Desulfurization wastewater softening and membrane concentration method

A desulfurization wastewater and membrane concentration technology, which is applied in the direction of descaling and water softening, chemical instruments and methods, water pollutants, etc., can solve the problems of increasing operating costs and consuming chemicals, so as to reduce operating costs, realize step-by-step utilization, and facilitate The effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

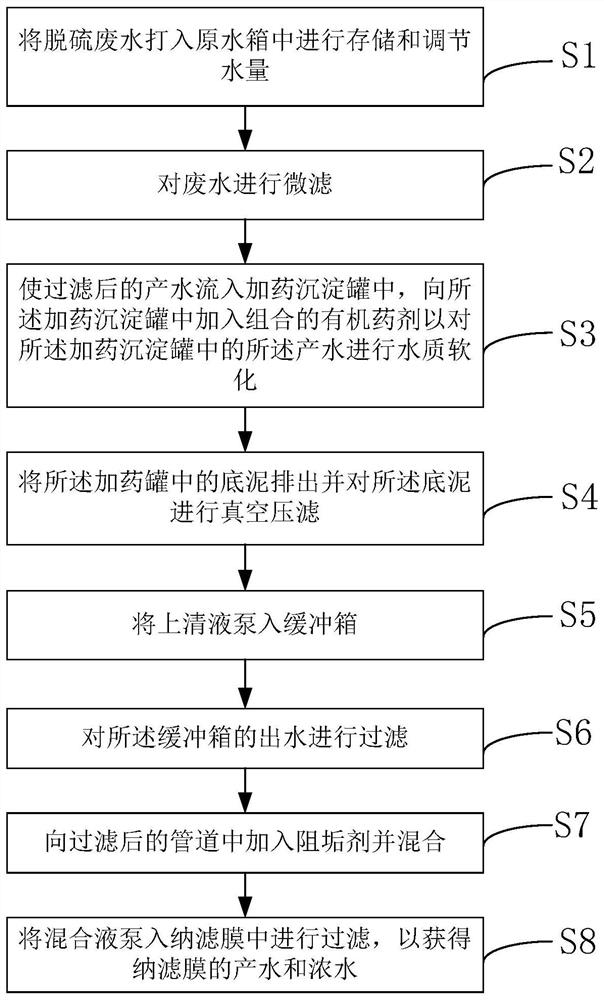

[0022] Such as figure 1 As shown, in the embodiments of the present application, the desulfurization wastewater softening and membrane concentration methods include:

[0023] Step S1, put the desulfurization wastewater into the raw water tank to store and adjust the water volume.

[0024] Step S2, performing microfiltration on the waste water.

[0025] Step S3, making the filtered product water flow into the medicine-dosing sedimentation tank, and adding combined organic chemicals into the medicine-dosing sedimentation tank to soften the water quality of the product water in the medicine-dosing sedimentation tank.

[0026] Step S4, discharging the bottom sludge in the dosing tank and performing vacuum pressure filtration on the bottom sludge.

[0027] Step S5, pump the supernatant into the buffer tank.

[0028] Step S6, filtering the outlet water of the buffer tank.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com