel substrate is polished by mechanical processing, and then polished with a grinding and polishing machine, ultrasonically cleaned with alcohol, and dried for later use;

[0048] 2) Laser processing: using high-power picosecond laser, green light with laser wavelength of 532nm, laser beam with Gaussian distribution, pulse width of 3 picoseconds, repetition frequency of 100K, average power of 40W, and ablation threshold Laser energy density 1.2J / cm 2 , With the 3D scanning galvanometer, ablate the surface of the high-speed steel to form a symmetrical negative structure of the lotus leaf mic...

Embodiment 3

[0050] Example 3: Preparation of cemented carbide mold with superhydrophobic micro / nano surface imprinted by high-power femtosecond laser

[0051] In this embodiment, using a high-power femtosecond laser to prepare a cemented carbide mold for imprinting superhydrophobic micro / nano surfaces includes the following steps:

[0052] 1) Preparation of the metal base material: first, the surface of the cemented carbide base material is polished by mechanical processing, and then polished with a grinding and polishing machine, ultrasonically cleaned with alcohol, and dried for later use;

[0053] 2) Laser processing: high-power femtosecond laser, near-infrared laser with a wavelength of 1.06 microns, Gaussian distribution of laser beam, pulse width of 100 femtoseconds, repetition frequency of 1K, average power of 4W, and ablation threshold exceeding The laser energy density is 1.5J / cm 2 , Cooperate with the XY platform to move the laser beam to scan the cemented carbide substrate for ablatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com