Metal mold for embossing superhydrophobic micro-nano surface and laser preparation method thereof

A micro-nano surface and metal mold technology, applied in laser welding equipment, metal processing equipment, nanotechnology, etc., to achieve high durability, wide practicability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

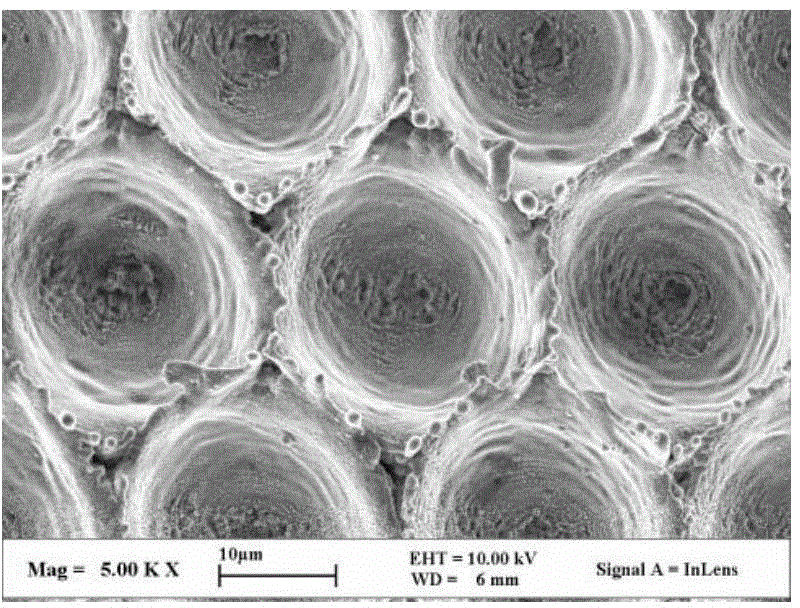

[0040] Example 1. High-power picosecond laser preparation of mold steel molds for embossing superhydrophobic micro-nano surfaces

[0041] In this embodiment, a high-power picosecond laser is used to prepare an H13 hot work die steel mold for embossing a superhydrophobic micro-nano surface, including the following steps:

[0042] 1) Preparation of the metal base material: First, the surface of the H13 hot work die steel base material is ground flat by mechanical processing, then polished with a grinding and polishing machine, ultrasonically cleaned with alcohol, and dried for use;

[0043] 2) Laser treatment: using high-power picosecond laser, the laser wavelength is 1.06 micron near-infrared, the laser beam is Gaussian distribution, the pulse width is 15 picoseconds, the repetition frequency is 4M, and the average power is 100W. The laser energy density is 3.0J / cm 2 , with the X-Y scanning galvanometer, ablate the surface of H13 hot work die steel to form a symmetrical negati...

Embodiment 2

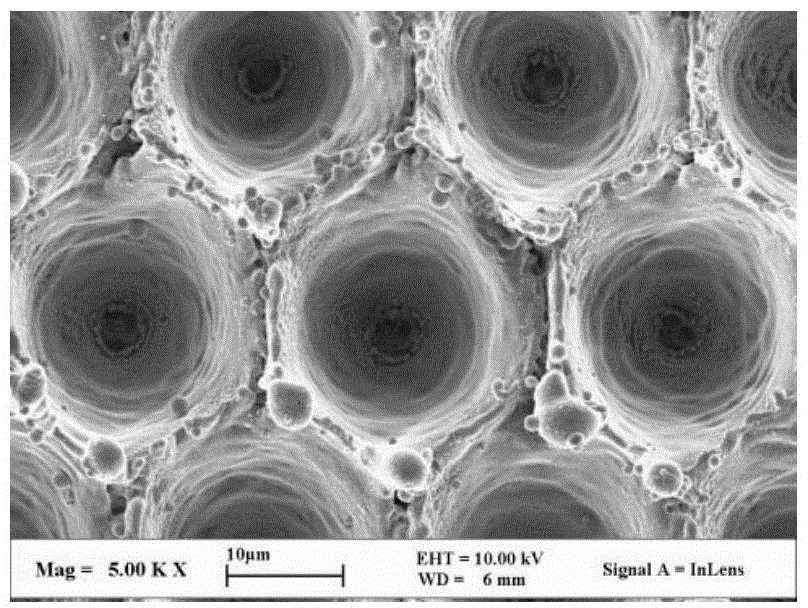

[0045] Example 2. High-power picosecond laser preparation of high-speed steel molds for embossing superhydrophobic micro-nano surfaces

[0046] In this embodiment, a high-power picosecond laser is used to prepare a mold steel mold for embossing a superhydrophobic micro-nano surface, including the following steps:

[0047] 1) Preparation of the metal base material: First, the surface of the high-speed steel base material is ground flat by mechanical processing, then polished with a grinding and polishing machine, ultrasonically cleaned with alcohol, and dried for use;

[0048] 2) Laser treatment: high-power picosecond laser, green light with a laser wavelength of 532nm, a Gaussian distribution of the laser beam, a pulse width of 3 picoseconds, a repetition rate of 100K, and an average power of 40W. Laser energy density 1.2J / cm 2 , cooperate with 3D scanning galvanometer to ablate the surface of high-speed steel to form a symmetrical negative structure of lotus leaf micro-nano ...

Embodiment 3

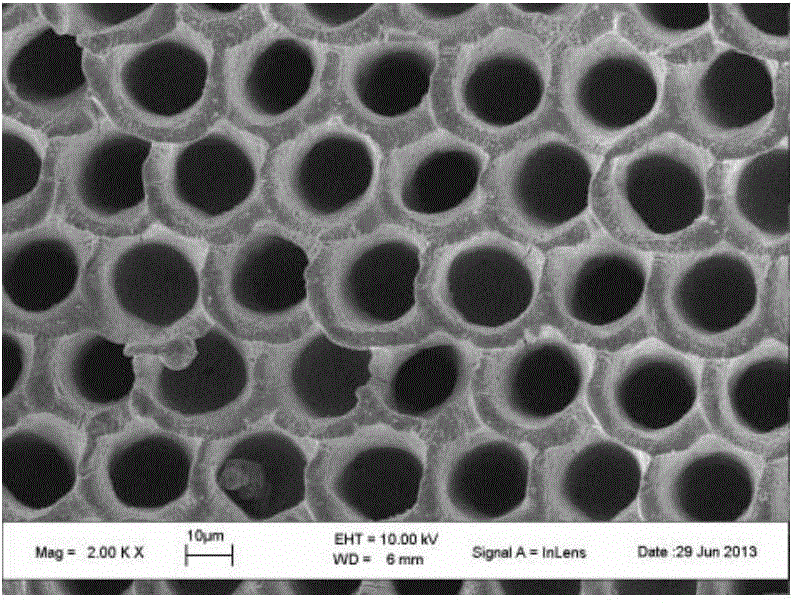

[0050] Example 3, High-power femtosecond laser preparation of cemented carbide molds for embossing superhydrophobic micro-nano surfaces

[0051] In this embodiment, a high-power femtosecond laser is used to prepare a cemented carbide mold for embossing a superhydrophobic micro-nano surface, including the following steps:

[0052] 1) Preparation of the metal base material: First, use mechanical processing to smooth the surface of the cemented carbide base material, then polish it with a grinding and polishing machine, perform ultrasonic cleaning with alcohol, and dry it for use;

[0053] 2) Laser treatment: high-power femtosecond laser is used, the laser wavelength is 1.06 micron near-infrared, the laser beam is Gaussian distribution, the pulse width is 100 femtoseconds, the repetition frequency is 1K, and the average power is 4W. Laser energy density of 1.5J / cm 2 , cooperate with the X-Y platform to move the laser beam to scan the cemented carbide substrate for ablation, form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com