All-paper buffering packing case for medical instrument

A technology for medical equipment and packaging boxes, applied in the field of all-paper cushioning packaging boxes, which can solve problems such as high cost, long degradation cycle, and artificial molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

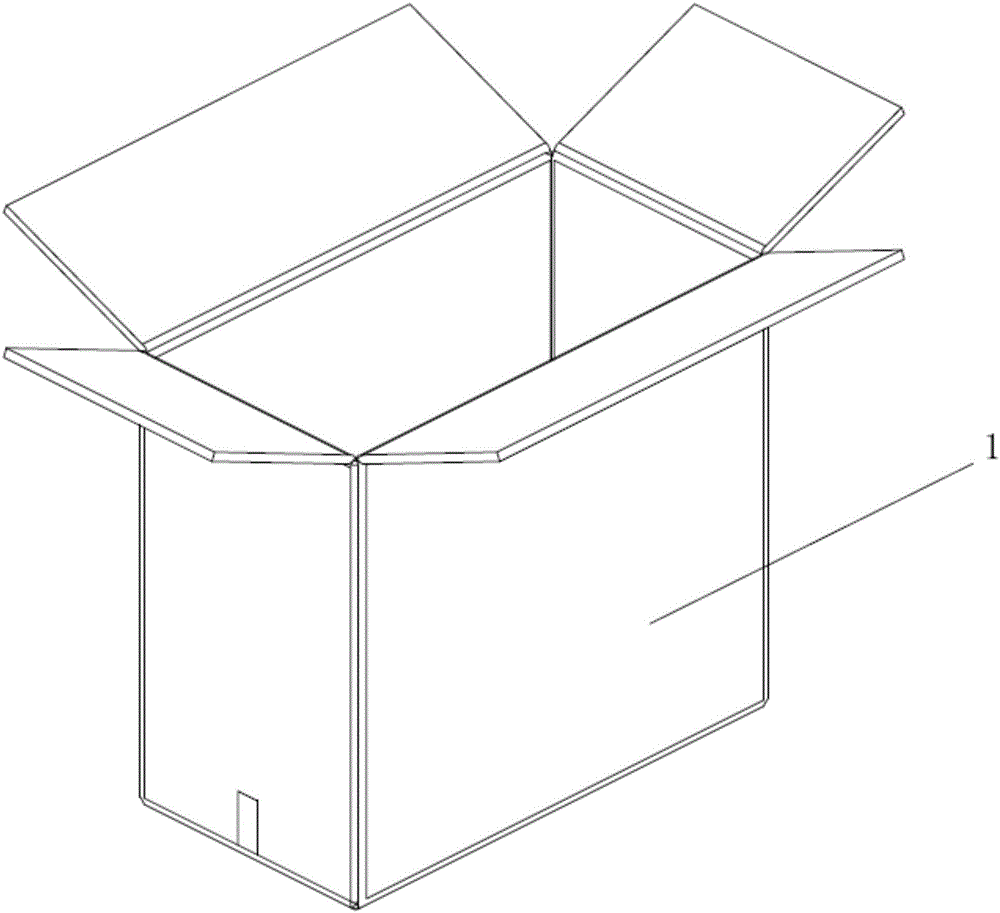

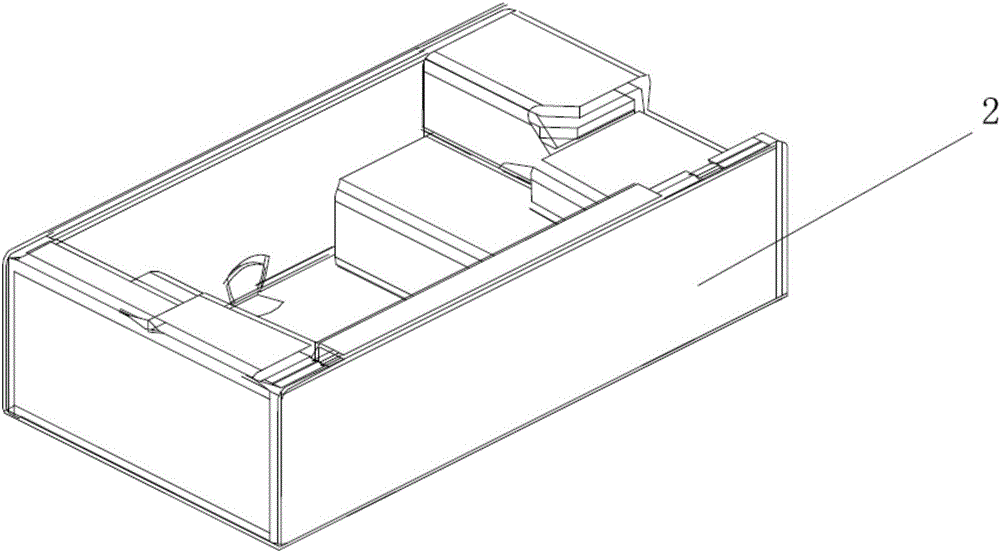

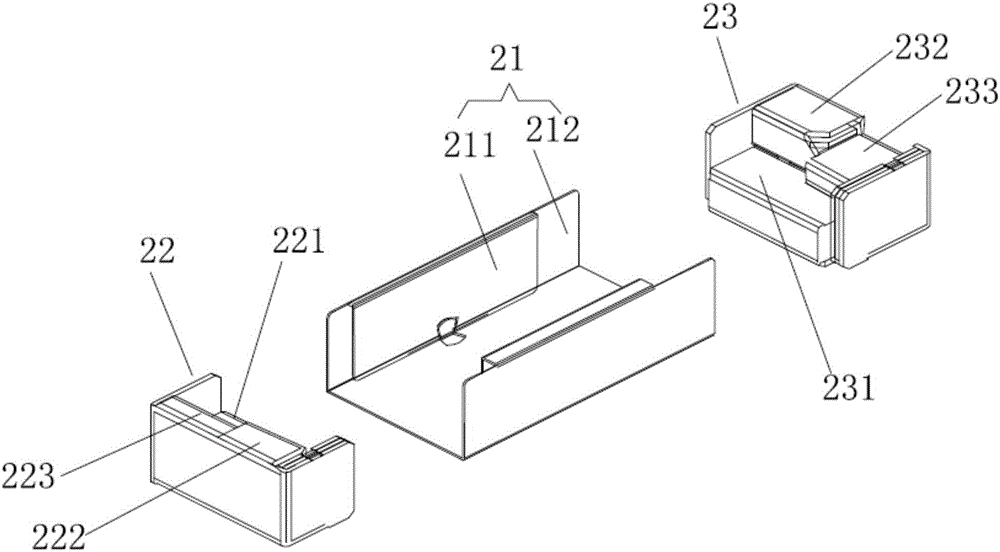

[0029] Such as Figure 1-5 As shown, the present invention provides a full paper buffer packaging box for medical instruments, including a box body 1, a lower tray 2 and an upper tray 3, and the box body 1, the lower tray 2 and the upper tray 3 are all made of corrugated paper according to the required shape. Crease and fold according to the crease. Corrugated paper packaging has low cost, good mechanical processing performance, and can adapt to large-scale mechanized production. Moreover, corrugated paper has the characteristics of green and environmental protection. The packaging box made of corrugated paper is pollution-free when used, and can meet the requirements of breathability, moisture resistance, shock resistance and compression resistance. Requirements, but also easy to recycle.

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com