Energy-saving method for recycling wastewater containing phenol and ammonia

A treatment method and wastewater recycling technology, which is applied in the directions of heating water/sewage treatment, degassed water/sewage treatment, extraction water/sewage treatment, etc., can solve the problem of high energy consumption, reduce capacity consumption, save consumption, and realize step-by-step The effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

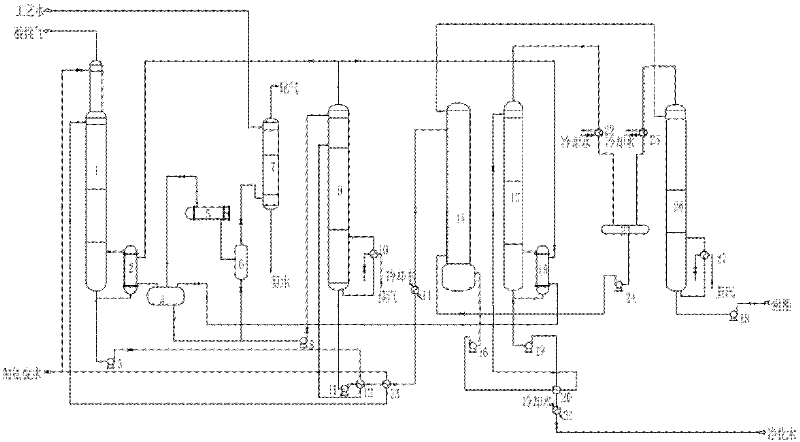

Image

Examples

Embodiment 1

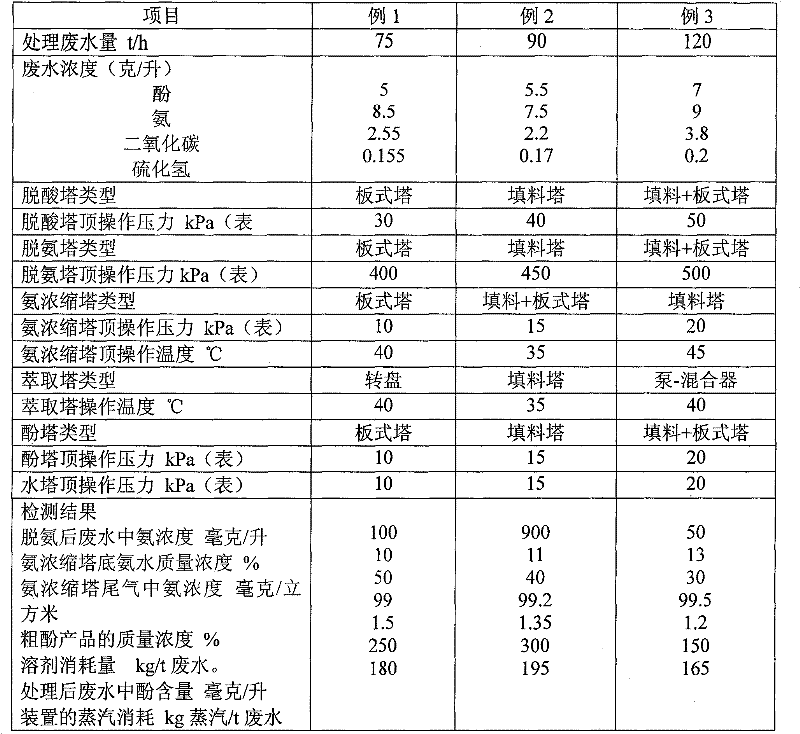

[0061] (1) After the 75t / h waste water is transported from the gas-water separator, the suspended solids, tar and light oil are removed, the temperature is 40°C, and the pressure is 1.0MPa. The concentration is 5 g / L of phenol, 8.5 g / L of ammonia, 2.55 g / L of carbon dioxide, and 0.155 g / L of hydrogen sulfide.

[0062] (2) The phenol ammonia-containing wastewater coming over is divided into two streams: one stream directly enters the top of the tower at 20 t / h; the other stream is heated to 85° C. through the preheater 2 (13) and enters the middle of the deacidification tower (1).

[0063] (3) The deacidification tower is a plate tower. The operating pressure of the deacidification tower is 30kPa (gauge pressure), the temperature at the top of the tower is 40°C, and the bottom of the tower is 110°C. The bottom of the tower is heated by a reboiler (2), and the heat source is the heat released by the condensation of the crude gas at the top of the deamination tower (9). The cond...

example 1

[0071] (1) The ammonia concentration in the wastewater after deammonification is 100 mg / L.

[0072] (2) The mass concentration of ammonia water at the bottom of the ammonia concentration tower is 10%, and the ammonia concentration in the tail gas is 50 mg / m3.

[0073] (3) The mass concentration of the crude phenol product is 99%.

[0074] (4) The solvent consumption is 1.5kg / t waste water.

[0075] (5) The content of phenol in the treated wastewater is 250 mg / L

[0076] (6) The steam consumption of the device is 180kg steam / t waste water.

Embodiment 3

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com