System and method for utilizing nuclear energy to conduct waste pyrolysis gasification treatment

A technology of pyrolysis gasification and waste, which is applied in the field of nuclear power, can solve the problems of unstable process, expensive plasma power consumption, large difference in domestic waste components, etc., and achieve the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

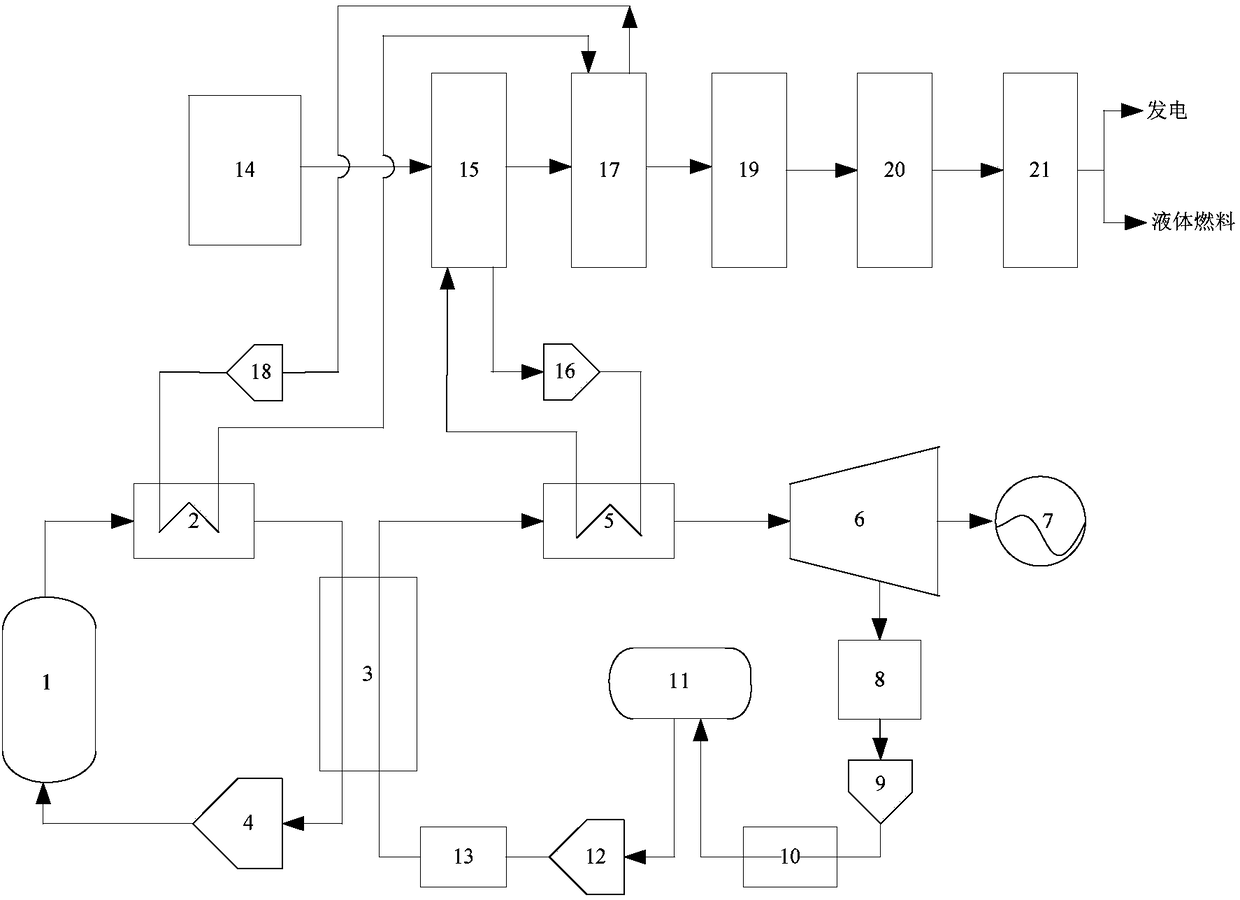

Image

Examples

Embodiment 1

[0055] Take the fourth-generation high-temperature gas-cooled reactor nuclear power unit that is being researched and developed in China as an example. The nuclear power plant is mainly composed of two modular high-temperature gas-cooled reactors and a steam turbine generator. Each reactor 1 is composed of fuel elements. It consists of pebble bed core, graphite and carbon brick internals, metal internals, control rods and their driving mechanism, absorbing ball shutdown system, and reactor 1 pressure vessel. The core of reactor 1 uses helium as the coolant, and the rated generating power of the unit is 211MW. The specific implementation steps of the present invention are described as follows below:

[0056] Step 1: The temperature of the helium gas at the outlet of the high-temperature gas-cooled reactor core is 1000-1100 °C, and the helium gas enters the high-temperature heat exchanger 2 for heat exchange. After the heat exchange, the average temperature of the helium gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com