Puller

A technology of the main body and the matching part, which is applied to the puller. field, it can solve problems such as poor clamping, inability to effectively disassemble, and changes, and achieve the effects of simple structure, guaranteed reliability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

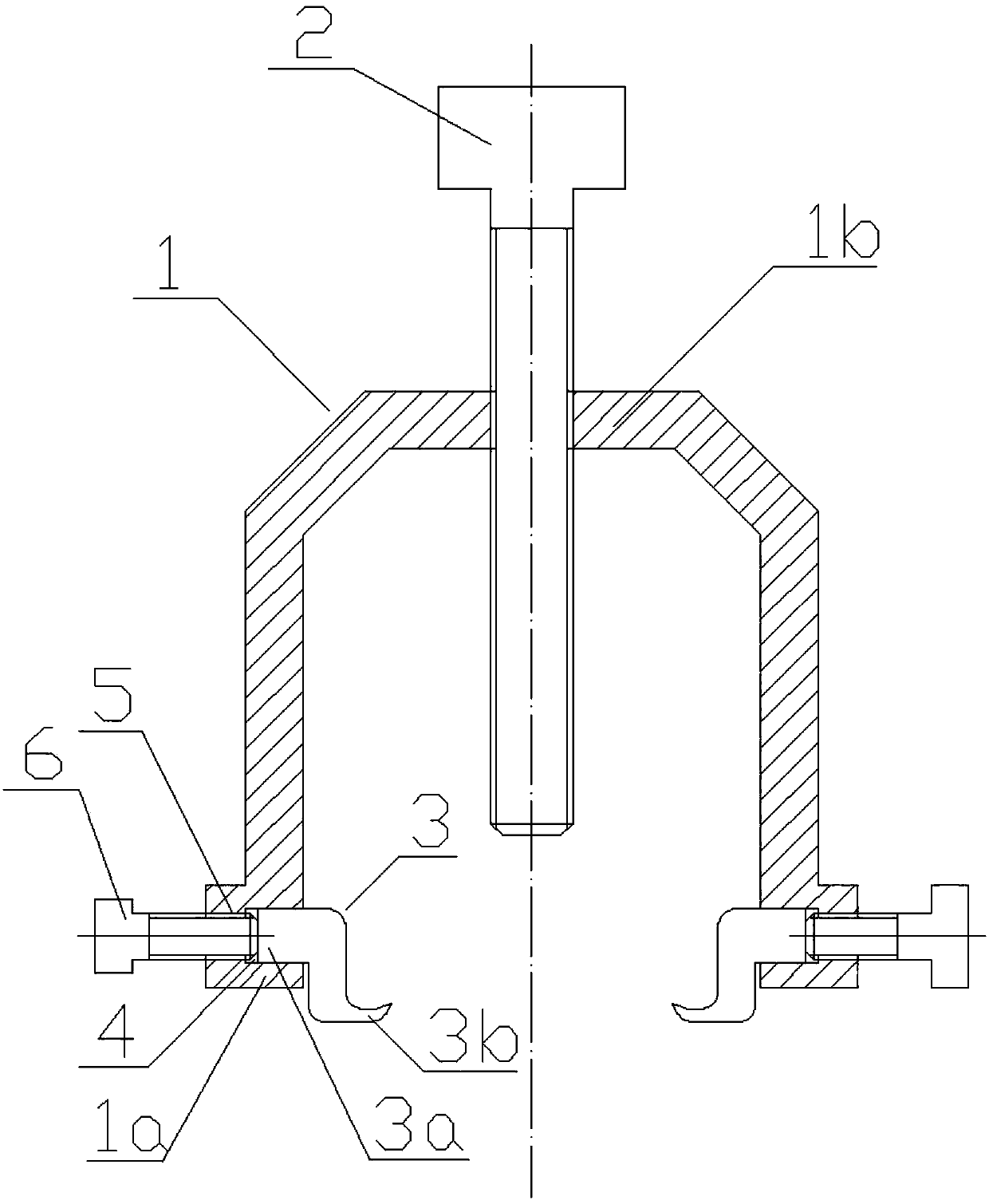

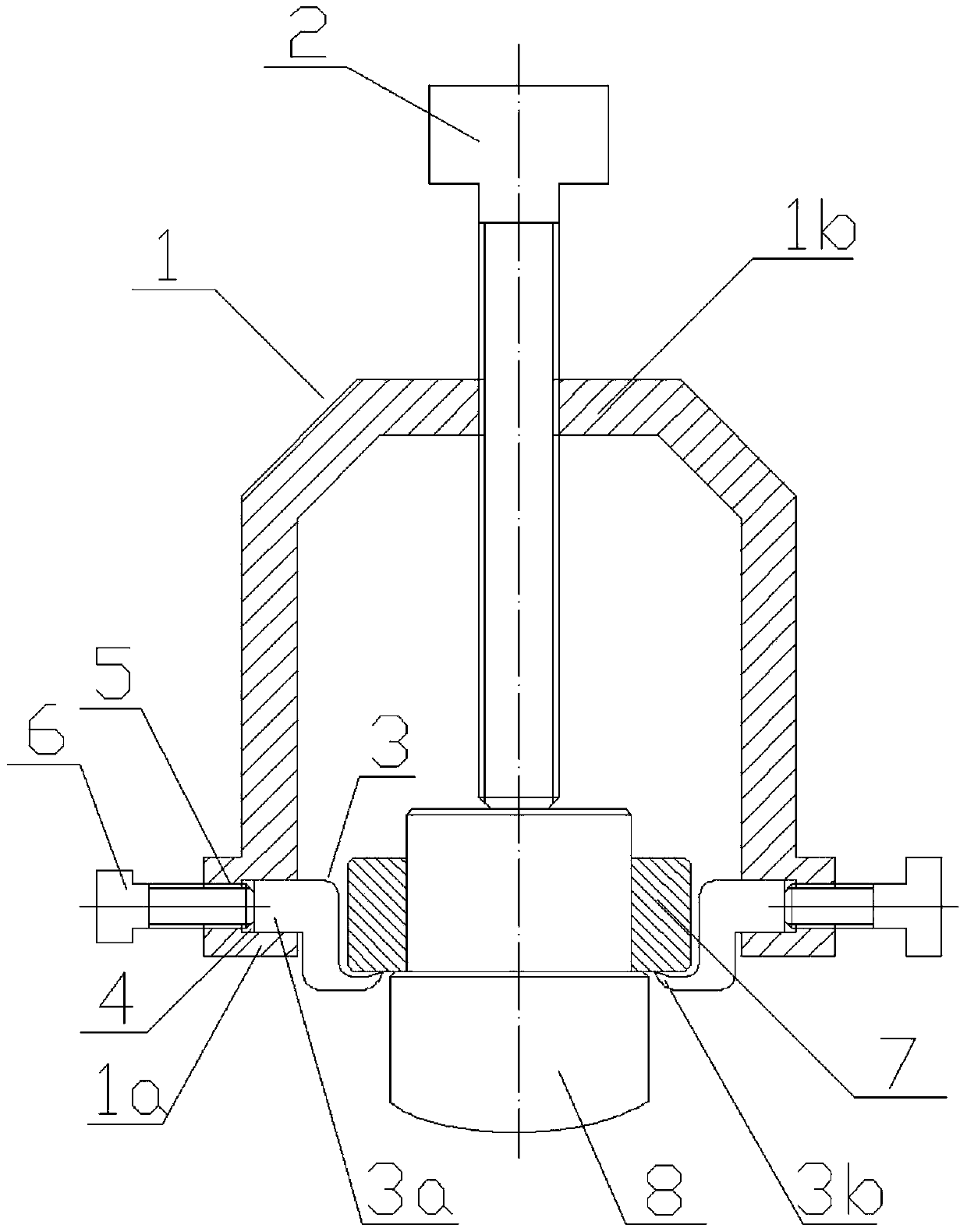

[0018] Such as figure 1 As shown, the puller corresponding to a preferred embodiment of the present invention is used to disassemble the ring-shaped workpiece 7 from the shaft 8, and the workpiece 7 can be workpieces such as bearings, pulleys and gears. The puller includes a body 1 , an extruding screw 2 and a hook 3 .

[0019] The body 1 includes at least two ends 1a that work together to clamp the workpiece 7. The body 1 also includes a connecting portion 1b connecting each end. The extruding screw 2 is arranged at the center of the connecting portion 1b. When the puller clamps the workpiece 7 , the axis of the extruding screw 2 is basically consistent with the axis of the workpiece 7 . In this embodiment, the body 1 is U-shaped, which includes two opposite end portions 1a.

[0020] A hooking m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com