Production method for dimethyl ether

A production method and technology of dimethyl ether, applied in the field of dimethyl ether production, can solve problems such as energy waste, high energy consumption, and increased production cost of dimethyl ether, so as to reduce production cost, increase heat exchange area, and achieve good economical efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

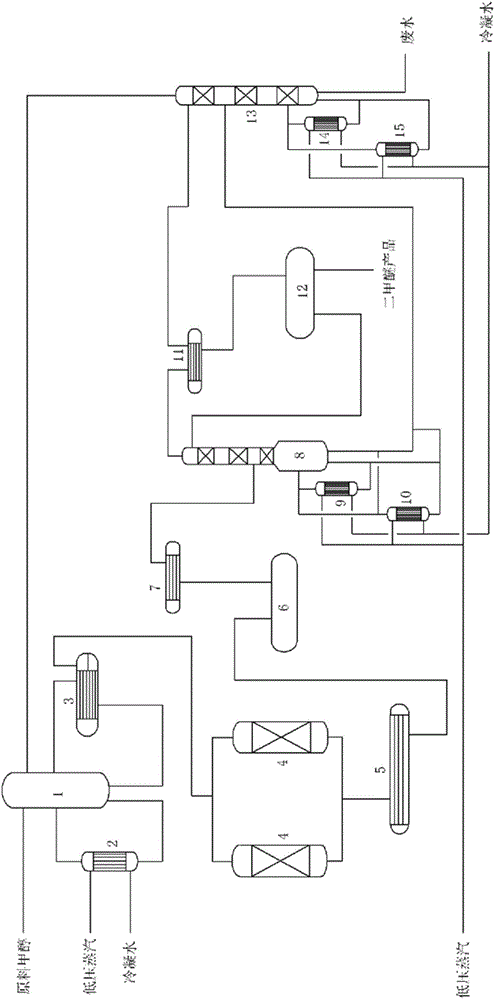

Image

Examples

Embodiment 1

[0020] The dimethyl ether production method of the present embodiment comprises the following steps:

[0021] 1) The raw material methanol enters the methanol vapor-liquid separator, and is vaporized into methanol vapor by heating at 260°C. The methanol vapor is further heated to 320°C by the heat exchanger and enters the dimethyl ether reactor. In the presence of a catalyst, methanol dehydration occurs at 380°C Reaction generates crude methyl ether gas;

[0022] 2) The crude methyl ether gas obtained in step 1) is preheated to 120°C by the crude methyl ether preheater and enters the rectification system, and the low-pressure steam with a pressure of 0.55MPa and a temperature of 260°C passes through the reboiler of the rectification system to The crude methyl ether gas is heated and rectified to obtain the refined dimethyl ether product;

[0023] 3) The still liquid produced by the rectification in step 2) enters the recovery system, and the low-pressure steam with a pressure...

Embodiment 2

[0027] The production method of present embodiment dimethyl ether comprises the following steps:

[0028] 1) The raw material methanol enters the methanol vapor-liquid separator, and is vaporized into methanol vapor by heating at 280°C. The methanol vapor is further heated to 325°C through the heat exchanger and enters the dimethyl ether reactor. In the presence of a catalyst, methanol dehydration occurs at 395°C Reaction generates crude methyl ether gas;

[0029] 2) The crude methyl ether gas obtained in step 1) is preheated to 121°C by the crude methyl ether preheater and then enters the rectification system, using low-pressure steam with a pressure of 0.60 MPa and a temperature of 240°C to pass through the reboiler of the rectification system The crude methyl ether gas is heated and rectified to obtain the refined dimethyl ether product;

[0030] 3) The still liquid produced by the rectification in step 2) enters the recovery system, and the low-pressure steam with a press...

Embodiment 3

[0033] The dimethyl ether production method of the present embodiment comprises the following steps:

[0034] 1) The raw material methanol enters the methanol vapor-liquid separator, and is vaporized into methanol vapor by heating at 270°C. The methanol vapor is further heated to 325°C by the heat exchanger and enters the dimethyl ether reactor. In the presence of a catalyst, methanol dehydration occurs at 390°C Reaction generates crude methyl ether gas;

[0035] 2) The crude methyl ether gas obtained in step 1) is preheated to 119°C by the crude methyl ether preheater and then enters the rectification system, and the low-pressure steam with a pressure of 0.55MPa and a temperature of 260°C passes through the reboiler of the rectification system to The crude methyl ether gas is heated and rectified to obtain the refined dimethyl ether product;

[0036] 3) The still liquid produced by the rectification in step 2) enters the recovery system, and the low-pressure steam with a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com