Rich oil debenzolizing equipment and method

A technology for enriching oil and removing benzene, applied in the field of coking, can solve problems such as polluted air, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

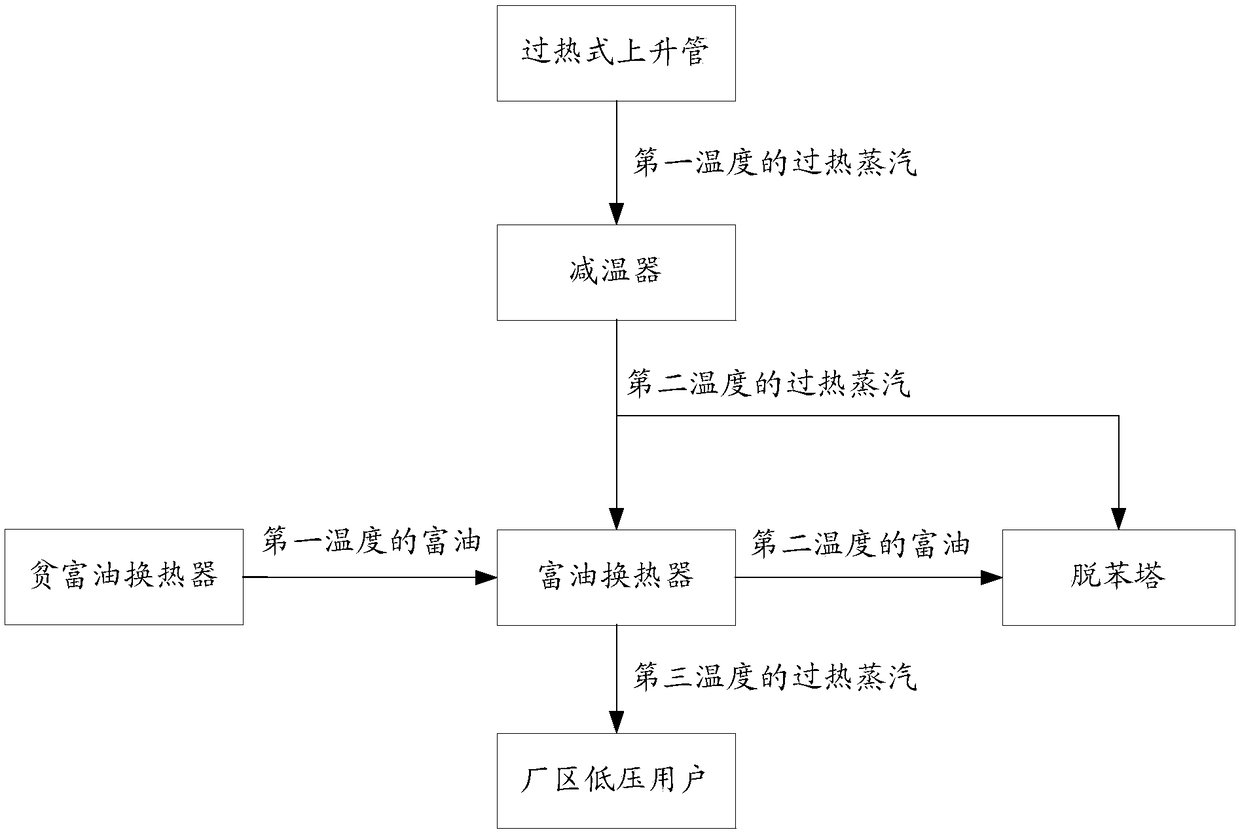

[0038] like figure 1 As shown, the present embodiment provides a kind of equipment for removing benzene and rich oil, including: a superheated riser, a desuperheater, and a debenzene tower; wherein, the superheated riser has a first pipeline and a second pipeline, and the first pipeline has Raw coal gas is passed through, saturated steam is passed through the second pipeline, the second pipeline wraps the first pipeline, and the saturated steam is heated to the superheated steam of the first temperature by using the waste heat of the raw gas in the first pipeline; the desuperheater is used to convert the first The superheated steam at the second temperature is reduced to the superheated steam at the second temperature; the debenzene tower is connected with the second pipeline steam path, and is used to debenzene the rich oil under the action of the superheated steam at the second temperature.

[0039] It can be seen from this that the equipment provided in this embodiment reli...

Embodiment 2

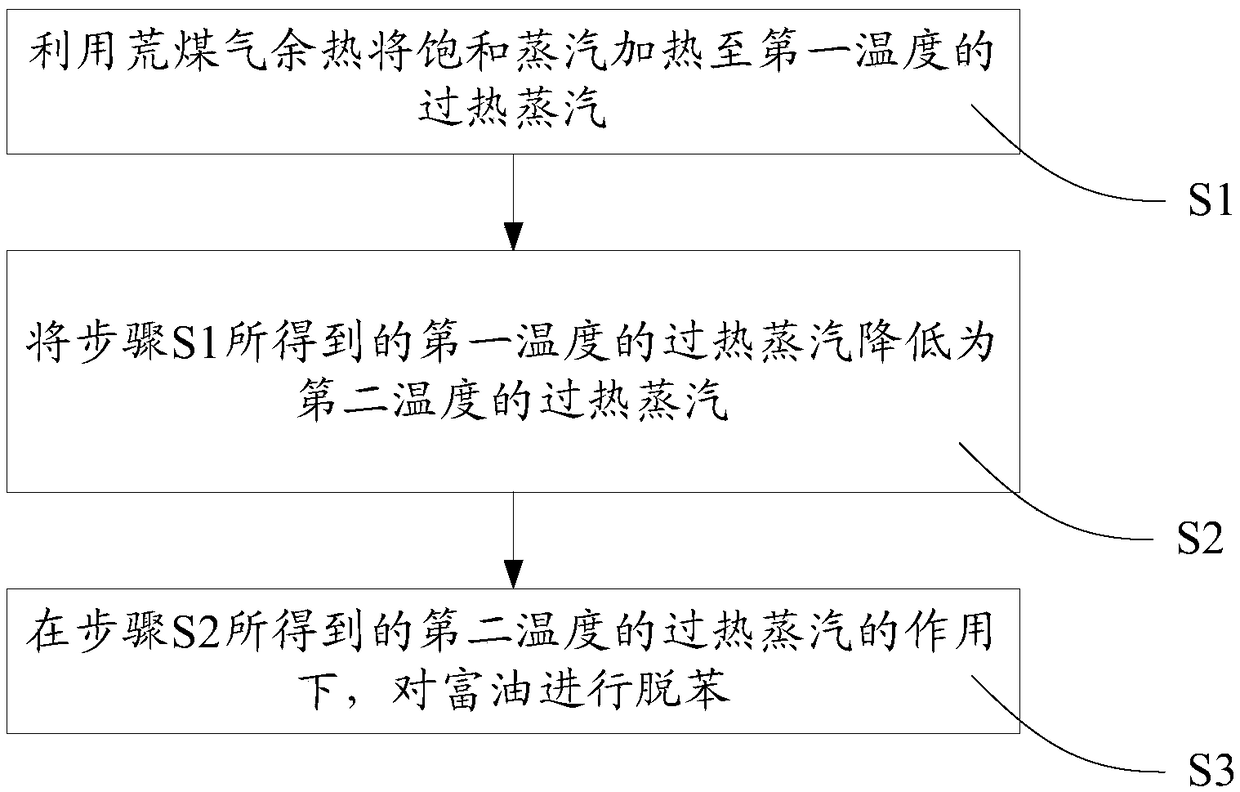

[0051] This embodiment provides a method for removing benzene and enriching oil. The method provided in this embodiment can be used to use the equipment in Example 1. Specifically, as figure 2 As shown, the method provided in this embodiment includes the following steps:

[0052] S1. Using the waste heat of raw coal gas to heat the saturated steam to the superheated steam of the first temperature.

[0053] Specifically, in this step, the subject of execution is the superheated riser in the equipment provided in Example 1, and the superheated riser has a first pipeline and a second pipeline, wherein raw gas is passed through the first pipeline, Saturated steam passes through the second pipeline, and the second pipeline wraps the first pipeline, so that the superheated riser uses the waste heat of raw coal gas in the first pipeline to heat the saturated steam to the superheated steam of the first temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com