Pellet flue gas desulfurization, denitration and dust removal integrated treatment system and method

A technology for processing systems and flue gas, applied in gas treatment, chemical instruments and methods, sulfur compounds, etc., can solve the problems of energy and heat loss consumption, high processing costs, etc., to improve work efficiency, realize energy recovery and utilization, and realize recovery and the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

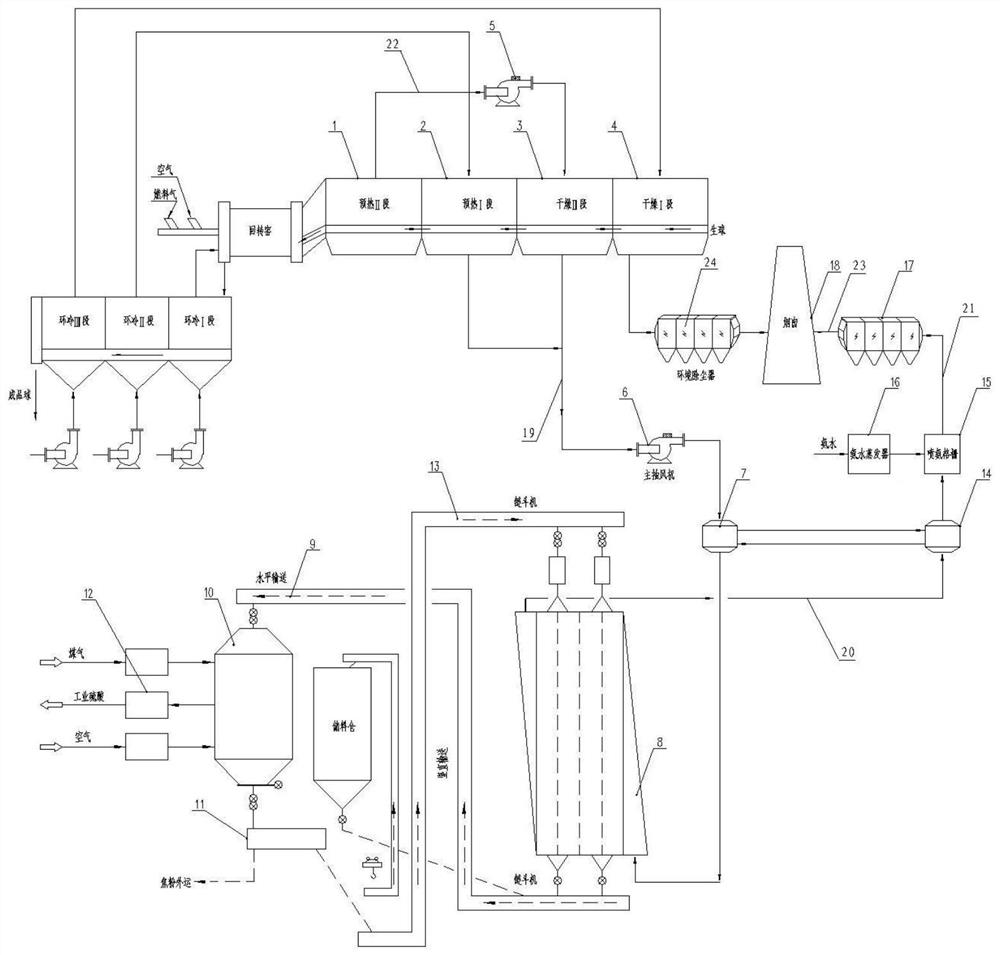

[0038] please join figure 1 , the present invention provides a pelletizing flue gas desulfurization, denitrification, and dust removal integrated treatment system, the system is used to process the flue gas generated by the pelletizing rotary kiln, the pelletizing rotary kiln is connected with the chain grate, and the chain The grate includes drying section 4, drying section 3, preheating section 2 and preheating section 1 connected in sequence; the integrated treatment system includes desulfurization subsystem, ammonia injection subsystem, denitrification and dust removal subsystem and heat exchange subsystem.

[0039] Among them, the desulfurization subsystem is connected to the flue gas outlet of the preheating section 2 and drying section 3 of the grate through the flue gas main pipe 19; the ammonia injection subsystem is connected to the outlet of the desulfurization subsystem through the first connecting pipe 20 It is used to spray ammonia on the flue gas after desulfur...

Embodiment 2

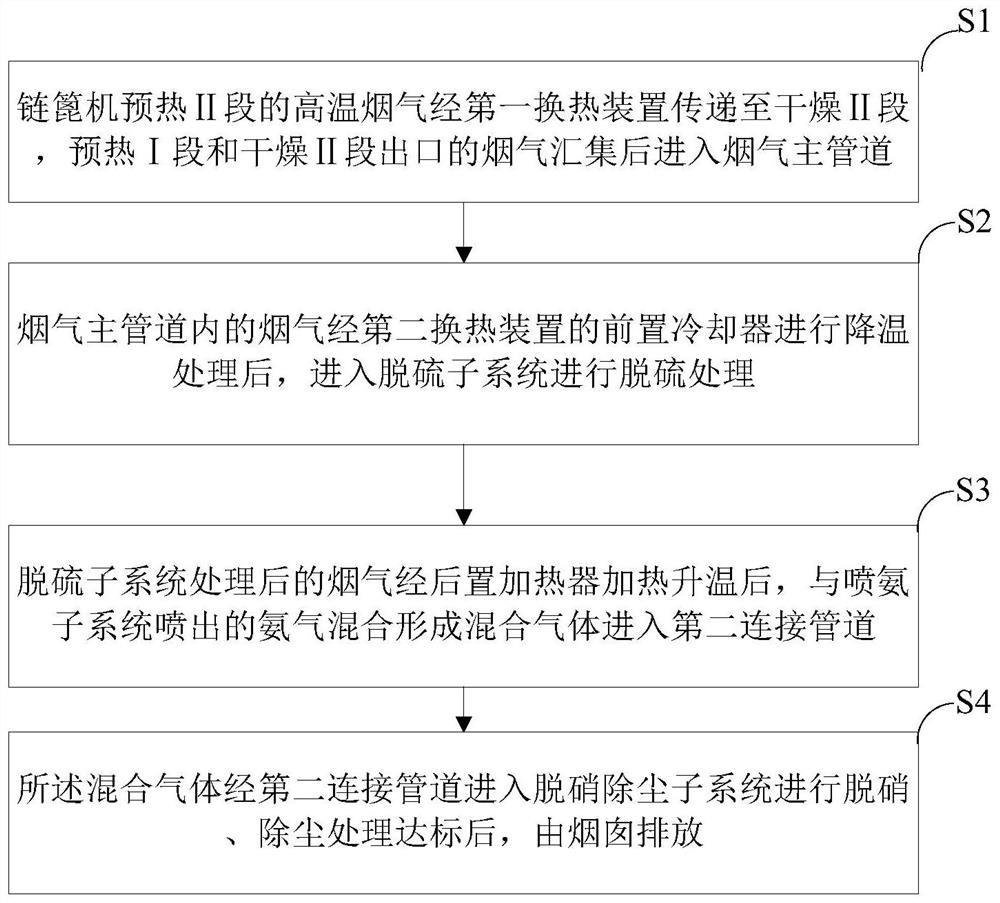

[0053] See figure 2 , the present invention also provides an integrated treatment method for pellet flue gas desulfurization, denitrification and dust removal, the method comprising the following steps:

[0054] S1. The high-temperature flue gas from the grate preheating section 1 is transferred to the drying section 3 through the first heat exchange device, and the flue gas from the outlet of the preheating section 2 and the drying section 3 is collected and then enters the main flue gas pipeline 19;

[0055] S2. After the flue gas in the flue gas main pipeline 19 is cooled by the pre-cooler 7 of the second heat exchange device, it enters the desulfurization subsystem for desulfurization treatment;

[0056] S3. After the flue gas processed by the desulfurization subsystem is heated by the rear heater 14, it is mixed with the ammonia gas emitted by the ammonia injection subsystem to form a mixed gas and enters the second connecting pipe 21;

[0057] S4. The mixed gas enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com