Method for preparing activated carbon with low-rank coal extracted solid

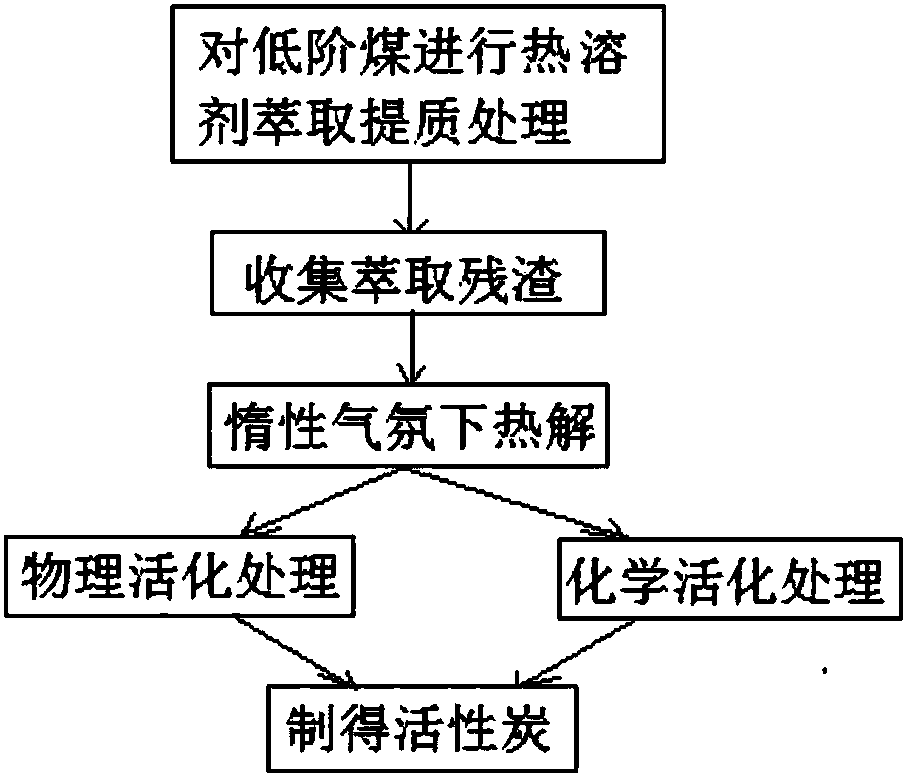

A technology for preparing activated carbon and low-rank coal, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem that the extraction residue cannot be well utilized, and achieve uniform internal and external pore volume, high quality, and simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Using a kind of lignite (LY) as the original low-rank coal, firstly mix lignite and organic solvent (1-methylnaphthalene) at a mass ratio of 1:10, place it in a reaction kettle, and heat it up to a temperature of 350°C , keep warm for 60min, and then conduct in-situ thermal filtration; obtain the extraction residue. Using lignite extraction residue as raw material, it was first pyrolyzed in a horizontal tube furnace at 500°C under a nitrogen atmosphere for 30 minutes. Then the temperature was raised to 900°C at 10°C / min, and then the nitrogen atmosphere was switched to CO 2 The atmosphere is physically activated, and a certain activation time of 0.25h is maintained to prepare high-quality activated carbon. The specific surface area of the resulting activated carbon is 935m 2 / g, the pore volume is 0.742cm 3 / g.

Embodiment 2

[0039] Taking a kind of lignite (LY) as the original low-rank coal, firstly mix lignite and organic solvent (1-methylnaphthalene) at a mass ratio of 1:15, place it in a reaction kettle, and heat it to a temperature of 350°C by program heating. , keep warm for 75min, and then perform in-situ thermal filtration; obtain the extraction residue. Using lignite extraction residue as raw material, it was first pyrolyzed in a horizontal tube furnace at 450°C under a nitrogen atmosphere for 30 minutes. Then the temperature was raised to 900°C at 12°C / min, and then the nitrogen atmosphere was switched to CO 2 The atmosphere is physically activated, and a certain activation time of 0.5h is maintained to prepare high-quality activated carbon. The specific surface area of the resulting activated carbon is 1302m 2 / g, the pore volume is 0.943cm 3 / g.

Embodiment 3

[0041] Taking a kind of sub-bituminous coal (SC) as the original low-rank coal, firstly, the sub-bituminous coal and the organic solvent (1-methylnaphthalene) were mixed in a mass ratio of 1:10, then placed in a reaction kettle, and heated to 350 °C by programming. After temperature, keep it warm for 60min, and then perform in-situ thermal filtration; obtain the extraction residue. The extraction residue of sub-bituminous coal was used as raw material, and it was first pyrolyzed in a horizontal tube furnace at 550°C and nitrogen atmosphere for 20 minutes. Then the temperature was raised to 920°C at 15°C / min, and then the nitrogen atmosphere was switched to CO 2 The atmosphere is physically activated, and a certain activation time is maintained for 1 hour to prepare high-quality activated carbon. The specific surface area of the resulting activated carbon is 816m 2 / g, the pore volume is 0.409cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com