Patents

Literature

43results about How to "Realize ladder utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

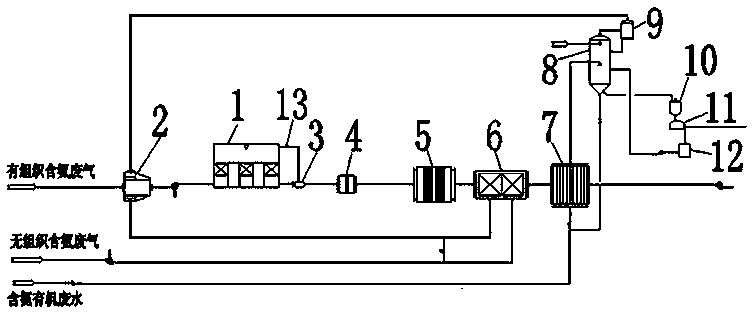

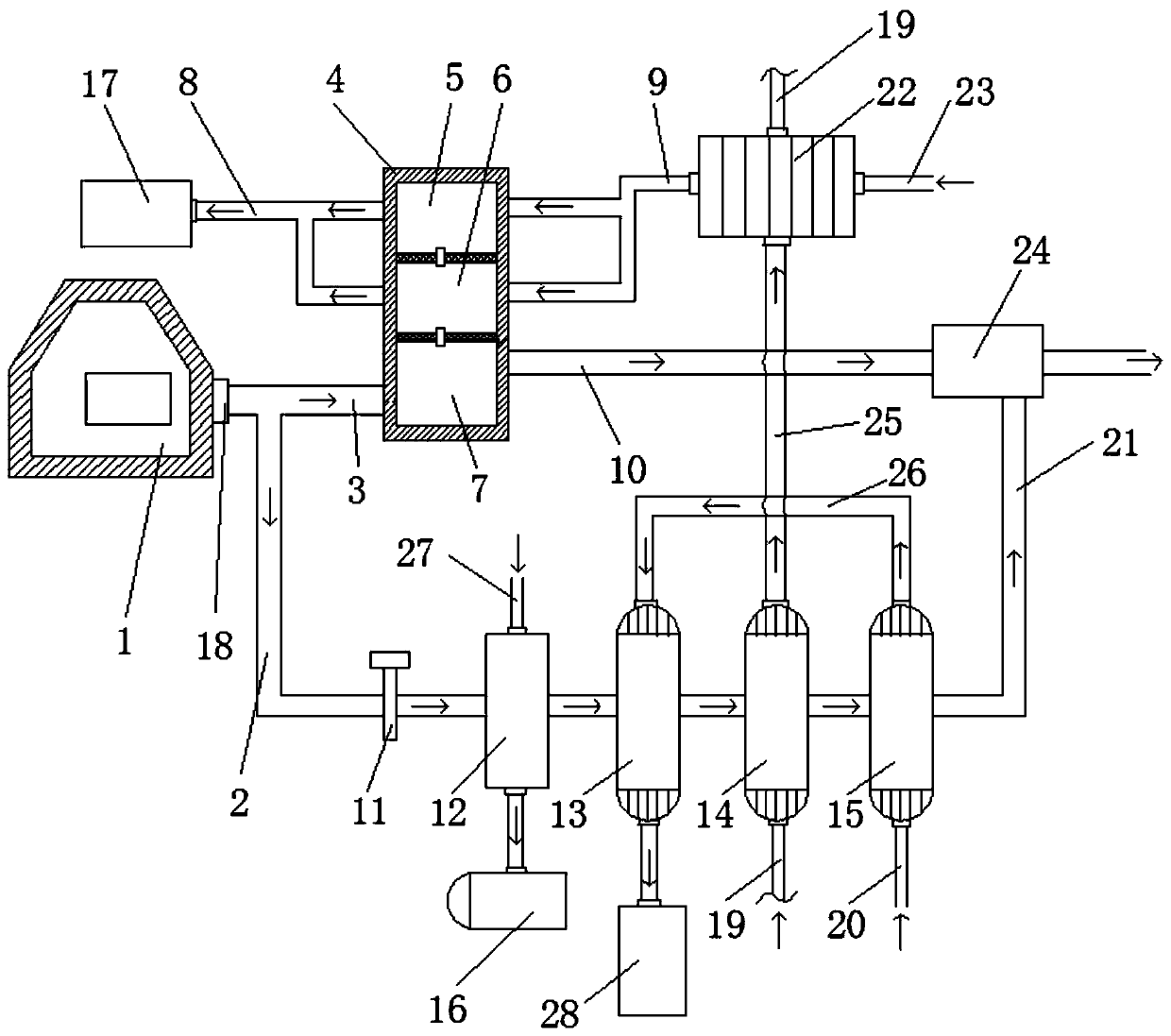

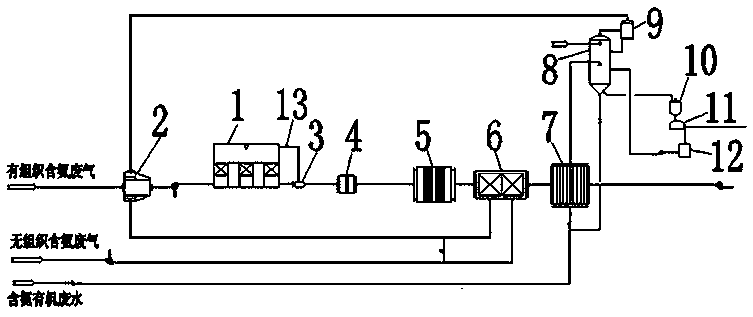

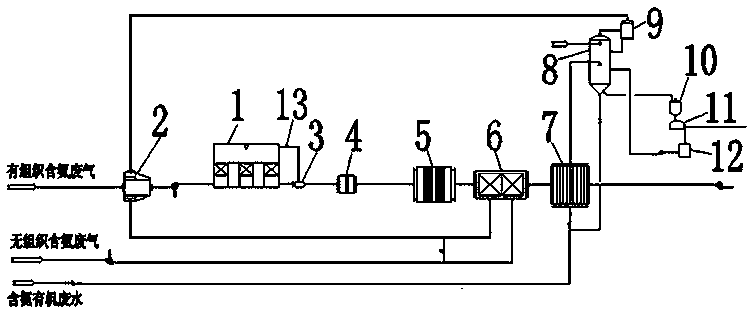

Comprehensive treatment technology and system for ammonia containing organic waste gas and ammonia containing organic waste water

ActiveCN109442438AHigh removal rateRaise the exhaust gas temperatureGas treatmentSpecific water treatment objectivesTreatment systemChemistry

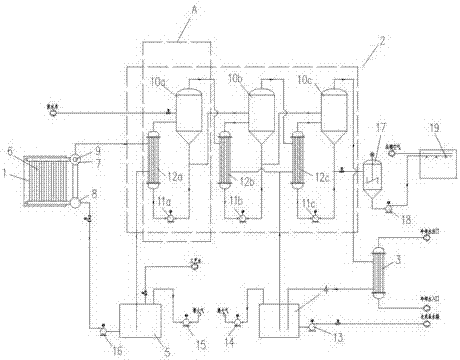

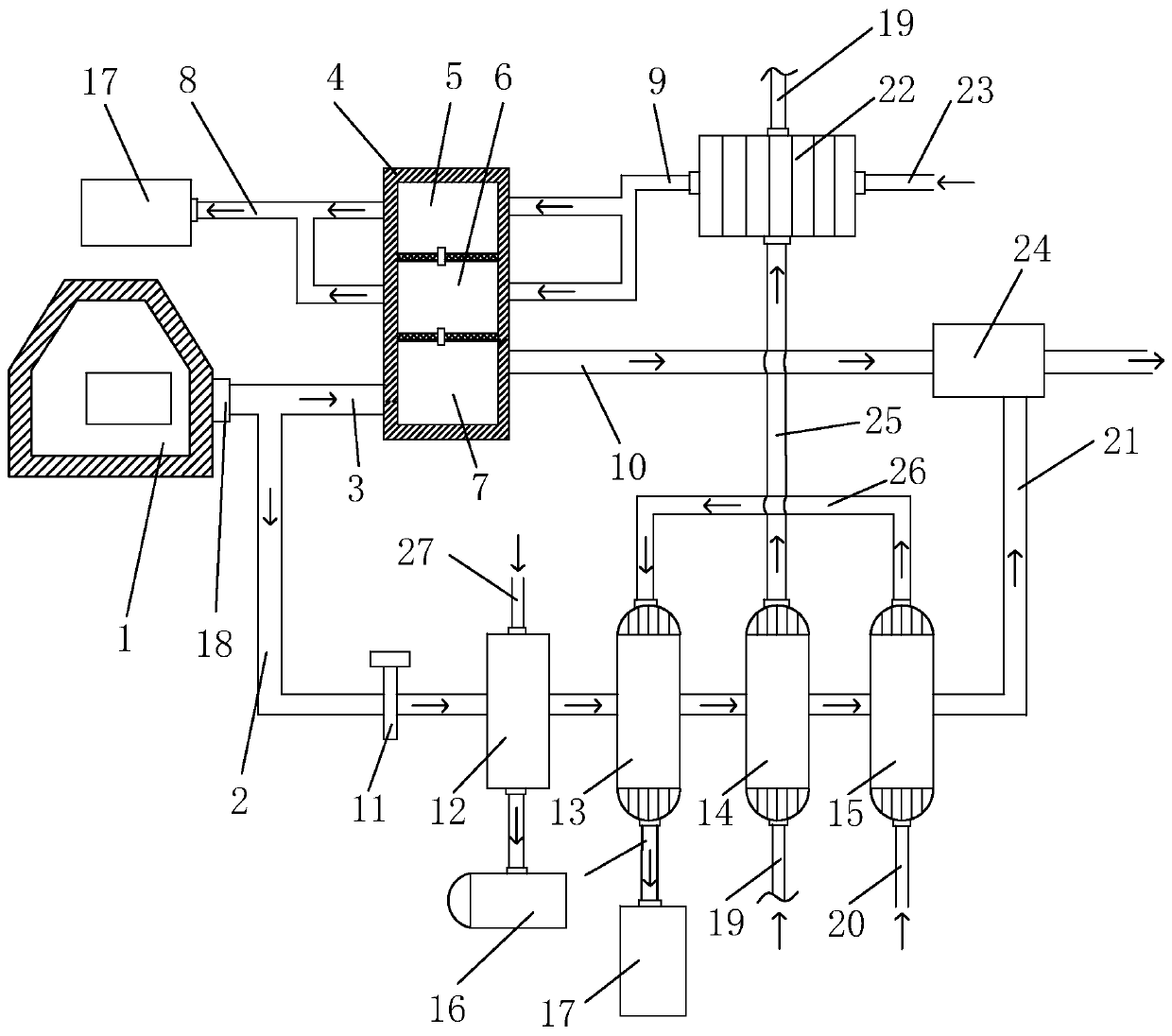

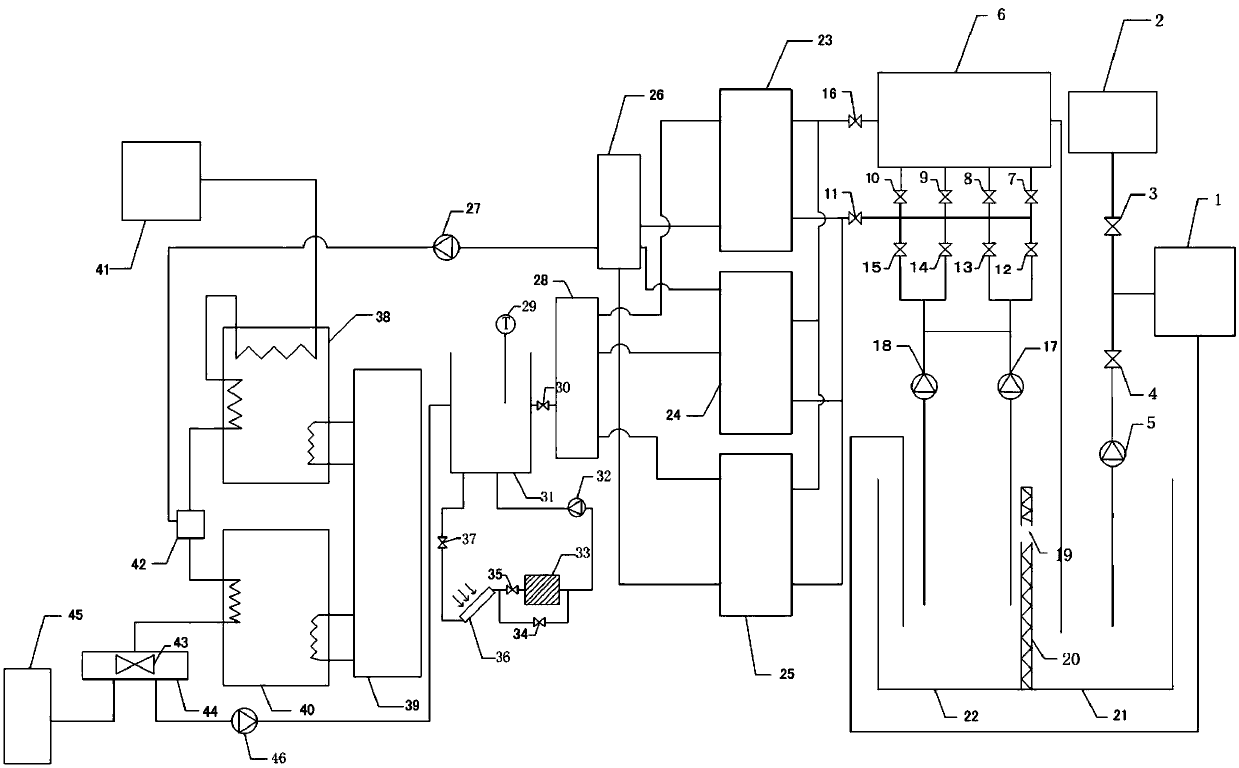

The invention relates to a comprehensive treatment technology and system for ammonia containing organic waste gas and ammonia containing organic waste water. The comprehensive treatment technology comprises the steps that high-temperature furnace inflow waste gas is conveyed into an RTO heat accumulation type incinerator through a waste gas draught fan to be incinerated, and clean smoke is subjected to nitrogen oxide catalytic reduction through an SCR reactor. The comprehensive treatment system comprises the RTO heat accumulation type incinerator, a waste gas mixer is arranged at the front endof the RTO heat accumulation type incinerator, a mixer is arranged at the rear end of the RTO heat accumulation type incinerator and connected with a metal filter, the metal filter is connected withthe SCR reactor, the SCR reactor is connected with a plate heat exchanger, and the plate heat exchanger is connected with a forcing heat exchanger. Low-temperature smoke waste heat is circularly utilized, the furnace feeding temperature is increased, the exhaust temperature of an incinerator system is increased and meets the smoke catalysis denitration technology requirement, no fuel consumption and no denitration agent consumption are achieved, waste water can be treated while waste gas is treated, and secondary pollutants are avoided.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

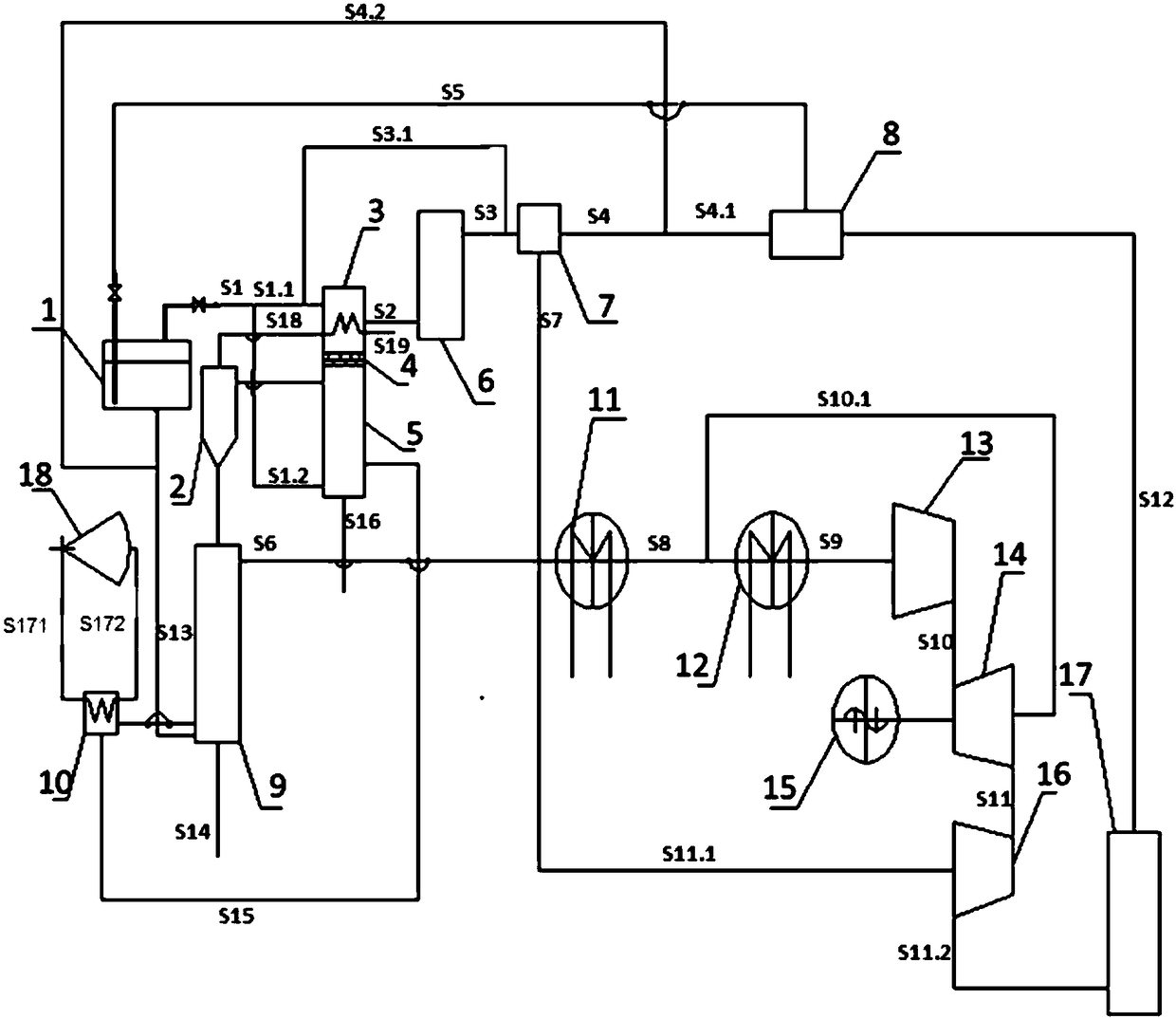

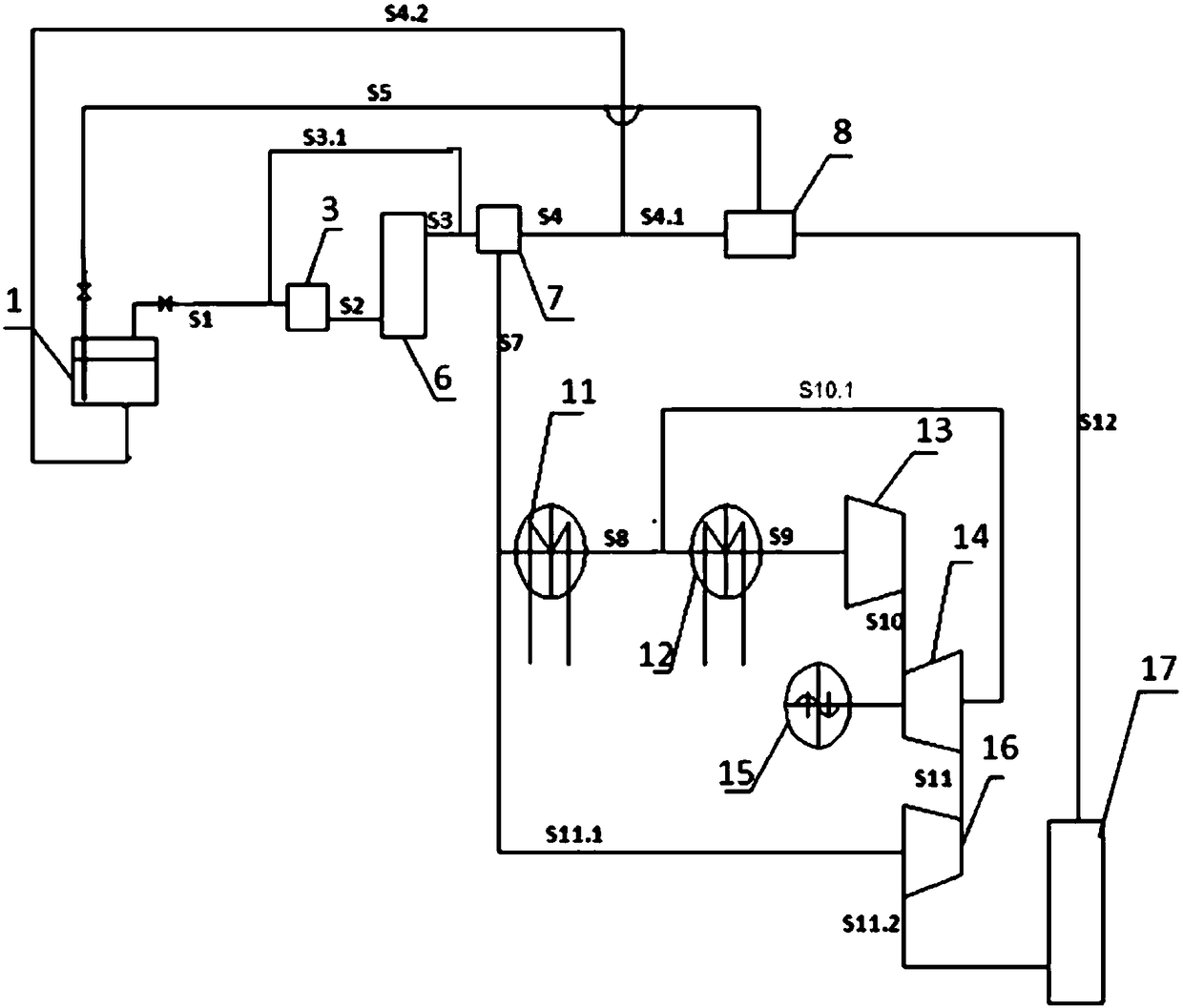

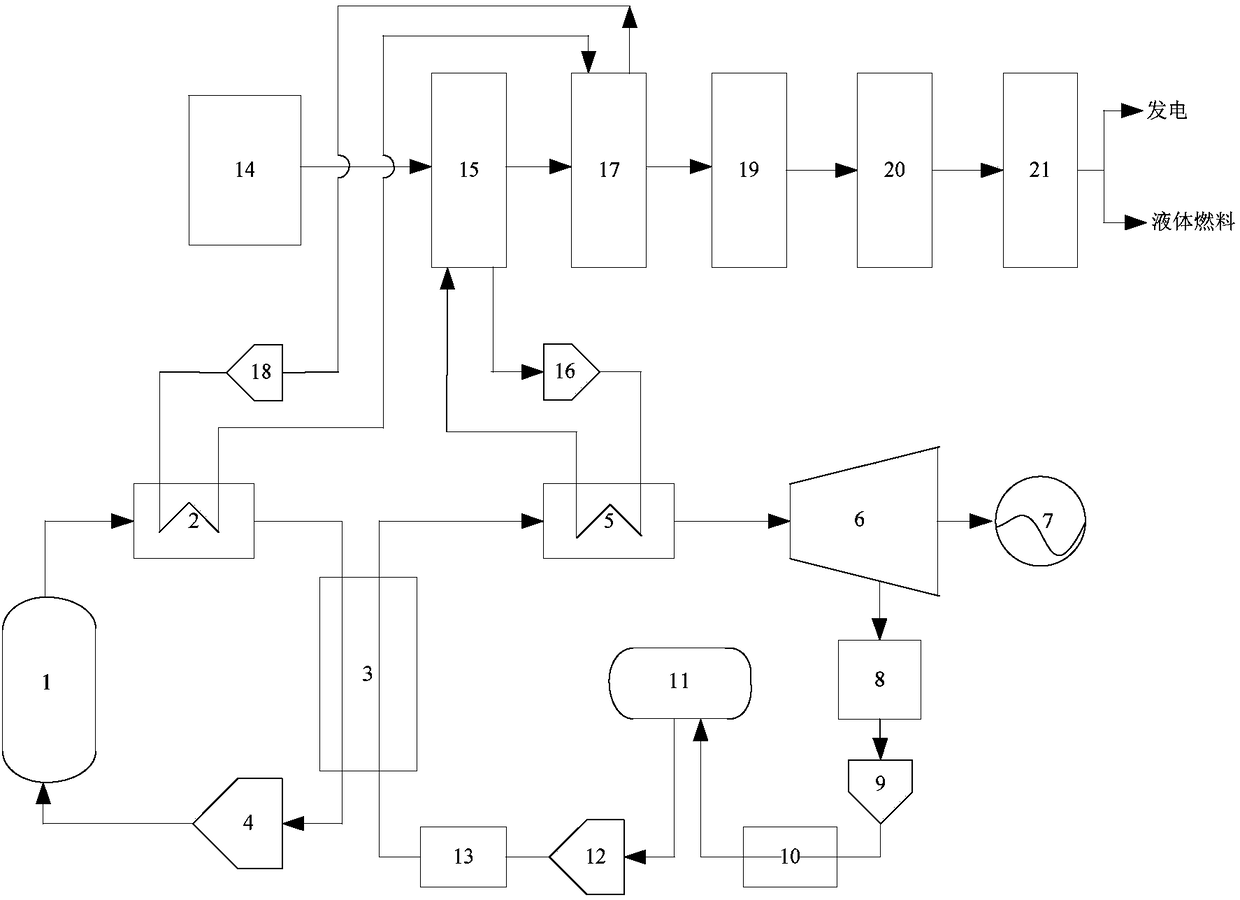

Combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and working method thereof

InactiveCN108507188AReduce sinteringBig investmentBioreactor/fermenter combinationsSolar heating energyHigh energyPower cycle

The invention discloses a combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and a working method thereof. A solar thermal chemistry process and a fuel power cycle are organically coupled by the system, so that the step utilization of the solar energy is realized; on one hand, a reduced oxygen-carrying body is usedfor converting the solar energy into chemical energy to be stored in an oxygen-carrying body heat accumulator, necessary heat energy is provided for the chemical looping combustion; and on the one hand, the characteristic that the CO2 is released by absorbing CO2 through the photosynthesis of microalgae under light illumination is utilized, pure O2 is provided for the oxygen-enriched combustion, and secondary air is provided for an air reactor; in addition, by complementary integration of the oxygen-enriched combustion system and the chemical looping combustion system, and the reasonable and efficient utilization of the fuel is realized; and meanwhile, the pure CO2 generated through oxygen-enriched combustion and chemical looping combustion is used for pushing a turbine to generate electricity for heat supply, so that the problem of high energy consumption and high cost due to the fact that CO2 is trapped and separated is solved, the CO2 flue gas waste heat can be effectively utilized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

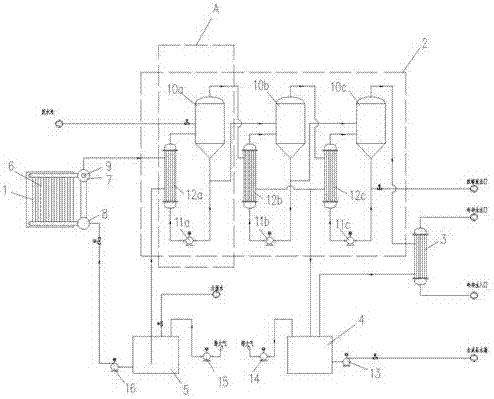

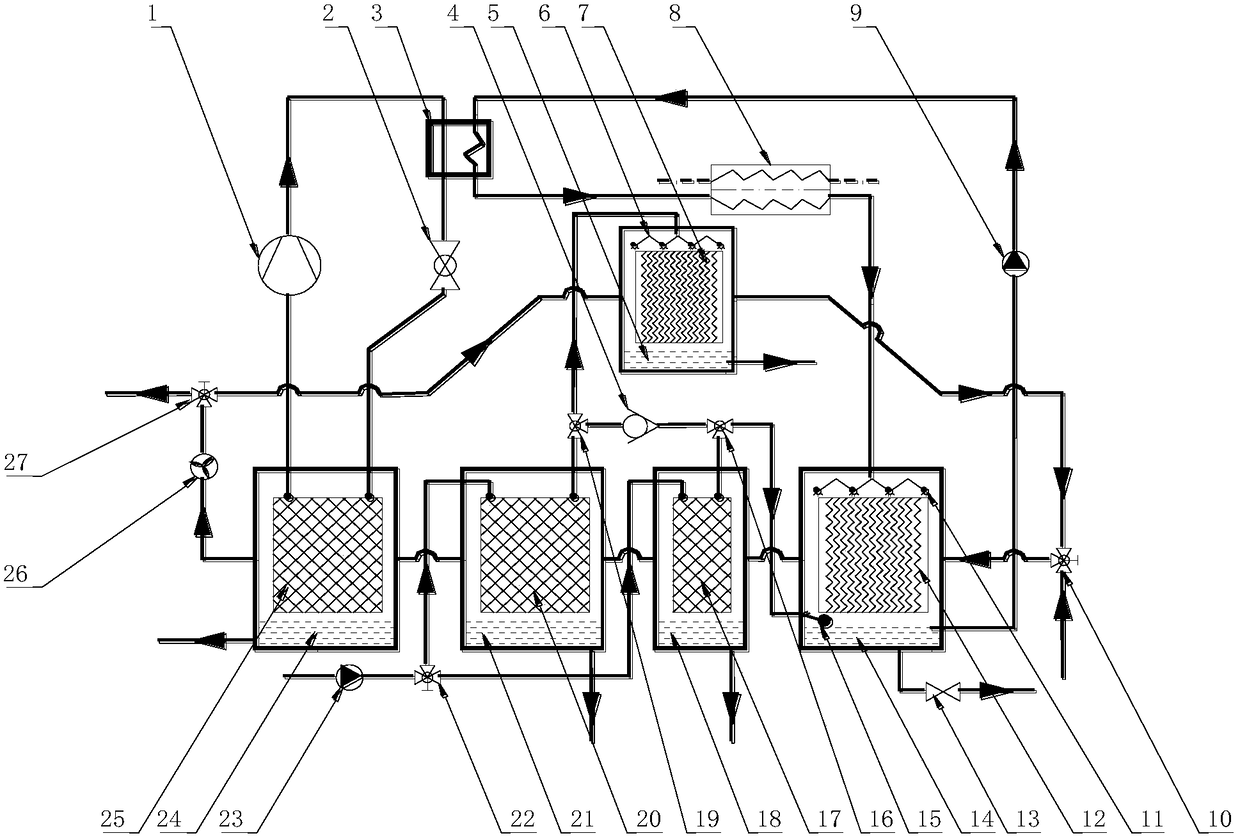

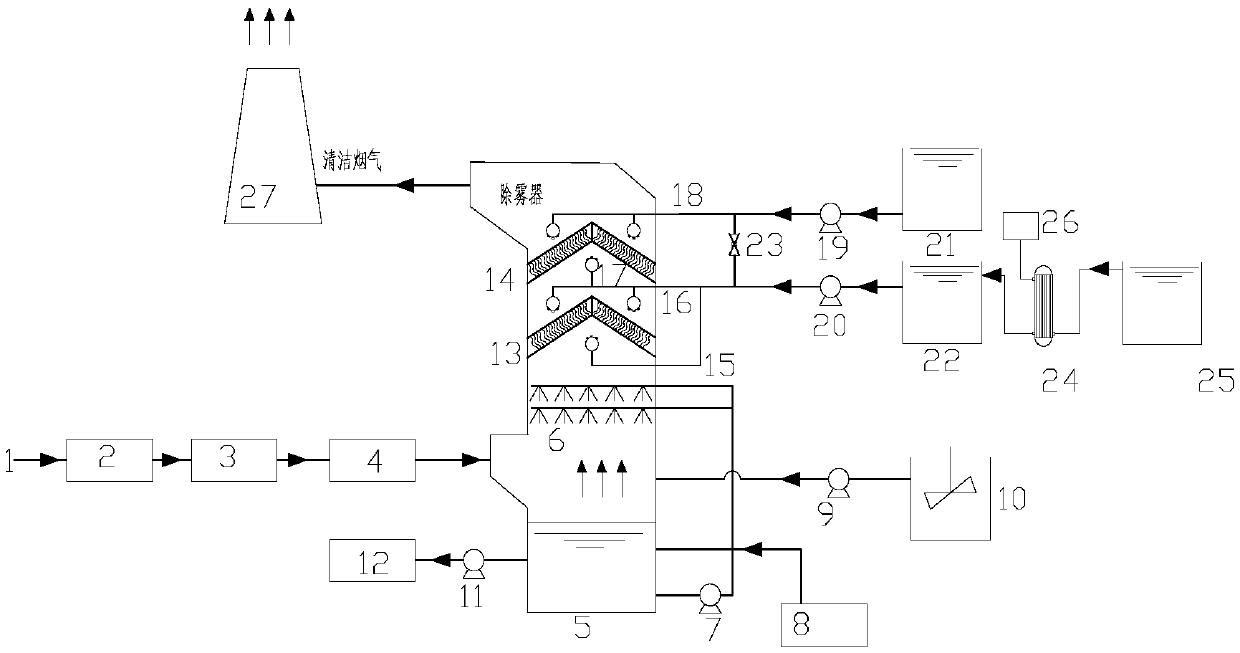

Spray system capable of concentrating desulfurization waste water by use of flue gas waste heat

PendingCN107337245AReduce the temperatureReduce water consumptionWater/sewage treatmentWaste water treatment from gaseous effluentsDistillationClean water

The invention discloses a spray system capable of concentrating desulfurization waste water by use of flue gas waste heat. The spray system comprises a flue heat exchanger, an evaporator set, a tail gas condenser, a tail gas condensation tank and a spray system body, wherein a desulfurization waste water pipeline and the flue heat exchanger are connected with the evaporator set, steam treated by the evaporator set sequentially enters the tail gas condenser and the tail gas condensation tank via pipelines, and a concentrated liquid treated by the evaporator set enters the spray system body through a pipeline; the flue heat exchanger heats the desulfurization waste water in the evaporator set by use of the flue gas waste heat; the evaporator set separates moisture and salt impurities in the desulfurization waste water in an evaporation manner; the evaporated steam is cooled to be condensed by the tail gas condenser; the tail gas condensation tank stores the condensed water and sends the condensed water into a finished product water tank; the spray system body atomizes the concentrated liquid and sprays the concentrated liquid in a boiler fuel gas exhaust channel. According to the system, no chemicals are added in the concentration process of the desulfurization waste water, clean water obtained after distillation is recycled, and the water recovery rate of a desulfurization waste water treatment system is higher than 90%.

Owner:北京尤科恩环保工程有限公司

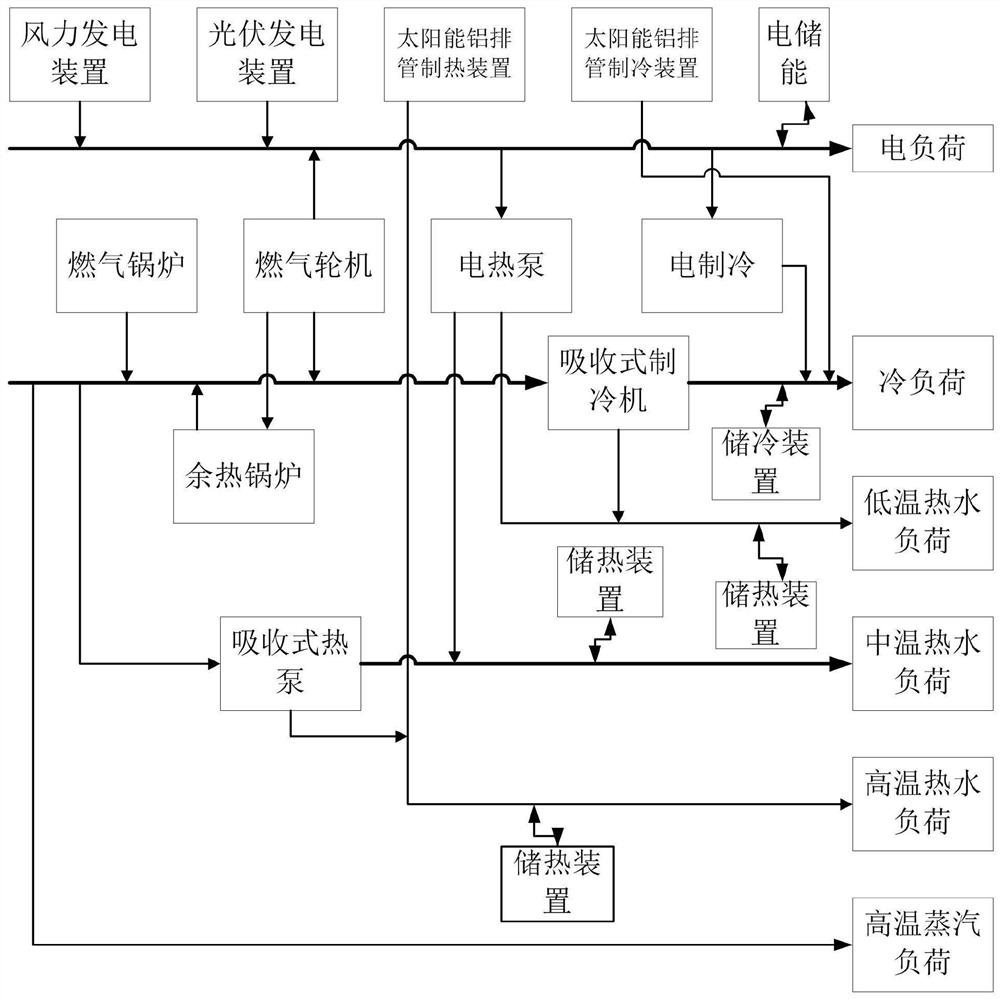

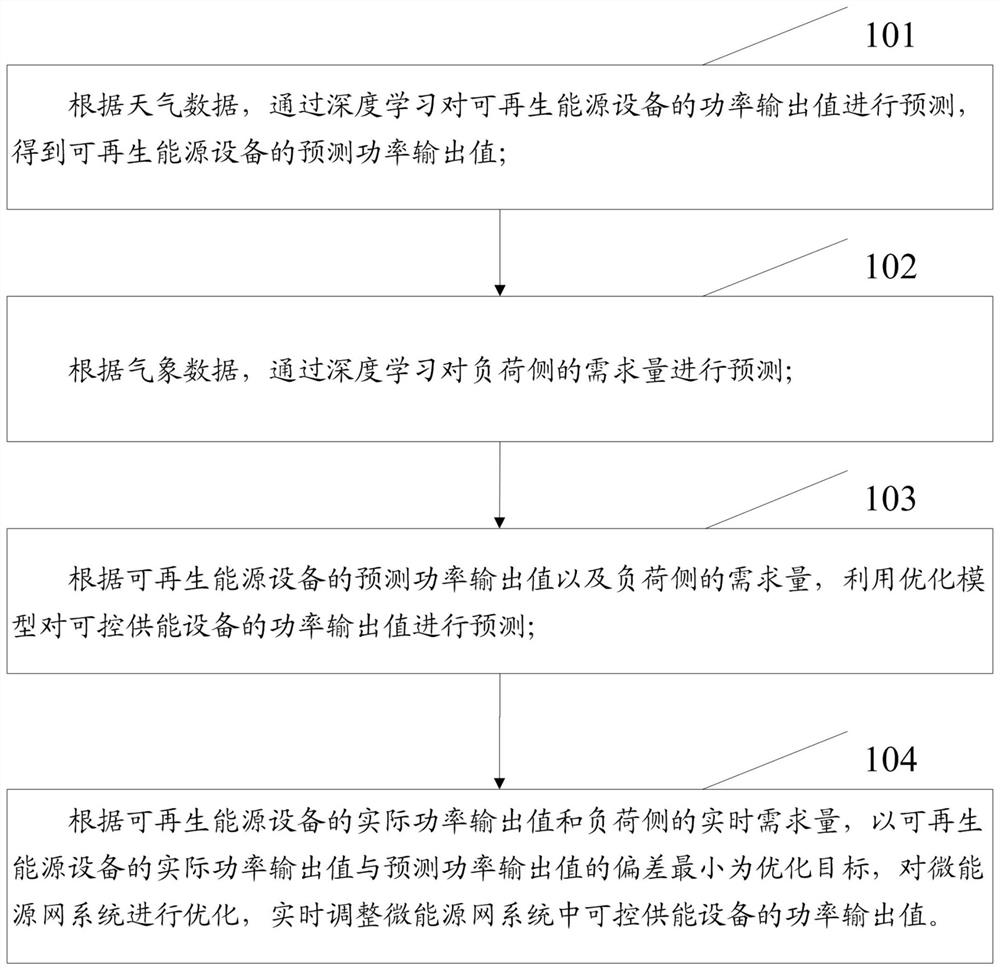

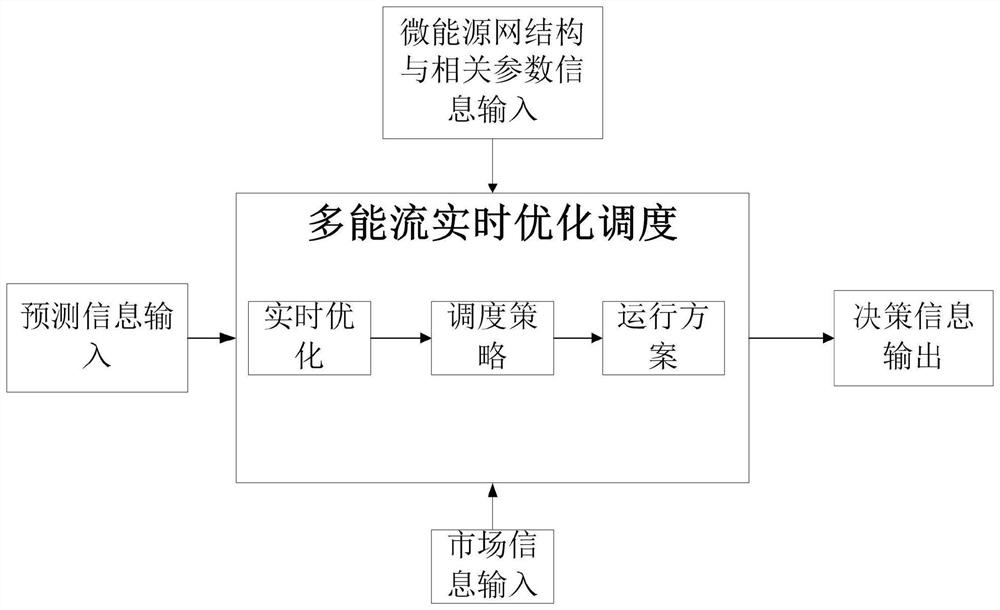

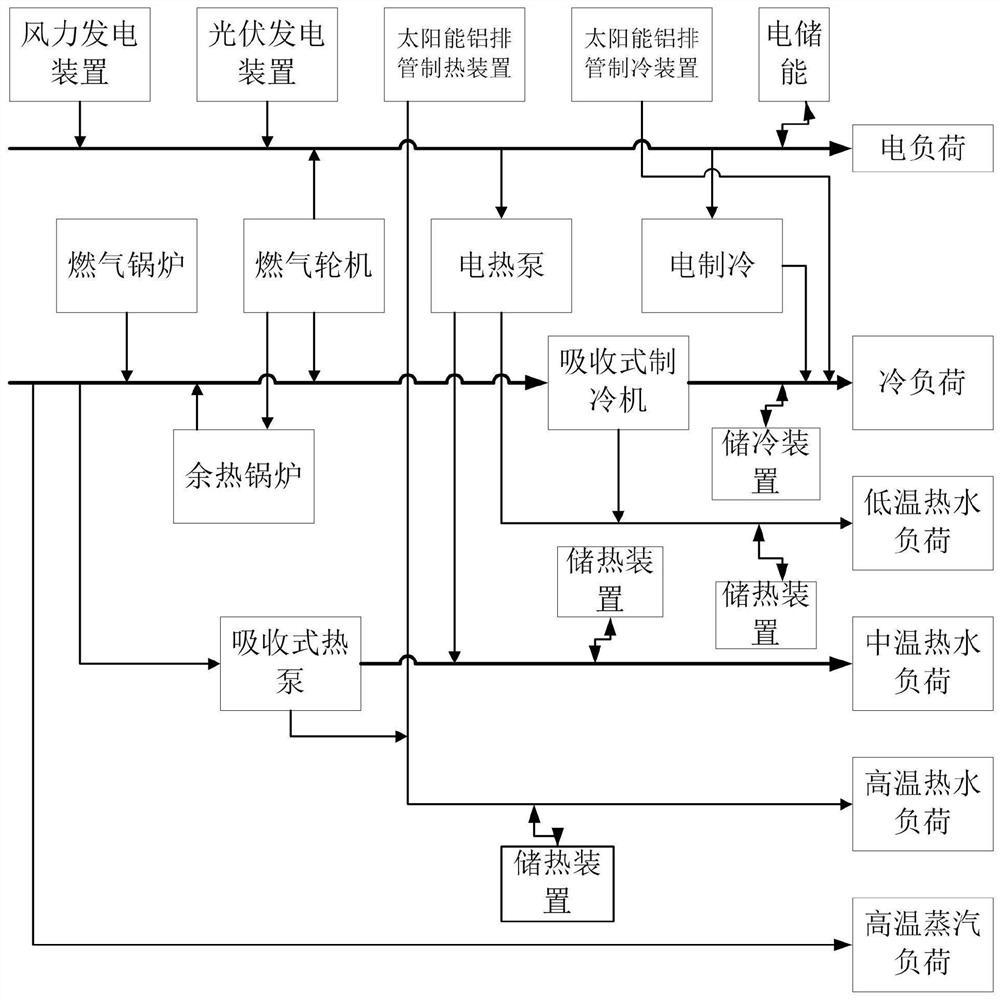

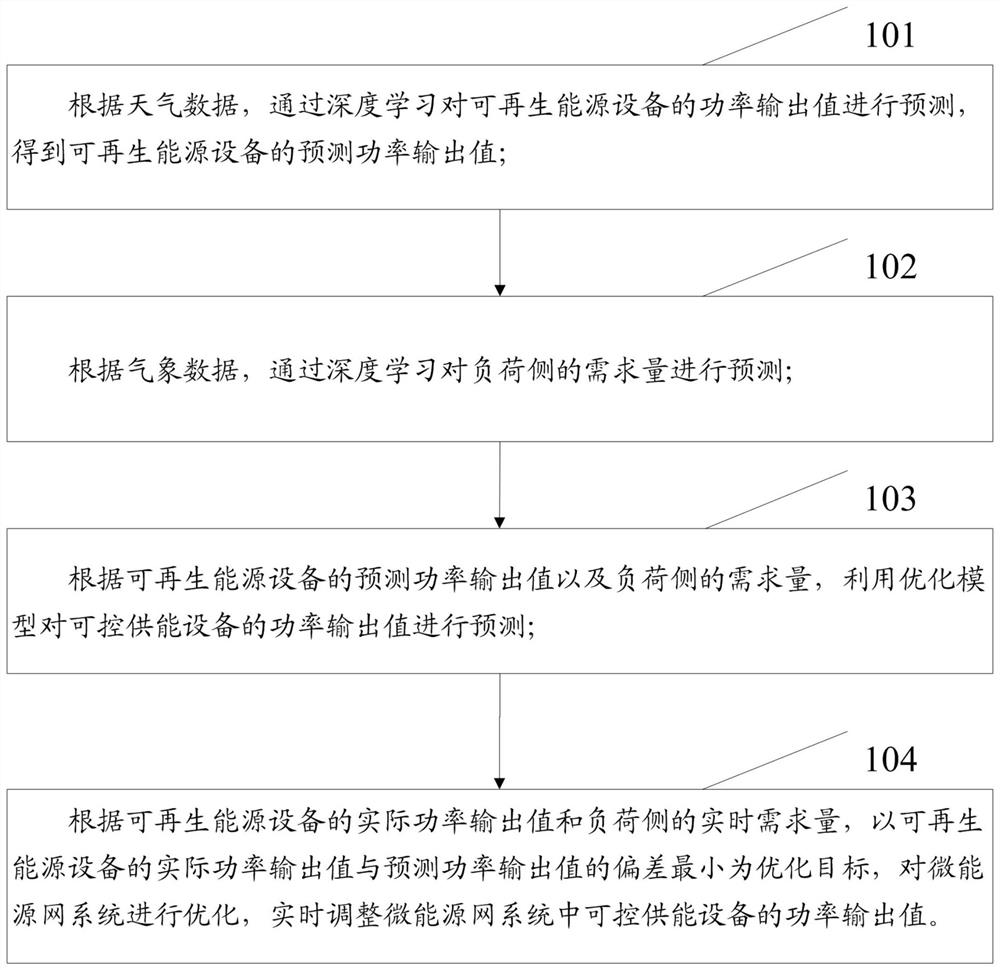

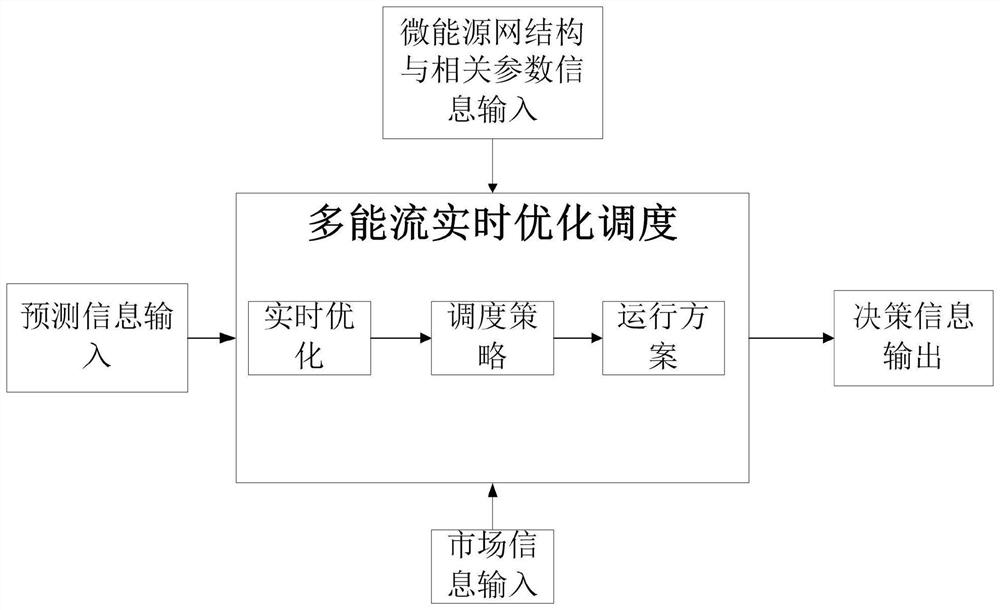

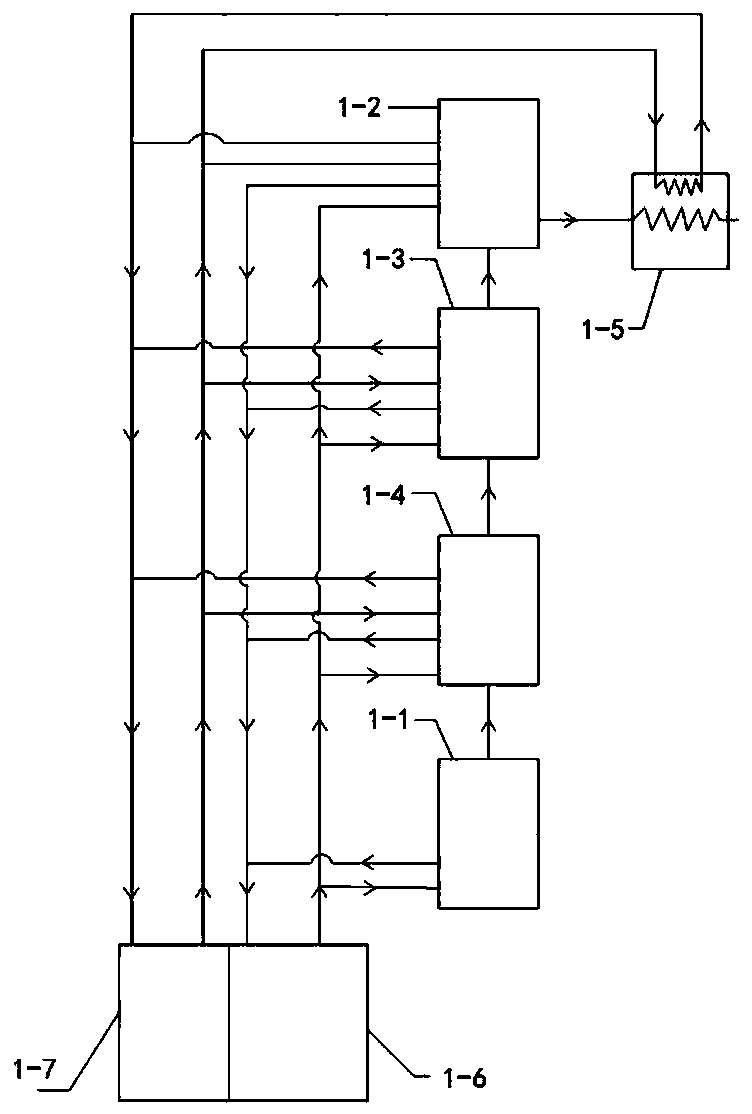

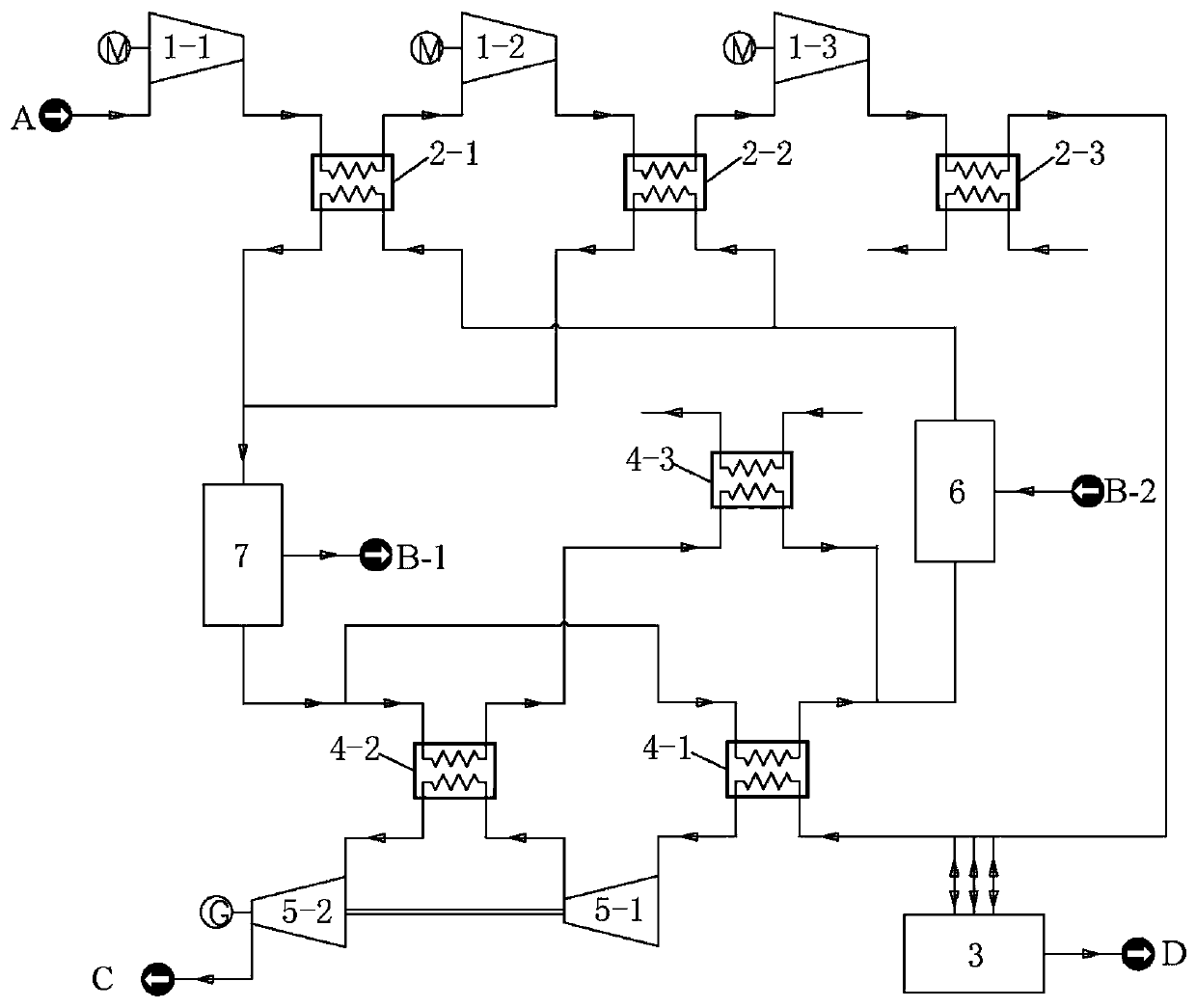

Micro-energy network system and collaborative optimization operation control method thereof

ActiveCN111969603ARealize ladder utilizationChange the way of useSolar heating energyHeat pumpsNew energyControl engineering

The invention relates to a micro-energy network system and a collaborative optimization operation control method thereof. Specific equipment contained in an energy supply side and an energy conversiondevice is reasonably configured; the formed micro-energy network system has the advantages that the new energy access proportion is higher; configuration can be optimized through the energy storage device; the power grid, the heat supply network and the air network meet the energy requirements of users; basic balance between local energy production and user energy consumption load is achieved; the collaborative optimization operation control method is used for carrying out rolling optimization on the micro-energy network system, the power output value of controllable energy supply equipment in the micro-energy network system is continuously adjusted, the micro-energy network system is made to operate economically on the premise that the real-time balance of supply and demand is met, and therefore the purpose of saving energy is achieved. Energy consumption, energy supply and energy storage are uniformly and cooperatively dispatched, multi-energy supply complementation in a micro-energy network system is achieved, the comprehensive utilization efficiency and stepped utilization of multi-energy supply in a micro-energy network are improved, emission is reduced, and local consumptionof energy is achieved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

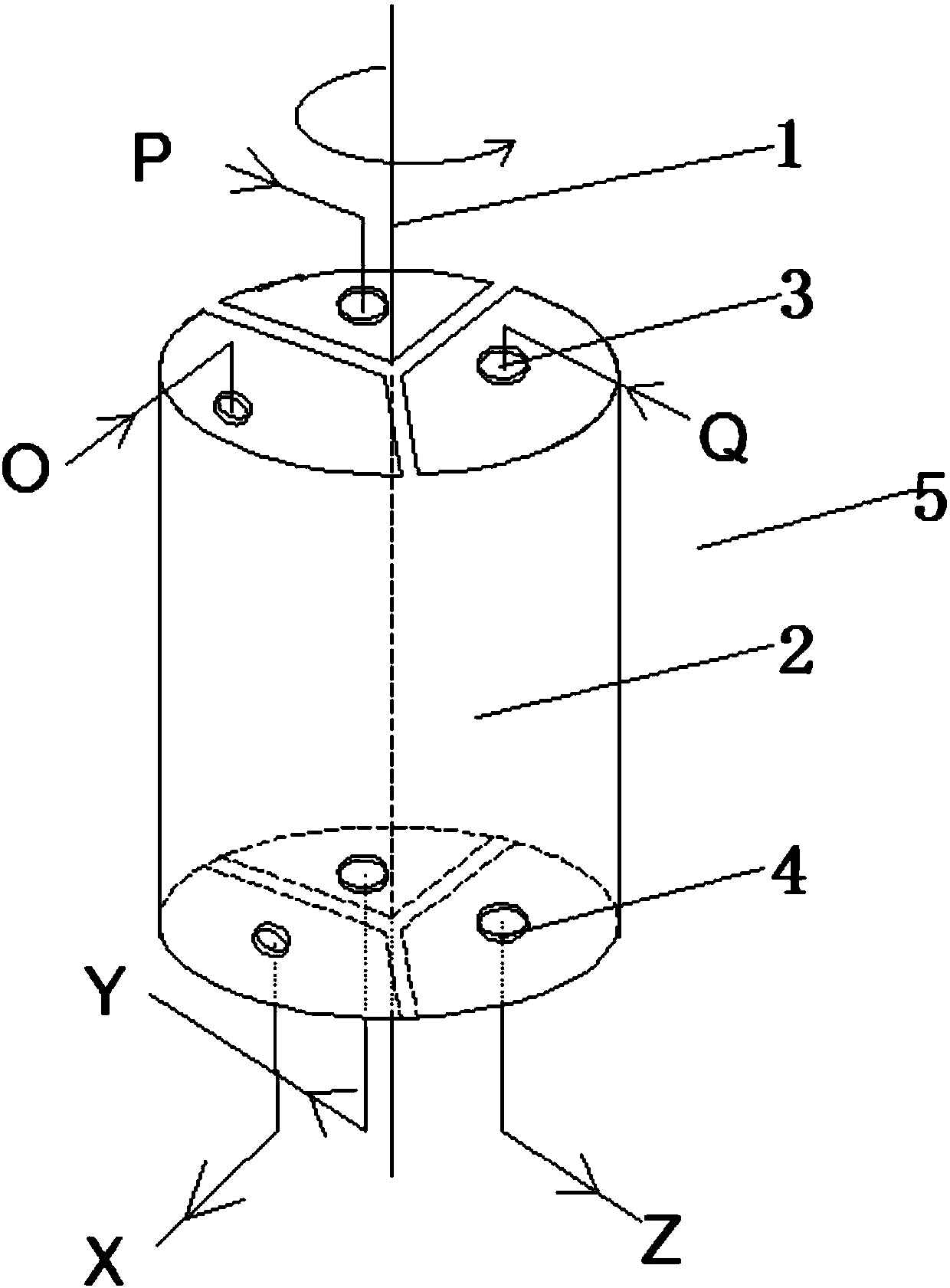

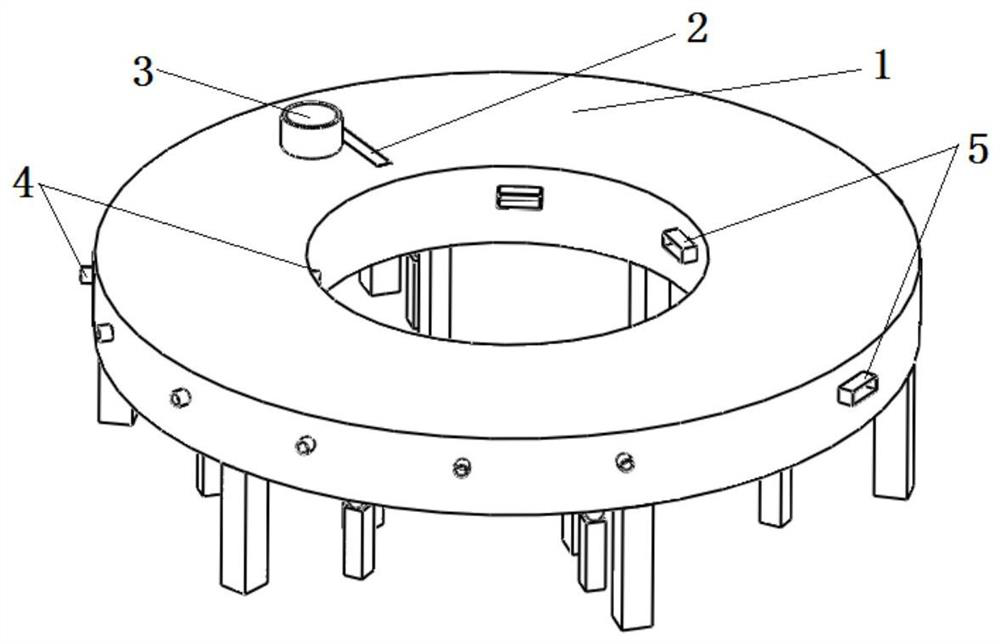

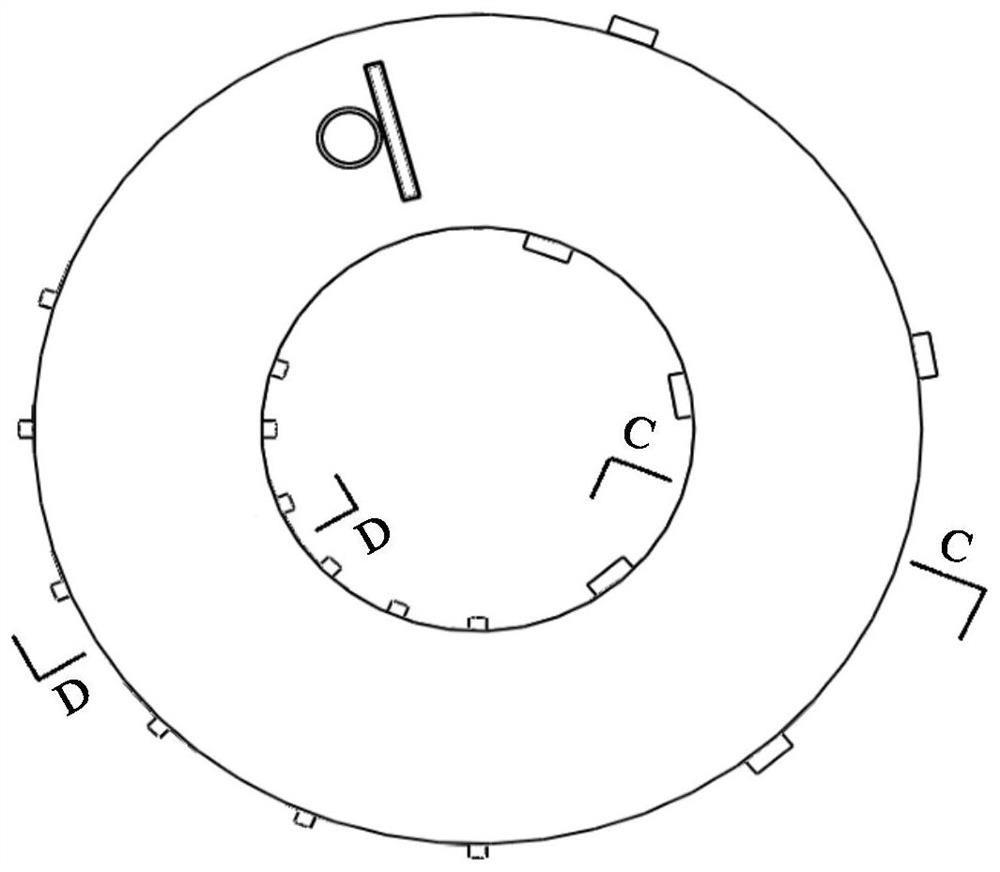

Rotary cyclic carbon capture device and method based on three-bed reaction

ActiveCN107684811AReduce inactivationImprove circulatory activityGas treatmentDispersed particle separationChemistryEnergy consumption

Owner:HUAZHONG UNIV OF SCI & TECH

Boiler fuel gas waste heat desulfurization waste water coupling, evaporating and concentrating system

PendingCN107324426ARealize ladder utilizationIncrease profitWaste water treatment from gaseous effluentsWater/sewage treatment by heatingClean waterWastewater disposal

The invention discloses a boiler fuel gas waste heat desulfurization waste water coupling, evaporating and concentrating system. The system comprises a flue heat exchanger, an evaporator group, a tail gas condenser and a tail gas condensation tank, wherein a desulfurization waste water pipeline is sequentially connected with the evaporator group, the tail gas condenser and the tail gas condensation tank, and a flue heating system is connected with the evaporator group; the flue heat exchanger is arranged in a boiler fuel gas emission channel, and desulfurization waste water in the evaporator group is heated by utilizing fuel gas waste heat; the evaporator group comprises at least one group of evaporators, each group of evaporators include a heater, a circulating pump and a separator which are connected into a ring through a pipeline, the flue heat exchanger is connected with the heater, and a vapor outlet and a concentrated liquid outlet are formed in the separator; the tail condenser cools and condenses the evaporated vapor; and the tail condensation tank stores and delivers condensed water into a finished water tank. According to the system, no chemicals are added during the concentration process of the desulfurization waste water, the distilled clean water is recycled, and the water recovery rate of the desulfurization waste water treatment system is greater than 90%.

Owner:北京尤科恩环保工程有限公司

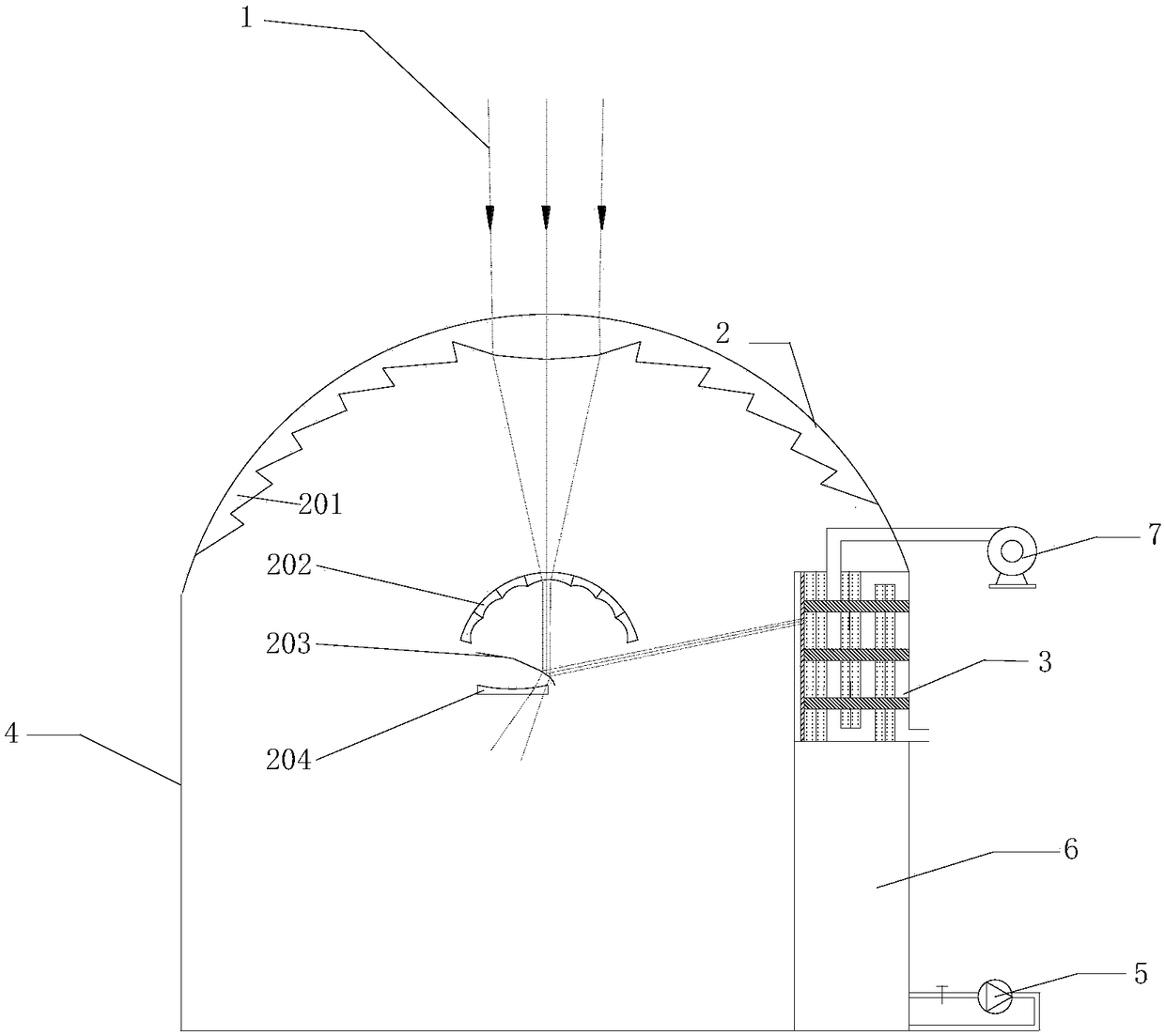

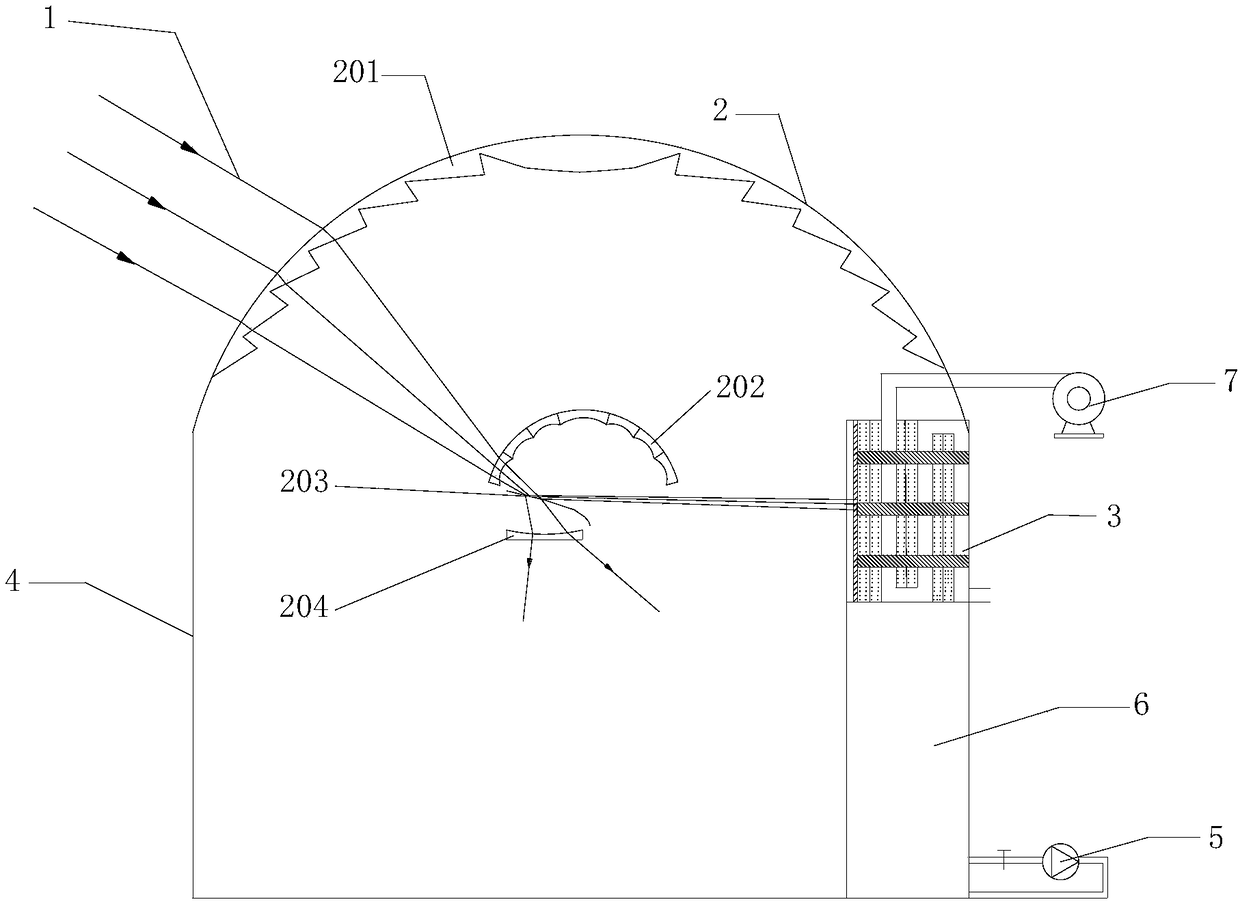

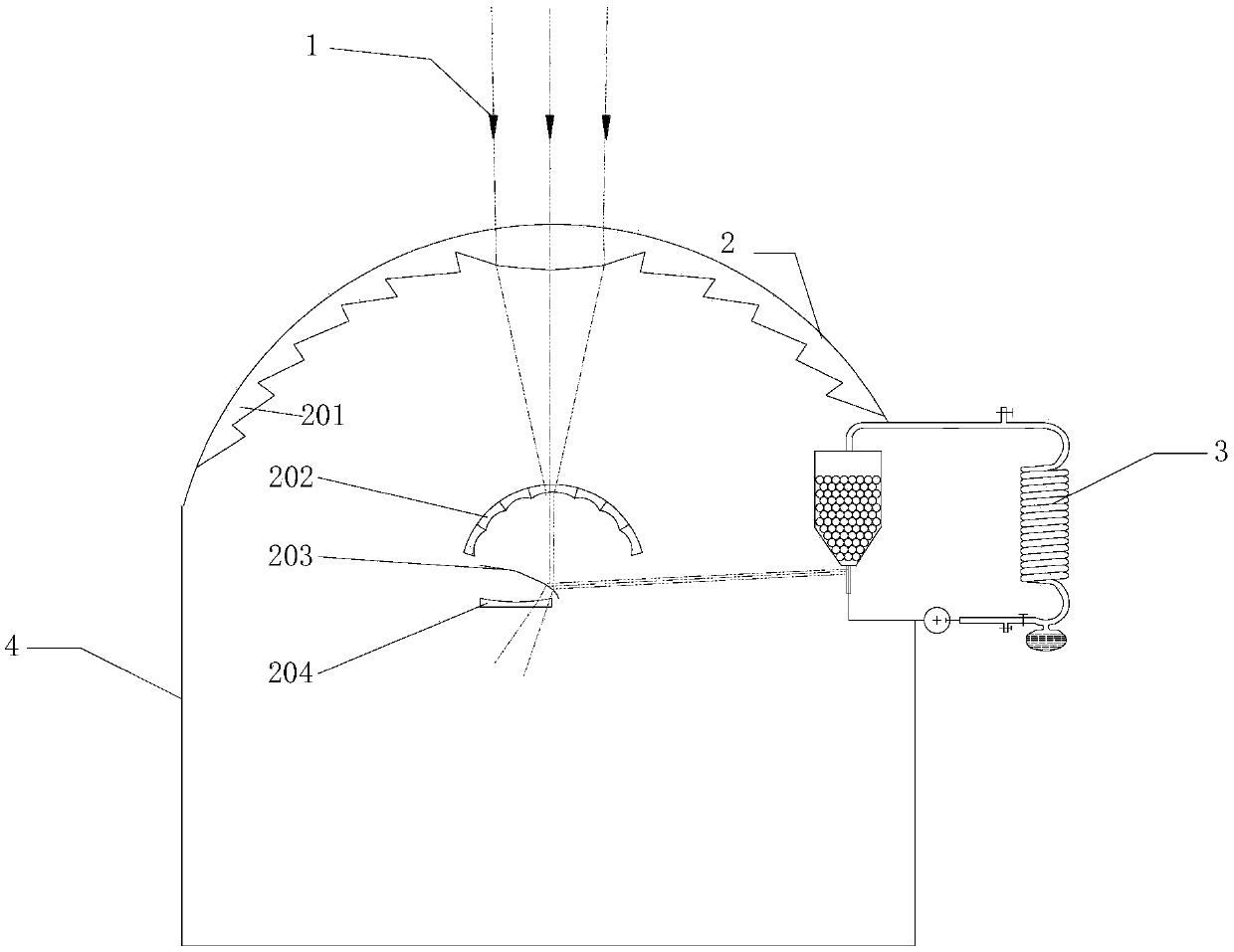

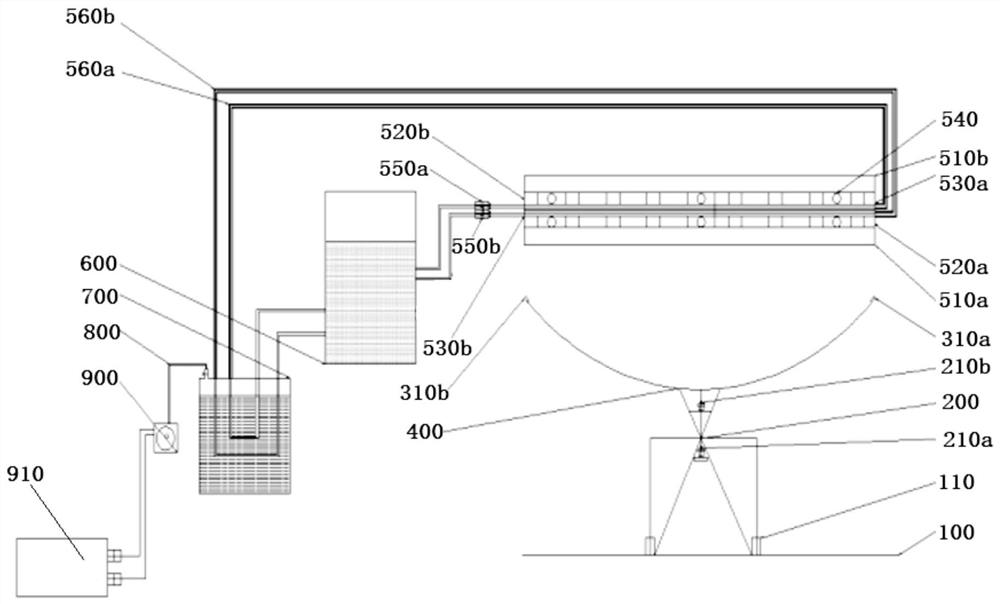

Water self-supplying agricultural greenhouse system

ActiveCN108925309ARealize self-supply water functionRealize ladder utilizationClimate change adaptationGreenhouse cultivationFresnel lensGreenhouse

The invention belongs to the technical field of agricultural greenhouses, and specifically discloses a water self-supplying agricultural greenhouse system. The system includes an optical system disposed in the greenhouse, a water generating system disposed on one side of the optical system and a blower connected with the water generating system, wherein the optical system includes a Fresnel lens,a first concave lens disposed at the condensing point of the Fresnel lens and solar limited-frequency reflecting glass disposed under the first concave lens, and the water generating system comprisesan insulating layer, a selective absorbing coating and a moisture adsorbing layer; the moisture adsorbing layer includes a adsorbent material layer and a metal thermally conductive rod, and the insulating layer is transmissive to infrared light reflected by the solar limited-frequency reflecting glass. Through the system, gradient utilization of sunlight is realized, cleanness and environmental protection can be achieved, consumption of non-renewable energy is reduced, and meanwhile the water self-supplying function of the greenhouse can be achieved; in a water-deficient area, not only agricultural water can be provided, but also supplementing of domestic water can be achieved, so that the problem of water shortage is alleviated.

Owner:HUAZHONG UNIV OF SCI & TECH

Two-stage humidification heat pump sea water desalination device

InactiveCN108190987AImprove recycling ratesIncrease water production rateGeneral water supply conservationSeawater treatmentWater desalinationCirculator pump

The invention discloses a two-stage humidification heat pump sea water desalination device, which comprises a compressor, a condenser, a throttle valve, an evaporator, an auxiliary heat exchanger, a hot sea water circulation pump, a cooling sea water circulation pump, a cooling sea water three-way regulating valve, a primary sea water sprayer, a primary humidifier, a primary thick sea water collector, a secondary sea water sprayer, a secondary humidifier, a secondary thick sea water collector, a primary precooler, a primary fresh water collector, a secondary precooler, a secondary fresh watercollector, a tertiary fresh water collector, a flow division three-way valve, a flow merging three-way valve and a centrifugal fan. The two stages of humidifiers are used for completing the heating humidification on the circulation air; the two stages of precoolers and evaporators are used for completing the condensation on wet ingredients in the circulation air and fresh water separation; the condensation potential heat is recovered and reutilized for completing the water supplementation on the system and the preheating humidification on the circulation air; the system heat recovery efficiency and water yield are improved; the equipment scale is simplified; the equipment scale formation trends are reduced; fresh water can be provided for different occasions.

Owner:SHANGHAI JIAO TONG UNIV +1

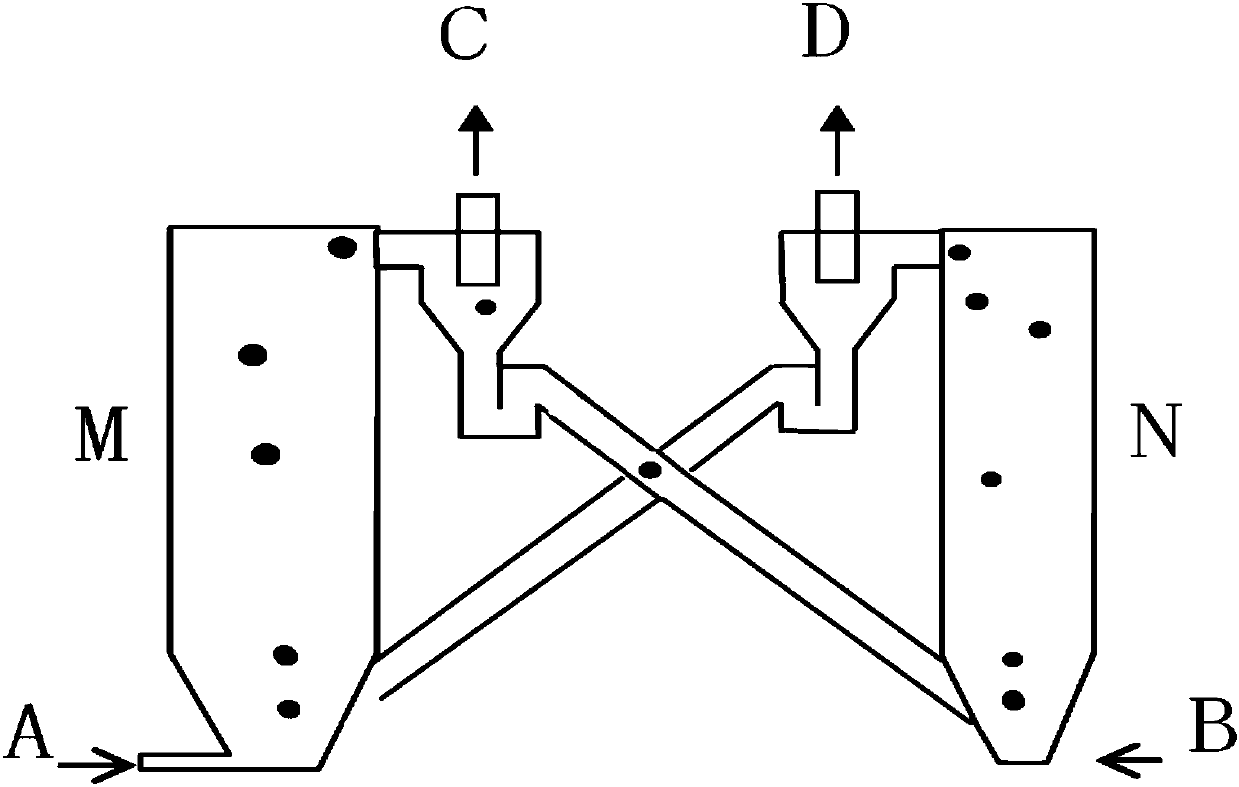

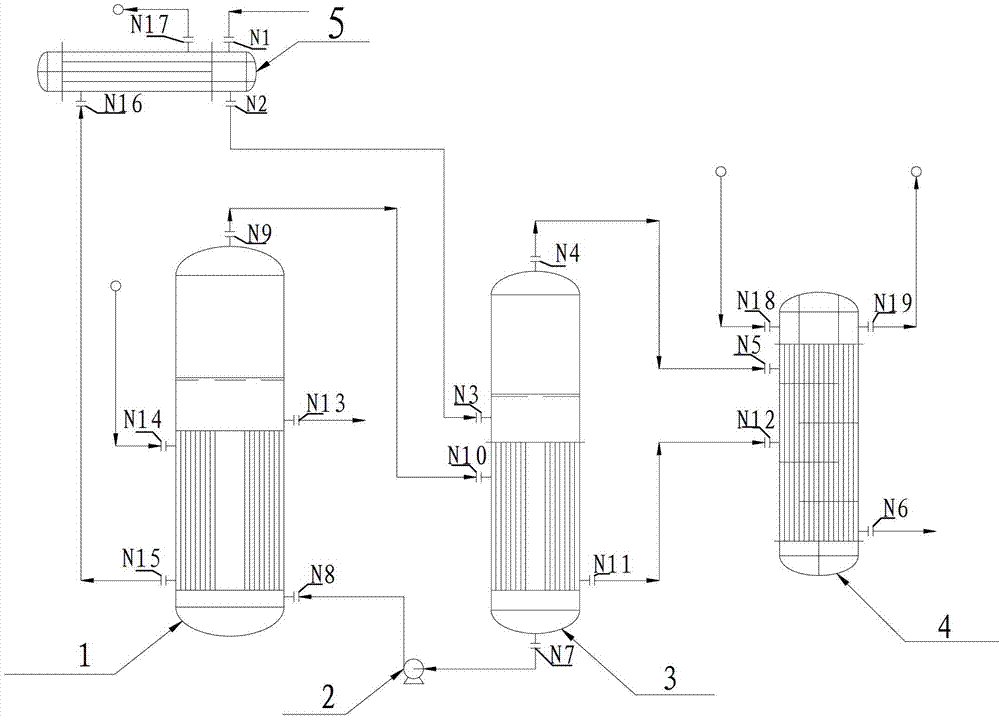

Double-effect evaporation method for crude toluene mixed solution and device using double-effect evaporation method

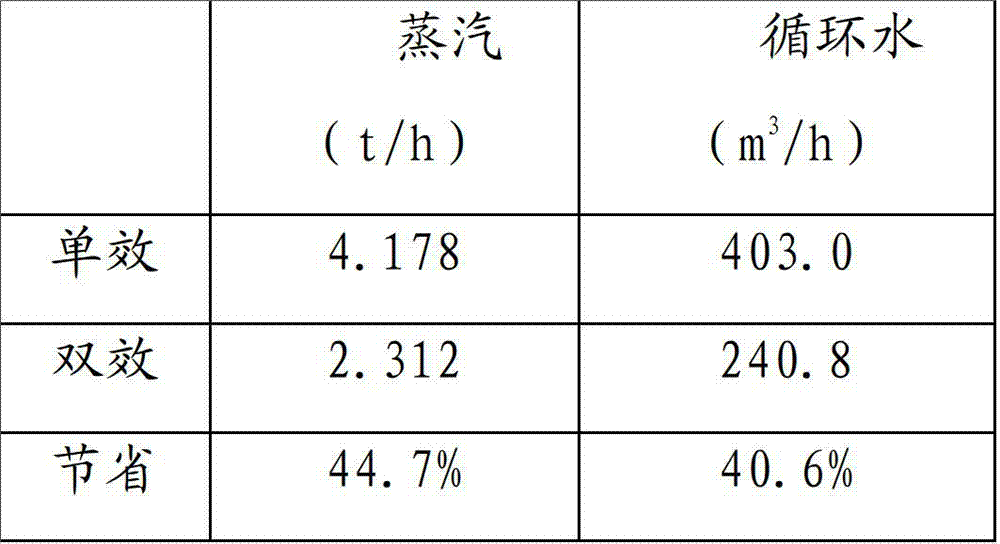

ActiveCN102886150ARealize ladder utilizationIncrease profitChemical industryHydrocarbon purification/separationEvaporationSingle effect

The invention relates to a double-effect evaporation method for a crude toluene mixed solution and a device using the double-effect evaporation method. Crude toluene enters a double-effect evaporator from a double-effect evaporator material inlet for evaporating; the double-effect toluene vapour overflows from the top part of the double-effect evaporator; a toluene concentrated solution flows out from the bottom of the double-effect evaporator and enters a single-effect evaporator from a concentrated toluene inlet on the lower part of the single-effect evaporator through a pump; the toluene concentrated solution inside the single-effect evaporator is distilled, so that single-effect toluene vapour overflows from the top part of the single-effect evaporator; toluene raffinate is discharged from an overflow port at the middle part of the single-effect evaporator; the single-effect toluene vapour enters a shell side of a heat exchange part of the double-effect evaporator from a single-effect toluene vapour pipeline, and performs heat exchange with the crude toluene in the double-effect evaporator, so that the crude toluene is heated and gasified, is overflown from the top part of the double-effect evaporator, and enters a condenser from a double-effect toluene vapour output tube, so as to be discharged after being condensed and cooled by circulating cooling water. The method uses double-effect evaporation, so an energy-saving effect is remarkable.

Owner:YANTAI DONGJIE ENVIRONMENTAL PROTECTION MACHINERYENG

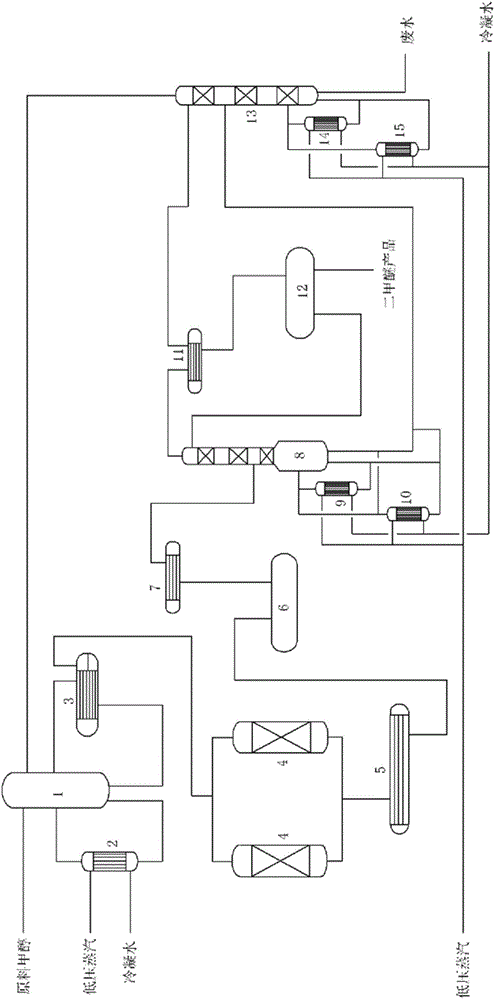

Production method for dimethyl ether

InactiveCN104151145ARealize ladder utilizationIncrease the heat exchange areaEther separation/purificationEther preparation by compound dehydrationVapor–liquid separatorReboiler

The invention discloses a production method for dimethyl ether, which comprises the following steps: 1) feeding a raw material methanol into a methanol vapor-liquid separator, vaporizing the methanol into methanol vapor by heating, further heating the methanol vapor to 320-325 DEG C by a heat exchanger, feeding the methanol vapor into a dimethyl ether reactor, and in the presence of a catalyst, carrying out a methanol dehydration reaction at a temperature of 380-395 DEG C, so that crude methyl ether gas is generated; and 2) after the crude methyl ether gas obtained in the step 1) is preheated to 119-121 DEG C by a crude methyl ether preheater, feeding the crude methyl ether gas into a distillation system, passing the crude methyl ether gas through a reboiler of the distillation system so as to heat the crude methyl ether gas by using low-pressure vapor, so that a fine dimethyl ether product is produced by distilling. According to the production method, a situation that a dimethyl ether system obtains enough heat, so that the production is running stably is ensured; the stepped utilization of vapor is realized, and the heat of vapor is maximumly utilized, and therefore, a problem that when an original dimethyl ether system uses medium-pressure vapor, a large amount of low-pressure vapor is emptied, so that the wasting of resources is caused, is solved; and the method saves resources, reduces the production cost, and has good economic benefits.

Owner:SUIPING CHEM FACTORY OF CHINA PINGMEI SHENMA GRP LANTIAN CHEM

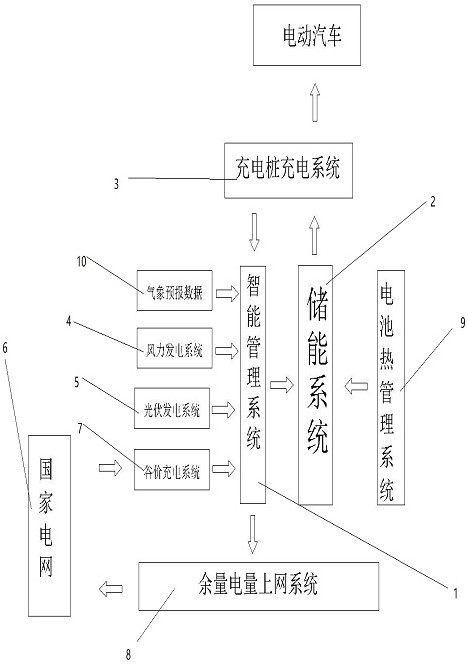

Semi-off-grid wind-solar complementary intelligent charging station

PendingCN112537215AGuaranteed uptimeTake advantage ofCharging stationsPV power plantsPower batteryPower grid

The invention belongs to the technical field of electric vehicle charging stations, and particularly discloses a semi-off-grid wind-solar complementary charging station which comprises a power supplysystem, an intelligent management system, an energy storage system and a charging pile charging system, and is characterized in that the power supply system comprises a wind power generation system, aphotovoltaic power generation system and a state grid power supply system. The charging station has low dependence on the power grid, Stepped utilization of retired power batteries can be realized, peak clipping and valley filling are carried out on the power grid, and the expenditure of an electric vehicle user is reduced and the remaining electric quantity is transmitted to the grid.

Owner:郑州新开元科技有限公司

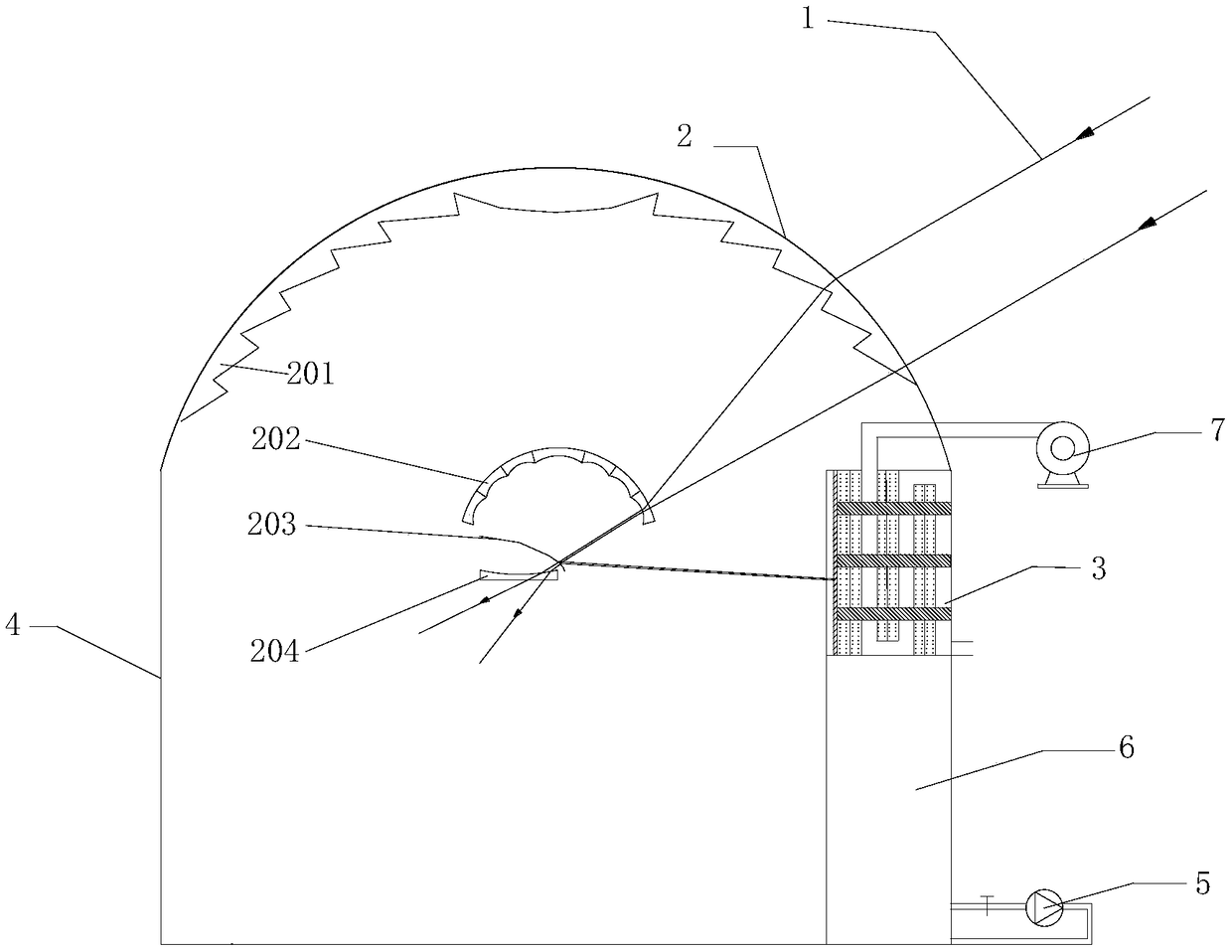

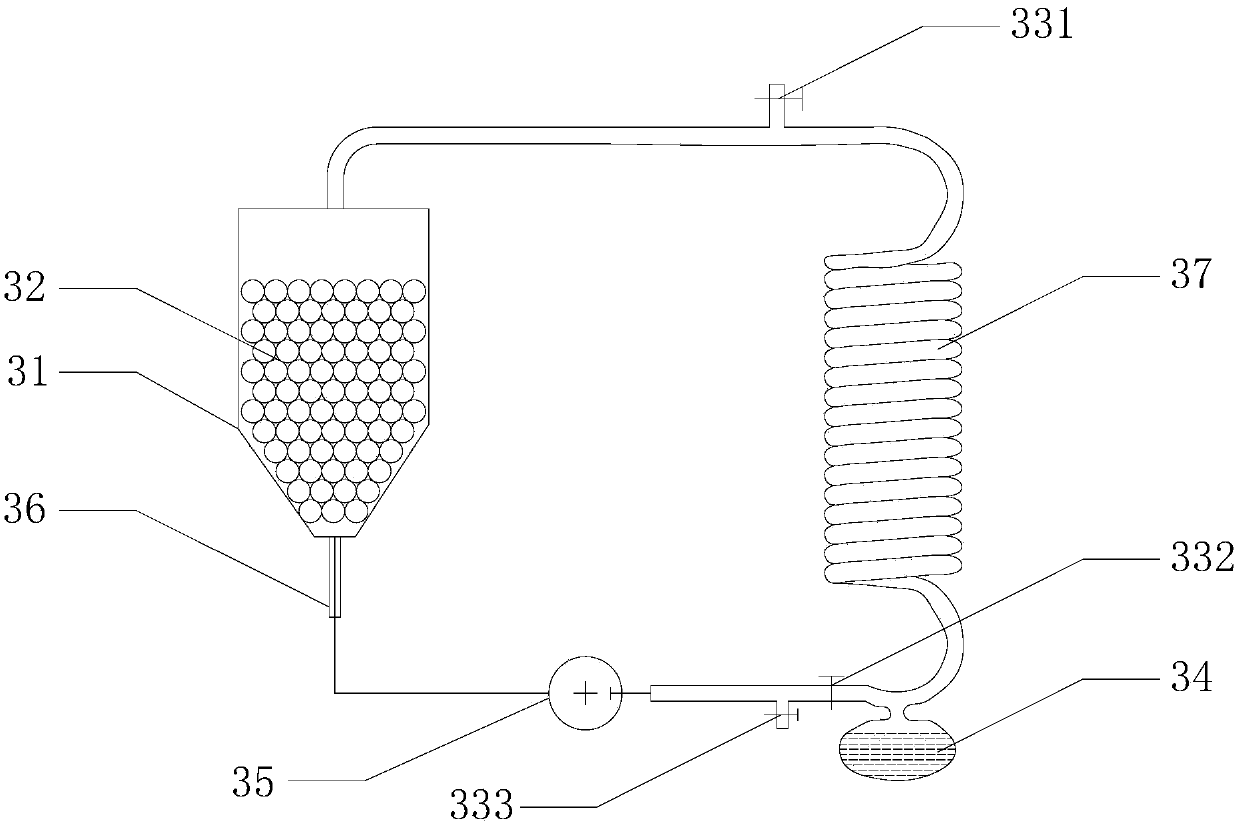

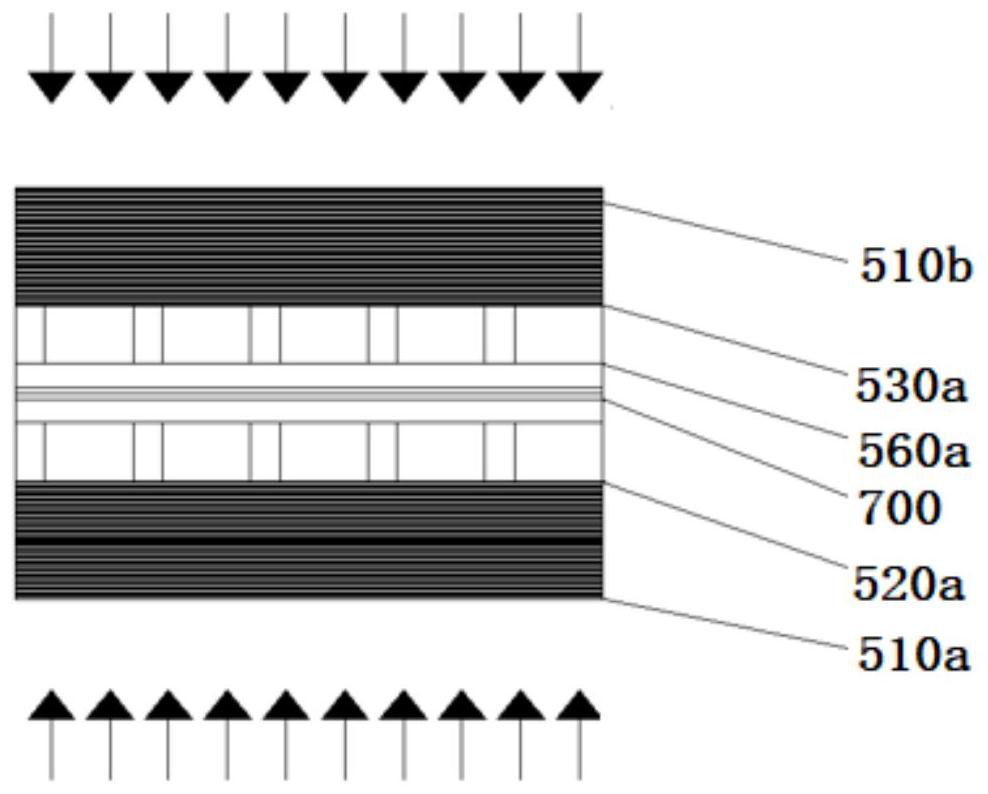

Agricultural greenhouse self-water-supply system based on fluidized bed

ActiveCN109566200AIncrease profitRealize ladder utilizationClimate change adaptationRenewable energy machinesSolar lightWater vapor

The invention belongs to the technical field of agricultural greenhouses, and discloses an agricultural greenhouse self-water-supply system based on a fluidized bed. The system comprises an optical subsystem and a water making subsystem. The water making subsystem comprises a solar heat absorption plate of a hollow structure inside, the fluidized bed, a draught fan arranged at the other end of thesolar heat absorption plate, a condensing pipe arranged at the tail end of the fluidized bed, and a water collecting tank arranged at the lower end of the condensing pipe, wherein a water absorptionmaterial is arranged in the fluidized bed, the water collecting tank is connected with the draught fan through an air pipe, and then the whole water making subsystem forms a closed loop. The inventionfurther discloses a method corresponding to the system. By means of the mechanism that the energy of infrared light in solar light is used as the heat energy for dewatering an adsorption material anddesorbed water is converted into vapor to be collected, the problem that desorbed water cannot be sufficiently collected in existing problems is solved, and the agricultural greenhouse self-water-supply system has the advantages of being compact in structure, simple in operation process and high in solar energy utilization rate.

Owner:HUAZHONG UNIV OF SCI & TECH

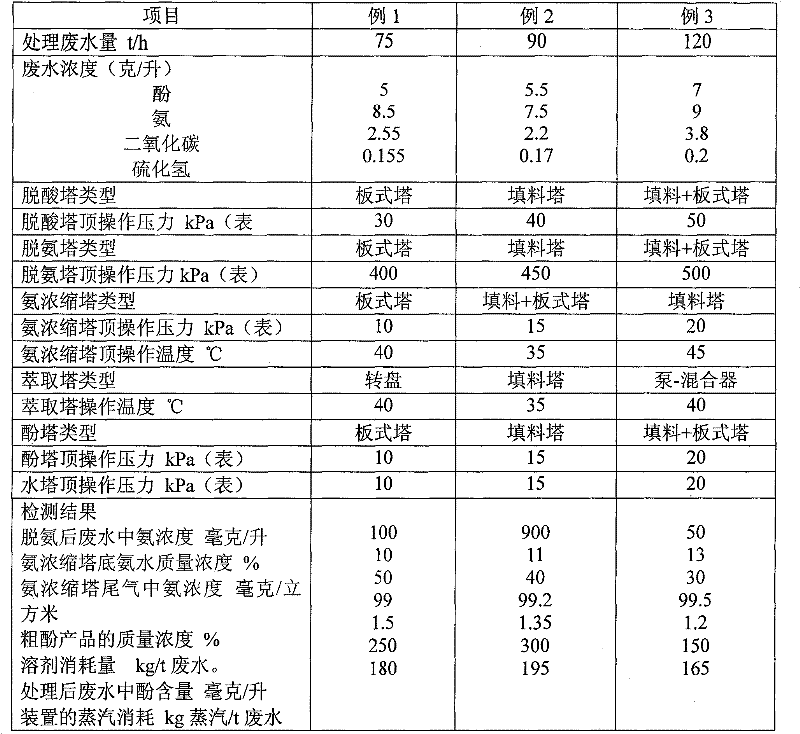

Energy-saving method for recycling wastewater containing phenol and ammonia

InactiveCN102259943BNo recyclingAchieve recyclingChemical industryWater/sewage treatment by heatingCoal gasification wastewaterReboiler

The invention relates to a method for treating wastewater containing phenol and ammonia, in particular to an energy-saving process for recycling the wastewater containing the phenol and the ammonia. Equipment among an acid removing tower, an ammonia removing tower and a water tower is coupled, namely a crude ammonia condenser on the top of the ammonia removing tower is taken as a reboiler of the acid removing tower and the water tower; and a differential pressure rectification technology is utilized, so that the step comprehensive utilization of a heat resource is realized, the energy consumption of wastewater treatment is reduced, and the using amount of steam and circulating water is greatly saved; particularly the equipment is coupled, the differential pressure rectification technologyis utilized and the ammonia and the phenol in the coal gasification wastewater are recycled simultaneously, so that the aims of saving energy and reducing emission in the wastewater treatment and recycling process are fulfilled. The technical problem that the energy consumption is high when the wastewater containing the phenol and the ammonia is recycled in the coal gasification process is solved; and the comprehensive utilization of energy is realized, and the method is high in social value and economic value.

Owner:TIANJIN HAOYONG CHEM TECH

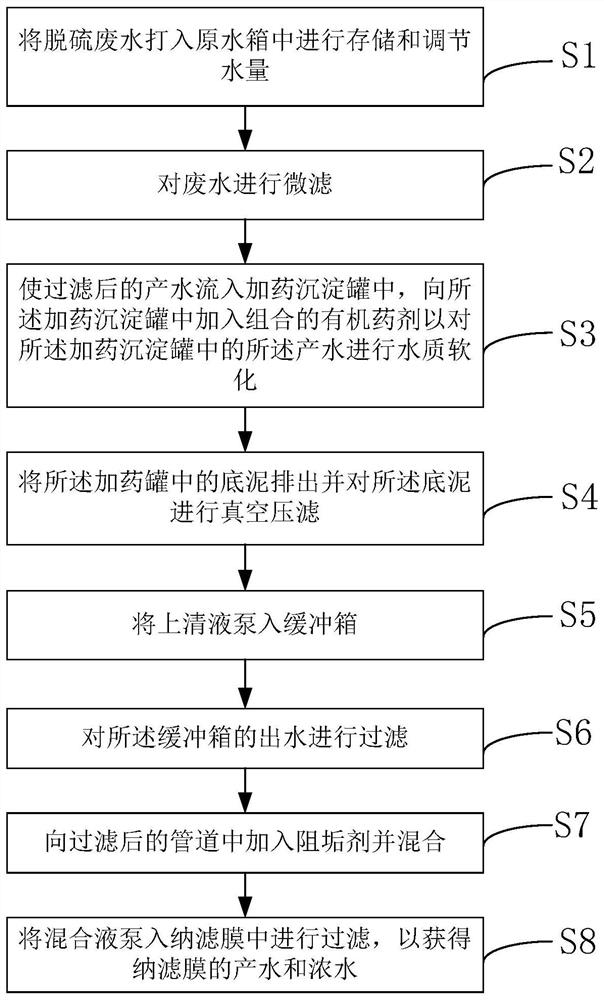

Desulfurization wastewater softening and membrane concentration method

PendingCN113003762ANo foulingReduce retentionWater contaminantsScale removal and water softeningSulfate radicalsWastewater

The invention relates to a desulfurization wastewater softening and membrane concentration method. The method comprises the following steps: pumping desulfurization wastewater into a raw water tank for storage and water quantity adjustment; carrying out microfiltration on the wastewater; enabling the filtered produced water to flow into a dosing settling tank, and adding a combined organic medicament into the dosing settling tank so as to soften the water quality of the produced water in the dosing settling tank; discharging the bottom mud in the dosing tank, and carrying out vacuum filter pressing on the bottom mud; pumping the supernate into a buffer tank; filtering water discharged from the buffer tank; adding a scale inhibitor into the filtered pipeline and mixing; and pumping the mixed solution into a nanofiltration membrane for filtering to obtain produced water and concentrated water of the nanofiltration membrane. The desulfurization wastewater softening and membrane concentration method disclosed by the invention has the advantages that calcium ions are complexed and precipitated, the removal rate of magnesium ions is relatively low, the magnesium ions and chloride ions and sulfate ions in the wastewater are not precipitated under an acidic condition, and the membrane is not polluted and blocked, so that a large amount of dosing cost can be reduced.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

A micro-energy grid system and its collaborative optimization operation control method

ActiveCN111969603BRealize ladder utilizationChange the way of useSolar heating energyHeat pumpsControl engineeringPower grid

Owner:INNER MONGOLIA UNIV OF SCI & TECH

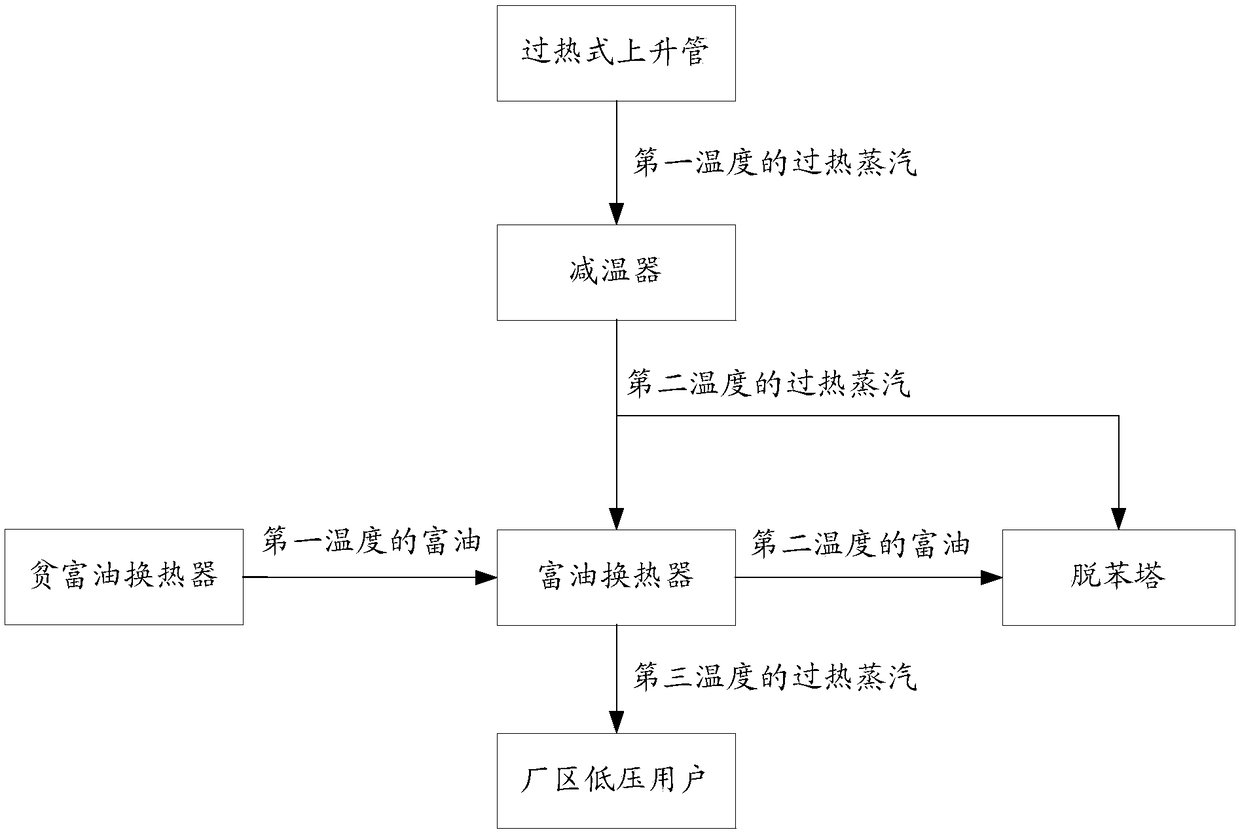

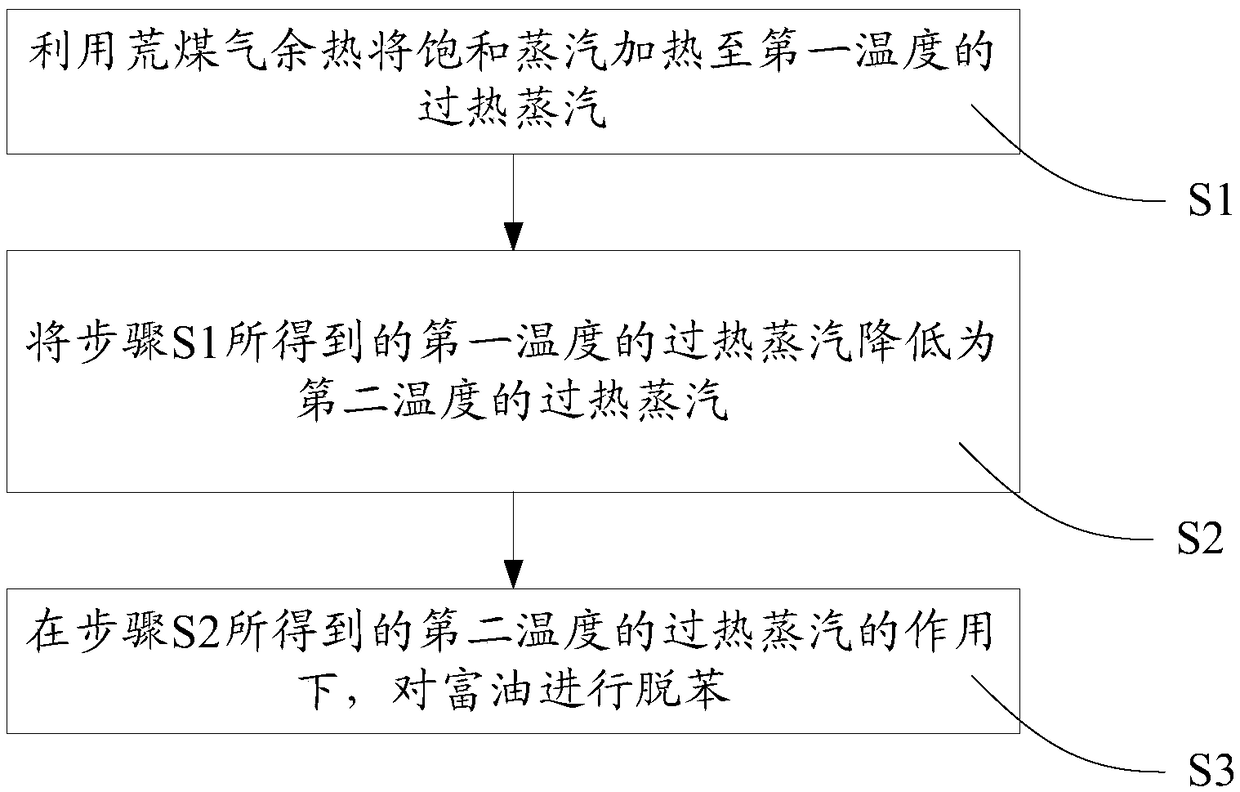

Rich oil debenzolizing equipment and method

PendingCN109054887ASolve pollutionRealize ladder utilizationRefining by heating/coolingCombustionTube furnace

The invention provides rich oil debenzolizing equipment and method, belongs to the technical field of coking, and can solve the problem of air pollution caused by combustion in the conventional tubular furnace. The rich oil debenzolizing equipment comprises an overheating riser, a desuperheater and a debenzolizing tower, wherein the overheating riser comprises a first pipe and a second pipe; the first pipe is inflated with raw coke oven gas; the second pipe is inflated with saturated steam; the second pipe enwraps the first pipe; afterheat of the raw coke oven gas in the first pipe is utilizedfor heating the saturated steam into overheated steam with a first temperature; the desuperheater is used for cooling the overheated steam with the first temperature into overheated steam with a second temperature; the debenzolizing tower is communicated with a gas path of the second pipe and is used for debenzolizing rich oil under the action of the overheated steam with the second temperature.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

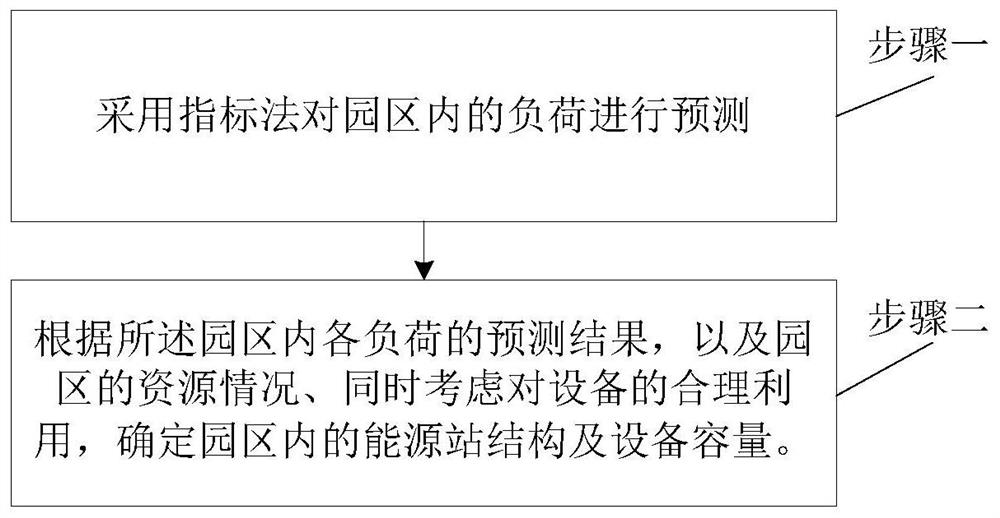

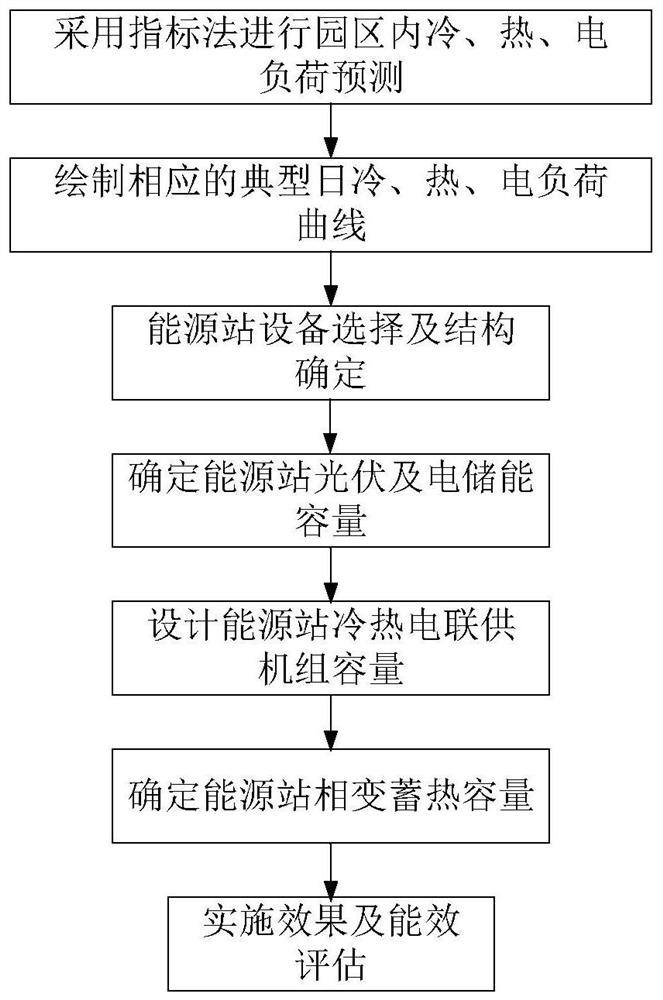

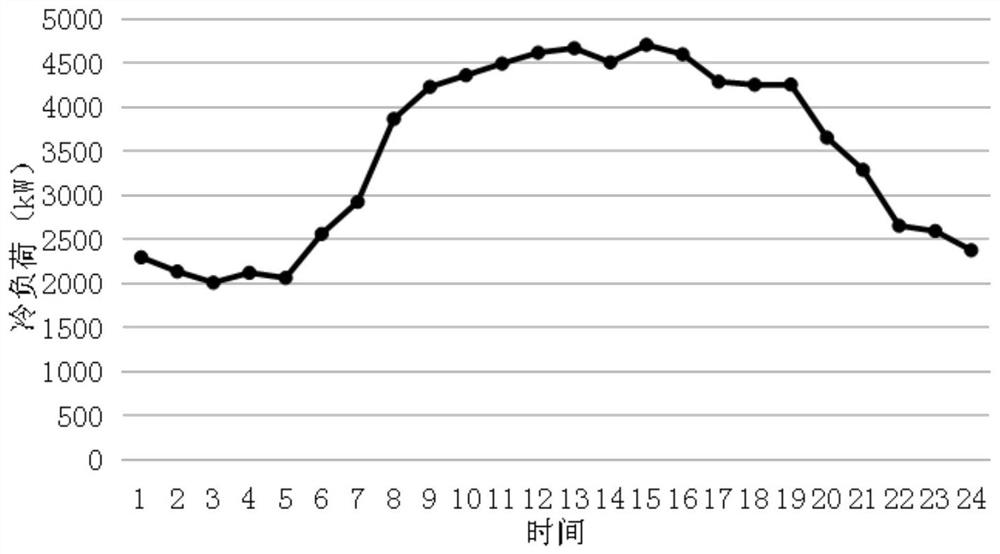

Park comprehensive energy station planning and designing method and system

PendingCN113496300AImprove energy efficiencyImprove utilization efficiencyForecastingSystems intergating technologiesPower gridElectrical load

The invention provides a park comprehensive energy station planning and designing method and system. The method comprises the steps of adopting an index method to predict loads in a park; according to the prediction result of each load in the park and the resource condition of the park, considering reasonable utilization of equipment, and determining an energy station structure and equipment capacity in the park, wherein the loads include cold, hot and electrical loads. According to the method provided by the invention, the energy utilization efficiency can be improved, the diversified individual requirements of electric load, thermal load and cold load of the park are met, peak clipping and valley filling of cold and hot energy are realized, and the utilization rate of power grid equipment is effectively improved.

Owner:CHINA ELECTRIC POWER RES INST +1

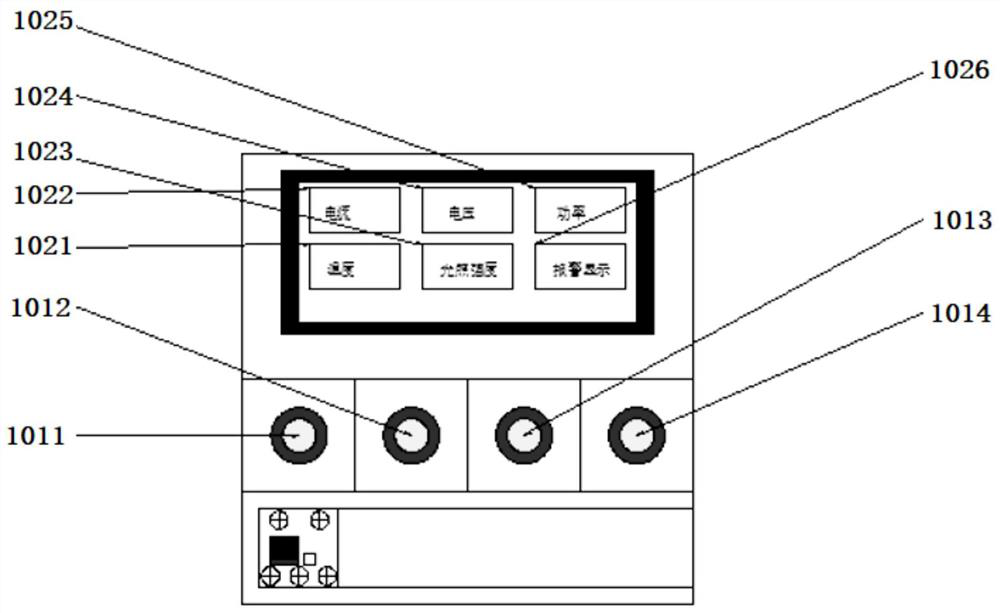

Photovoltaic-temperature difference combined heat and power generation device and maximum power point tracking algorithm thereof

InactiveCN111756070AIncrease profitRealize ladder utilizationSolar heating energySolar heat collector controllersElectricityTemperature difference

The invention discloses a photovoltaic-temperature difference combined heat and power generation device. The device comprises a base, a fixing support, a driving mechanism, a rotating shaft, a collecting lens, a power generation mechanism, a cooling pool, a water tank, a steam generator and a storage battery, wherein the fixing support is arranged on the base; the driving mechanism is arranged onthe fixing support; one end of the rotating shaft is connected with the power output end of the driving mechanism, and the rotating shaft is rotatably supported on the fixing support; the collecting lens is connected with the other end of the rotating shaft; the power generation mechanism is arranged above the collecting lens in a supporting manner; the cooling pool is communicated with the powergeneration mechanism; the water tank is communicated with the cooling pool and the power generation mechanism; the steam generator is connected with the water tank; and the storage battery is electrically connected with the steam generator. The power generation mechanism is condensed through the collecting lens, the height and angle of the collecting lens can be adjusted, and the power generationefficiency is improved. The invention further provides a maximum power point tracking algorithm of the photovoltaic-temperature difference combined heat and power generation device.

Owner:JIAMUSI UNIVERSITY

System and method for heating primary air, feed water and circulating water through bypass smoke

PendingCN110779036ARealize ladder utilizationReduce lossIndirect carbon-dioxide mitigationCentral heating systemWater pipeAir heater

The invention discloses a system and method for heating primary air, feed water and circulating water through bypass smoke. A hot smoke outlet of a coal-fired boiler of the system comprises a hot smoke main way and a hot smoke bypass. The hot smoke main way communicates with a smoke bin chamber of a tri-section bin preheater, and the smoke bin chamber communicates with a cold smoke main way. A baffle door is mounted in the hot smoke bypass and sequentially communicates with a feed water heat exchanger, a high-temperature primary air heat exchanger, an air heater circulating water heat exchanger and a low-temperature primary air heat exchanger. The low-temperature primary air heat exchanger communicates with a cold smoke bypass. The feed water heat exchanger heats the feed water, the low-temperature primary air heat exchanger and the high-temperature primary air heat exchanger heat the cold primary air, and a water pipe and the air heater circulating water heat exchanger heat the circulating water. The method includes the steps that the feed water, the primary air and the circulating water are simultaneously heated through waste heat of the bypass smoke. Utilization of the waste heat of the smoke is greatly improved, and the system and method are more beneficial for environmental protection, energy saving and cost reduction.

Owner:江苏慧峰仁和环保科技有限公司 +1

System and method for heating primary air, fed water and circulating water through bypass flue gas

The invention discloses a system and method for heating primary air, fed water and circulating water through bypass flue gas. A hot flue gas outlet of a coal-fired boiler of the system is divided intoa hot flue gas main path and a hot flue gas bypass; the hot flue gas main path communicates with flue gas bins of a three-portion bin preheater, and the flue gas bins communicate with a cold flue gasmain path; the hot flue gas bypass is provided with a baffle door and communicates with a fed water heat exchanger, a high-temperature primary air heat exchanger, a steam air heater circulating waterheat exchanger and a low-temperature primary air heat exchanger in sequence; the low-temperature primary air heat exchanger communicates with a cold flue gas bypass; wherein the fed water heat exchanger heats the fed water, the low-temperature primary air heat exchanger and the high-temperature primary air heat exchanger heat cold primary air, and a water pipe and the steam air heater circulatingwater heat exchanger heat the circulating water. According to the method, the fed water, the primary air and the circulating water are heated at the same time through waste heat of bypass flue gas. Through the system and method, utilization of the waste heat of the flue gas is substantially improved, and environment protecting, energy saving and cost reducing are more facilitated.

Owner:北京慧峰仁和科技股份有限公司 +1

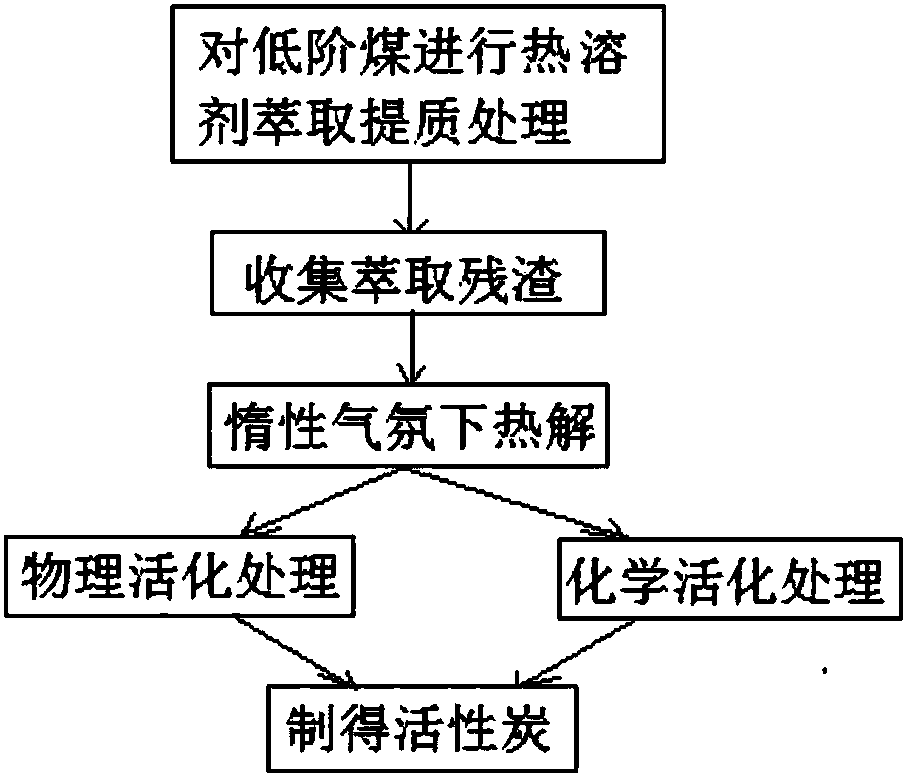

Method for preparing activated carbon with low-rank coal extracted solid

InactiveCN107619049AImprove qualityIncrease the areaCarbon compoundsActivated carbonPhysical chemistry

The invention belongs to the field of coal chemical industry and activated carbon preparation and particularly relates to a method for preparing activated carbon with low-rank coal extracted solid. The method includes: subjecting low-rank coal to hot-solvent extraction process and collecting the extracted solid discarded after extraction process as a raw materials for preparation of the activatedcarbon; subjecting the collected extracted solid subjected to hot-solvent extraction process to pyrolysis in an inert gas atmosphere prior to physical activation treatment or chemical activation treatment to obtain the activated carbon. The activated carbon prepared is large in specific area and pore volume and is widely applied; gradient utilization of the low-rank coal is realized, economical efficiency in hot-solvent extraction technology of the low-rank coal is improved, and the activated coal with high quality is prepared; the method is simple in process, high in added value of products,good in economic and environmental benefits and broad in spreading use.

Owner:HUAZHONG UNIV OF SCI & TECH

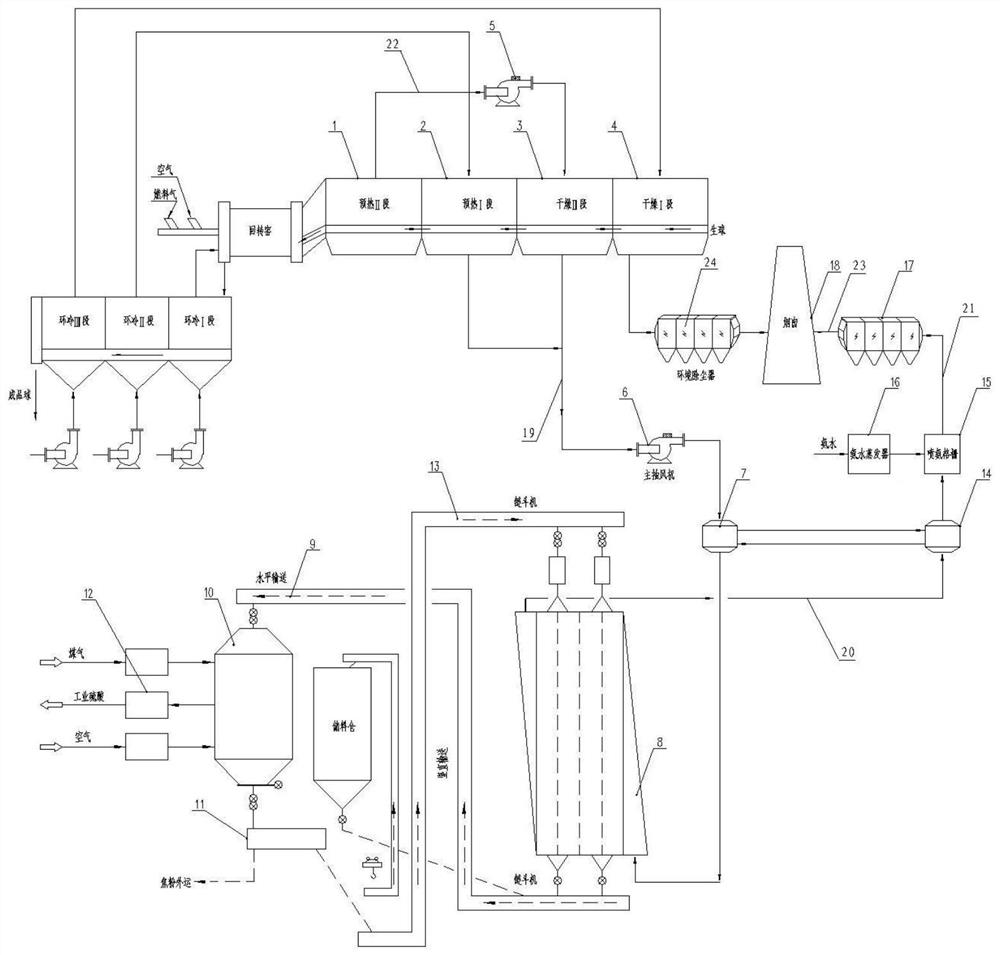

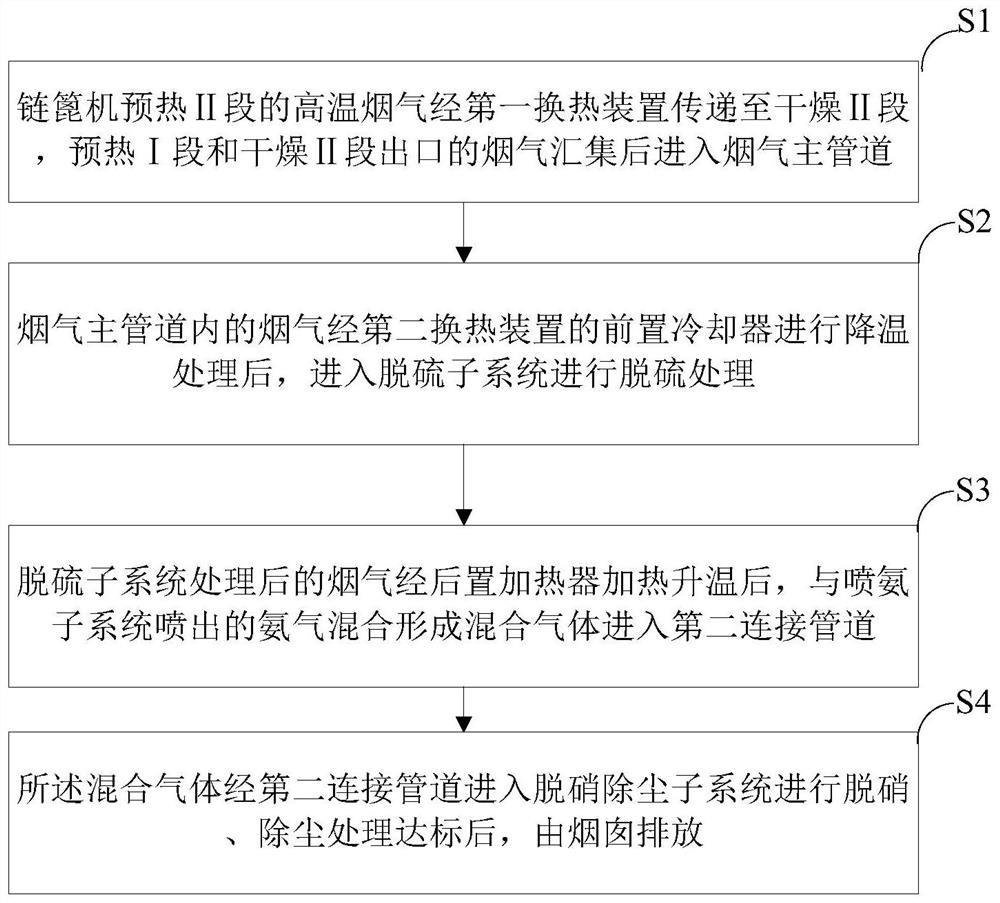

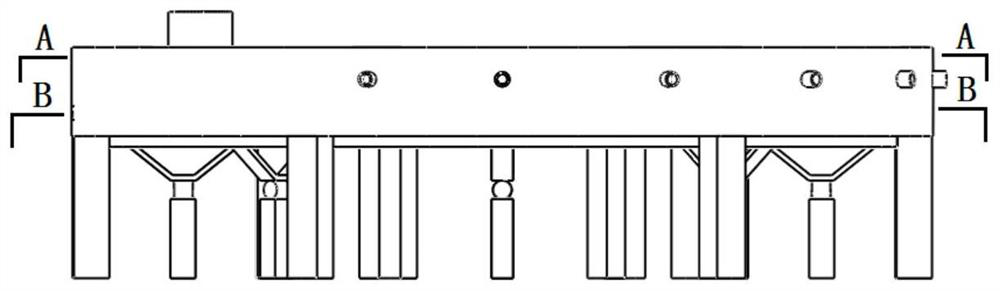

Pellet flue gas desulfurization, denitration and dust removal integrated treatment system and method

PendingCN113941243AAvoid lostAchieve recyclingGas treatmentUsing liquid separation agentFlue gasDust control

The invention provides a pellet flue gas desulfurization, denitration and dust removal integrated treatment system and method. The system comprises a desulfurization subsystem, an ammonia spraying subsystem, a denitration and dust removal subsystem and a heat exchange subsystem, wherein a first heat exchange device of the heat exchange subsystem is used for pumping high-temperature flue gas of a preheating section II to a drying section II to provide heat for drying green pellets; and a second heat exchange device of the heat exchange subsystem comprises a front cooler and a rear heater, so that proper treatment temperature can be provided for the desulfurization subsystem and the denitration and dust removal subsystem, and reutilization of heat energy and full recovery of energy can be realized. According to the integrated treatment system provided by the invention, the pellet flue gas is subjected to desulfurization, denitration and dust removal integrated treatment, meanwhile, energy and heat are recycled and reasonably utilized, the treated flue gas can meet the ultra-clean emission requirement, the investment and operation cost of the system is remarkably reduced, and the flue gas treatment efficiency is improved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

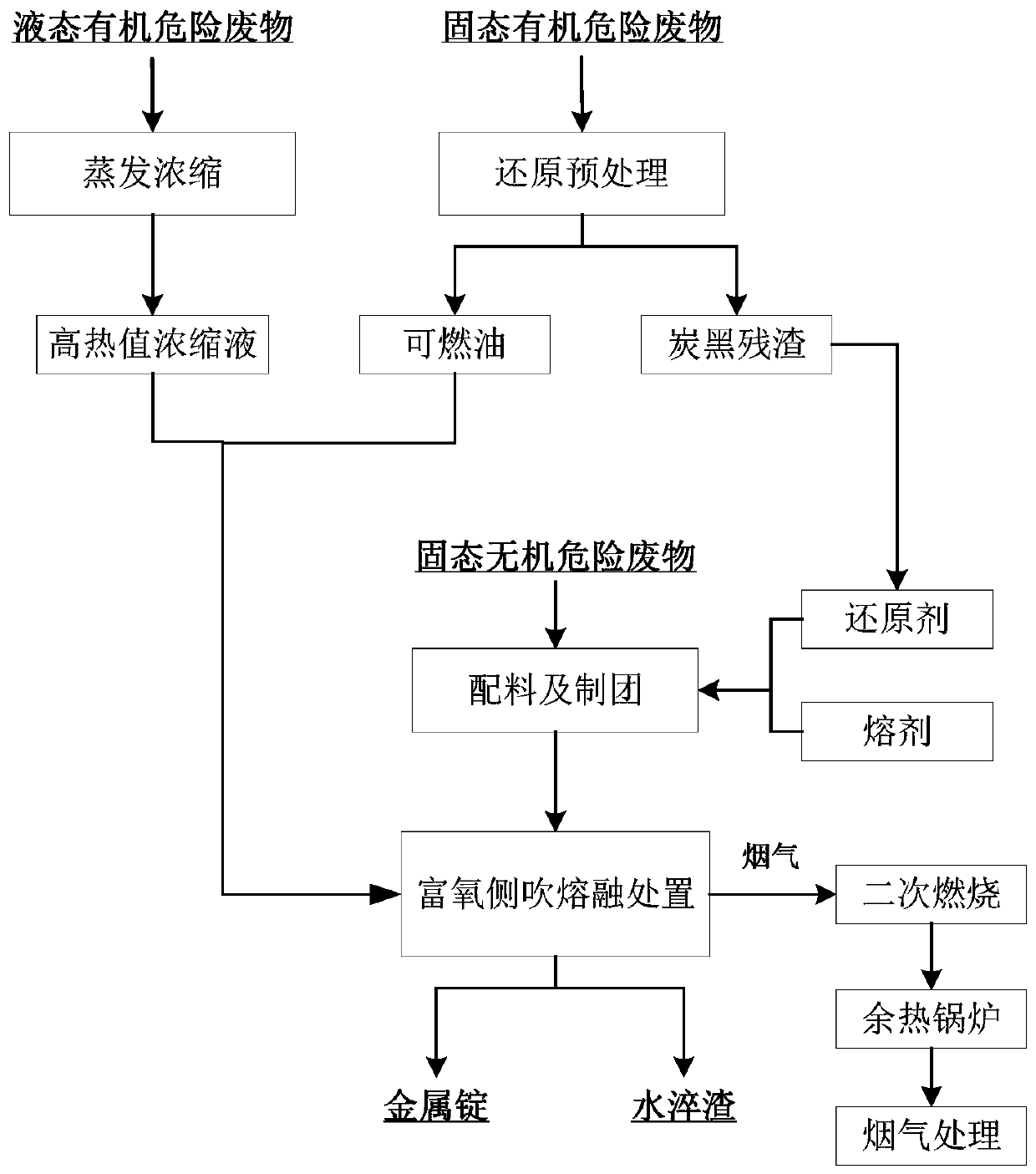

A melting disposal method for hazardous waste

ActiveCN108380642BEasy to handleReduce productionWaste processingTransportation and packagingWaste treatmentQuenching

The invention discloses a hazardous waste melting disposal method, which belongs to the field of hazardous waste treatment. The invention can simultaneously process solid organic hazardous waste, liquid organic hazardous waste and solid inorganic hazardous waste. The main steps of the present invention include: reducing and pretreating solid organic hazardous waste, concentrating and pretreating liquid organic hazardous waste, batching, mixing, and forming solid inorganic hazardous waste, flux, and reducing agent to obtain agglomerate materials, and The bulk material and the intermediate product obtained in the pretreatment step are transferred to an oxygen-enriched side-blowing melting treatment furnace for melting treatment, and the crude metal ingot and vitreous water-quenched slag products are obtained from the melting treatment. The flue gas generated by melting treatment is subjected to secondary combustion, heat energy recovery, and flue gas purification to meet the standard discharge. The invention has a wide application range of raw materials and can completely realize the safe disposal and recycling of hazardous wastes.

Owner:ZHEJIANG SHENLIAN ENVIRONMENTAL PROTECTION GRP CO LTD

A comprehensive treatment process and system for ammonia-containing organic waste gas and ammonia-containing organic wastewater

ActiveCN109442438BHigh removal rateRaise the exhaust gas temperatureGas treatmentSpecific water treatment objectivesPlate heat exchangerNitrogen oxides

The invention relates to a comprehensive treatment technology and system for ammonia containing organic waste gas and ammonia containing organic waste water. The comprehensive treatment technology comprises the steps that high-temperature furnace inflow waste gas is conveyed into an RTO heat accumulation type incinerator through a waste gas draught fan to be incinerated, and clean smoke is subjected to nitrogen oxide catalytic reduction through an SCR reactor. The comprehensive treatment system comprises the RTO heat accumulation type incinerator, a waste gas mixer is arranged at the front endof the RTO heat accumulation type incinerator, a mixer is arranged at the rear end of the RTO heat accumulation type incinerator and connected with a metal filter, the metal filter is connected withthe SCR reactor, the SCR reactor is connected with a plate heat exchanger, and the plate heat exchanger is connected with a forcing heat exchanger. Low-temperature smoke waste heat is circularly utilized, the furnace feeding temperature is increased, the exhaust temperature of an incinerator system is increased and meets the smoke catalysis denitration technology requirement, no fuel consumption and no denitration agent consumption are achieved, waste water can be treated while waste gas is treated, and secondary pollutants are avoided.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

System and method for utilizing nuclear energy to conduct waste pyrolysis gasification treatment

PendingCN108375073ARealization of pyrolysis gasification treatmentRealize rationalitySteam engine plantsIncinerator apparatusFiltrationVaporization

The invention discloses a system and method for utilizing nuclear energy to conduct waste pyrolysis gasification treatment. The system comprises a waste pyrolysis gasification system, a nuclear powersystem and a steam power generation system; the waste pyrolysis gasification subsystem comprises a waste conveying chamber, a primary vaporization chamber, a high-temperature gasification chamber, a filtration tower, a washing tower and a desulfurization tower; an outlet of the waste conveying chamber is communicated with an inlet of a heat absorption side of the primary vaporization chamber, an outlet of the heat absorption side of the primary vaporization chamber is communicated with an inlet of a heat absorption side of the high-temperature gasification chamber, and an outlet of the heat absorption side of the high-temperature gasification chamber is communicated with an inlet of the desulfurization tower through the filtration tower and the washing tower in sequence. The system and method achieve pyrolysis gasification treatment on waste with nuclear power as a heat source, the energy consumption and cost are low, and meanwhile no harmful substances are generated in the pyrolysis process.

Owner:XIAN THERMAL POWER RES INST CO LTD

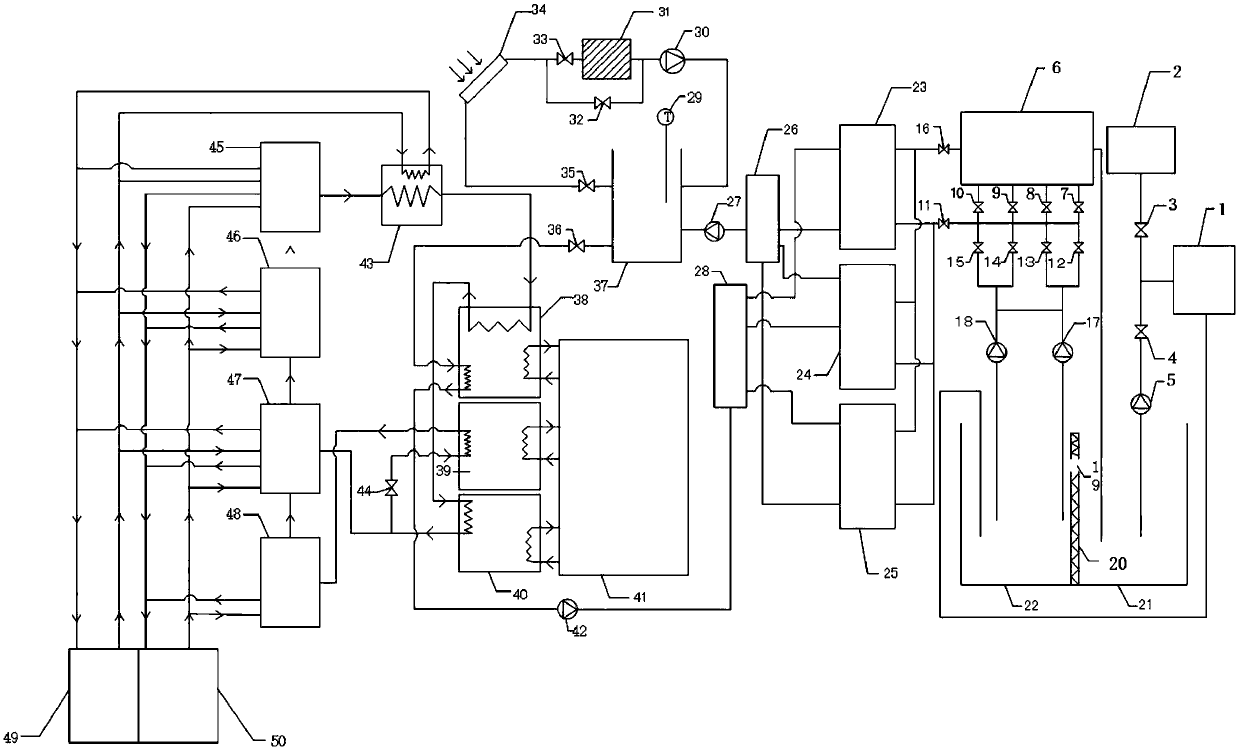

Heating apparatus, heated at rear, comprising lithium bromide heat pump and used in combined heat and power generation of power plant

InactiveCN109682109AAchieve recyclingRealize ladder utilizationHeat pumpsHeat recovery systemsLithium bromideSolar water

The invention discloses a heating apparatus, heated at the rear, comprising a lithium bromide heat pump and used in combined heat and power generation of a power plant, belongs to the field of residual heat recovery of heat supply and heat distribution, and aims to solve the problems about provision of a high-temperature heat source for the lithium bromide heat pump and a mismatch between heat supply and demand. An outlet of a water storage tank is connected with a solar water heater through a pipeline; a sixteenth control valve is arranged on the pipeline; two branches of a water outlet pipeof the solar water heater are connected with water pipes in parallel; a thirteenth control valve is arranged on one water pipe, which is connected with a fifth circulating pump; each lithium bromide heat pump unit comprises a high-temperature heat source, a low-temperature heat source and a medium-temperature heat source; and a heat exchange pipeline of a waste steam device is communicated in parallel with an evaporator of a steam heat pump unit and the low-temperature heat sources of all the lithium bromide heat pump units. The effects are: providing the high-temperature heat source for the lithium bromide heat pump and realizing water recycling in the power plant.

Owner:DALIAN NATIONALITIES UNIVERSITY

Muffle reduction ironmaking device

PendingCN112063788AAvoid secondary oxidationIncrease metallization rateRotary drum furnacesCombustion chamberFlue gas

The invention discloses a muffle reduction ironmaking device, belongs to the technical field of non-blast furnace ironmaking, and solves the problems of low metalization ratio, low flue gas utilization efficiency and high energy consumption of an existing rotary hearth furnace. The muffle reduction ironmaking device comprises a rotary hearth furnace. The inner space of the rotary hearth furnace isdivided into a heating segment and a reduction segment through a partition wall in the axial direction of the rotary hearth furnace, and the partition wall is arranged in the radial direction. The heating segment is a heating chamber, and the reduction segment is divided into a reduction chamber and a combustion chamber located above the reduction chamber through a muffle plate in the axial direction of the rotary hearth furnace. A feed port is formed in the heating chamber, a discharge port is formed in the reduction chamber, and combustion gas is introduced into the heating chamber and thecombustion chamber. The ironmaking device can be used for reduction of iron-containing furnace charge.

Owner:钢研晟华科技股份有限公司 +1

Combined heat and power generation method for power plant

PendingCN111351252ARealize ladder utilizationAchieve recyclingHeat pumpsEnergy efficient heating/coolingLithium bromideCogeneration

The invention discloses a combined heat and power generation method for a power plant, belongs to the field of heat supply waste heat recovery and heat distribution, and aims to solve the problem thatthe heat of power plant water is increased step by step. Power plant water at about 5 DEG C enters a cold water inlet of a condenser of the steam heat pump unit (48), steam exhaust water generated bythe steam exhaust device (50) exchanges heat with power plant water at about 5 DEG C of the condenser end of the steam heat pump unit (48) at the evaporator end of the steam heat pump unit (48), primary heat exchange water at about 30 DEG C is output from the condenser end of the steam heat pump unit (48), the first-stage heat exchange water enters a medium-temperature heat source of the third lithium bromide heat pump unit (47) and serves as inlet water of the third lithium bromide heat pump unit (47), and the effect is that heat is increased step by step.

Owner:DALIAN NATIONALITIES UNIVERSITY

Water optimization system and method for wet flue gas desulfurization device with high-efficienty dust removal in thermal power plant

PendingCN109647147AGood economic benefitsIncrease reuse rateGas treatmentElectrostatic separationWater pipeEngineering

The invention discloses a water optimization system and method for a wet flue gas desulfurization device with high-efficiency dust removal in a thermal power plant, wherein a flue gas pipeline at theoutlet of a boiler is communicated with a flue gas inlet of a desulfurization absorption tower, a spray layer, a first layer of a flushing water pipe, a first layer of a ridge type demister, a secondlayer of the flushing water pipe, a third layer of the flushing water pipe, a second layer of the ridge type demister and a fourth layer of the flushing water pipe are sequentially arranged in the desulfurization absorption tower from bottom to top; the outlet of an oxidation fan and the inlet of the spray layer are both communicated with a slurry pool at the bottom of the desulfurization absorption tower, and a chimney is communicated with a flue gas outlet at the top of the desulfurization absorption tower. The system and method can meet the environmental protection requirement that the concentration value of smoke dust at the outlet of the chimney is lower than 5mg / Nm3, and the cost is lower.

Owner:HUANENG POWER INTERNATIONAL +1

Compressed air energy storage system for multi-energy supply

ActiveCN109736909BRealize ladder utilizationIncrease profitPositive displacement pump componentsSteam engine plantsThermal energy storageEngineering

The invention relates to the field of energy storage, and provides a multi-energy combined supply compressed air energy storage system. The system comprises multi-stage compressors, multi-stage coolers, multi-stage expansion machines, multi-stage heat regenerators, a high-pressure heat supply device and a low-pressure heat supply device, wherein every two adjacent stages of compressors communicatethrough the interstage coolers, the last-stage compressor communicates with an inlet of an air storage chamber through the high-pressure heat supply device, an outlet of the air storage chamber communicates with an inlet of the first-stage expansion machine through the first-stage heat regenerator, every adjacent stages of expansion machines communicate through the interstage heat regenerators, inlets and outlets of the low-temperature sides of the interstage coolers communicate with a regenerator and a heat accumulator respectively, high-temperature side inlets of the interstage heat regenerators and a high-temperature side inlet of the first-stage heat regenerator communicate with the heat accumulator, high-temperature side outlets of the interstage heat regenerators communicate with the regenerator through the low-pressure heat supply device, and a high-temperature side outlet of the first-stage heat regenerator communicates with the regenerator. According to the system, cooling, heating, electricity and gas combined supply can be realized, the gradient utilization of the heat energy of different grades can further be realized, and dynamic changes of loads can be met.

Owner:中盐华能储能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com