Double-effect evaporation method for crude toluene mixed solution and device using double-effect evaporation method

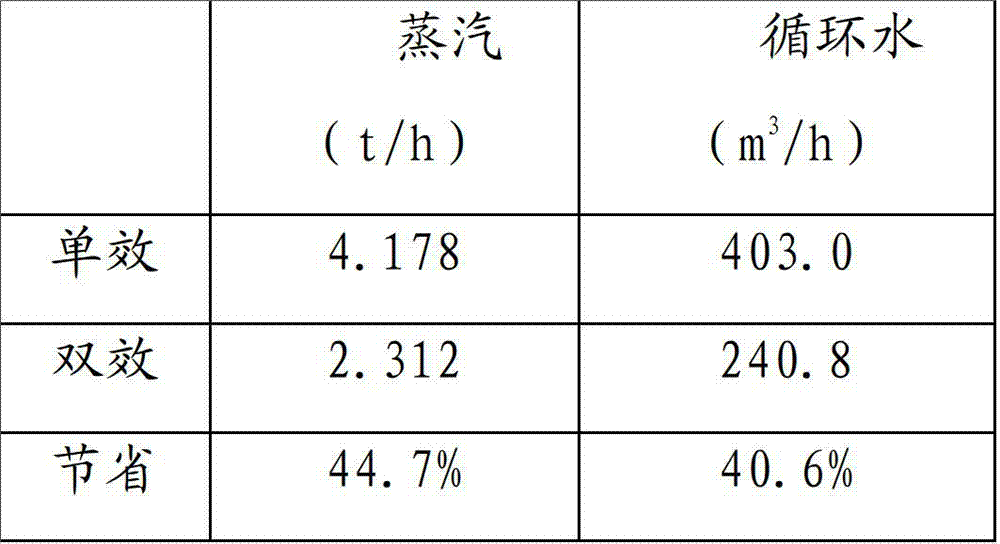

A double-effect evaporation and mixed solution technology, which is applied in multi-effect evaporation, separation methods, chemical instruments and methods, etc., can solve the problems of wasting water source and requiring more heat for direct crude toluene heating, so as to improve the utilization rate and save energy. , the effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

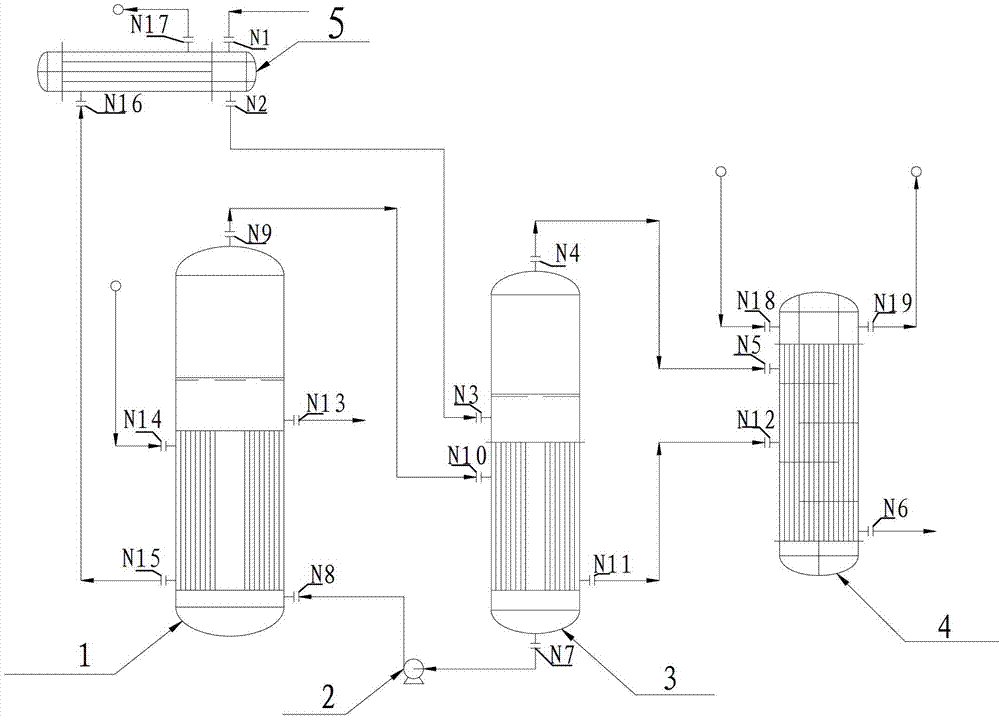

[0032] Example 1: A double-effect evaporation method for a crude toluene mixed solution. The crude toluene solution with a temperature of 30°C and containing 1.5% (wt) polyethylene passes through the heat exchanger 5, and the temperature rises to 70°C. N3 enters the tube pass of the second-effect evaporator 3 for evaporation, the temperature of the second-effect evaporator 3 is 70-90°C, and the operating pressure is 45-60KPa (A); the second-effect toluene vapor overflows through the outlet N4 at the top of the second-effect evaporator 3, It enters the condenser 4 through the second-effect toluene steam output pipe, is condensed by circulating cooling water, and then discharged after being cooled; the toluene concentrated liquid flows out through the bottom of the second-effect evaporator 3 and enters the first-effect evaporator 1 through the pump 2 from the concentrated toluene inlet at the lower part of the first-effect evaporator 1. Tube side of effect evaporator 1. Wherein ...

Embodiment 2

[0035] Example 2: A double-effect evaporation method for a crude toluene mixed solution. The crude toluene solution containing 2.0% (wt) polyethylene at a temperature of 30°C is heated by the heat exchanger 5, and the temperature rises to 70°C. N3 enters the second-effect evaporator 3 for evaporation, the temperature of the second-effect evaporator 3 is 80°C, and the operating pressure is 55KPa (A); the second-effect toluene vapor overflows through the top of the second-effect evaporator, and passes through the second-effect toluene vapor output pipe Enter the condenser 4, be discharged after being condensed by circulating cooling water; the toluene concentrated liquid flows out through the bottom of the second-effect evaporator 3 and enters the tube side of the first-effect evaporator 1 through the pump 2 from the concentrated toluene inlet at the lower part of the first-effect evaporator. Wherein the polyethylene content in the toluene concentrate is 5.5% (wt), and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com