Technique for processing high-strength high-tractility magnesium alloy member

A processing technology, magnesium alloy technology, applied in metal processing equipment, metal extrusion control equipment, metal extrusion and other directions, can solve the problems of magnesium resource advantages that cannot be transformed into high added value, process technology, product quality gap, confidentiality and other issues , to solve the casting pollution and safety problems, the quality of parts is stable, and the cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

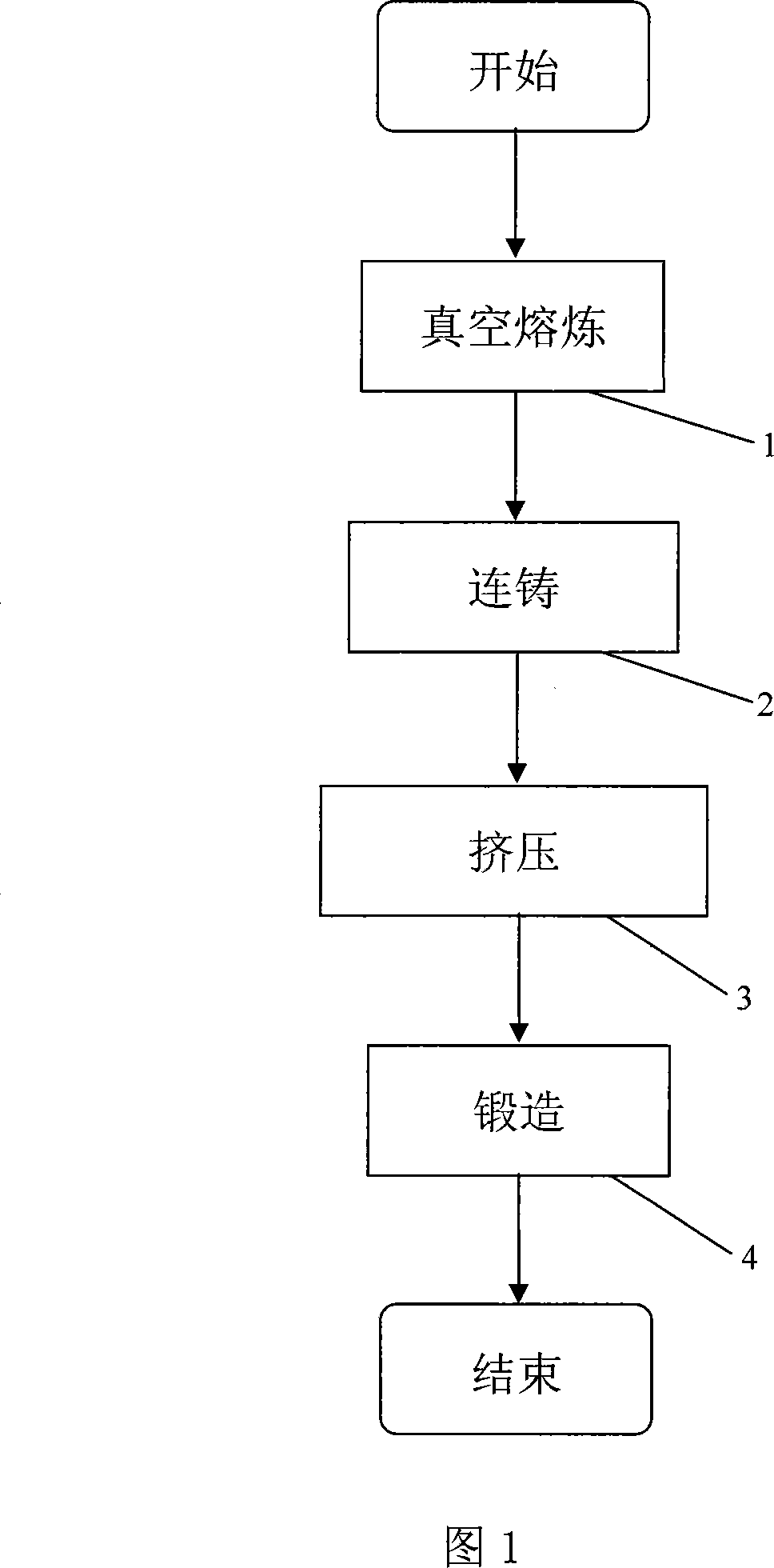

[0023] As shown in Figure 1, the processing technology of high-strength and high-ductility magnesium alloy parts sequentially includes four steps: vacuum melting 1, continuous casting 2, extrusion 3, and forging 4.

[0024] Vacuum smelting 1: Heating the magnesium alloy material to 700°C-800°C in a functional vacuum furnace, adding an intermediate alloy to adjust the composition of the melt, and adding a modifier to refine the grains.

[0025] Fine equiaxed grains can improve the plastic deformation ability of magnesium alloys, and the actual size of grains is also the main factor that determines whether magnesium alloy ingots can be directly forged; when the temperature is 350 °C and the processing rate is 0.01S -1 , the pier roughness ratio of AZ80 increases almost linearly with the decrease of grain size. The research on the microstructure control of magnesium alloys mainly focuses on the promotion effect of foreign particles on nucleation, the effect of inhibiting grain gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com