Well drilling waste mud recycling and reusing low-temperature treatment system

A waste mud and low-temperature treatment technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of increasing the complexity of equipment and secondary pollutants, and the sewage cannot be recycled Use, groundwater pollution and other issues, to achieve the effect of recycling environmental treatment costs, large social and economic value, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

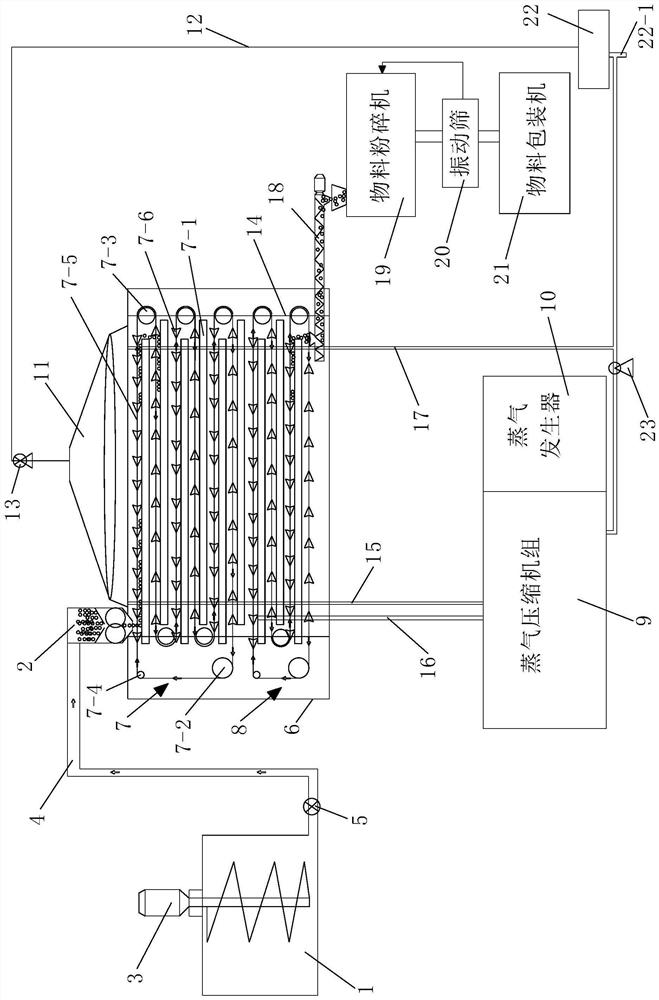

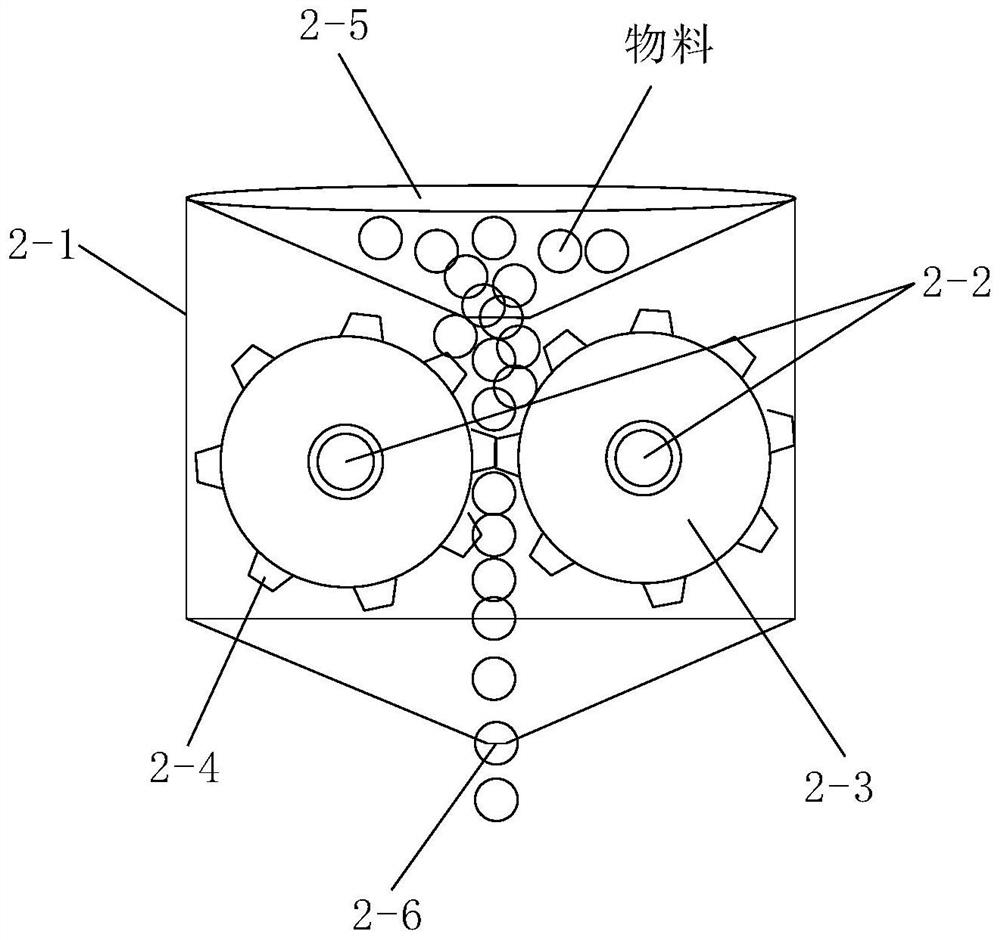

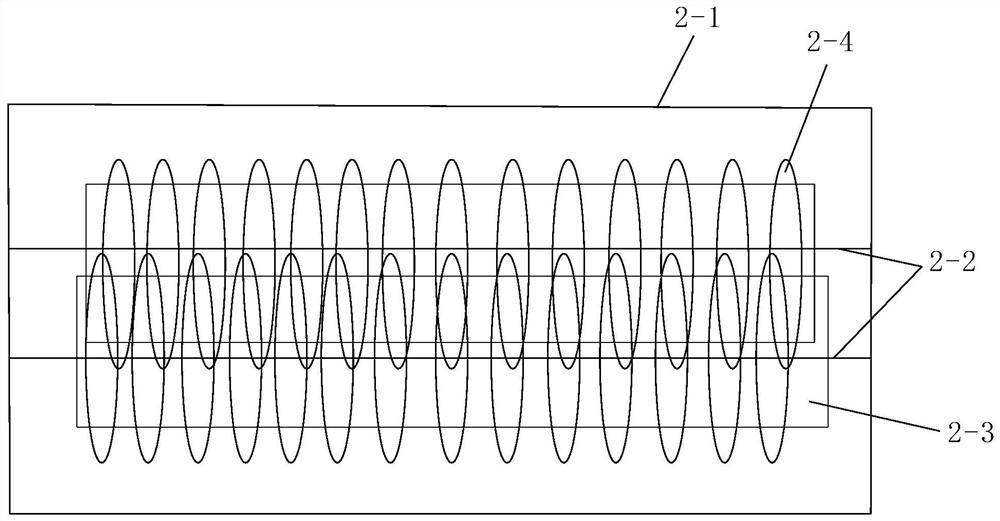

[0047] like figure 1 As shown, the present invention includes a drilling waste mud collection and pumping system, a material distributor 2, a low-temperature drying mechanism, a steam generation and conveying system and a material post-processing system, and the material distributor 2 is located at the feed of the low-temperature drying mechanism. and evenly distribute the drilling waste mud in the drilling waste mud collection and pumping system in the low temperature drying mechanism, and the steam generation and conveying system is connected with the low temperature drying mechanism and is used for the low temperature drying The mechanism provides the steam required for low-temperature drying, and the material post-processing system is arranged at the material outlet of the low-temperature drying mechanism and pulverizes and packs the dried materials; the drilling waste mud collection and pumping system includes: Drilling waste mud collection pool 1, mud mixer 3, mud convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com