Muffle reduction ironmaking device

A flame trap and flame trap technology, applied in the non-blast furnace ironmaking field, can solve the problems of low metallization rate, low flue gas utilization efficiency, high energy consumption, etc., achieve high metallization rate, realize efficient reduction, and improve metallization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

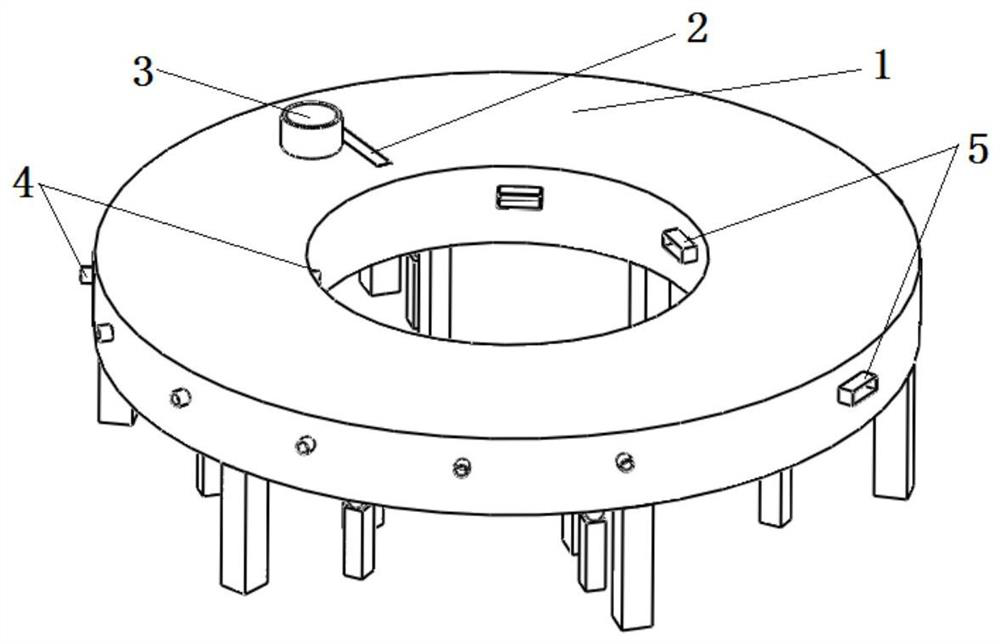

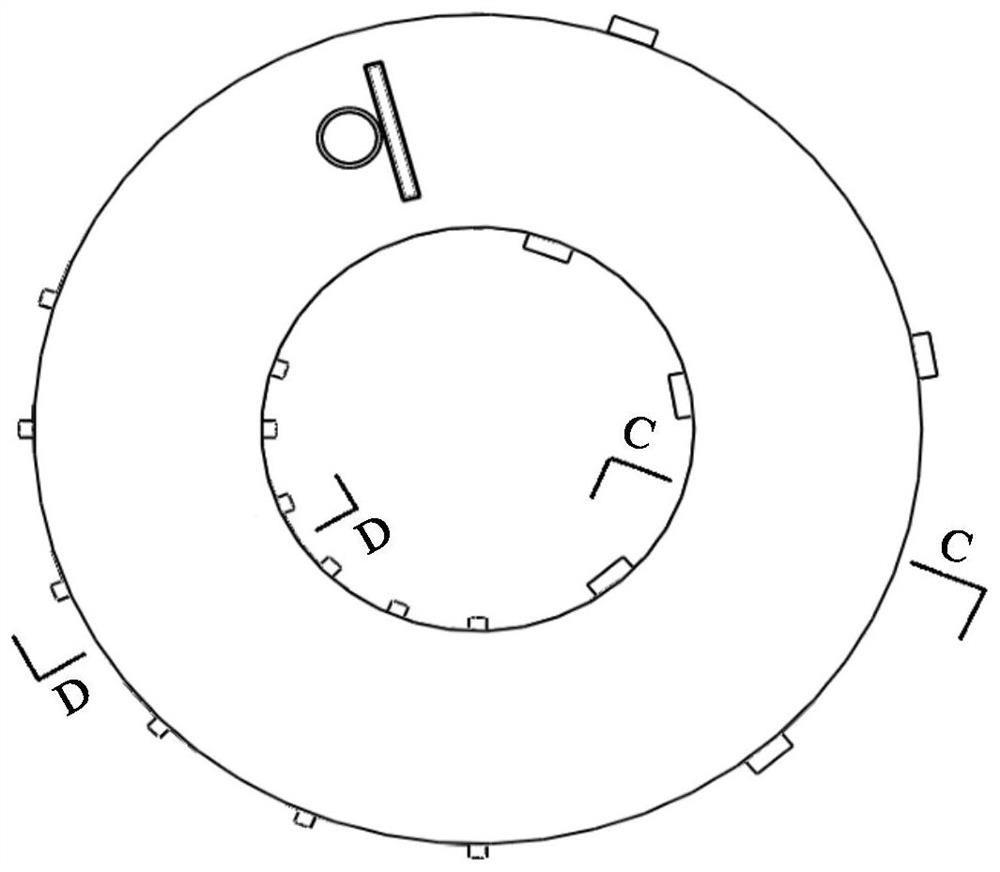

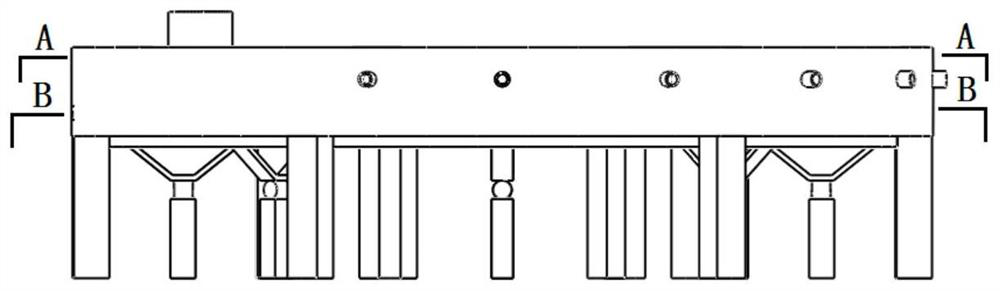

[0051] The invention provides a flame reduction ironmaking device, see Figure 1 to Figure 8, comprising a rotary hearth furnace 1, the inner space of the rotary hearth furnace 1 is divided into a heating section and a reducing section along the axial direction of the rotary hearth furnace 1 through a partition wall 6 arranged radially, the heating section is a heating chamber 14, and the reducing section is The axial direction of the bottom furnace 1 is divided into a reduction chamber 12 and a combustion chamber 10 located above the reduction chamber 12 through a flame shield 11. The combustion chamber 10 is set independently and does not communicate with the heating chamber 14 and the reduction chamber 12. The heating chamber 14 has a feeding port 2. The reduction chamber 12 is provided with a discharge port 8, and the combustion gas is passed into the heating chamber 14 and the combustion chamber 10.

[0052] During implementation, the furnace bottom 13 of the rotary heart...

Embodiment 2

[0073] This embodiment provides a method for direct reduction ironmaking in a muffled rotary hearth furnace, using the muffled reduction ironmaking device provided in Example 1, see Figure 9 , including the following steps:

[0074] Step 1: Iron-containing raw materials, flux and coal powder are mixed according to the design ratio, and the carbon-containing pellets after briquetting or pelletizing are directly loaded into the heating chamber 14 of the rotary hearth furnace 1, and the combustion gas in the heating chamber 14 (such as , air and / or oxygen) to carry out open flame preheating of carbonaceous pellets;

[0075]Step 2: The preheated carbon-containing pellets enter the reduction chamber 12 with the rotation of the bottom of the rotary hearth furnace 1, and the combustion gas in the combustion chamber 10 above the reduction chamber 12 is burned, and the preheated pellets are passed through the flame shield 11. The carbon-containing pellets are heated through the flame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com