Production method of low-alkali-value sulfonate clearing agent

A base value sulfonate and production method technology, applied in the field of oil additives, can solve the problems of high single-pot utilization rate, environmental protection and low production efficiency, and achieve the effects of good cleaning performance, high production efficiency and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

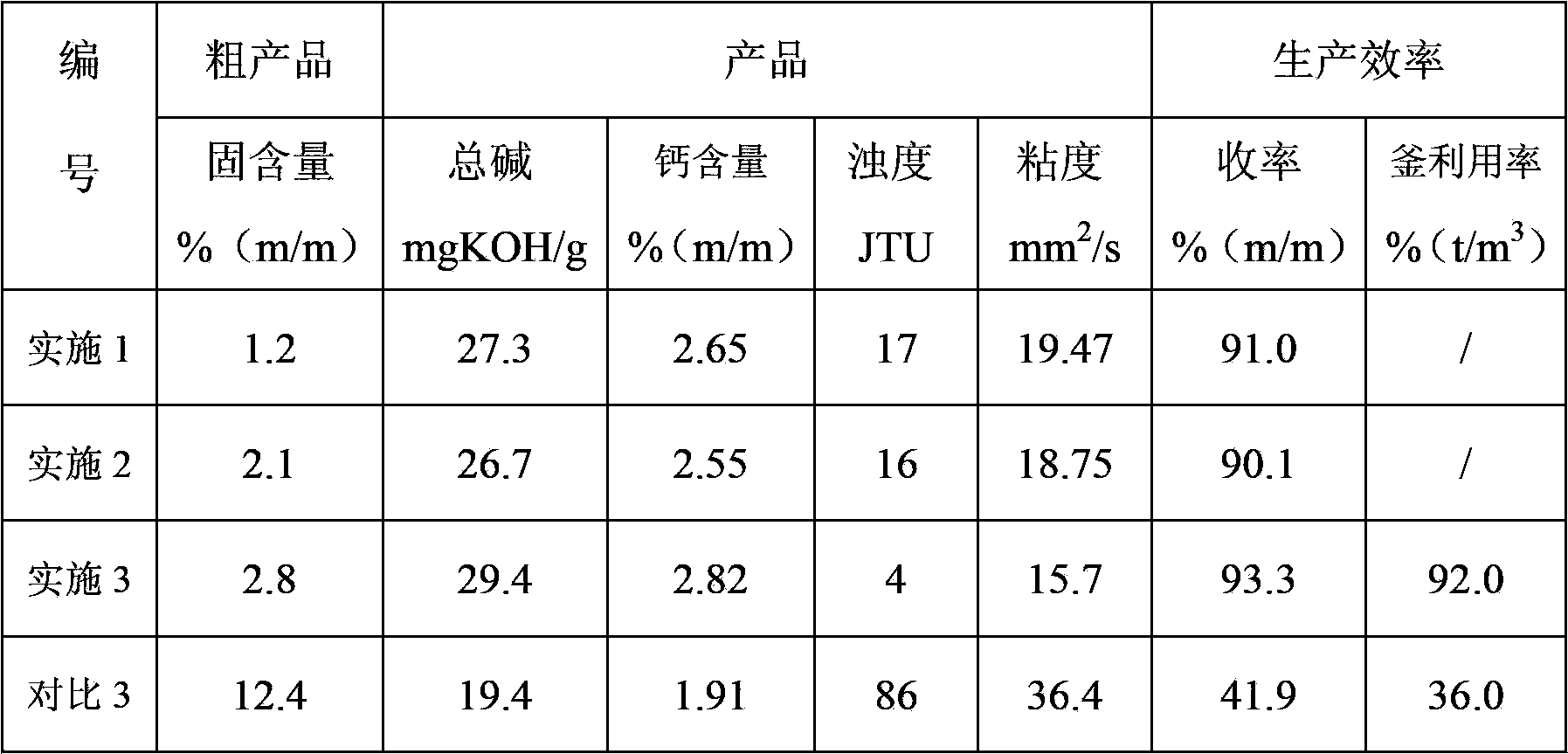

Embodiment 1

[0035] At room temperature, add 170g of neutral oil, 24.5g of water, 28g of slaked lime (industrial product, purity 95%), 230g of heavy alkylbenzene sulfonic acid (industrial product of Jinzhou Company, direct acid value 90.5mgKOH / g), stir evenly, and the material temperature is 61°C. Heating with an electric heating mantle, after 1 hour and 45 minutes, the temperature of the material was raised to 98° C., stirred at constant temperature for 20 minutes, and the metallization reaction was completed. Then, continue to use the electric heating mantle to heat and evaporate the water. When the temperature of the material rises to 118°C, pass the dry air through the gas distribution pipe at a flow rate of 200ml / min, rise to about 150°C, and dry at a constant temperature for half an hour, then stop the flash evaporation dry. The measured solid content of the crude product was 1.2% (m / m). Finally, 20g of diatomite filter aid (Jilin Changbai) was added to the material, mixed evenly, a...

Embodiment 2

[0039] At room temperature, add 375g of neutral oil, 49.0g of water, 57g of slaked lime (industrial product, purity 95%), 425g of heavy alkylbenzene sulfonic acid (industrial product of Jinzhou Company, direct acid value 121.4mgKOH / g), stir evenly, and the material temperature is 60°C. Heating with an electric heating mantle, after 2 hours and 15 minutes, the temperature of the material was raised to 98° C., and the metallization reaction was completed. Then, continue to use the electric heating mantle to heat and evaporate the water. When the temperature of the material rises to 115°C, the dry air is passed through the gas distribution pipe at a flow rate of 300ml / min, and the temperature rises to about 150°C. Dry at a constant temperature for half an hour and stop the flash evaporation dry. The solid content of the crude product was measured to be 2.1% (m / m). Finally, 30g of diatomite filter aid (Jilin Changbai) was added to the material, mixed evenly, and filtered to obtai...

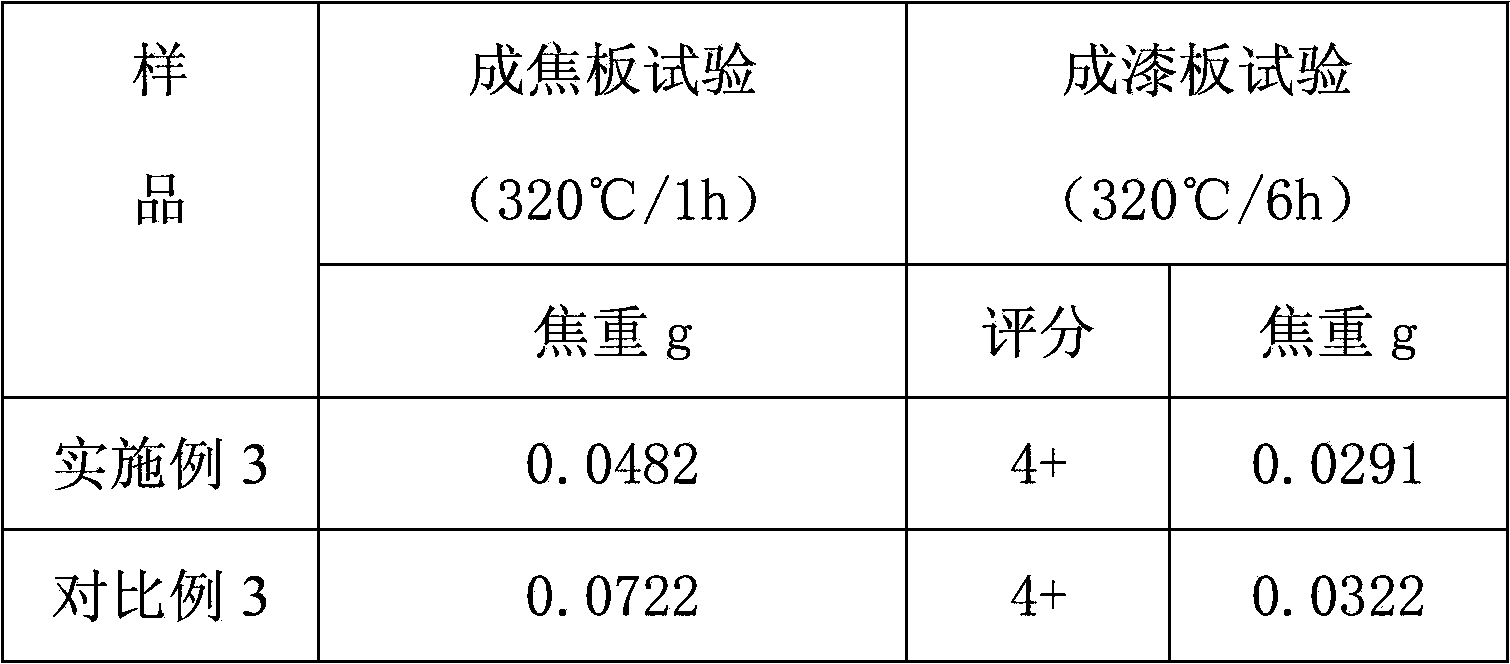

Embodiment 3

[0043] At normal temperature, add 26909Kg neutral oil, 2840Kg water, 3558Kg slaked lime (industrial product, purity 95%), 15791Kg heavy alkylbenzene sulfonic acid (industrial product of Jinzhou Company, direct acid value 138.8 mgKOH / g), mix the materials in the kettle evenly, and the display value of the kettle temperature is 60°C. Use the heating system of the reactor to raise the temperature of the materials in the kettle. After 7 hours, the temperature rises to 97° C., and the metallization reaction is completed. Then, heat up flash evaporation, meanwhile, pass into dry air with 100Kg / h flow rate by the gas distribution pipe at the bottom of the reaction still, take a sample after 2 hours, analyze the moisture value in the material in the kettle to be 0.12%, stop passing dry air, and The solid content of the crude product was measured to be 2.8% (m / m). Finally, add 2000Kg of diatomite filter aid (Jilin Changbai) to the material containing impurities such as solids, mix wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com