Concrete production system

A production system and concrete technology, applied in the field of concrete, can solve problems such as environmental pollution, and achieve the effects of reducing production costs, improving production environment, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

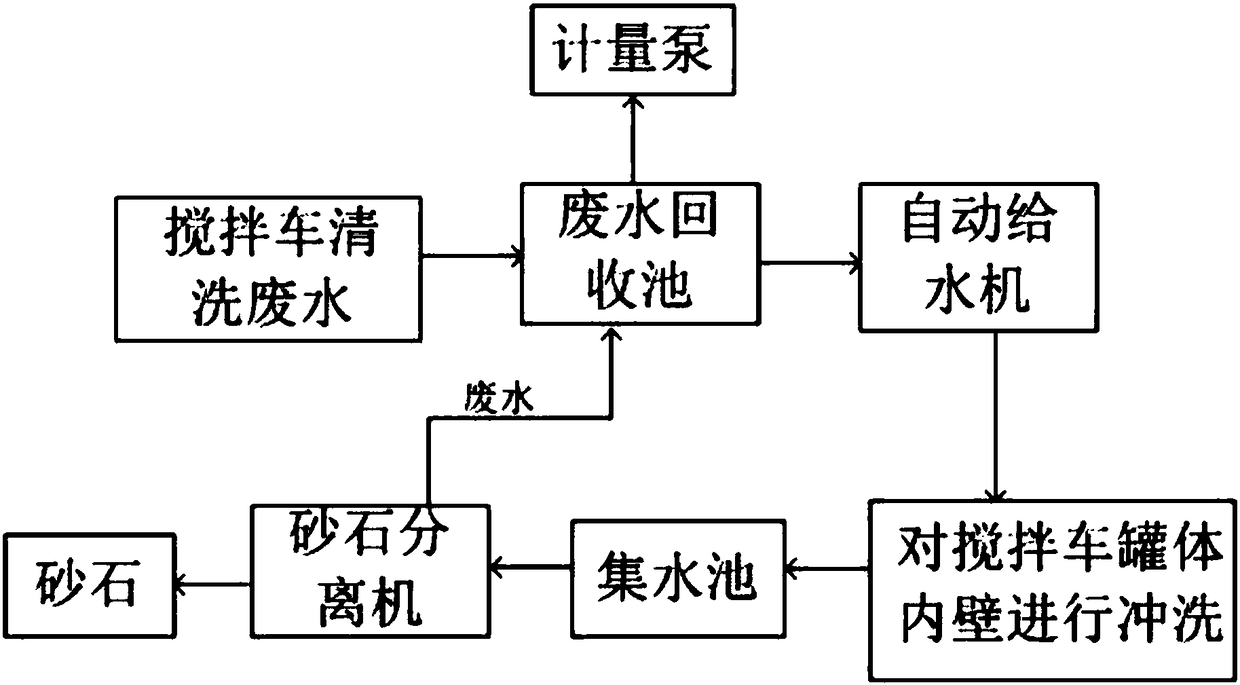

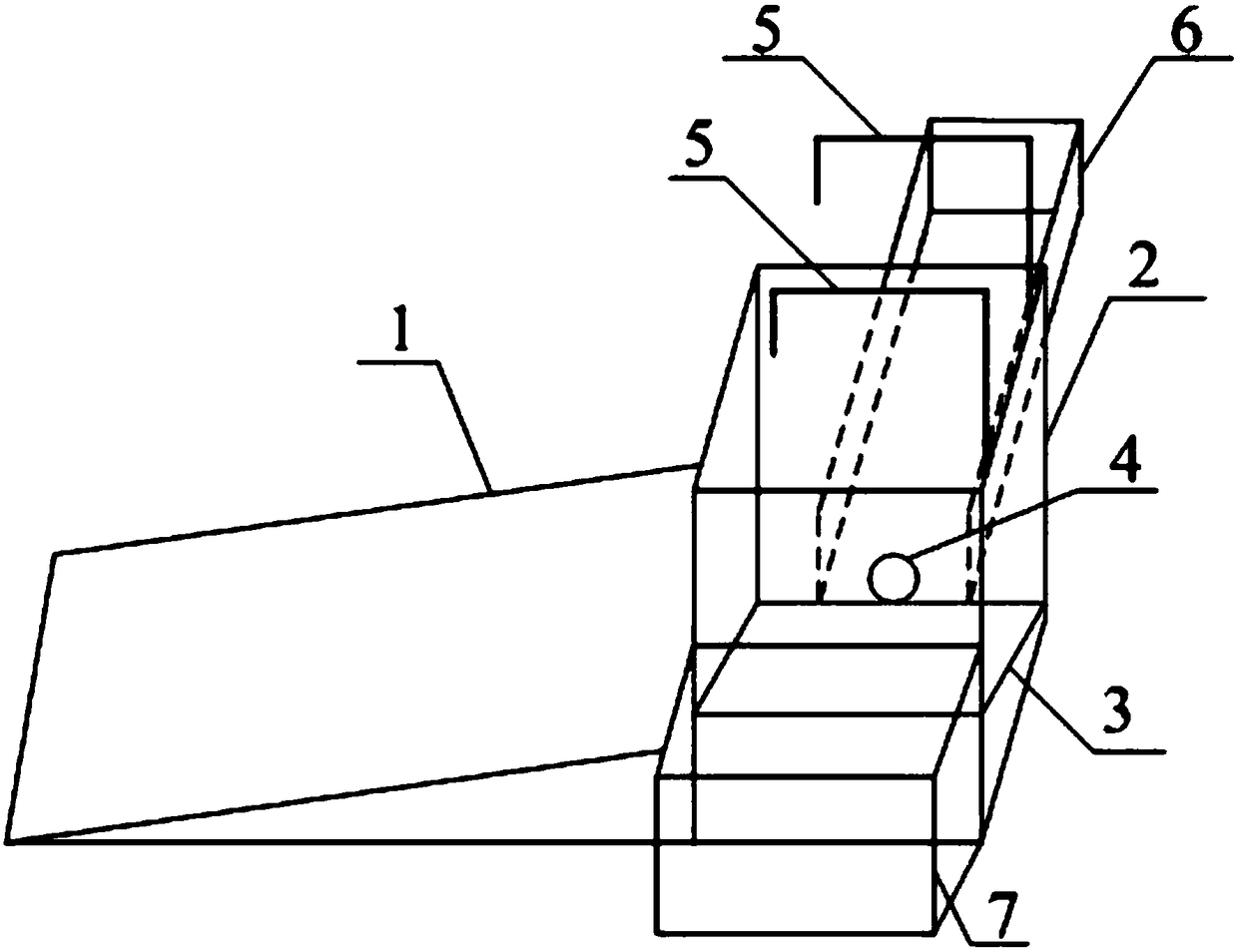

[0012] as attached figure 1 As shown, the concrete production system is characterized in that: it includes a waste water recovery tank for collecting and cleaning the waste water of the concrete mixer truck, and the waste water recovery tank is connected with an automatic water feeder, and the automatic water feeder is used for cleaning the inside of the concrete mixer truck pipe body, The automatic water feeder includes a controller 7, a sump 2 and a flushing nozzle 5. The controller 7 controls the flushing nozzle 5 to flush the tank body of the concrete mixer truck, and the waste water after flushing enters the sump 2, and the bottom 3 of the sump 2 It is an inclined type, and the height of the bottom of the pool on one side of the water outlet 4 is lower than that of the other side of the pool bottom, so that the waste water in the sump 2 can smoothly enter the water inlet channel 6 of the sand and gravel separator from the water outlet 4, and the sand and gravel is separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com